Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Soft voice" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

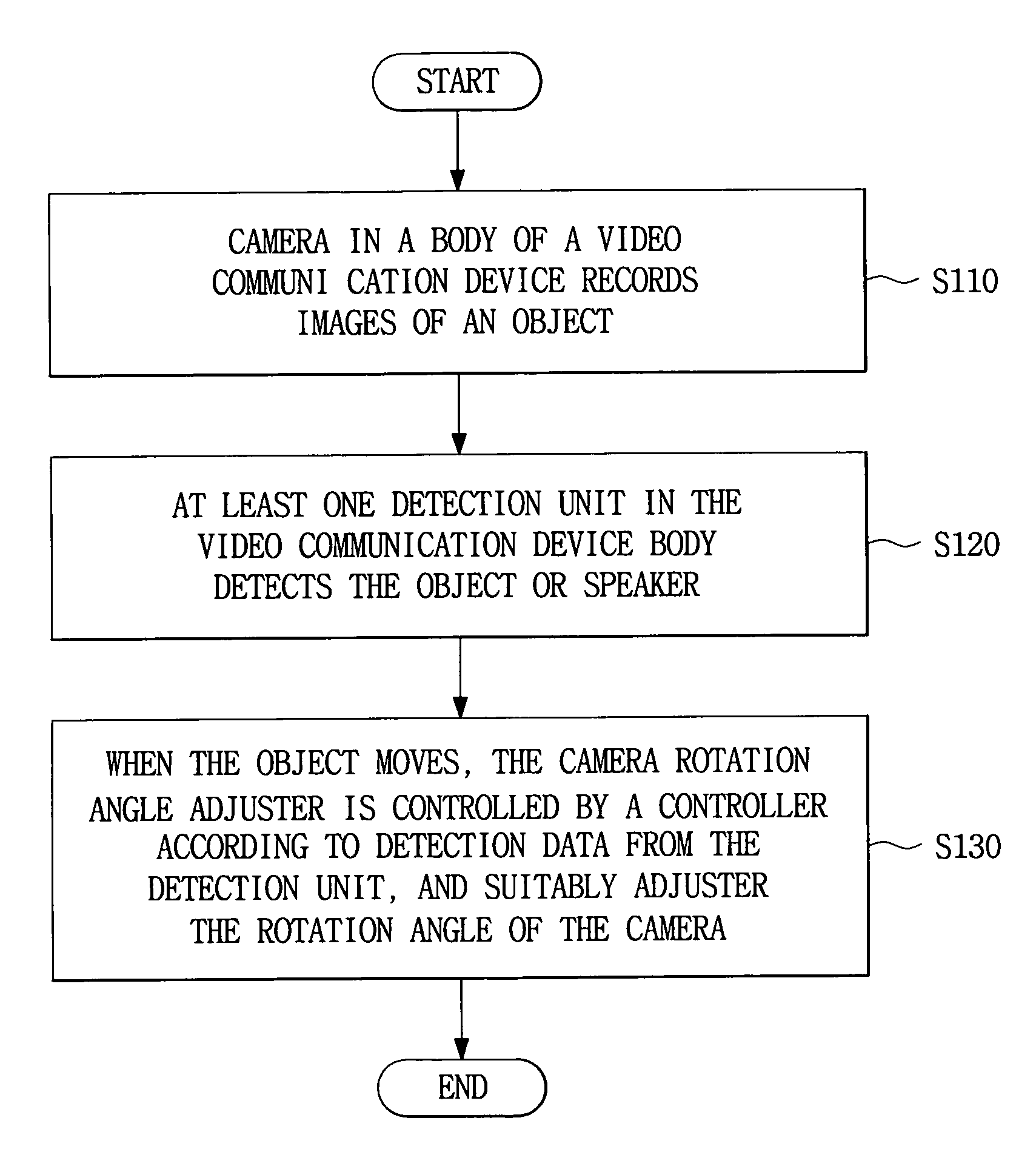

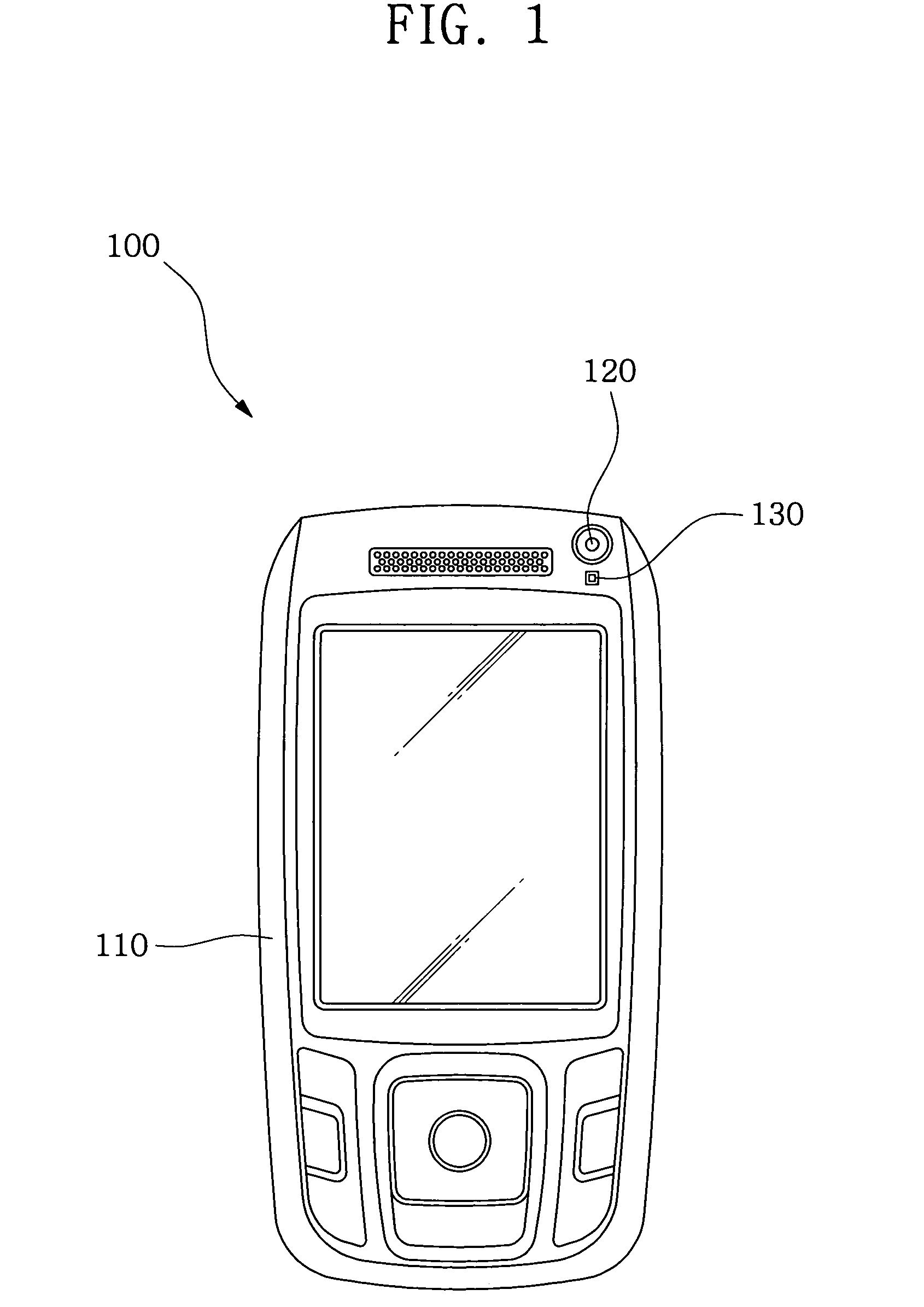

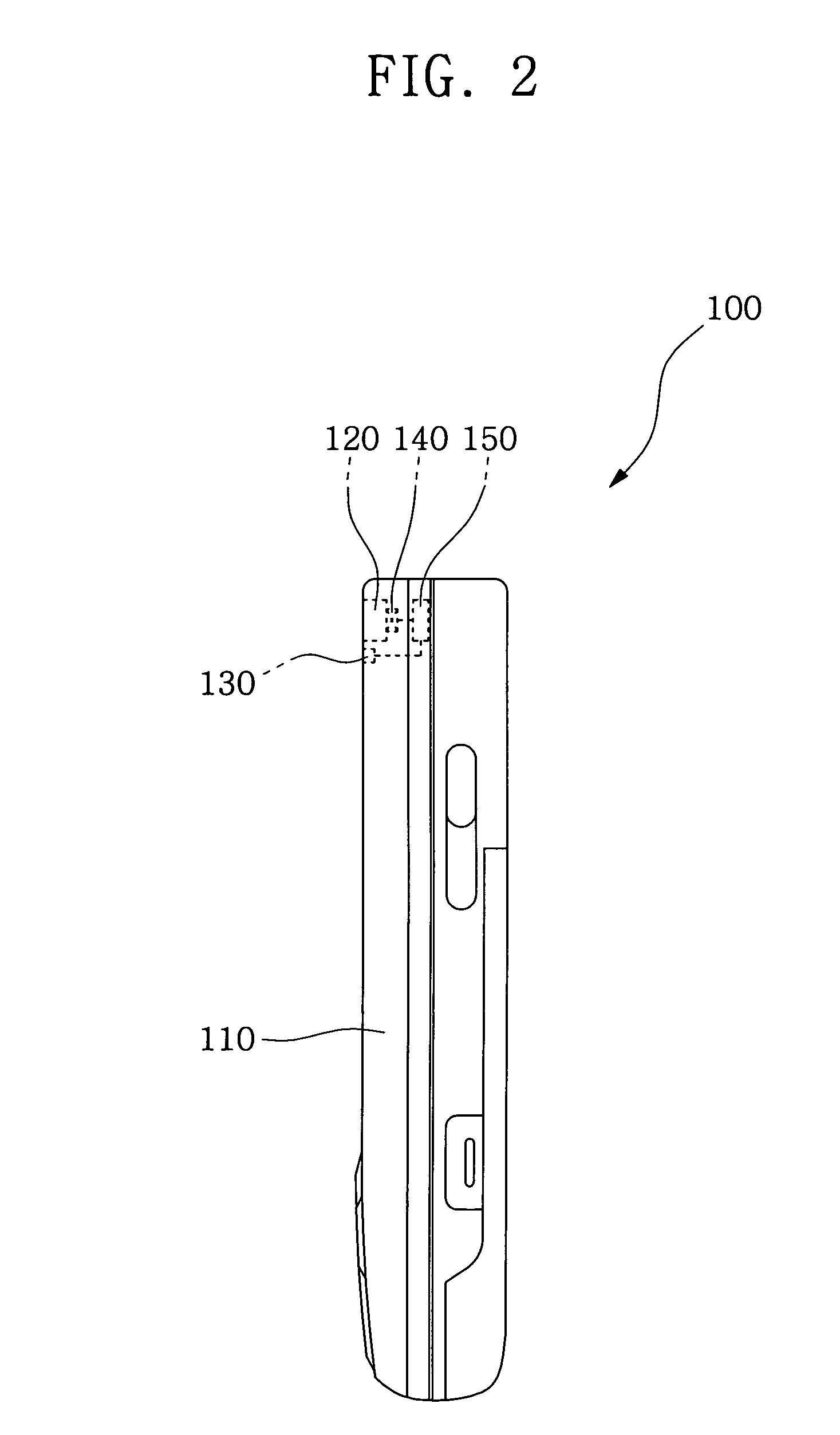

Video communication device and camera tracking method thereof

ActiveUS20090096858A1Wide angular fieldQuality improvementTelevision system detailsColor television detailsColor sensorCommunication device

