Scribing device and scribing method

A scribing device and technology for cutting and scribing lines, applied in glass cutting devices, glass manufacturing equipment, glass production, etc., can solve problems such as inability to scribing lines, and achieve the effect of increasing the degree of freedom and reducing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

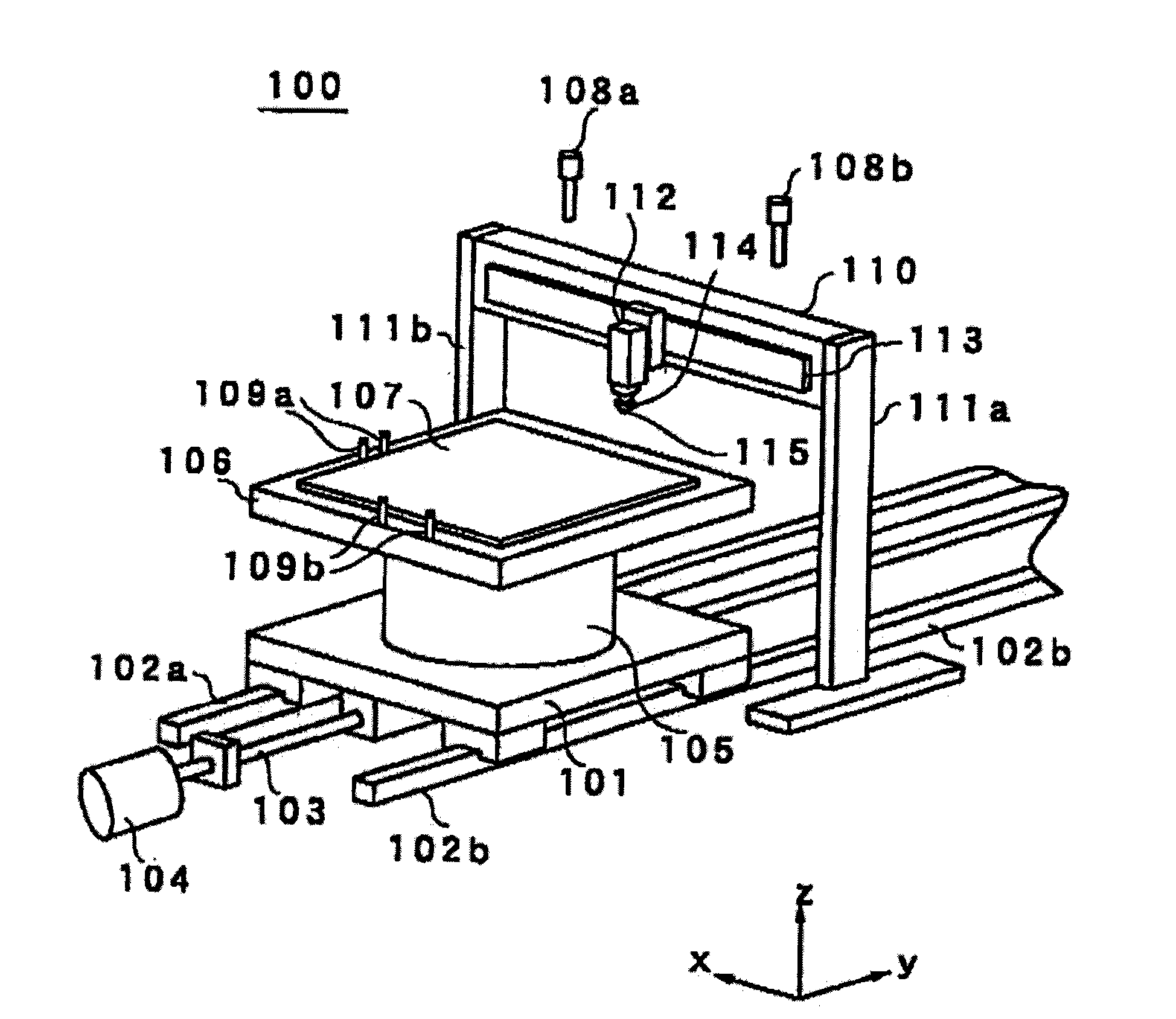

[0055] image 3 It is a schematic perspective view of an example of a scribing device according to an embodiment of the present invention. The moving table 101 of the scribing device 100 is held so as to be movable in the y-axis direction along a pair of guide rails 102a, 102b. The ball screw 103 is screwed with the moving table 101 . The ball screw 103 is rotated by the drive of the motor 104 to move the moving table 101 in the y-axis direction along the guide rails 102a and 102b. A motor 105 is provided on the mobile platform 101 . The motor 105 rotates the platform 106 on the xy plane to be positioned at a predetermined angle. Here, the brittle material substrate 107 is assumed to be a low-temperature fired ceramic substrate. The brittle material substrate 107 is placed on the stage 106 and held by a vacuum suction means not shown in the figure. Two CCD cameras 108a and 108b for imaging the alignment marks of the brittle material substrate 107 are installed on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com