Systems and methods for cooling electronics components employing vapor compression refrigeration with selected portions of expansion structures coated with polytetrafluorethylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

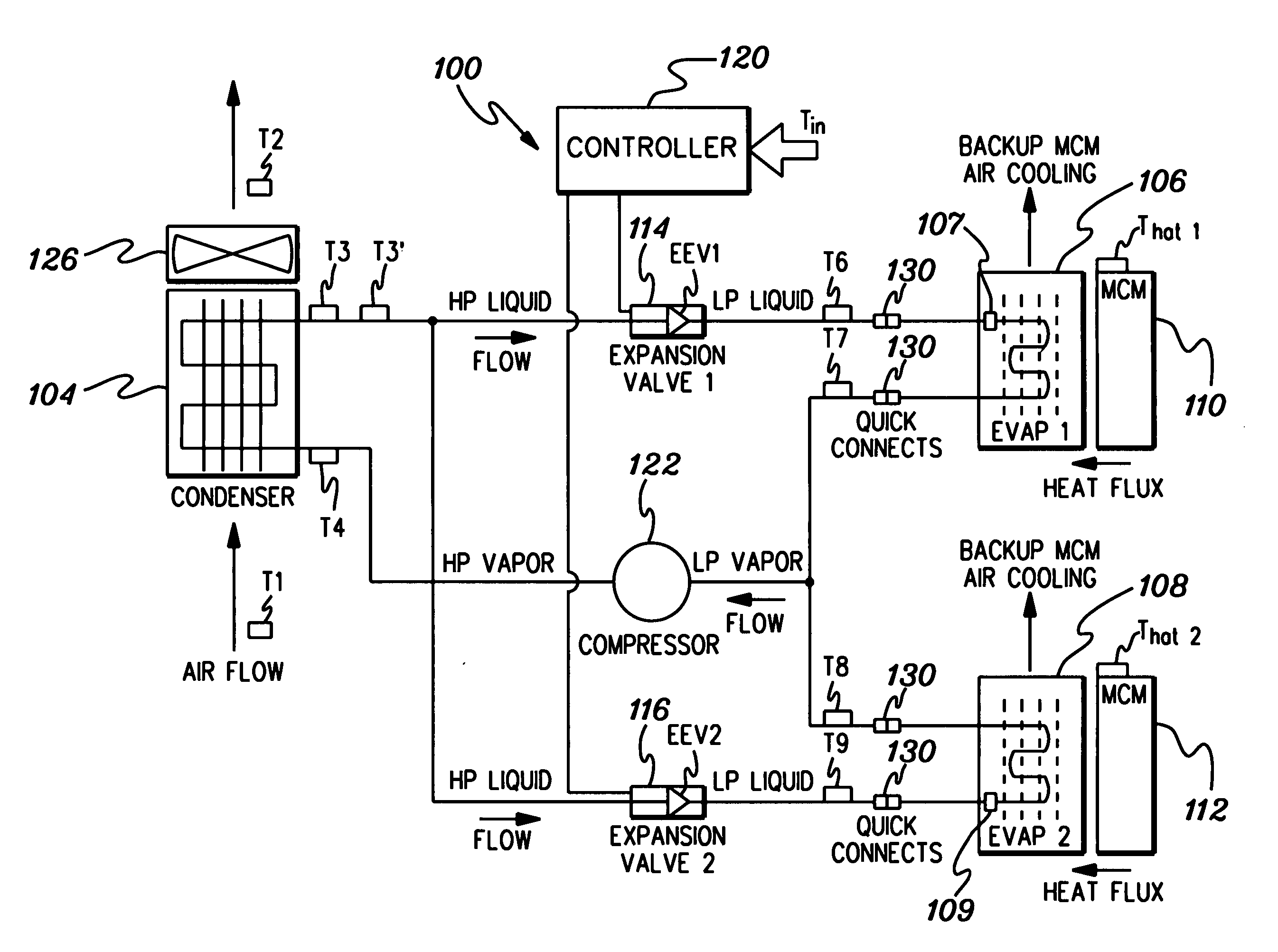

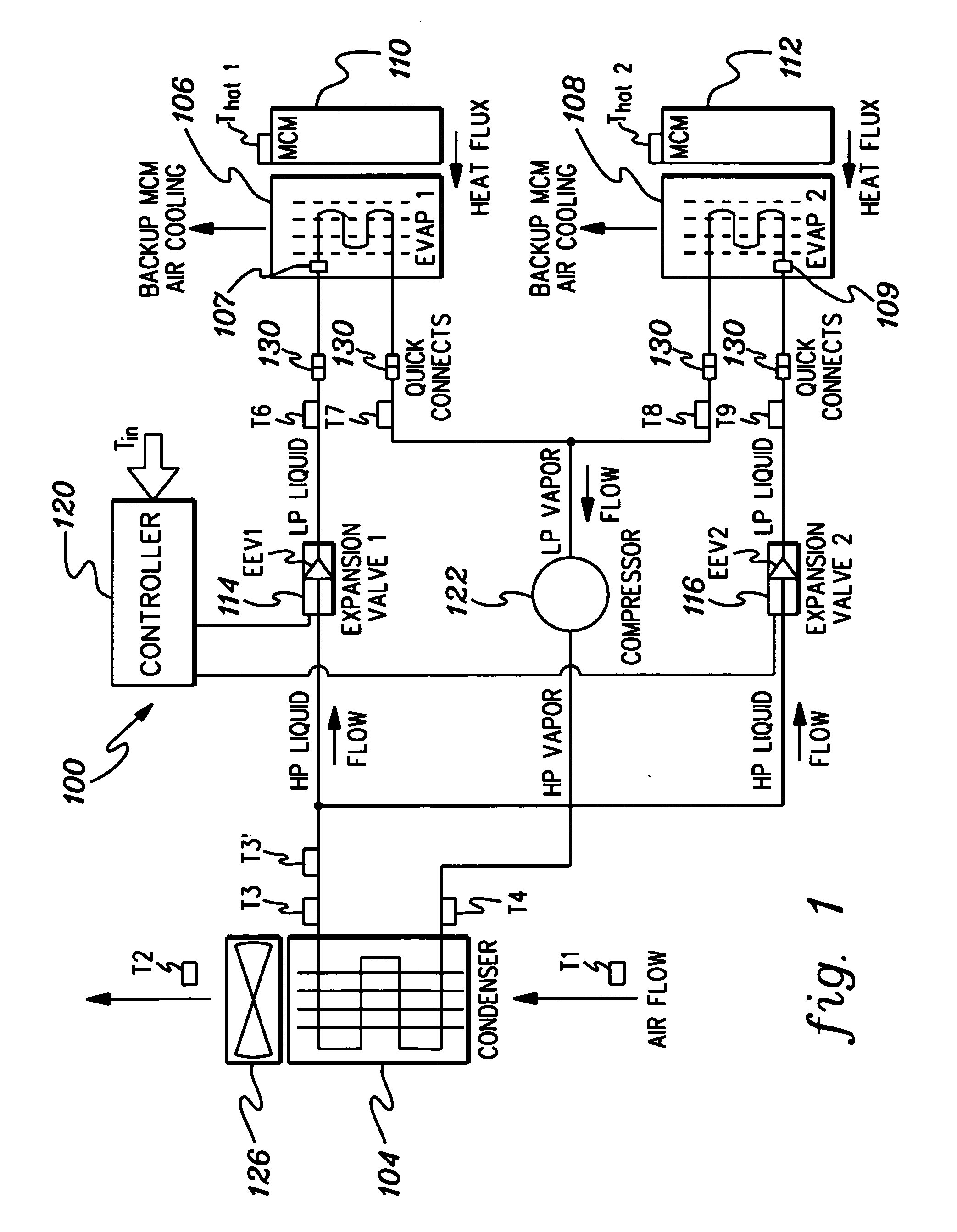

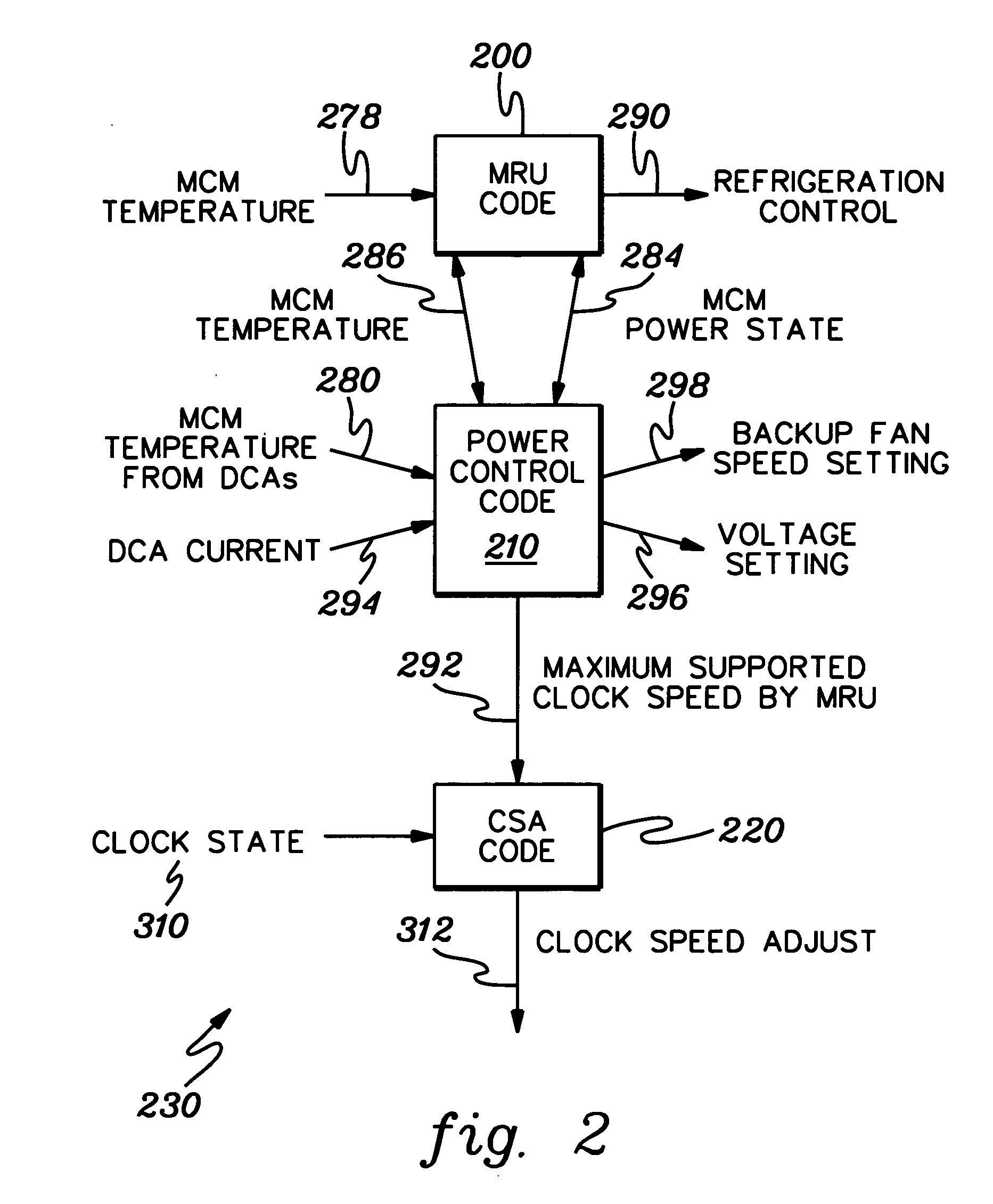

[0019] As used herein, the term “electronics rack” includes any frame, rack, blade server system, etc., having at least one heat generating electronics component of a computer system or electronics system, and may be, for example, a stand alone computer processor having high, mid or low end processing capability. In one embodiment, an electronics rack may comprise multiple books, each book having one or more heat generating electronics components requiring cooling. Each “heat generating electronics component” may comprise an electronic device, an electronics module, an integrated circuit chip, a multi-chip module, etc. An “expansion structure” is any structure or area in a vapor compression refrigeration system where there is a pressure drop, and thus refrigerant expansion during a refrigerant compression / expansion cycle. As used herein, the term “expansion structure” includes any structure of a pressure drop area and adjacent areas where an agglomeration would effect an expansion s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com