Traverse device for yarn, and textile machinery including the same

A technology of traversing device and yarn, which is used in transportation and packaging, electromechanical devices, electric components, etc., can solve the problems that the structure of document 2 cannot be considered reasonable, lengthened, and inertia increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

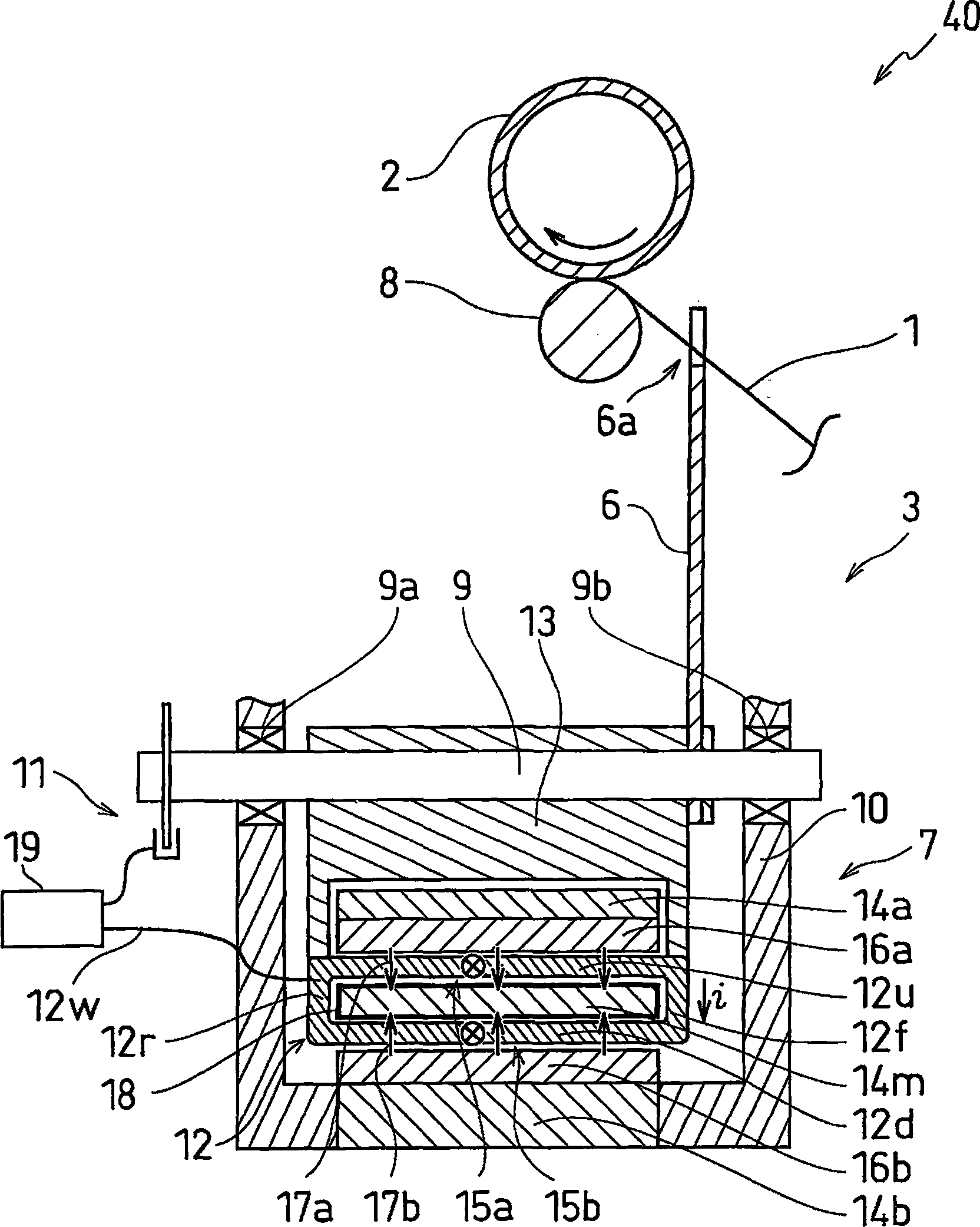

[0044] Next, a first embodiment of the traversing device according to the present invention will be described with reference to the drawings.

