Preparation method of large-porosity porous tungsten tube

A large-porosity, porous tungsten technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of low production cost and inability to prepare high-purity large-porosity porous tungsten tubes, and achieve low production costs and high hardness , the effect of uniform density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

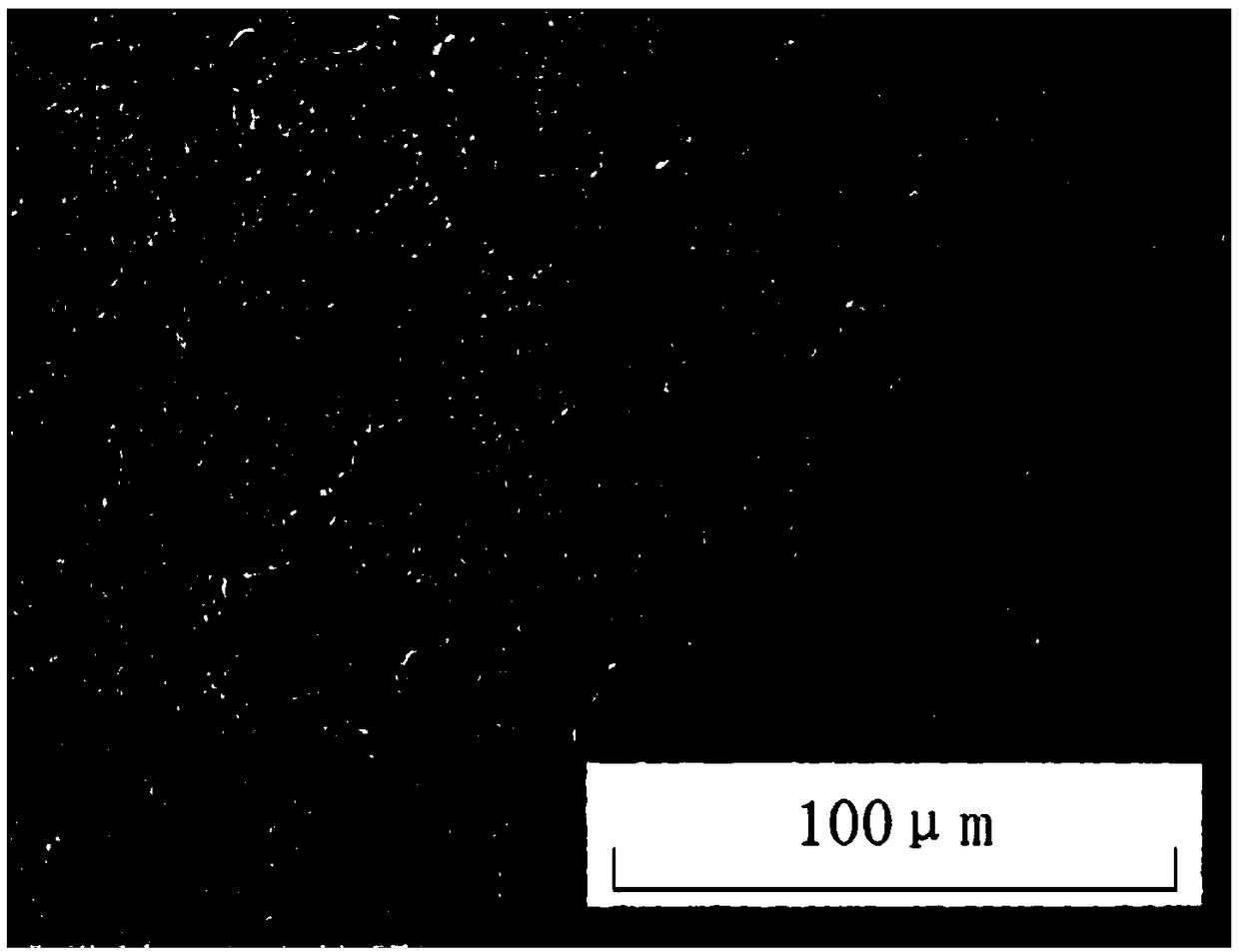

[0043] The large-porosity porous tungsten tube prepared in this embodiment has a density of 8.22g / cm 3 , the porosity is 57.5%, and the finished product specification is D50*d40*110mm (outer diameter*inner diameter*height).

