Cloth device and method

A fabric distributing device and fabric technology, applied in the direction of supply devices, manufacturing tools, etc., can solve the problems of low fabric efficiency, and achieve the effect of improving work efficiency, continuous lines, and beautiful surface patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

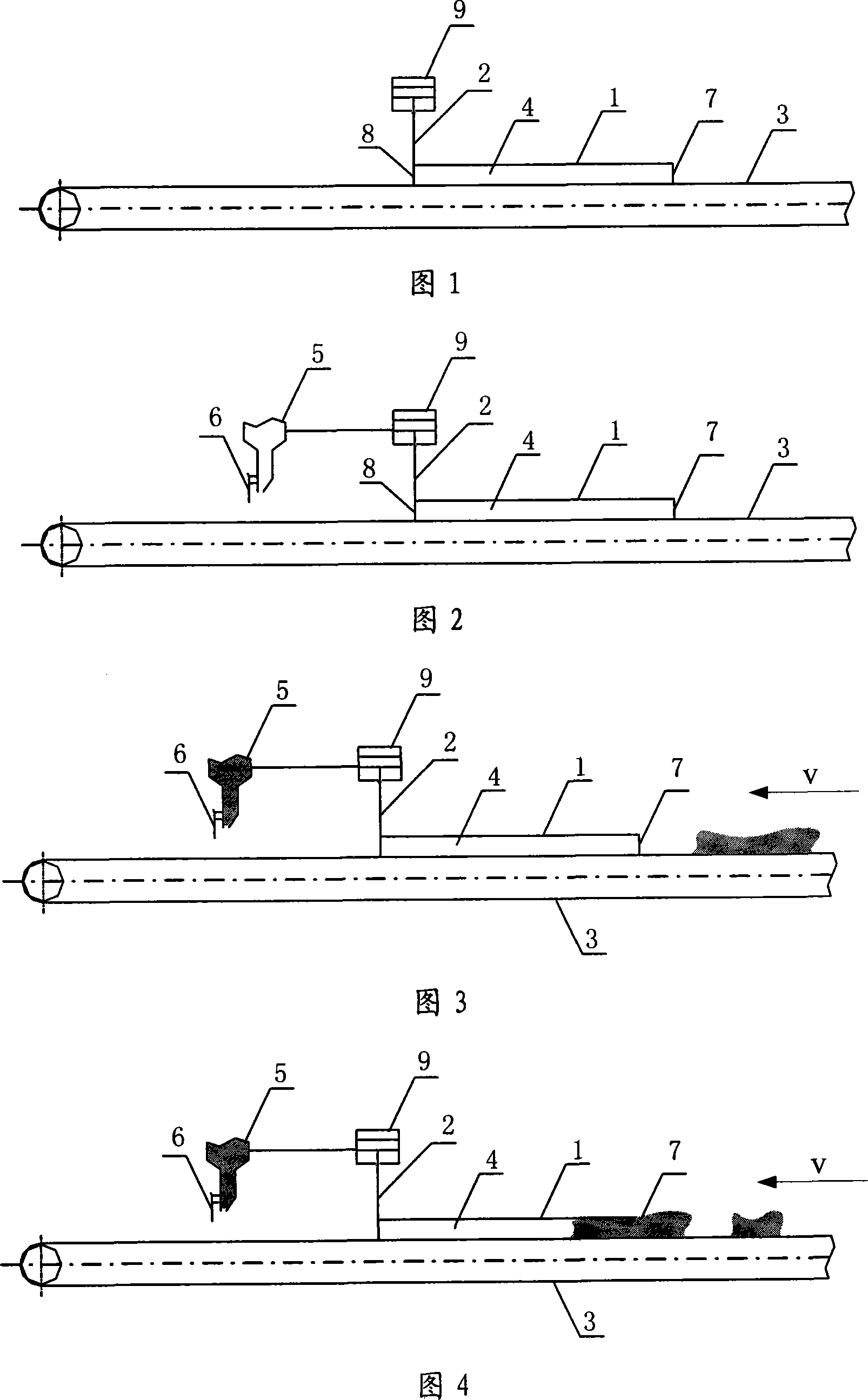

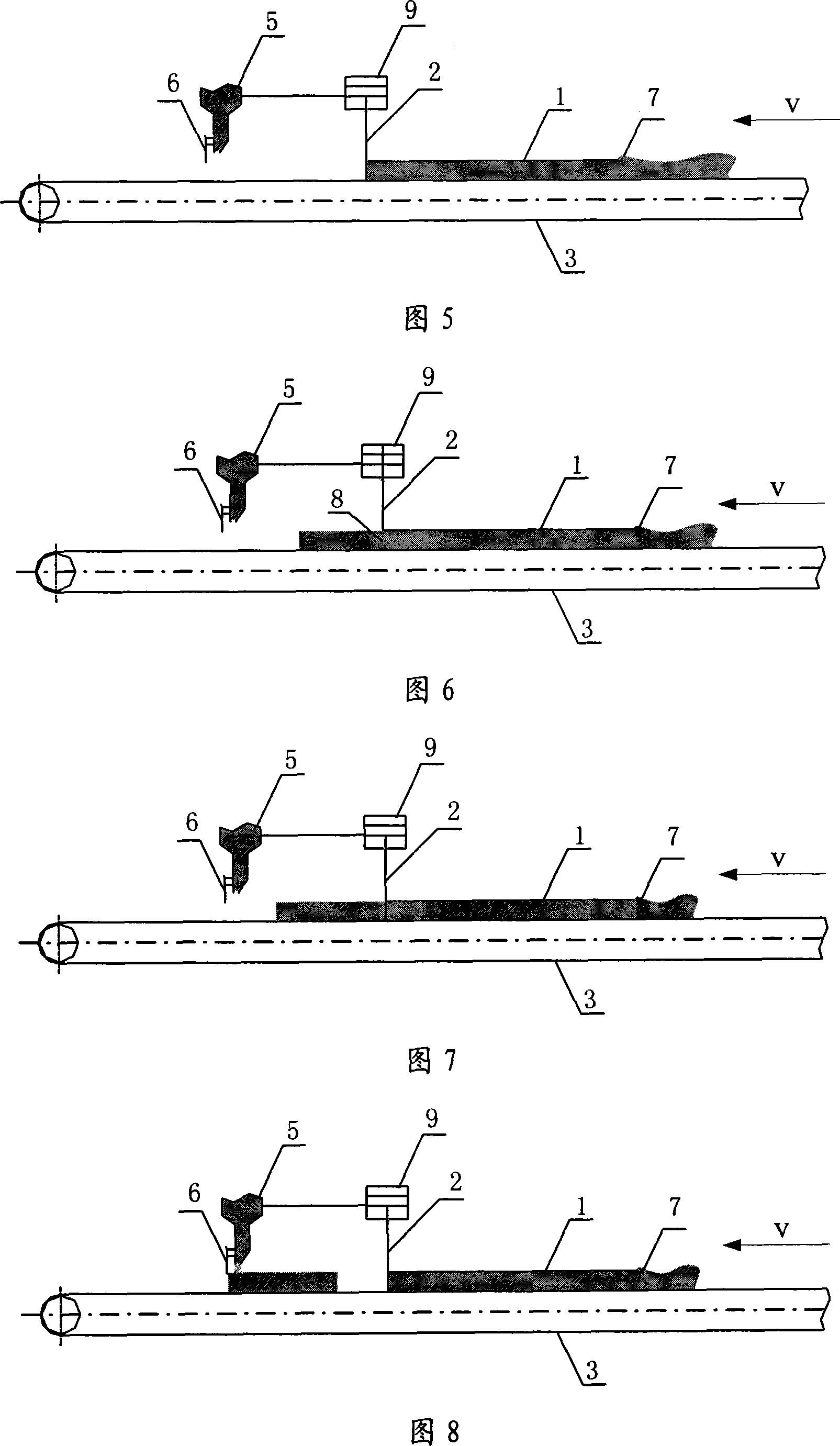

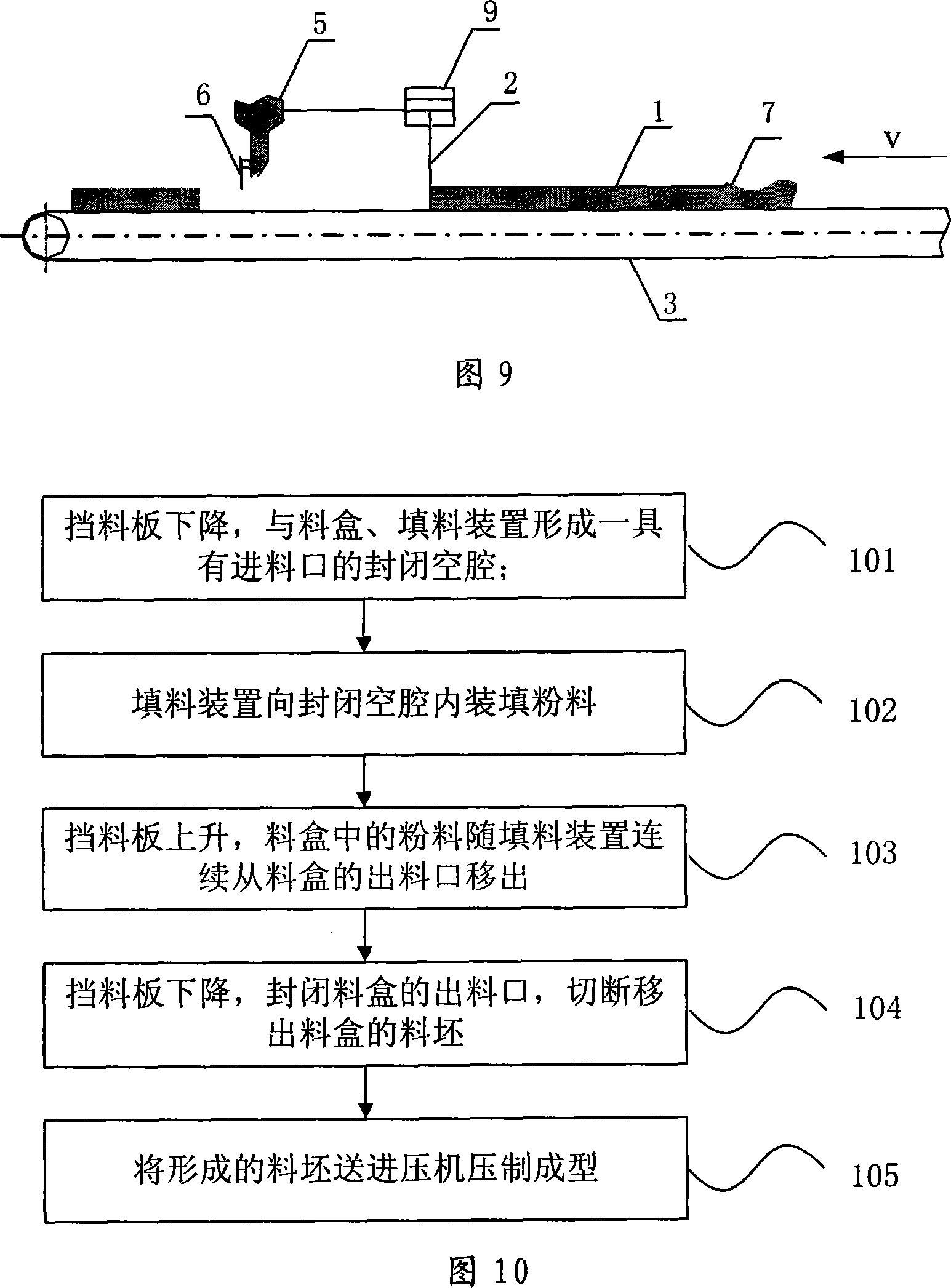

[0037] Fig. 1 is a schematic structural view of the distributing device of the present invention. As shown in FIG. 1 , the main structure of the material distribution device includes a material box 1 , a material baffle plate 2 , and a filling device 3 . Both ends of the material box 1 are provided with openings, the material inlet 7 is used for feeding materials, and the material outlet 8 is used for material discharge; the material box 1 is buckled on the surface of the filling device 3 and does not move with the filling device 3; the baffle plate 2. It is set at the outlet 8 of the material box 1, and can move vertically up and down. When it moves downward and closes the output, it can form a closed space with the material inlet 7 together with the material box 1 and the filling device 3. Cavity 4; filling device 3 is used to fill powder into the closed cavity 4;

[0038] Specifically, the material box 1 is a rectangular body composed of two side plates and a top plate. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com