Foam concrete distributing machine and distributing method thereof

A foam concrete and placing machine technology, which is applied to ceramic molding machines, supply devices, manufacturing tools, etc., can solve the problems of reducing the impact force of foam concrete, uneven size and unevenness of pores, etc., to improve quality and avoid uneven density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

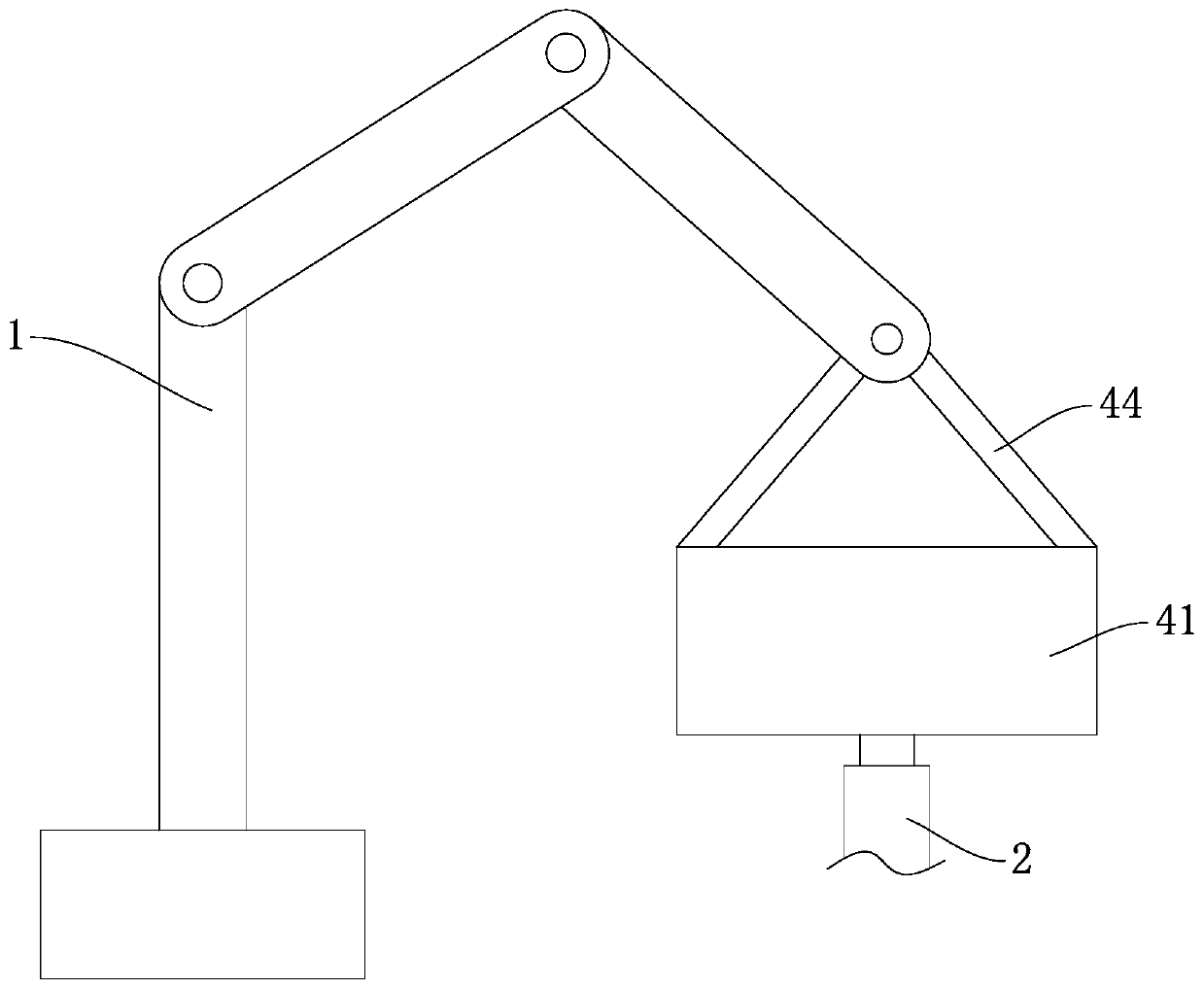

[0029] A foam concrete distributing machine includes a mechanical arm 1. The front end of the mechanical arm 1 is fixed with a buffer pressure reducing device for reducing the impact force of the foam concrete, and the buffer pressure reducing device is connected with a supply for conveying the foam concrete to the buffer pressure reducing device. The material pipe 2, the end of the supply pipe 2 away from the buffer pressure reducing device is connected to the discharge port of the foam concrete production equipment. The buffer pressure reducing device is used to pour the foam concrete into the pouring area 3; the robot arm in the above content is an existing There is technology, so I won't repeat it here.