A video communication device includes a video communication device body; a camera fitted to the video communication device body to record images of an object; at least one detection unit fitted to the video communication device body to detect the object according to a predetermined condition; and a camera rotation angle adjuster fitted to the video communication device body to adjust a rotation angle of the camera according to detection data from the detection unit so that the camera automatically tracks a position of the object when the object moves. The moving object can be located through a detection unit, such as a voice sensor, a codec, a color sensor and an IR sensor, and be automatically tracked by suitable adjustment of the rotation angle of a camera. A wide angular field is ensured and video telephony quality is improved.

Owner:SAMSUNG ELECTRONICS CO LTD

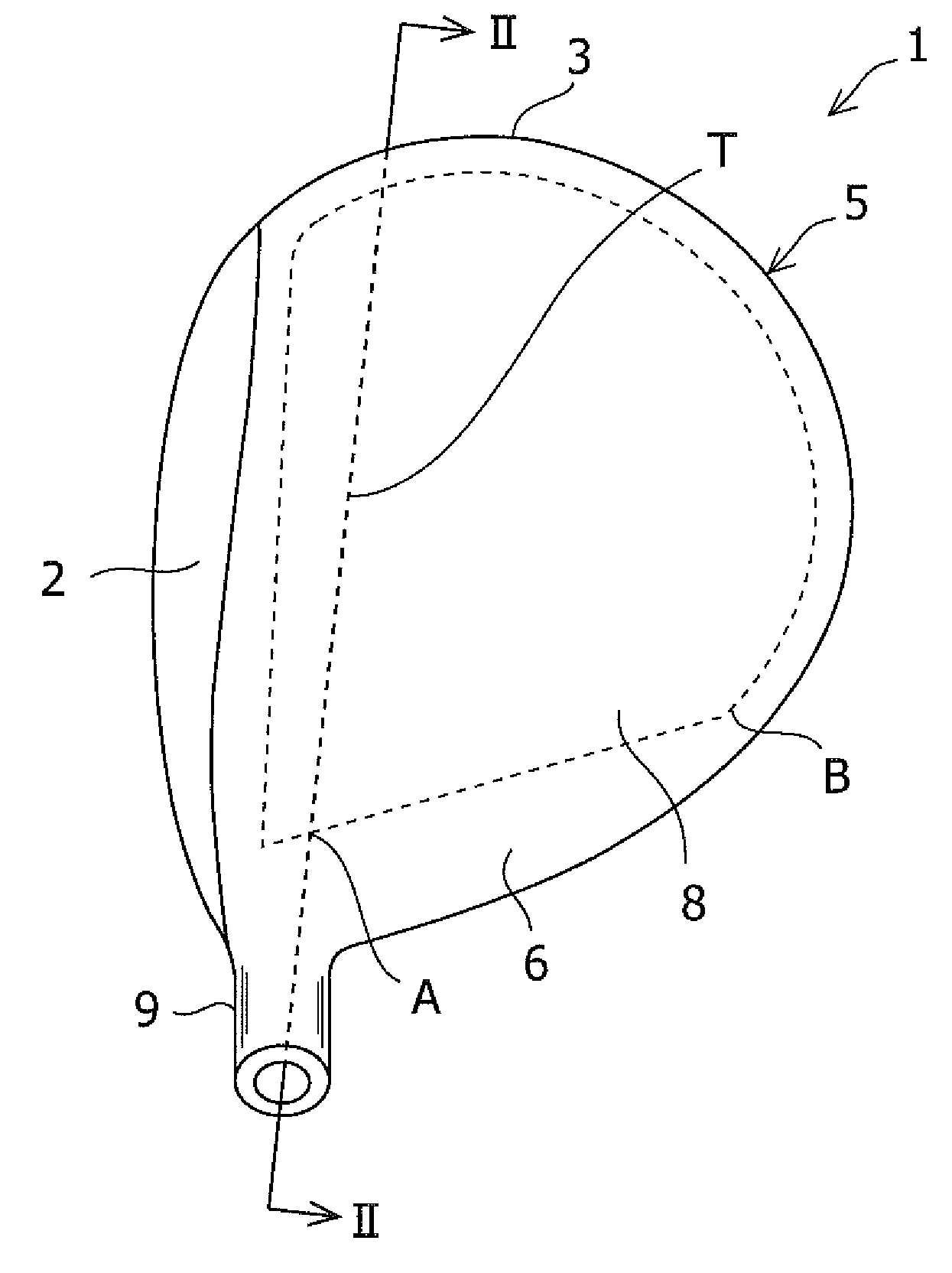

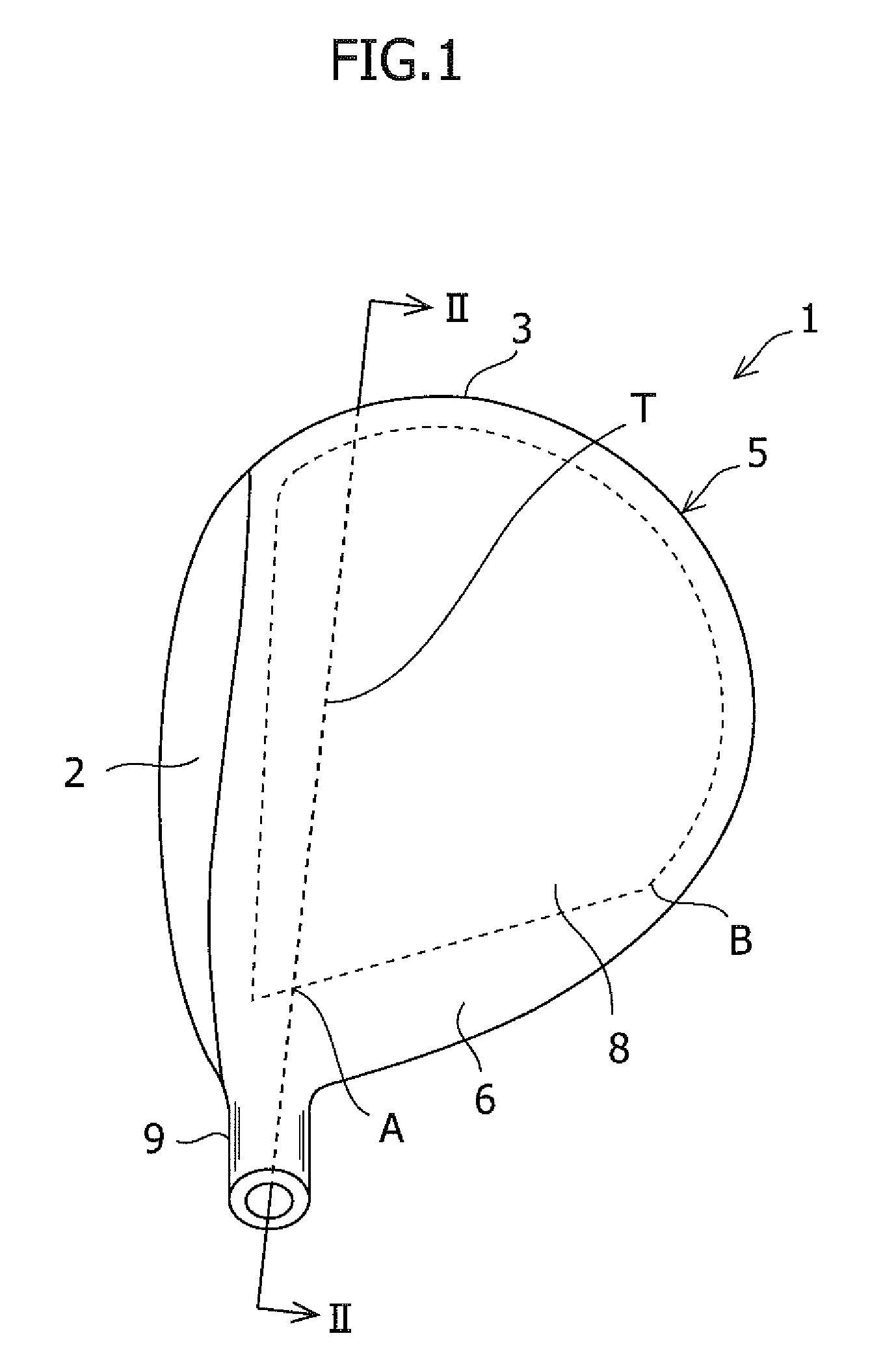

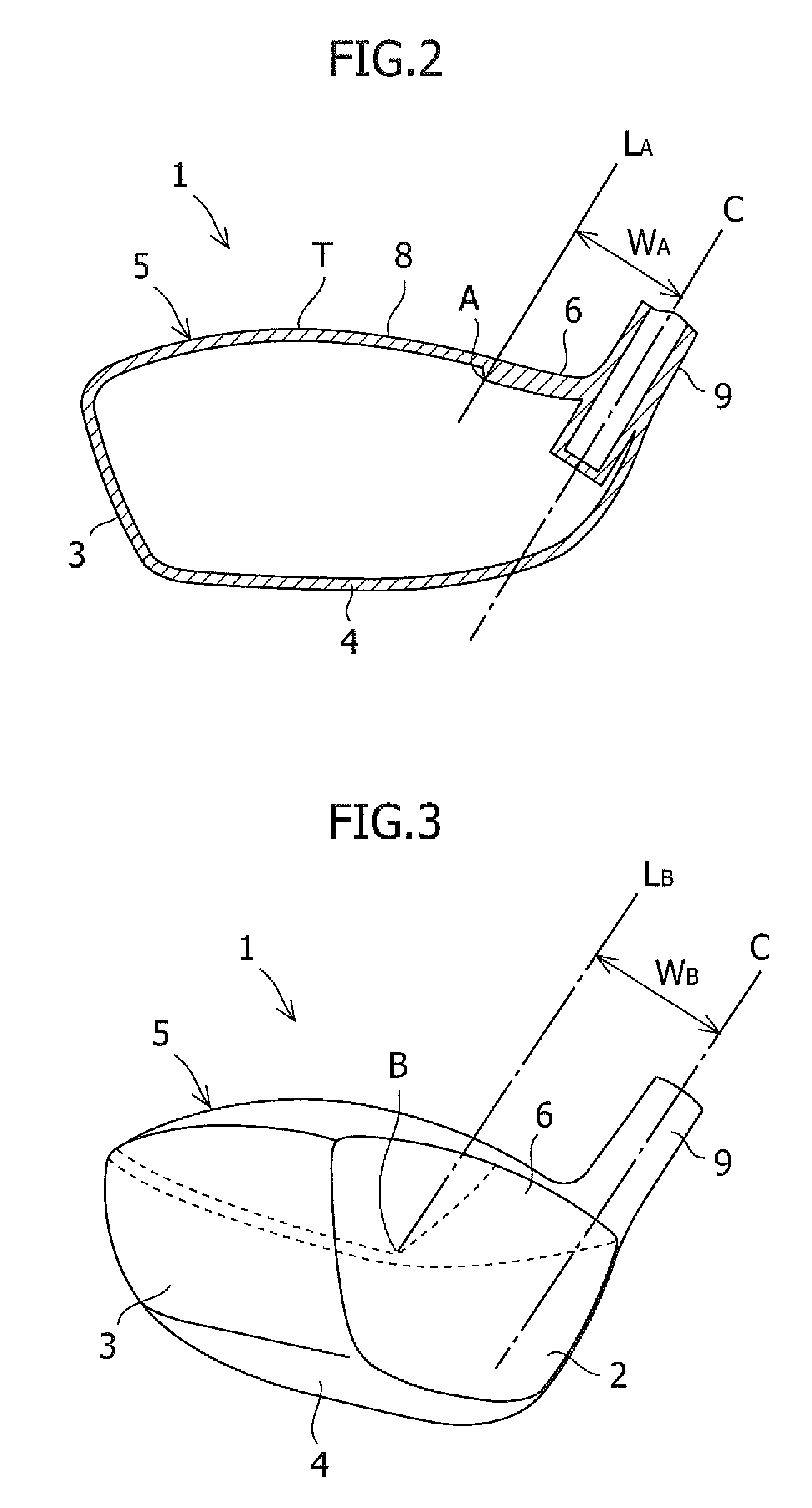

Golf club head

Owner:BRIDGESTONE SPORTS

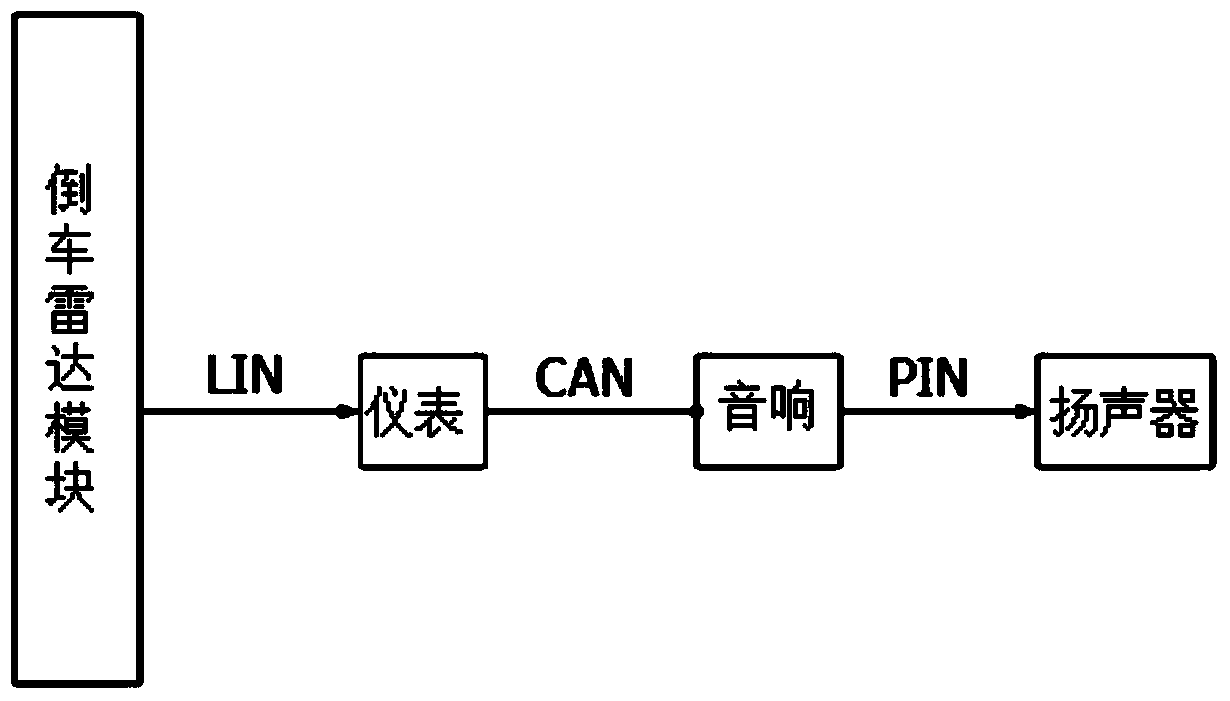

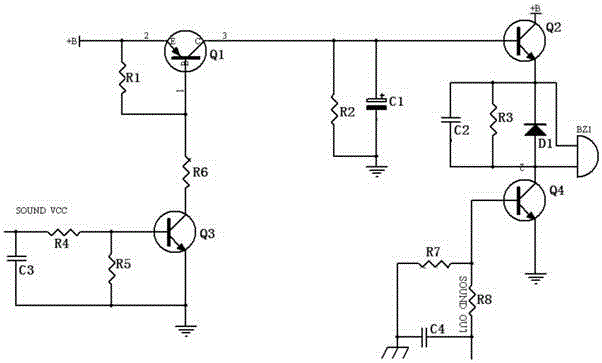