[0045] Here, an example of an automatic winder using the present invention is explained as an example of a fiber machine.

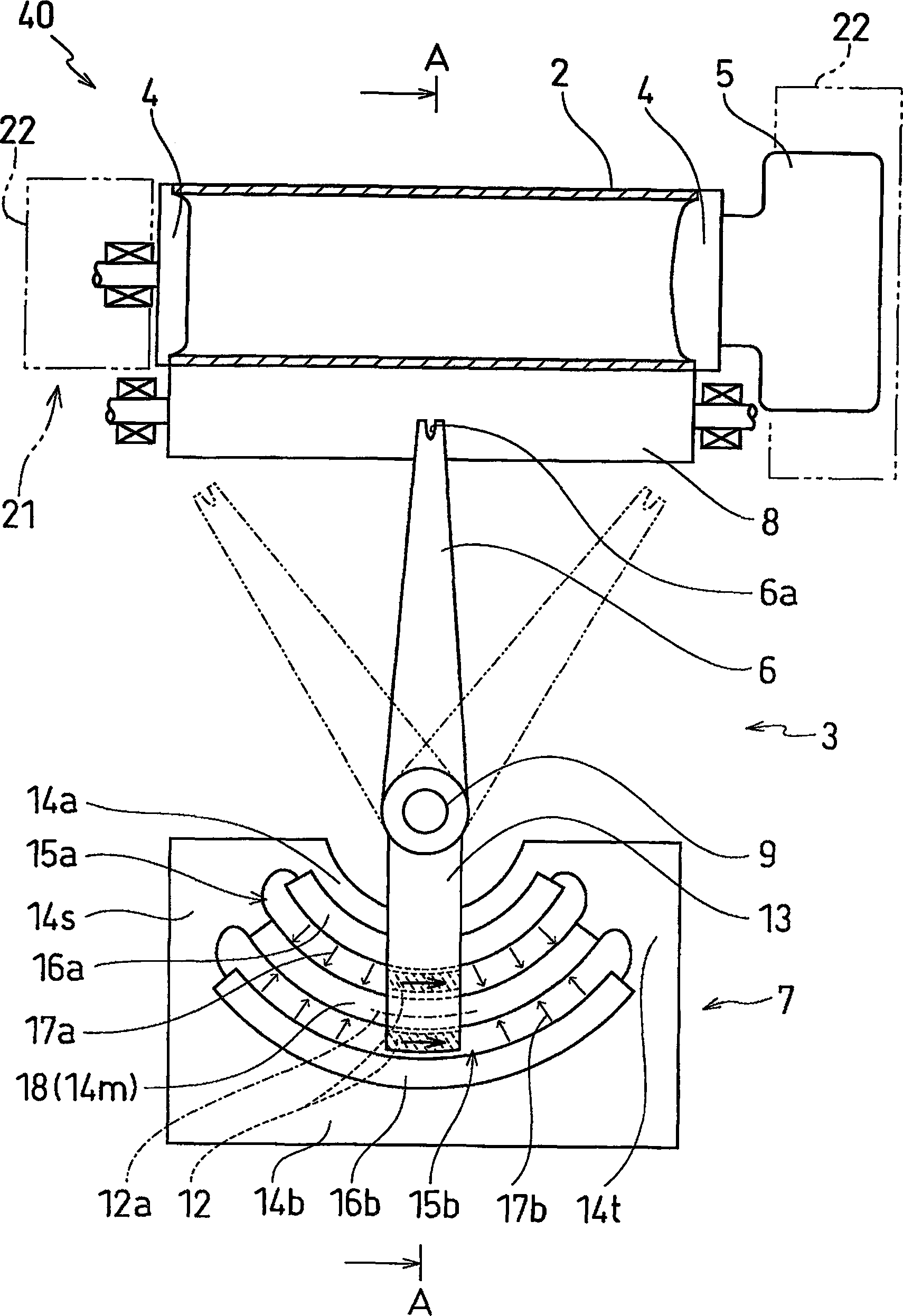

[0046] figure 1 is a schematic front view of the winding section of the automatic winding machine according to the first embodiment.

[0047] figure 2 is along figure 1 The cross-sectional view of the middle arrow A-A.

