Inkjet printing apparatus and inkjet printing method

a technology of inkjet printing and inkjet printing, which is applied in the direction of printing, other printing apparatus, etc., can solve the problems of deviating dot landing positions, and achieve the effect of reducing density unevenness and minimizing air current disturban

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]Now, the first embodiment of this invention will be described by referring to the accompanying drawings.

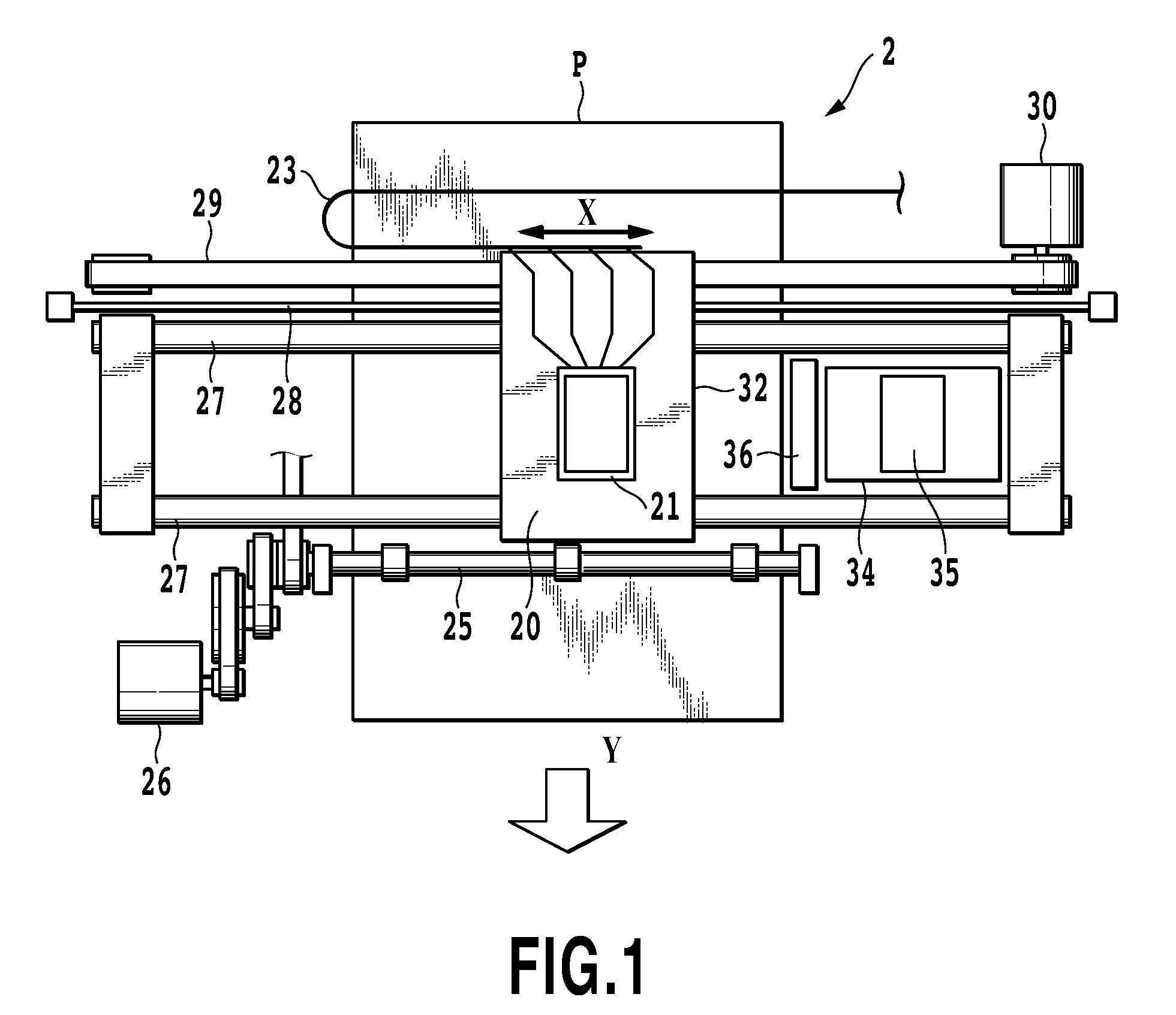

[0030]FIG. 1 is a front view showing an outline construction of a serial type inkjet printing apparatus capable of implementing the present invention. A carriage 32 is supported by guide shafts 27 and a linear encoder 28 so as to be reciprocally movable in a main scan direction (arrow X direction). This carriage 32 is reciprocally moved along the guide shafts 27 by operating a carriage motor 30 to drive a drive belt 29. The carriage 32 has an inkjet print head (simply referred to as a print head) 21 removably mounted therein. The print head 21 has a plurality of nozzle arrays comprising many ink ejecting portions (also referred to as nozzles). In the ink path formed in each of the nozzles of the print head 21 there is provided a heating element (or heater) that generates a thermal energy to eject ink supplied to the ink path.

[0031]The serial type inkjet printing apparatus ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com