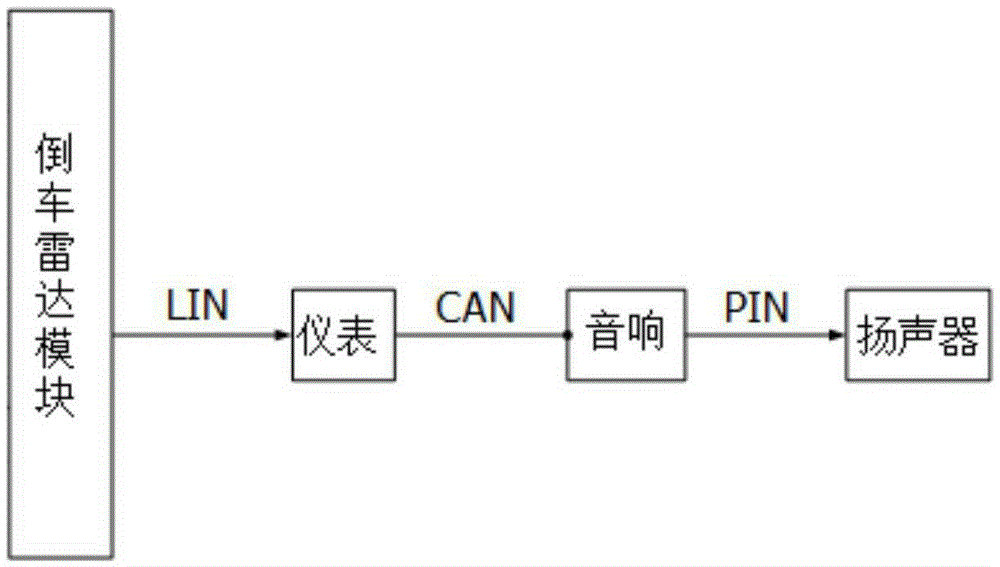

Voice prompt and alarm system based on vehicle-mounted sound system

The invention discloses a voice prompt and alarm system based on a vehicle-mounted sound system. An automobile reversing radar sends detection signals to an automobile instrument, the instrument sends alarm signals to a sound device through a CAN, and the sound device carries out alarming through loudspeakers. On the premise of not changing a current electronic frame and not increasing cost, an entertainment system in an automobile is used for carrying out relevant voice alarming, the vehicle-mounted sound system has the better loudspeaker effect and is provided with DSP sound processing software with the wider adjustable range, a driver is prompted, and meanwhile sounds are softer, more sweet-sounding and more beautiful. The loudspeakers at different positions carry out alarming to achieve different alarming functions, and a user can easily judge which function module breaks down and gives alarming / promoting sounds. Meanwhile, the probability that the driver frequently lowers the head to cause accidents can be reduced.