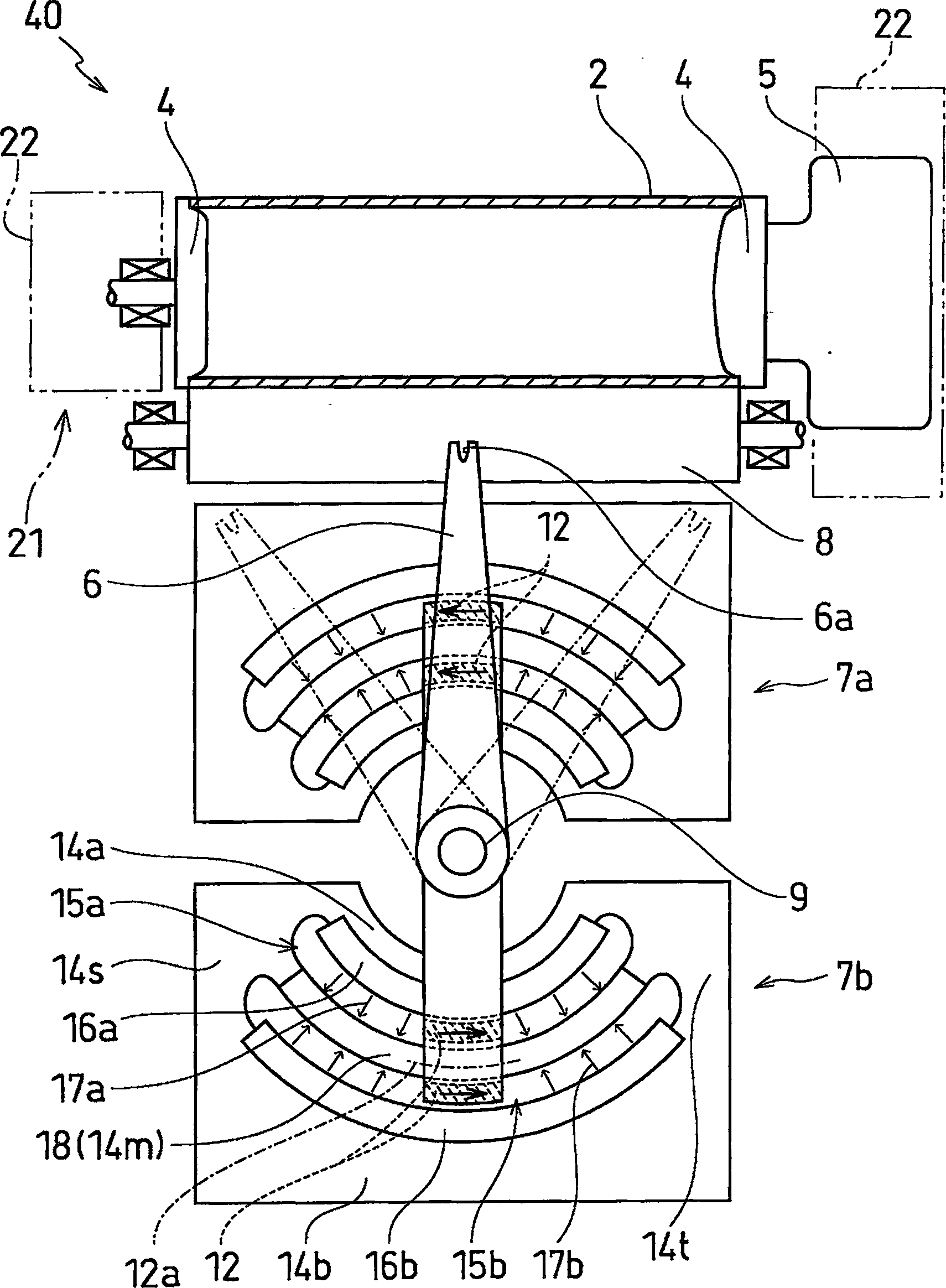

[0048] Figure 5 is a schematic front view of the winding unit of the automatic winding machine according to the embodiment of the present invention.

[0049] First, refer to Figure 5 The yarn winding unit 102 of the automatic winding machine 101 will be described.

[0050] Figure 5 The yarn winding unit 102 of the illustrated automatic winding machine 101 winds the yarn 1 unwound and supplied from the yarn supply bobbin 103 around the winding bobbin 2 while the yarn is traversed by the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com