Hogging moment tensioning tool device

A negative bending moment and tensioning technology, applied in the engineering field, can solve the problems of low construction efficiency, inconvenient use, and need for manpower, and achieve the effects of avoiding the decline of production efficiency, reducing physical fatigue, and stabilizing the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

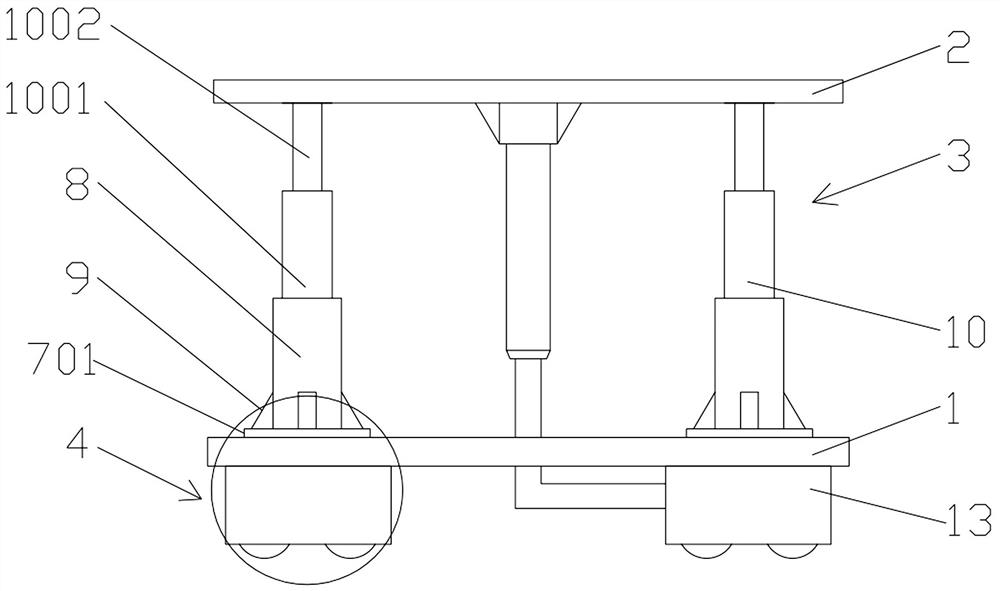

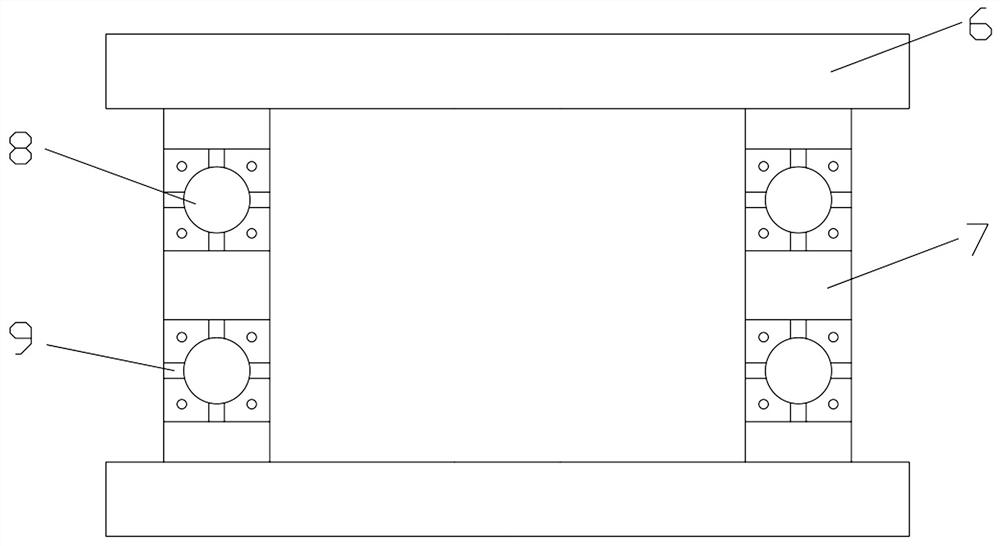

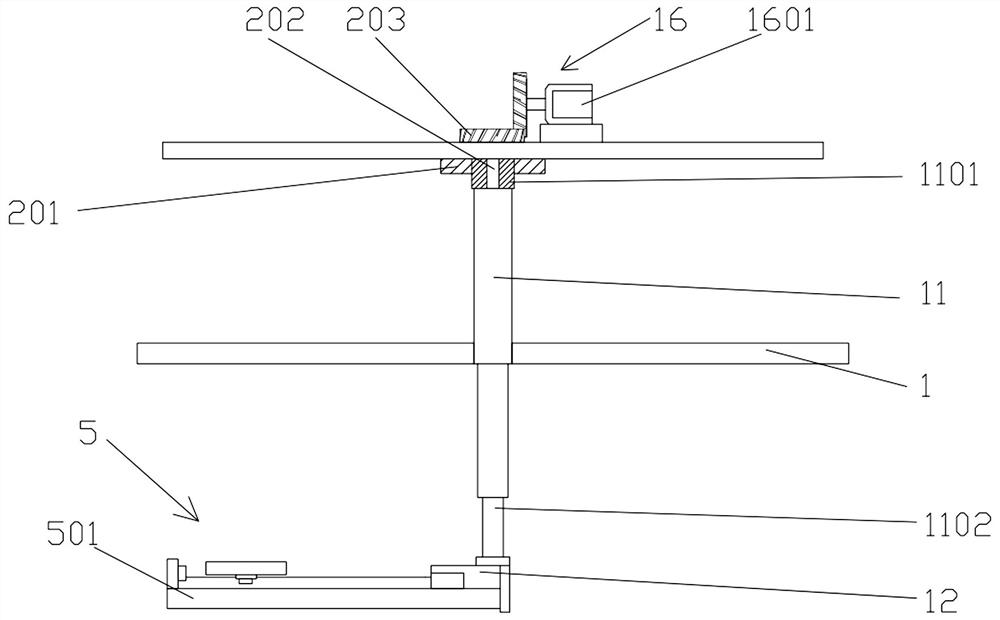

[0030] like Figure 1~6 As shown, it includes a base 1, an upper fixed plate 2, a supporting mechanism 3, a moving mechanism 4, a workbench 5 and a rotating mechanism 16. The supporting mechanism 3 is arranged between the base 1 and the upper fixed plate 2, and the moving The mechanism 4 is fixedly connected to the base 1, the workbench 5 is connected to the supporting mechanism 3, and the rotating mechanism 15 is arranged above the upper fixed plate 2; a controller is also provided, and the controller includes an operating hand, the The operating hand is used to control the work of the supporting mechanism 3, the moving mechanism 4, the workbench 5 and the rotating mechanism 16. With this structure, the supporting mechanism 3 is set between the base 1 and the fixed plate 2, which can ensure that the workbench 5 The center of gravity of the support is lowered during movement, so that the overall operation is more stable, the firmness of the system is increased and the anti-dum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com