Owner:CHERY AUTOMOBILE CO LTD

Video communication device and camera tracking method thereof

ActiveUS8284230B2Loud voiceSoft voiceTelevision system detailsColor television detailsColor sensorCommunication device

A video communication device includes a video communication device body; a camera fitted to the video communication device body to record images of an object; at least one detection unit fitted to the video communication device body to detect the object according to a predetermined condition; and a camera rotation angle adjuster fitted to the video communication device body to adjust a rotation angle of the camera according to detection data from the detection unit so that the camera automatically tracks a position of the object when the object moves. The moving object can be located through a detection unit, such as a voice sensor, a codec, a color sensor and an IR sensor, and be automatically tracked by suitable adjustment of the rotation angle of a camera. A wide angular field is ensured and video telephony quality is improved.

Owner:SAMSUNG ELECTRONICS CO LTD

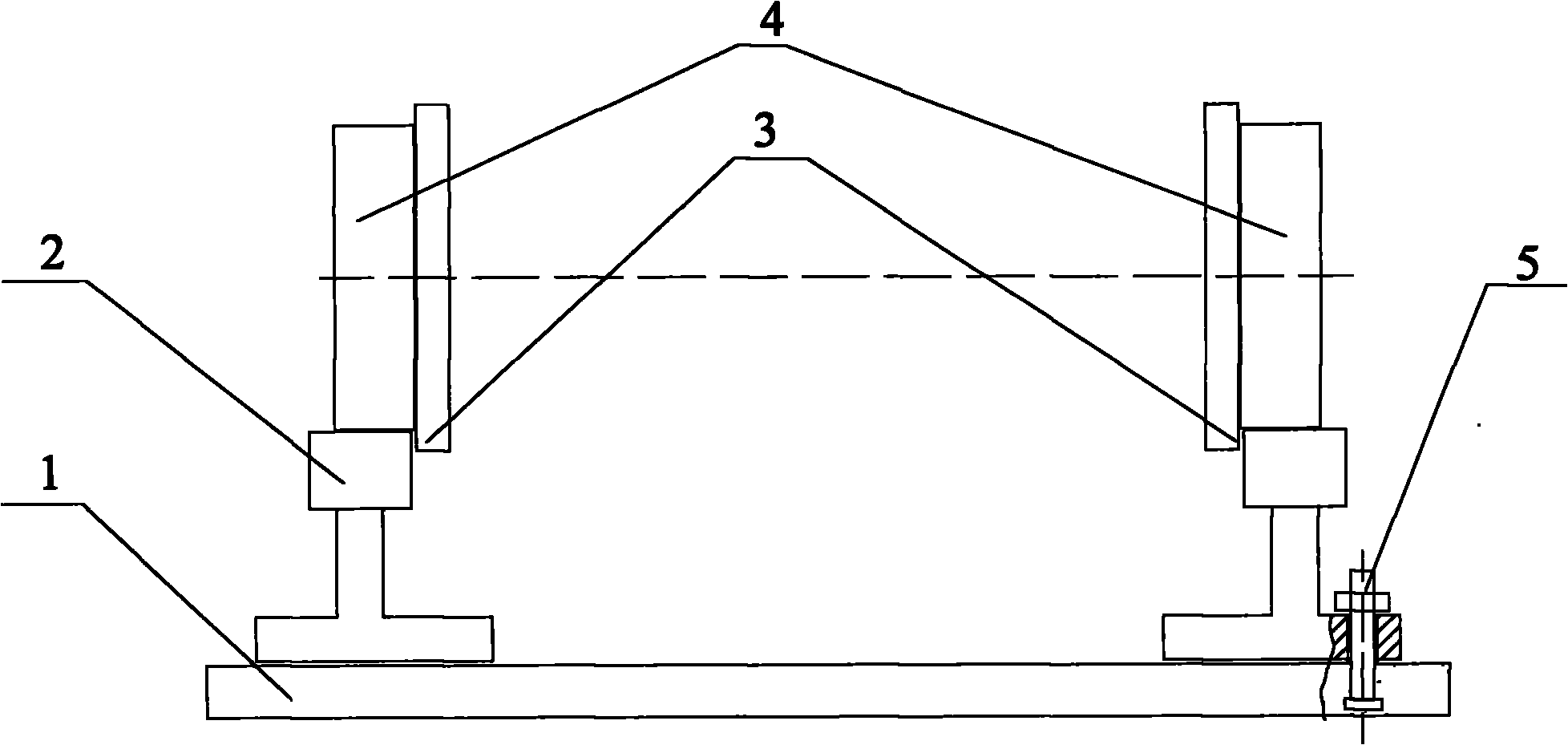

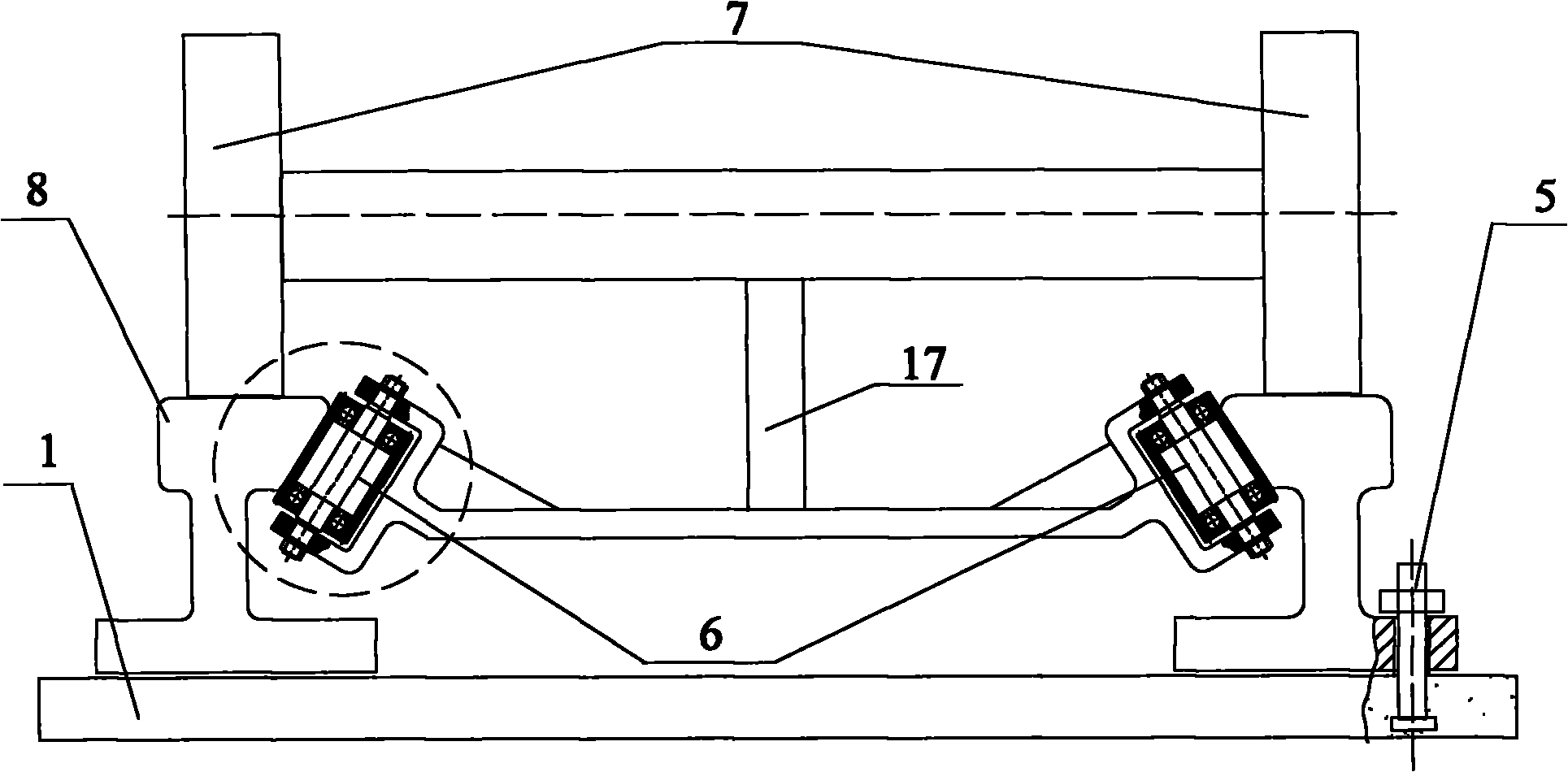

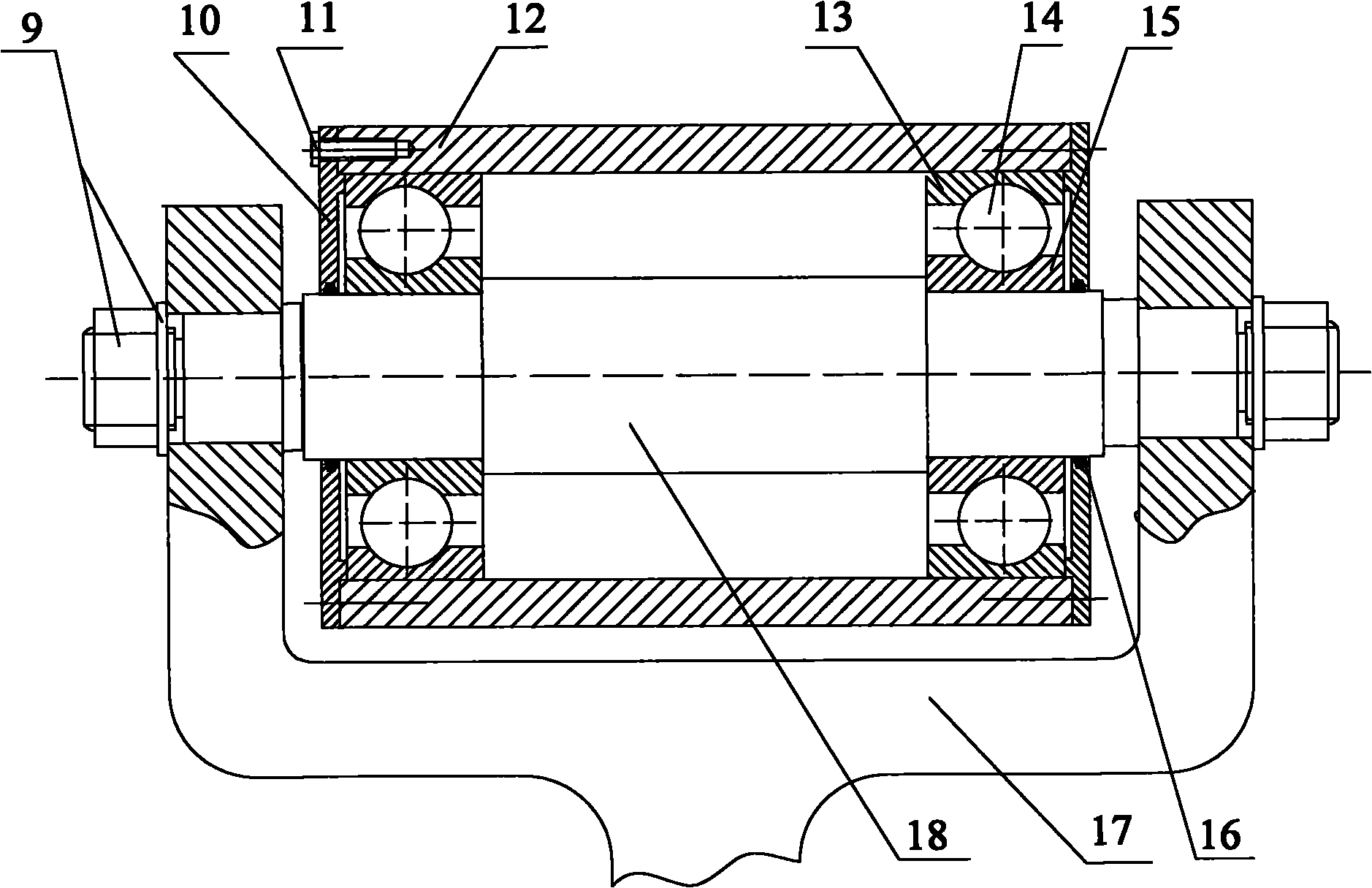

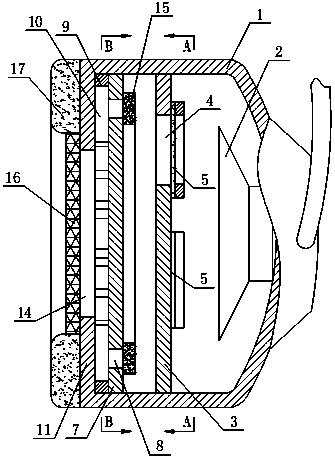

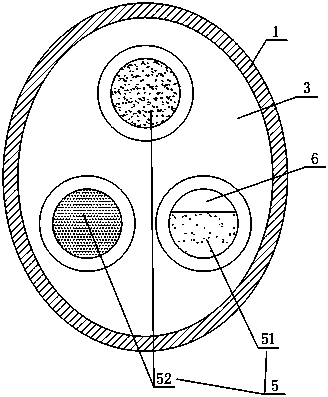

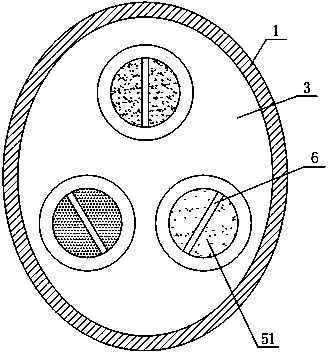