[0030] The buffer decompression device includes a first material box 41 with an upper end opening and a cavity provided therein, a first feed pipe 42 is communicated with the bottom of the first material box 41, and the first feed pipe 42 is connected to the feed pipe 2; A f...

Embodiment approach 2

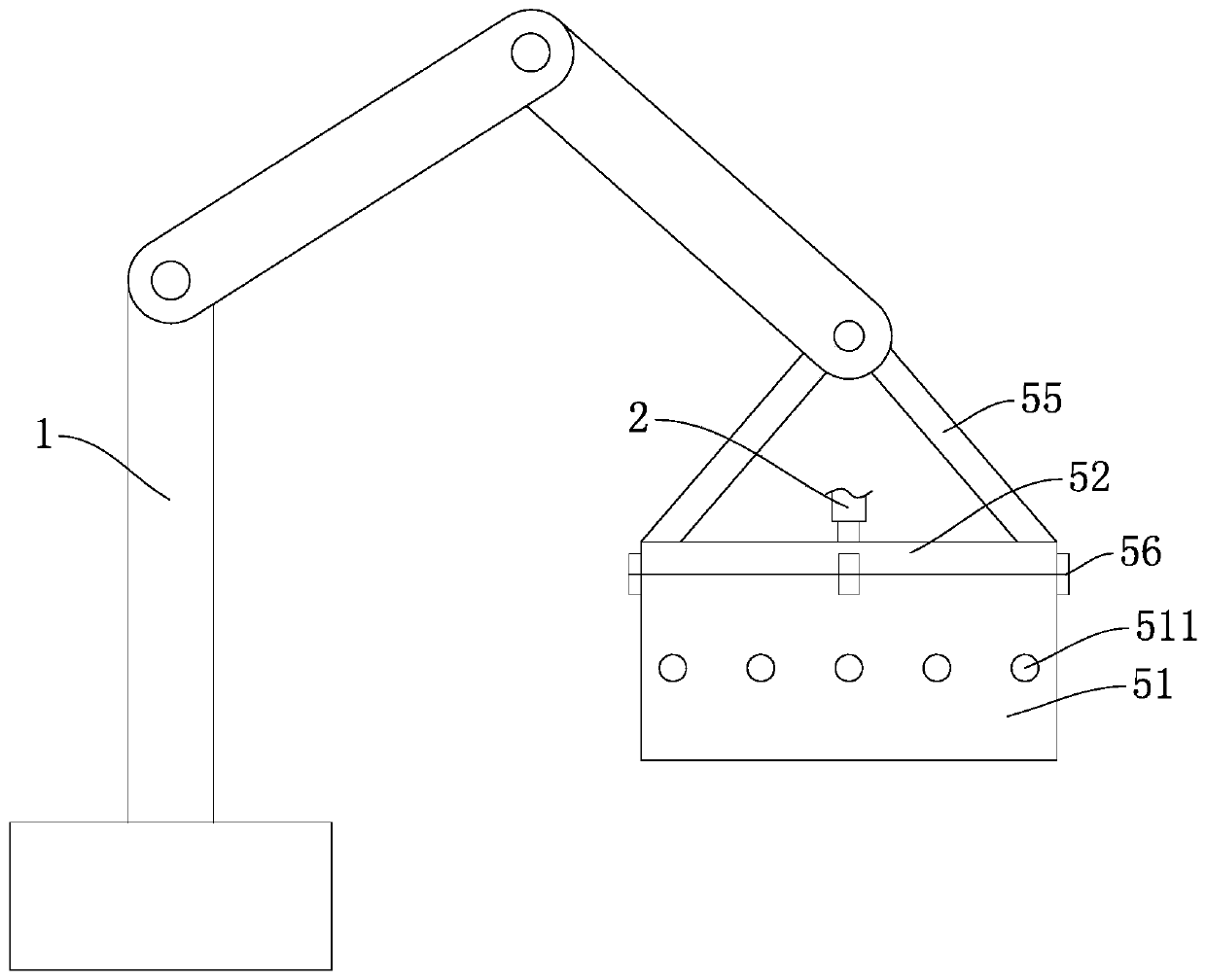

[0037] The difference from the first embodiment is that the cushioning and decompression device includes a second material box 51 with an open upper end and a cavity provided therein. A first cover plate 52 and a first cover plate 52 are fixed on the upper end surface of the second material box 51. There is a second feed pipe 53 connected to the center, the second feed pipe 53 is connected to the feed pipe 2, and the upper peripheral wall of the second feed box 51 is provided with a plurality of first discharge channels 511 evenly distributed in the circumferential direction; A second shaft sleeve 54 is provided above a cover plate 52. The second shaft sleeve 54 is connected to the front end of the mechanical arm 1 by a pin shaft. The outer walls of both sides of the second shaft sleeve 54 are welded and fixed with second connecting rods 55, two The end of the second connecting rod 55 away from the second shaft sleeve 54 is welded and fixed to the upper end surfaces of the left ...

