Gas processing apparatus and method and computer storage medium storing program for controlling same

a technology of computer storage medium and processing apparatus, which is applied in the direction of process and machine control, fluid pressure control, instruments, etc., can solve the problems of further cost increase of the apparatus itself, inability to properly cope with the case, and increase of the operation cost of the apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

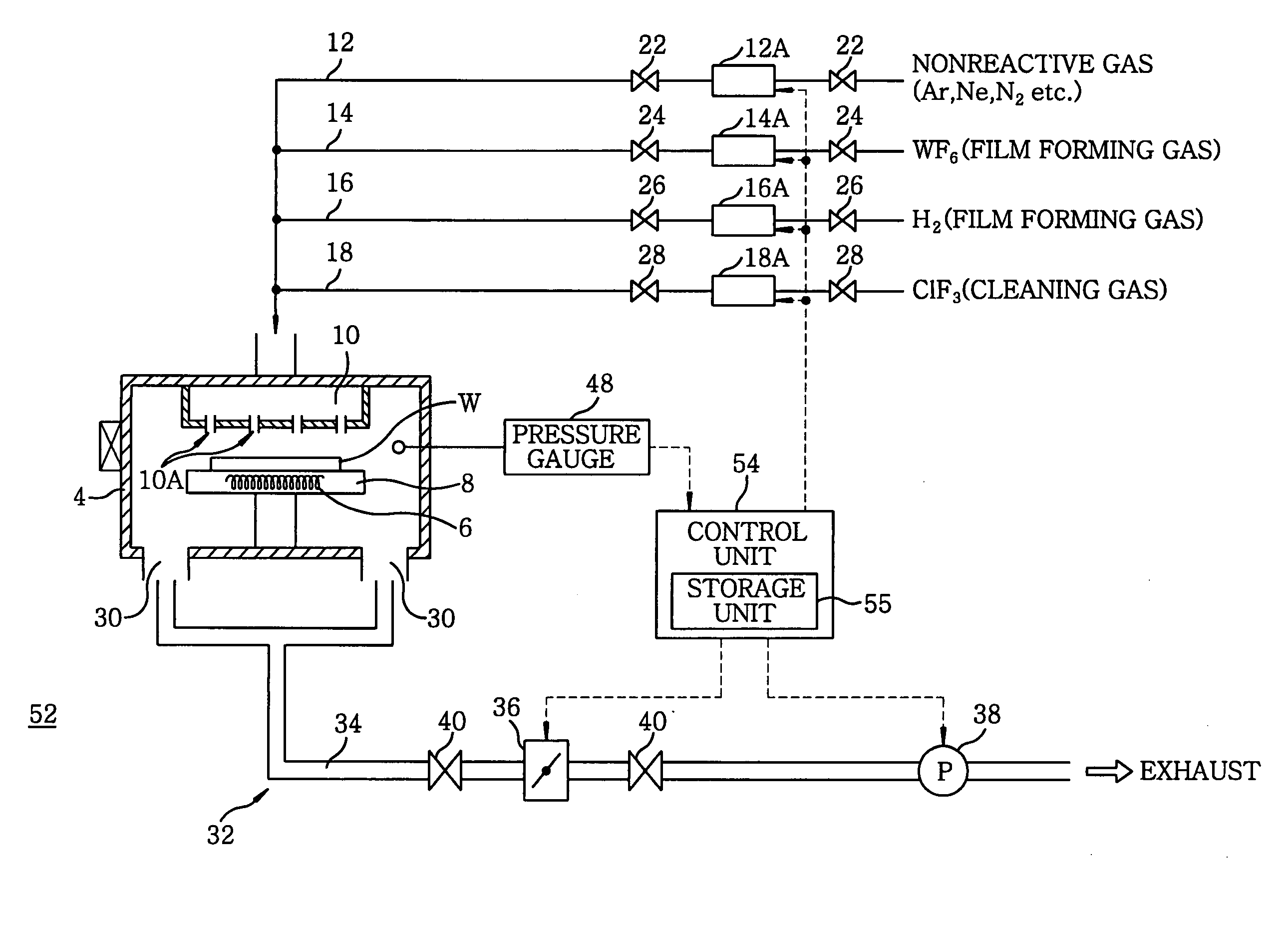

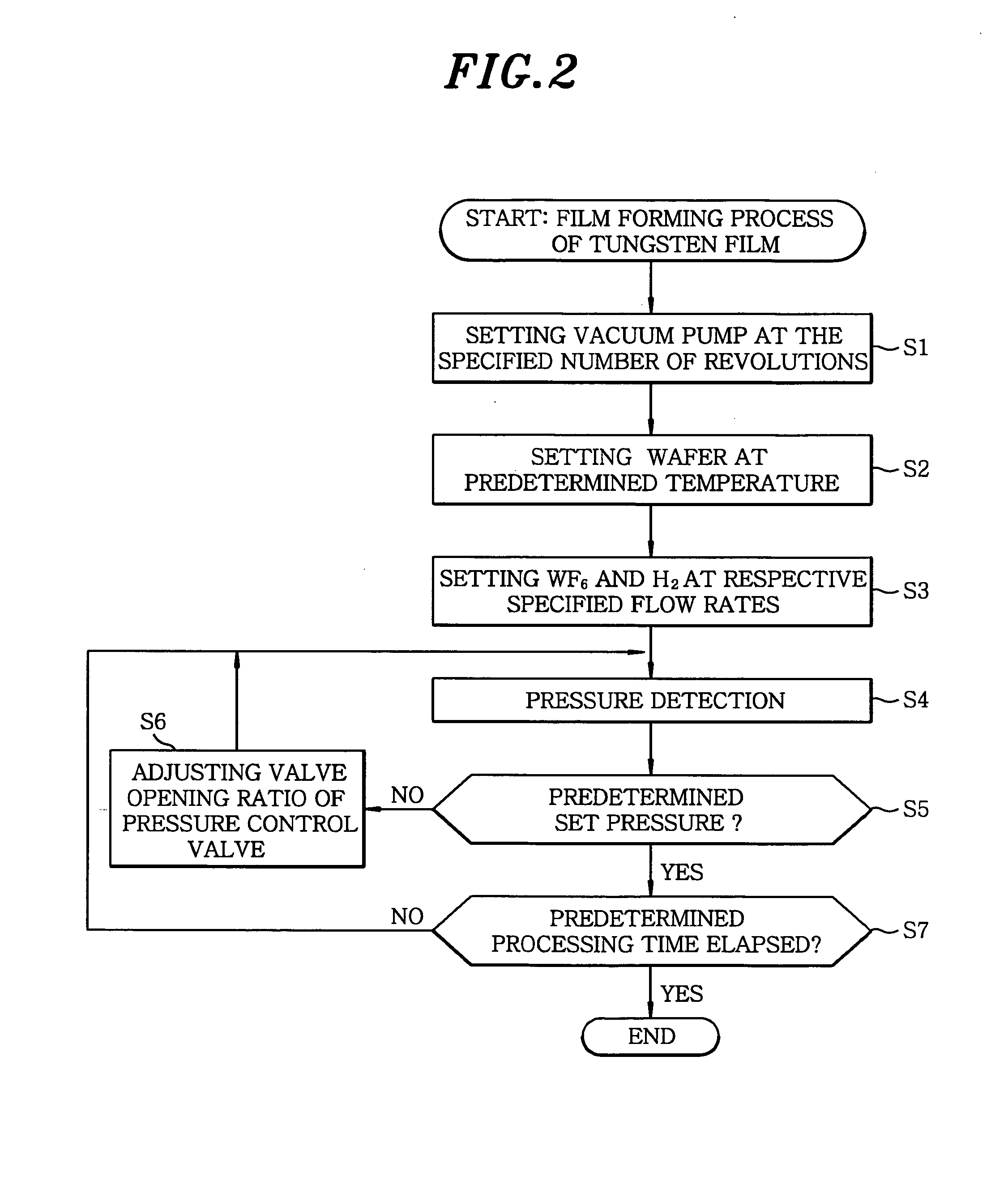

[0038]FIG. 1 is a schematic diagram showing a first embodiment of a processing apparatus in accordance with the present invention; FIG. 2 is a flowchart showing an embodiment of process in accordance with a first processing method; FIG. 3 is a flowchart showing an embodiment of process in accordance with a second processing method; FIG. 4 is a cross sectional view showing an embodiment of mounting table in case when a pre-cleaning process is carried out; and FIG. 5 is a flowchart showing an embodiment of process in accordance with a third processing method. Identical reference numerals will be assigned and explained for corresponding parts having substantially the same functions and configurations with those in FIG. 8. Further, the term “a process wherein a partial pressure of a processing gas is relatively important” to be explained below means a low processing pressure process (low pressure process), and the term “a process wherein a partial pressure of a processing gas is relativ...

second embodiment