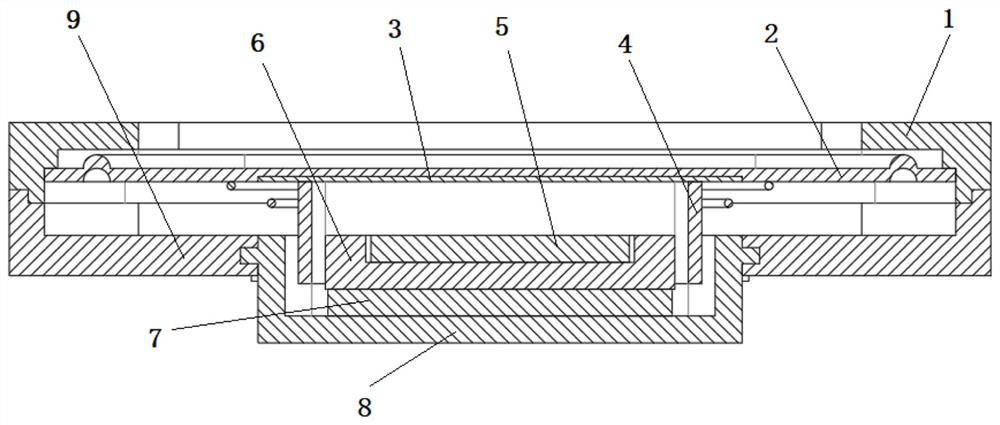

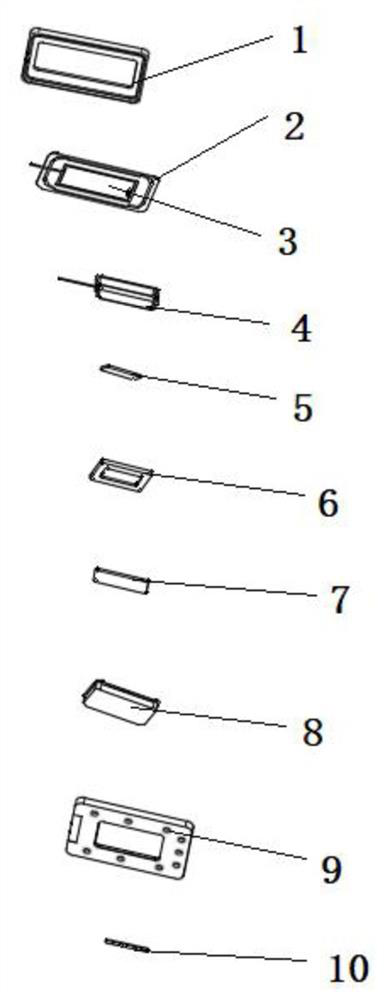

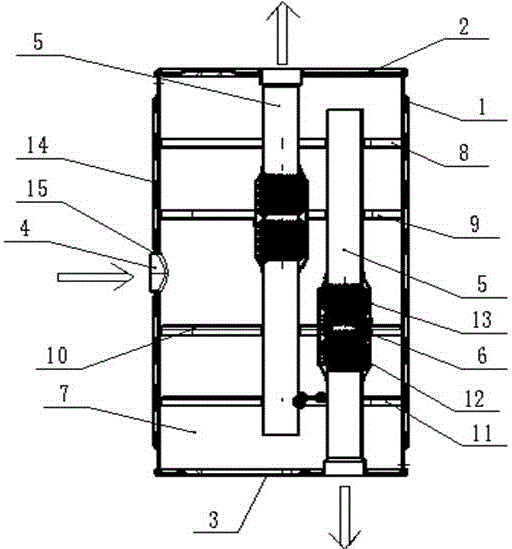

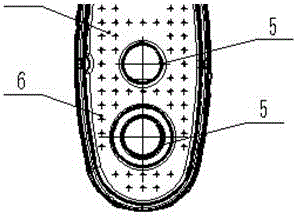

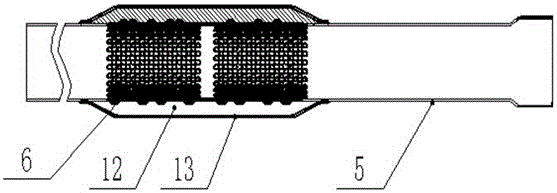

Pure rolling contact structure with low noise and low abrasion loss for rail transit wheel and guiding rail

InactiveCN102049965ASafe and reliable structureAvoid disadvantagesRail-engaging wheelsRailway componentsLow noiseEngineering

The invention discloses a pure rolling contact structure with low noise and low abrasion loss for a rail transit wheel and a guiding rail. The pure rolling contact structure comprises column-shaped wheels (7) and rolling guiding components (6), wherein, the outer round surfaces of the column-shaped wheels (7) are in contact with the upper surface of the guiding rail; the rolling guiding components (6) are assembled on a bracket (17) fixedly connected with a vehicle chassis and / or a wheel shaft; and the rolling guiding components (6) are in rolling contact with the inner side surfaces of the guiding rail. In the invention, the sliding contact between the wheels and the guiding rail is changed into the rolling contact, so that the structure is safer, and beneficial to overcome the defects such as high noise, high abrasion and the like in the existing contact manners.

