SCR catalyst crystallization detection method, detection device and clearing device

A technology of SCR catalytic converter and detection method, which is applied in the diagnosis device of exhaust treatment device, electronic control of exhaust treatment device, machine/engine, etc., can solve the problem that crystallization fault cannot be effectively identified, and achieve the reduction of DPF active Regeneration times, protection life, anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] figure 1 It is a schematic flow chart of a crystallization detection method for an SCR catalyst, comprising the following steps:

[0052] S1: Receive a crystallization detection instruction.

[0053] After the engine is powered on and started, receive crystallization detection command. Preferably, before receiving the crystallization detection instruction, it is judged whether the engine is in a special working state, if the engine is in a normal working state, then start to accumulate running time and fuel consumption and perform SCR crystallization detection; otherwise, abandon this detection process and reset the crystallization detection parameters. Among them, the normal working state means that the engine water temperature is suitable, and the engine is not running in a special working state. The special working state includes rapid warm-up, exhaust temperature management, active DPF regeneration, desulfurization regeneration, crystallization removal, engine bra...

Embodiment 2

[0067] On the basis of embodiment 1:

[0068]Before judging the crystallization state of the SCR catalyst according to the deviation value, if DPF complete active regeneration, SCR complete desulfurization regeneration and SCR complete decrystallization regeneration occur at the same time or any one of them occurs, it is necessary to judge DPF complete active regeneration and SCR complete desulfurization regeneration , SCR complete decrystallization regeneration is over respectively, if any one of DPF complete active regeneration, SCR complete desulfurization regeneration and SCR complete decrystallization regeneration ends, set the running time and fuel consumption to zero and repeat the steps from S1 to S4 Preset the number of times, get all the deviation values and calculate the average value of the deviation values; judge whether the average value is greater than the preset threshold value, if so, stop the detection of crystallization and output a vehicle failure reminder...

Embodiment 3

[0071] On the basis of embodiment 2:

[0072] After all the deviation values are obtained and the average value of the deviation values is calculated, the correction coefficient is calculated according to the average value, and the pre-calibrated intake air volume is corrected based on the correction coefficient to obtain the corrected intake air volume, and the corrected intake air volume is updated as The current pre-calibrated intake air volume.

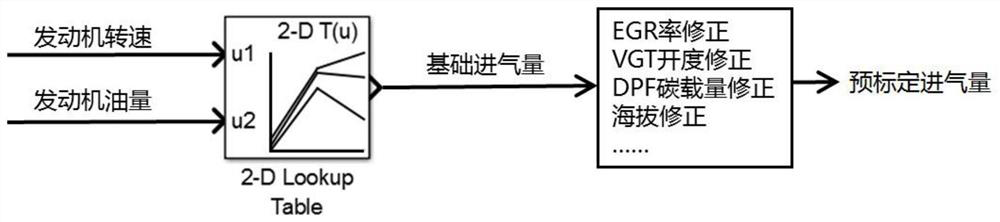

[0073] Specifically, due to the accumulative growth of DPF ash and the differences in the manufacturing consistency of engines and after-treatment systems, including differences in gas path structure and performance, and differences in sealing due to assembly tolerances, it is necessary to use the correction coefficient α to correct the pre-calibration The intake air volume is corrected and the corrected intake air volume is obtained, and the corrected intake air volume is updated to the current pre-calibrated intake air volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com