Method for manufacturing buried loop type inductor

A manufacturing method and technology of inductors, which are applied in the manufacture of inductors/transformers/magnets, inductors, fixed inductors, etc., can solve the problems of rising terminal resistance, increasing thermal effects, and deteriorating electrical characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

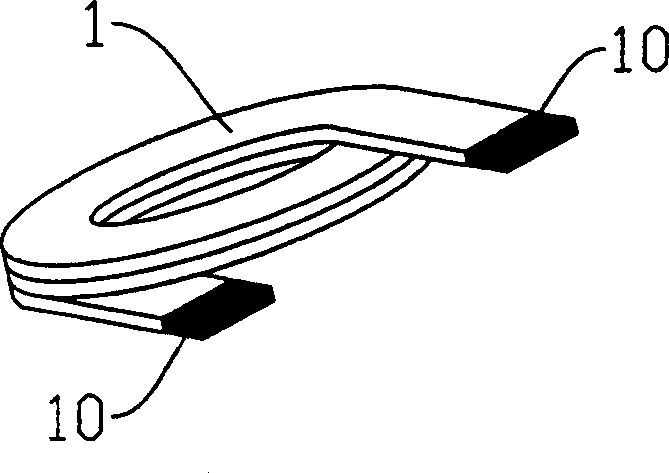

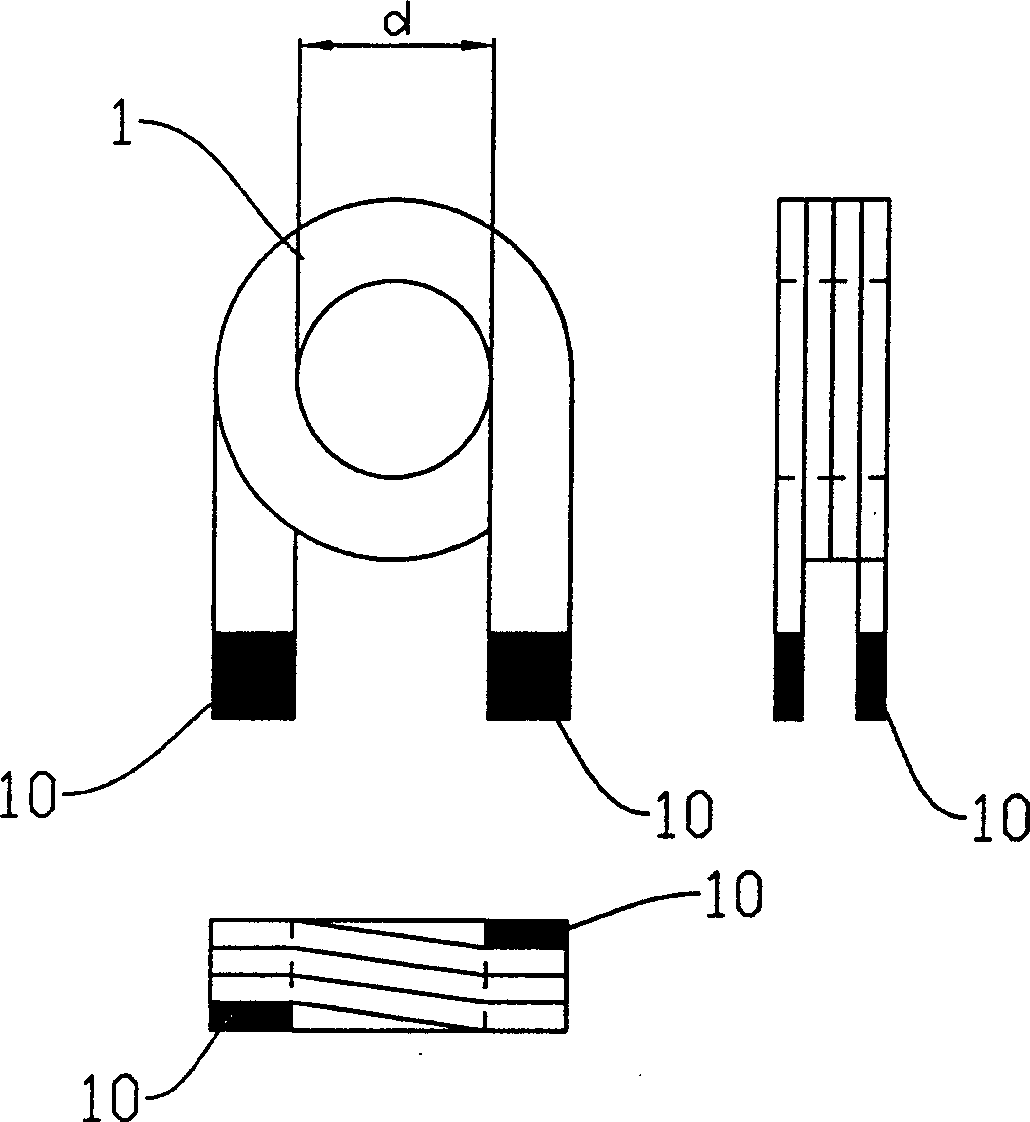

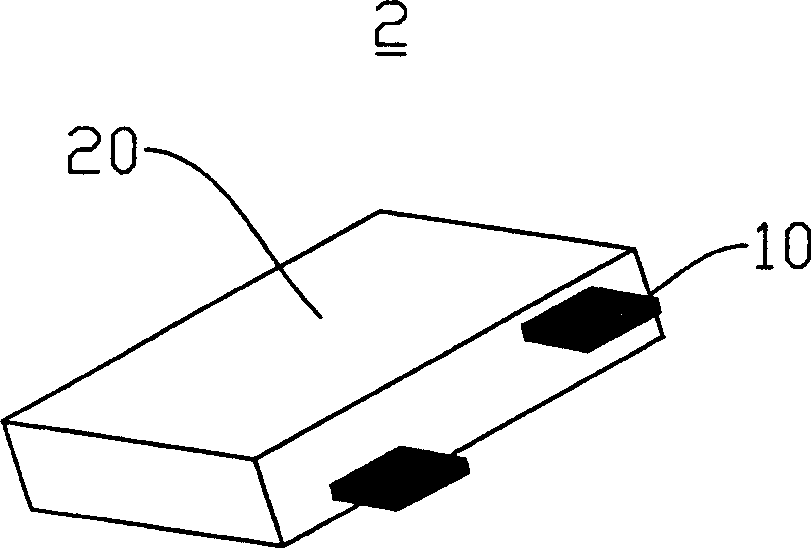

[0035] Embodiments of the present invention please refer to in sequence at the same time Figure 3A to Figure 3K , the figure presents a schematic diagram of the mold and the coil step by step according to the steps of the manufacturing method of the present invention.

[0036] First, please refer again to the Figure 3A, the present invention first provides a first mold 30 and fixes it, the center of the first mold 30 has a mold cavity 300, in order to make a coil positioning mold 31 enter the first mold cavity 300 from the lower end of the first mold 30 In a mold 30, and the coil positioning mold 31 can slide up and down in the mold cavity 300 of the first mold 30, when the coil positioning mold 31 moves to a preset position, as Figure 3A As shown, the coil positioning mold 31 is temporarily fixed so that a coil 1 can be inserted; wherein, the upper end surface of the coil positioning mold 31 has a first positioning block 310 and a second positioning block 311, and the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com