Owner:GUANGDONG IND TECHN COLLEGE

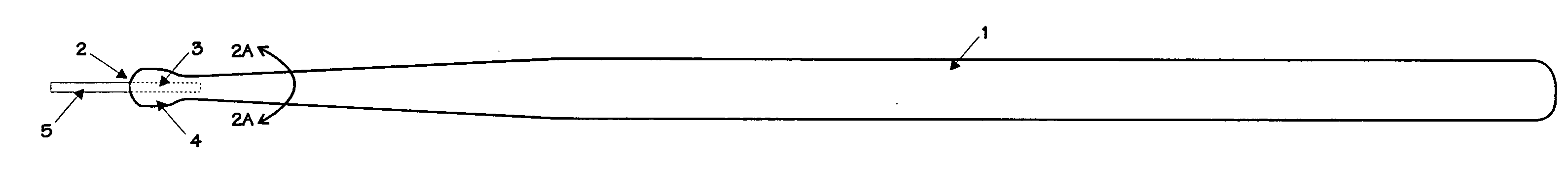

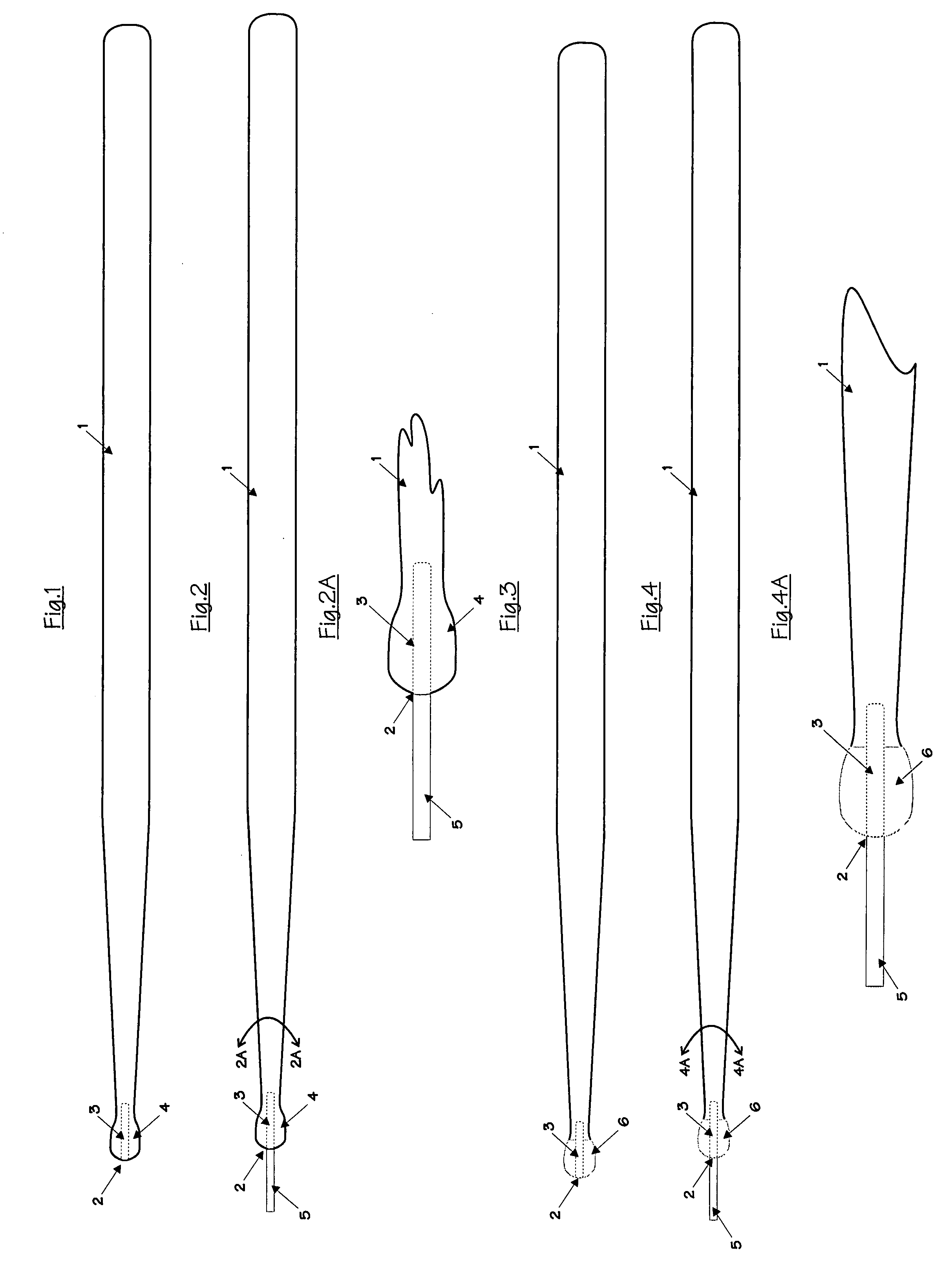

Filter tip drum stick

InactiveUS20090084247A1Improve dynamic rangeSmall diameterPercussion musical instrumentsEngineeringPolycarbonate

A stick type drum stick is disclosed which includes drum stick design featuring a hole drilled longitudinally in the playing striking end. The primary purpose is to accommodate a rod. The rod is inserted and glued into the hole of the tip. The rod can be cut to a desired length to suit its flex and resilient nature. Suitable material for the rod include nylon or delrin, PVC, ABS, polypropylene or polycarbonate. The result of combining these materials in this format produces a filter tip drum stick.

Owner:RUNDLE DAVID CHAPPELL

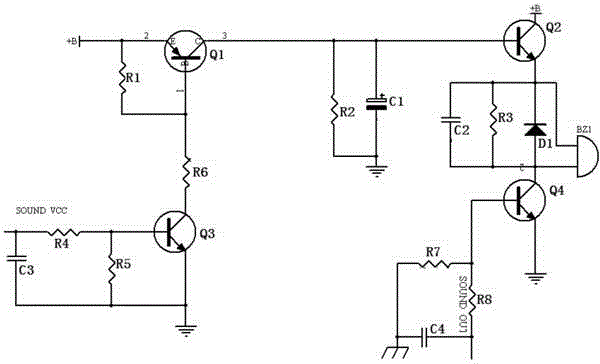

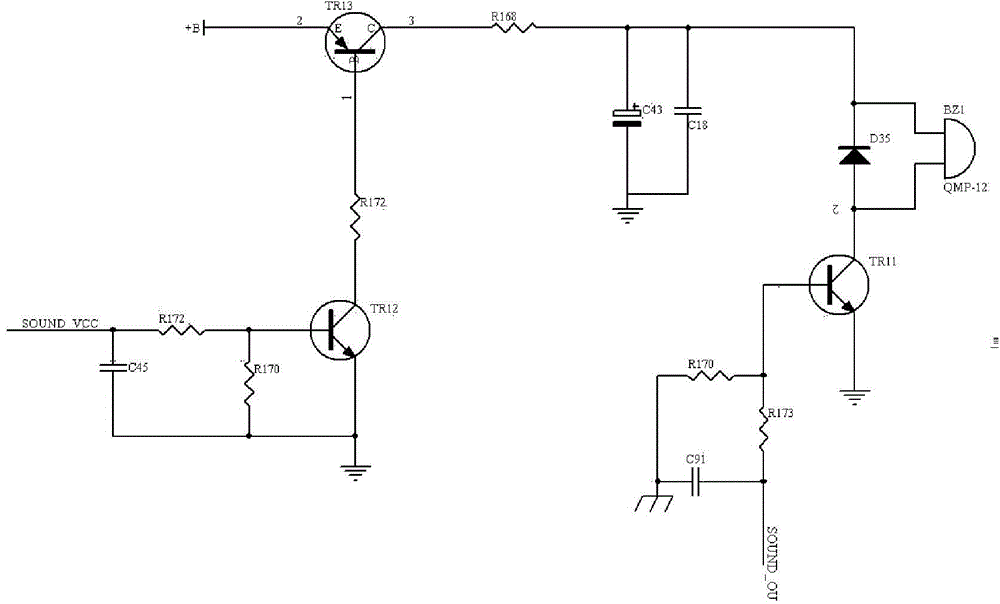

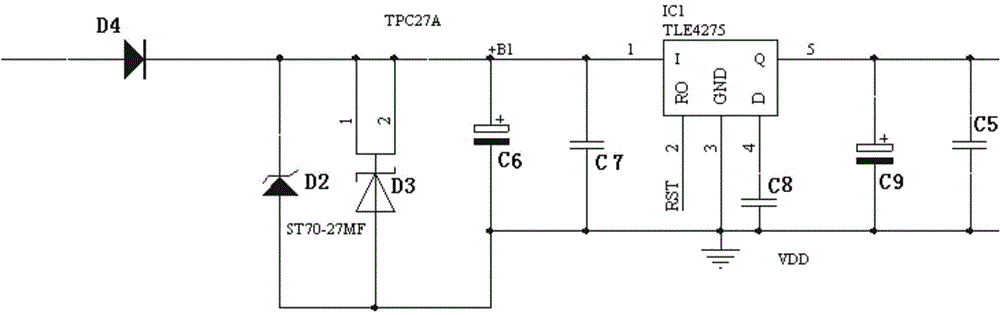

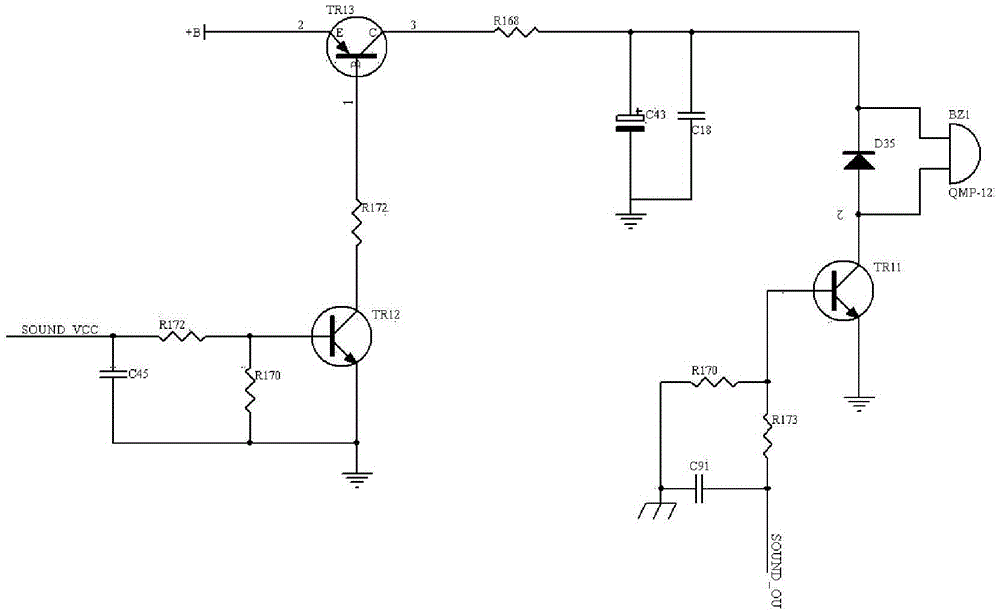

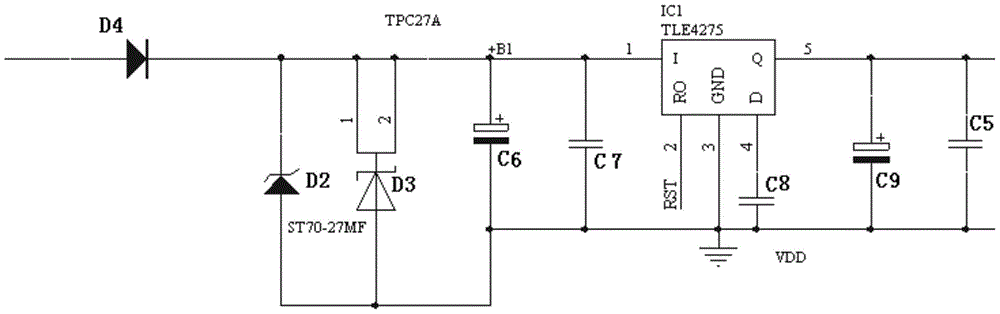

Automobile instrument shell and backlight module

ActiveCN104442400APrecise alignmentIngenious ideaVehicle interior lightingData displayDriver circuit

The invention discloses an automobile instrument shell and a backlight module. The backlight module comprises an anti-surge circuit, a buzzer drive circuit, a comprehensive data display circuit, a backlight adjustable circuit, an expansion indication lamp drive circuit, an anti-static device and a CPU. The output end of the anti-surge circuit is connected with the power input end of the CPU, the power input end of the buzzer drive circuit, the power input end of the comprehensive data display circuit, the power input end of the backlight adjustable circuit and the power input end of the expansion indication lamp drive circuit. The signal output end of the comprehensive data display circuit is connected with the signal input end of the backlight adjustable circuit, the buzzer signal output end of the comprehensive data display circuit is connected with the signal input end of the buzzer drive circuit, the indication lamp signal output end of the comprehensive data display circuit is connected with the signal input end of the expansion indication lamp drive circuit, and the signal output end of the expansion indication lamp drive circuit is connected with the signal input end of the backlight adjustable circuit.

