Three-dimensional printer and printing method thereof

A technology of a three-dimensional printer and a print head, which is applied in the field of printing, and can solve problems such as easy accumulation and solidification of print head nozzles, high cost of three-dimensional printers, and complex structure of the print head 11, so as to improve the quality of solid molding and avoid clogging of the print head and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

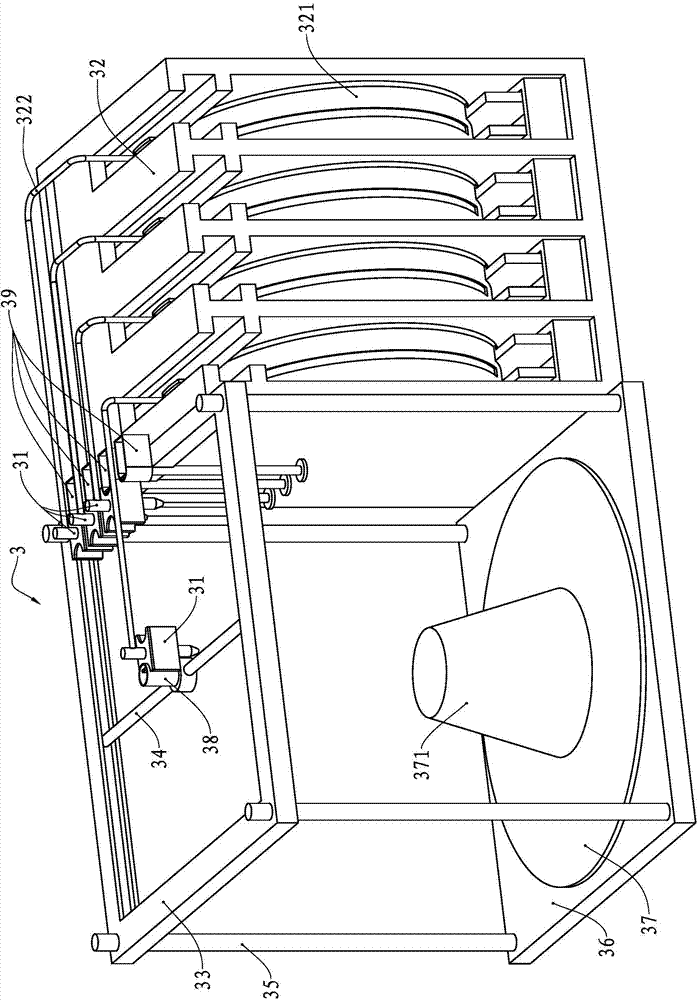

[0042] Reference figure 2 , figure 2 This is a structural diagram of the three-dimensional printer 3. The three-dimensional printer 3 includes four print heads 31, four switching devices 39, and a print box mounting frame 32. A plurality of print boxes 321 are installed in the print box mounting frame 32, and the print boxes 321 pass through them. The discharge port provides the consumables 322 contained therein to the print head 31. The consumables 322 can be solid filamentous consumables, and the consumables can also be powdered, liquid, etc. The structure of the print box that contains different consumables is different. Differently, this embodiment uses a printing box containing solid filamentary consumables as an example to describe the three-dimensional printer 3. Four switching devices 39 are installed on one end of the print cartridge mounting frame 32, and each switching device can be installed with a print head 31.

[0043] The three-dimensional printer 3 also include...

no. 2 example

[0052] On the basis of the first embodiment of the three-dimensional printer 3, the three-dimensional printer 3 may also be equipped with four protection devices 4 on the guide rods 392 below the four switching devices 39, respectively. Reference Figure 7 with Figure 8 The protection device 4 includes a housing 41. A mounting hole 411 is formed through one side of the housing 41. The mounting hole 411 is sleeved in the guide rod 392 and between the housing 41 and a fixing portion 394 provided under the guide rod 392. A spring 42 is provided, and the protection device 4 is provided with a restoring force through the spring 42. The protection device 4 further includes a wiper 43, a heat preservation device 45 and a cover 44. The wiper 43 is made of elastic materials such as rubber or polyolefin, and a slit 431 is opened in the middle of the wiper 43. The heat-preserving device 45 is a spring-shaped heat-preserving device made of metal material. By energizing the heat-preservin...

no. 3 example

[0056] On the basis of the second embodiment of the three-dimensional printer 3, the three-dimensional printer 3 can also add a cleaning device 5. The cleaning device 5 can be the cleaning device disclosed in the Chinese invention patent application entitled "Print head cleaning device and cleaning method" with the application publication number CN103317853A. Reference Picture 10 with Picture 11 , The pump 51 of the cleaning device 5 is a miniature vacuum pump. The pump 51 has an air outlet 511 and an air inlet 512. The cleaning device 5 also includes a first pressure relief valve 52, a first on-off valve 53, a second pressure relief valve 54, a second on-off valve 55, an air pressure sensor 56, a protection compartment 57, an upper cleaning box 58, and a lower cleaning box 59 And the pipe, wherein the pipe is composed of a main pipe 61, a first branch pipe 62 and a second branch pipe 63. The first end of the first branch pipe 62 is connected to the air outlet 511, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com