Structure for hogging moment area of steel-concrete composite continuous beam bridge

A technology of negative bending moment area and girder bridge, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of unreasonable force in the negative bending moment area of continuous composite beams, improve the quality of lap joints, and meet the requirements of prefabricated assembly. Construction, the effect of improving the ability to resist negative bending moments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

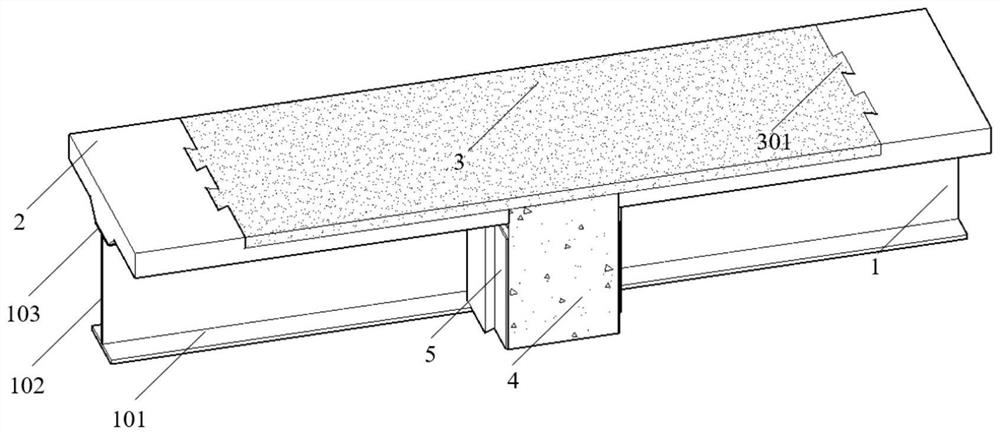

[0051] The present invention is a structure for the negative moment zone of steel-concrete composite continuous girder bridge. The prefabricated steel-concrete composite beam is connected by the lower I-beam 1 and the upper deck 2 made of ordinary concrete through bolts 6 connectors , the negative moment zone structure includes two prefabricated steel-concrete composite beams, the notches of the first prefabricated main girder and the second prefabricated main girder are spliced to form a rectangular strip with jagged edges on the upper part 3, The middle and lower parts are the cast-in-place wet joints of the vertical tank body 4 with jagged edges, and the UHPC layer filled in the upper part of the T-shaped joint has a longitudinal length of 6m and a thickness of 0.11m; the longitudinal length of the lower ordinary concrete layer is 1.2m and a height of 1.69m. The end of the first prefabricated main girder and the bridge deck 2 of the second prefabricated main girder are pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com