Owner:CHONGQING YAZAKI METER

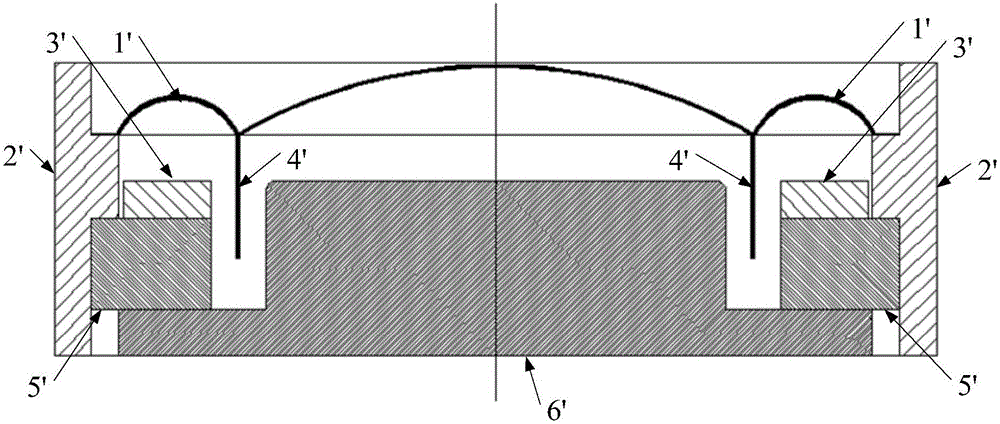

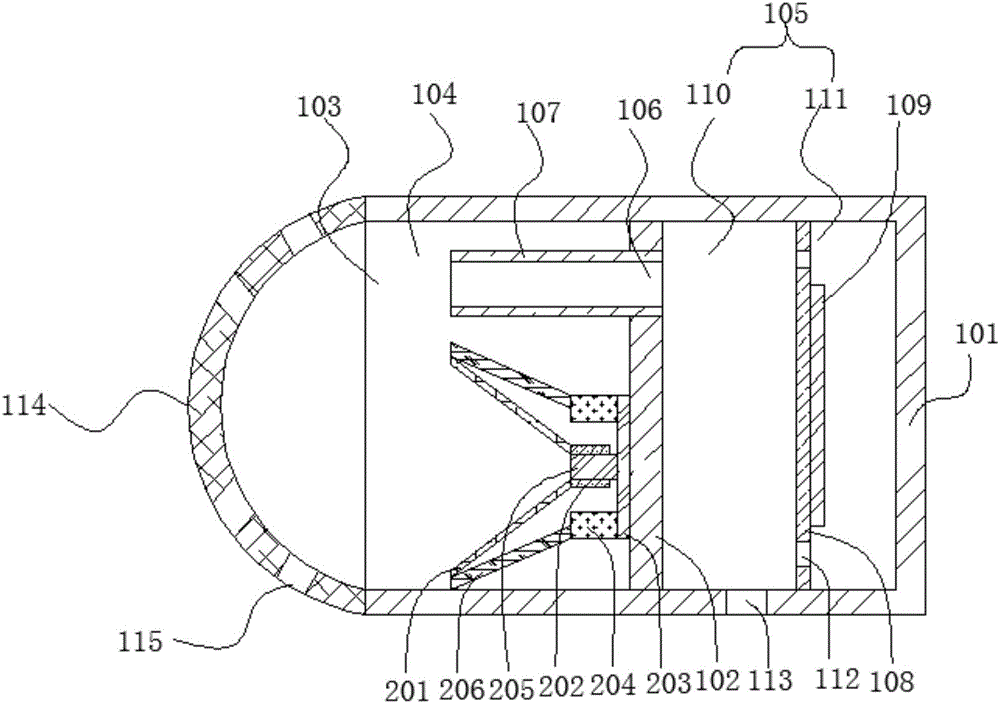

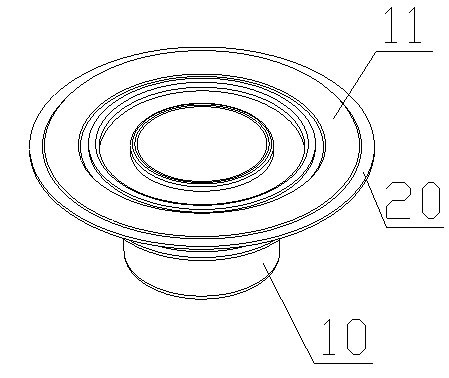

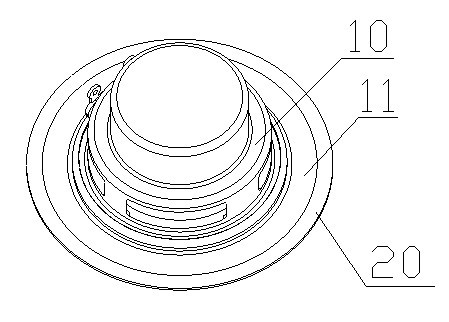

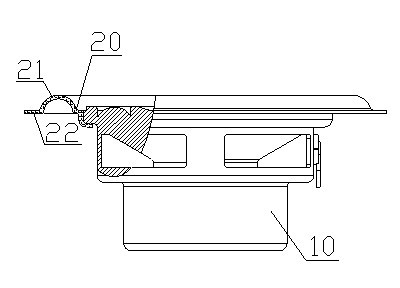

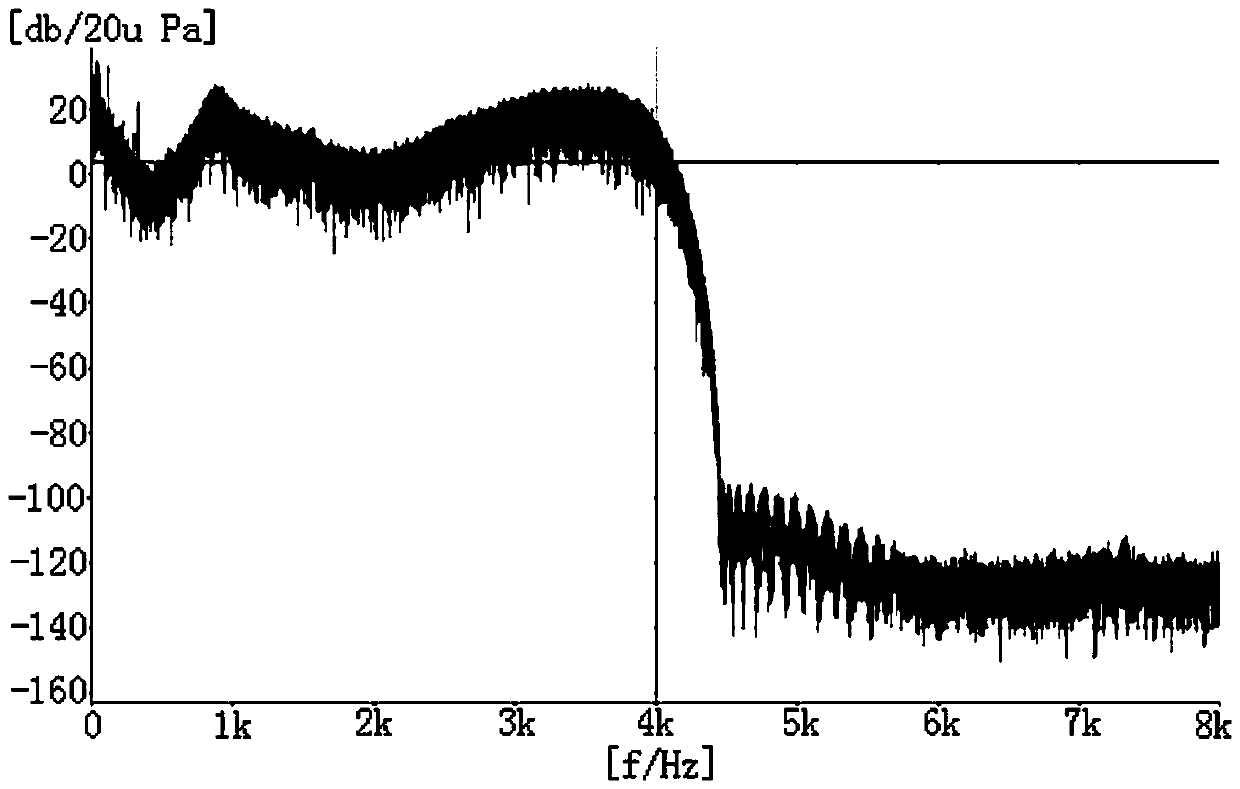

Loudspeaker of headset

InactiveCN105848071AHigh stiffnessIncrease the upper limit of high-frequency playbackElectrical transducersEngineeringHeadphones

Disclosed in the invention is a loudspeaker of a headset. The loudspeaker comprises a support frame, a magnetic circuit system, and a vibrating system, wherein the magnetic circuit system and the vibrating system are accommodated into the support frame. The magnetic circuit system is a ring-shaped magnetic circuit formed by a T iron, an annular magnet and an annular washer; and the annular washer and the T iron form an annular magnetic circuit gap. The vibrating system consists of a vibration membrane, a voice coil, and a gasket; the voice coil is attached to the vibration membrane and is suspended in the annular magnetic circuit gap; and the gasket is arranged on the upper end surface of the T iron. The vibration membrane is arranged above the magnetic circuit system and the edge of the vibration membrane is fixed on the support; and the middle part of the vibration membrane is fixed on the gasket. According to the technical scheme, because the e middle part of the vibration membrane is fixed on the gasket above the T iron, the strength of the root part of the vibration membrane is enhanced, so that the upper limit of the high-frequency replaying and the width of the relaying frequency band of the loudspeaker of the headset are improved and distortion caused by segmentation vibration is reduced.