[0068] In the aforementioned embodiment, such a case has been explained by using an example where an integrated exhaust line 34 is installed and one vacuum pump 38 is installed therein, as shown in FIG. 1. However, in case when pumping capacity is insufficient with one vacuum pump 38, a configuration of a second embodiment shown in FIG. 6 may be adopted. Namely, in this case, a second vacuum pump 60 formed of, e.g., a turbo molecular pump, is installed in series with the pressure control valve 36, and a bypass exhaust path 62 is connected to the exhaust line 34 such that it bypasses the pressure control valve 36 and the second vacuum pump 60. Further, a converting opening / closing valve 64 is installed in the bypass exhaust path 62. An inner diameter of the bypass exhaust path 62 is about in the range from 25 to 40 mm.

[0069] In this embodiment, the opening / closing valves 40 of the exhaust line 34 are first closed in case when vacuum-exhausting the inside of the processing vessel 4; ...

third embodiment

[0070] Next, a third embodiment of the present invention will be explained.

[0071]FIG. 7 is a schematic diagram showing a third embodiment of a processing apparatus in accordance with the present invention. Identical reference numerals will be assigned and explained for corresponding parts having substantially the same functions and configurations with those in FIGS. 1, 6 and 8. Further, the term “a relatively low processing pressure process” explained herein means a process wherein a partial pressure of a processing gas is important as was explained before, and the term “a relatively high processing pressure process” means a process wherein a partial pressure of a processing gas is unimportant.

[0072] As shown in FIG. 7, in the main exhaust line 34, there are installed the pressure control valve 36, the second vacuum pump 60 formed of, e.g., a turbo molecular pump and the first vacuum pump 38 formed of, e.g., a dry pump, in this order from the upstream side to the downstream side t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Partial pressure | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com