Embodiment approach 3

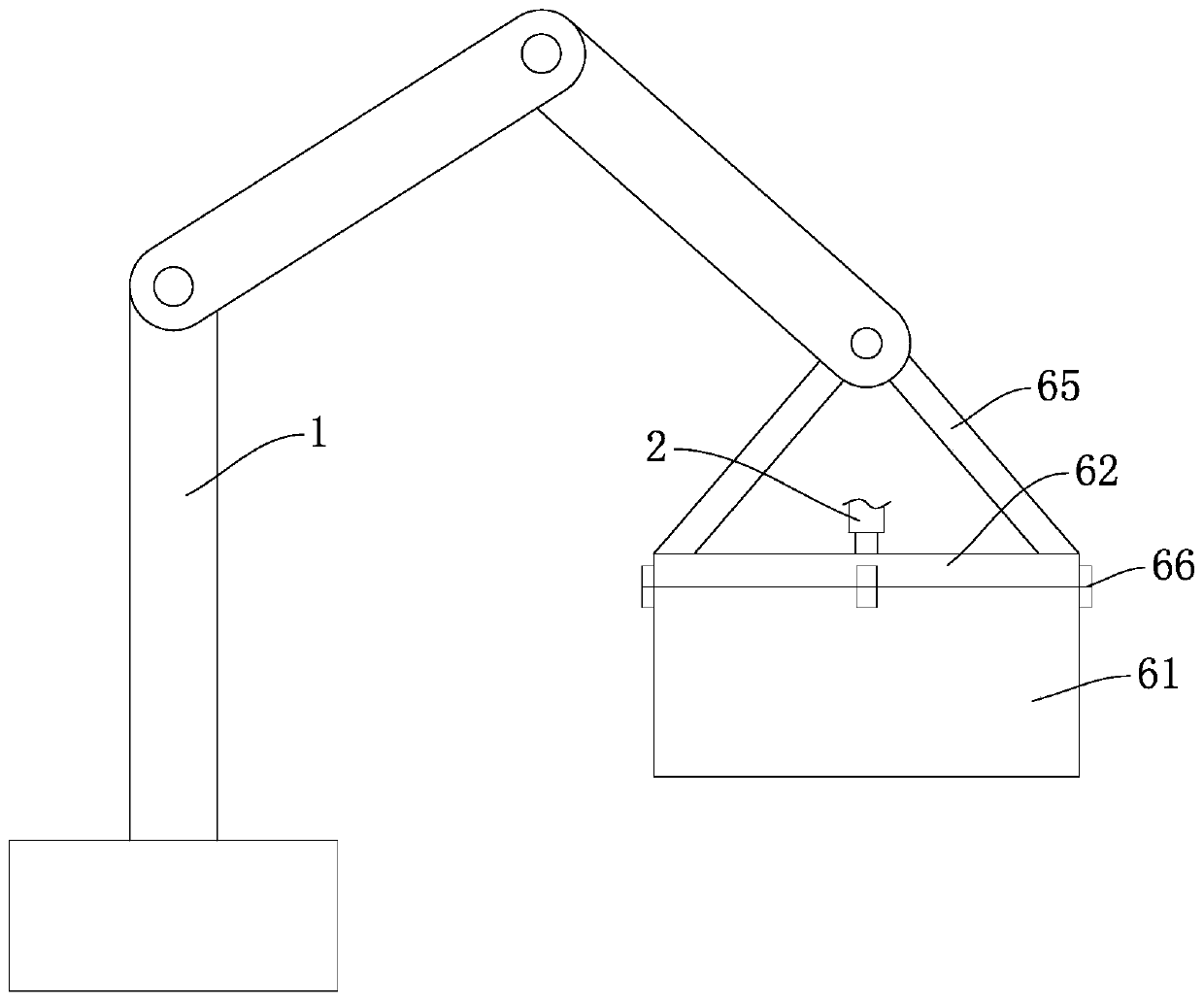

[0042] The difference from the first embodiment is that the cushioning and decompression device includes a third material box 61 with an open upper end and a cavity provided therein, a second cover 62 is fixed on the upper end surface of the third material box 61, and the third material box 61 An upward protrusion 611 is provided in the middle of the inner bottom part of the protrusion 611, and a groove 612 is provided at the upper end of the protrusion 611. The second cover plate 62 located directly above the groove 612 is connected with a third feeding pipe 63. 63 is connected to the feeding pipe 2, and the bottom of the third material box 61 located outside the protrusion 611 is provided with a number of second discharge channels 613 evenly distributed in the circumferential direction; a third shaft is provided above the second cover 62 A sleeve 64, the third shaft sleeve 64 is connected with the front end of the mechanical arm 1 by a pin, the third shaft sleeve 64 is welded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com