[0044] Its preparation method comprises the following steps:

[0045] (1) Preparation of tungsten powder and mold

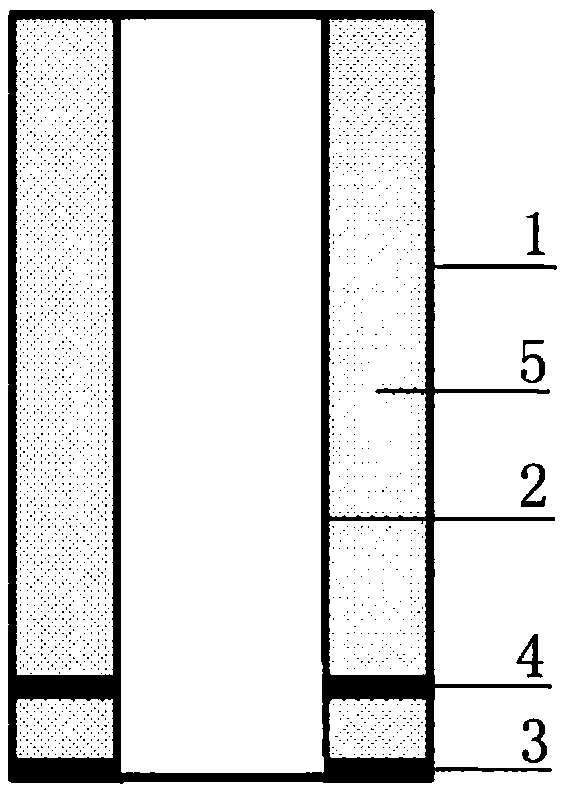

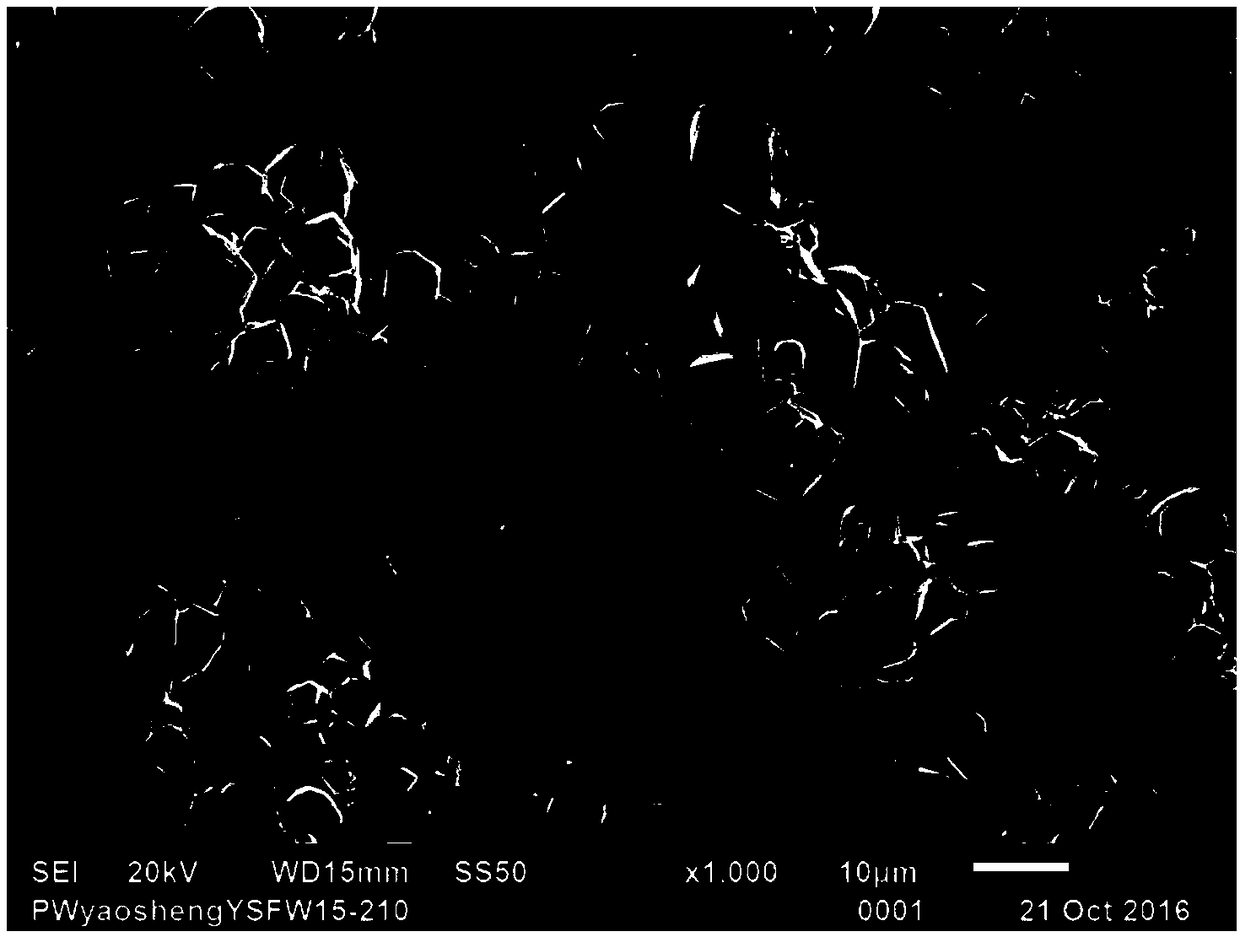

[0046] Take tungsten powder with a purity ≥ 99.95%, an average Fischer particle size of 7.0 μm, and a cumulative particle size distribution below 2 μm with a volume content of no more than 0.6%. Take 2 zirconia ceramic tubes and 2 ceramic rings with zirconia purity ≥ 99.9%; the specifications of the ceramic tubes are: D66*d62*170mm (ie thick tube 1) and D46*d42*170mm (ie thick tube 1) ; The specifications of the ceramic ring are: D62*d46*2mm (namely the bottom ring 3 and the spacer ring 4).

[0047] (2) Molding

[0048] Use a funnel to load the tungsten powder into the zirconia ceramic mold composed of ceramic tubes and ceramic rings in ...

Embodiment 2

[0064] A porous tungsten tube with large porosity, the density of the porous tungsten tube is 7.19g / cm 3 , the porosity is 62.8%, and the finished product specification is D50*d40*110mm.

[0065] Its preparation method comprises the following steps:

[0066] (1) Preparation of tungsten powder and mold

[0067]Take tungsten powder with a purity ≥ 99.95%, an average Fischer particle size of 8.7 μm, and a cumulative particle size distribution below 2 μm with a volume content of no more than 0.6%. Take 2 zirconia ceramic tubes and 2 ceramic rings with zirconia purity ≥ 99.9%; the specifications of the ceramic tubes are: D64*d60*170mm (thick tube 1) and D40*d36*170mm (thin tube 2) ; The specifications of the ceramic ring are: D60*d40*2mm (namely the bottom ring 3 and the spacer ring 4).

[0068] (2) Molding

[0069] Use a funnel to load the tungsten powder into the cavity of the zirconia ceramic mold composed of ceramic tubes and ceramic rings in two times. Each time it is load...

Embodiment 3-4

[0089] The difference between Examples 3-4 and Example 2 is only that the average Fischer particle size of the tungsten powder used is different, and other process steps and process parameters are the same as Example 2. See Table 1 for the average Fischer particle size of the tungsten powder used in Examples 3-4 and the properties of the finished porous tungsten tube. It can be seen that within the range of the average Fischer particle size of 5-10 μm, as the particle size increases, the density will decrease and the porosity will increase.

[0090] Table 1 embodiment 3-4 relevant parameter and result

[0091] Numbering

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com