Owner:QINGDAO GOERTEK

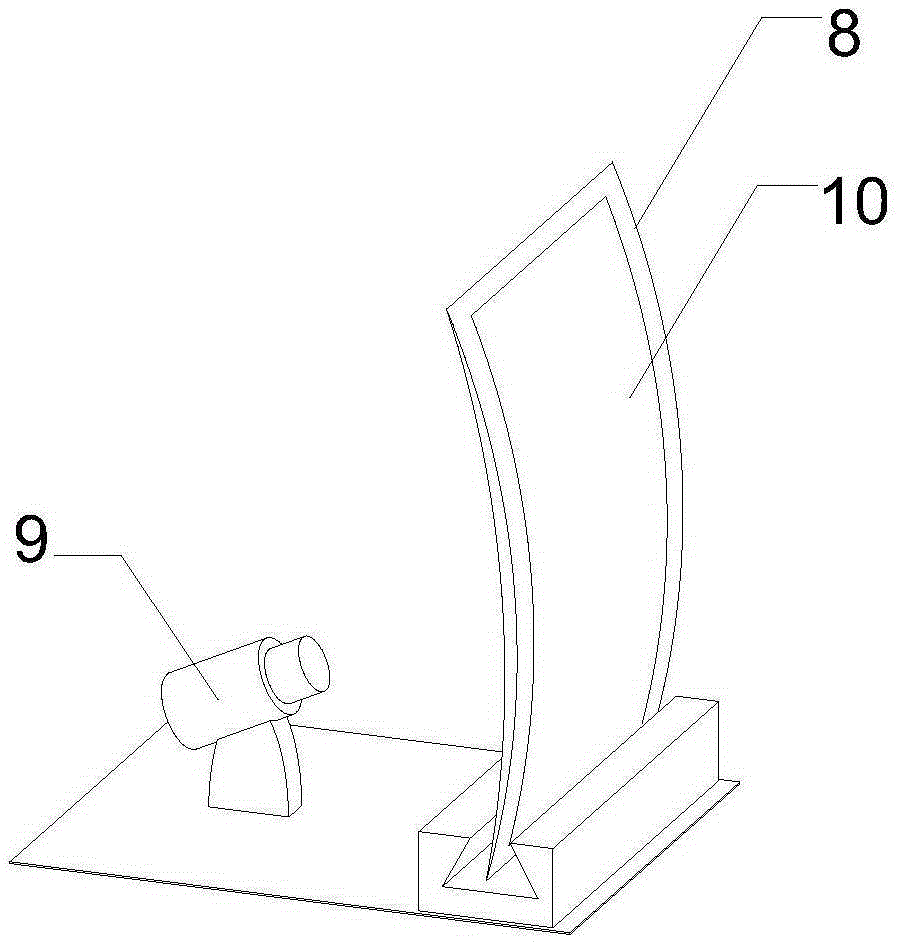

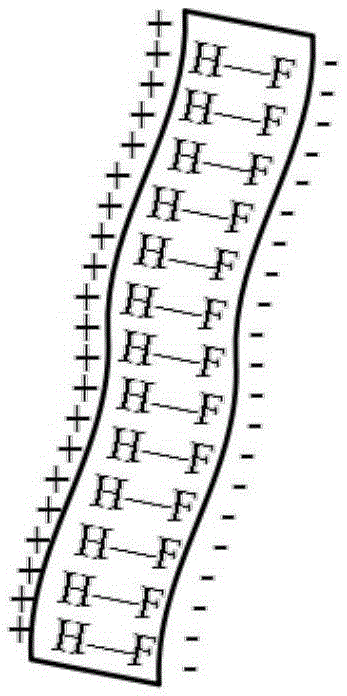

Curved sound player having projection display function

InactiveCN105246009AImprove practicalityAchieve two-in-one integrationElectrical transducersProjectorsSound filmDisplay device

The present invention discloses a curved sound player having a projection display function. The curved sound player having the projection display function comprises a curved display and a projection device, and also comprises a film speaker attached onto the curved display, wherein the film speaker comprises at least one sounding film, at least one conductive film, at least one insulating layer, and at least two conductive terminals; the at least one conductive film is coated on the at least one sounding film; the at least one conductive film is made from a nano-wire material; the at least one insulating layer is attached onto the at least one conductive film; the at least one insulating layer and / or a tone quality improving layer comprise(s) a plurality of groups of micro machining structures; the at least two conductive terminals are attached onto the at least one conductive film and are connected with a speaker driving circuit. According to the present invention, the film speaker and the curved projection display are combined, and the film speaker is attached onto the surface of the curved projection display; as the film speaker is transparent, the content displayed by the curved projection display is not influenced, and the display can play sound simultaneously while displaying videos or images, and therefore, the practicability of the display is enhanced, and the intelligence is relatively high.

Owner:李崇

Earphone

The invention relates to an earphone comprising a housing and a speaker disposed at the inner rear of the housing. A housing inner cavity in front of the speaker forms a front cavity. A first partition is disposed in the front cavity and provided with one to a plurality of sound holes, each which is covered with a diaphragm; the diaphragm on at least one sound hole is a gapped half diaphragm. The front cavity is also provided with an inner second partition close to the sound outlet end of the front cavity. The second partition is provided with a plurality of through holes in spaced circles and close to the perioral edge of the second partition. The front peripheral edge of the second partition is provided with a circular stop edge, and a plurality of unit partitions are fixed on the inner ring wall of the circular stop edge at intervals. The unit partitions divide space between the second partition and the front end wall of the front cavity into a plurality of unit cavities on the periphery and a central cavity communicated with every unit cavity. The front end wall of the front cavity is provided with a sound outlet communicated with the central cavity. The earphone is simple in structure, ingenious in design and capable of producing ideal sound effect, and has low damage to human ears.

Owner:李翰林

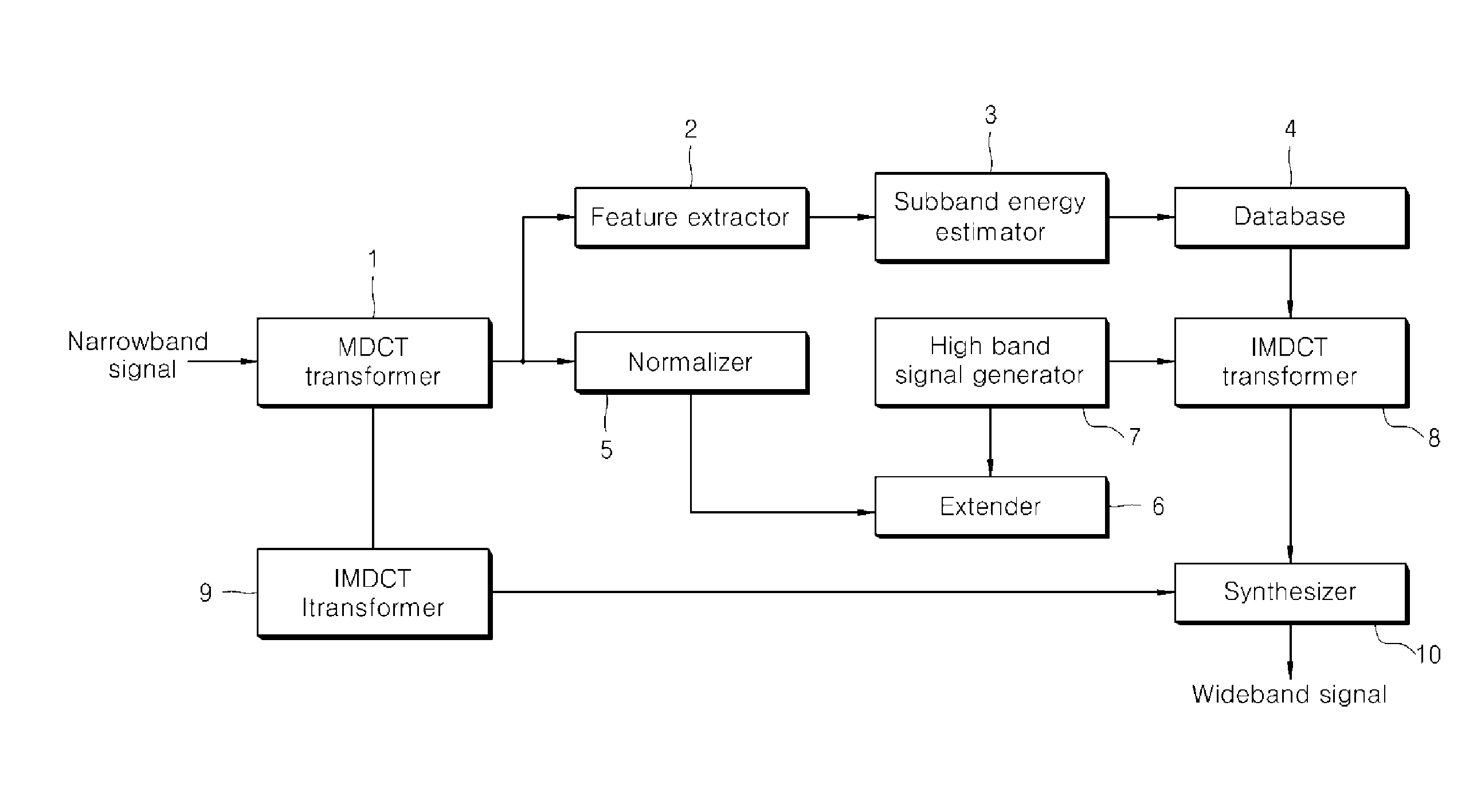

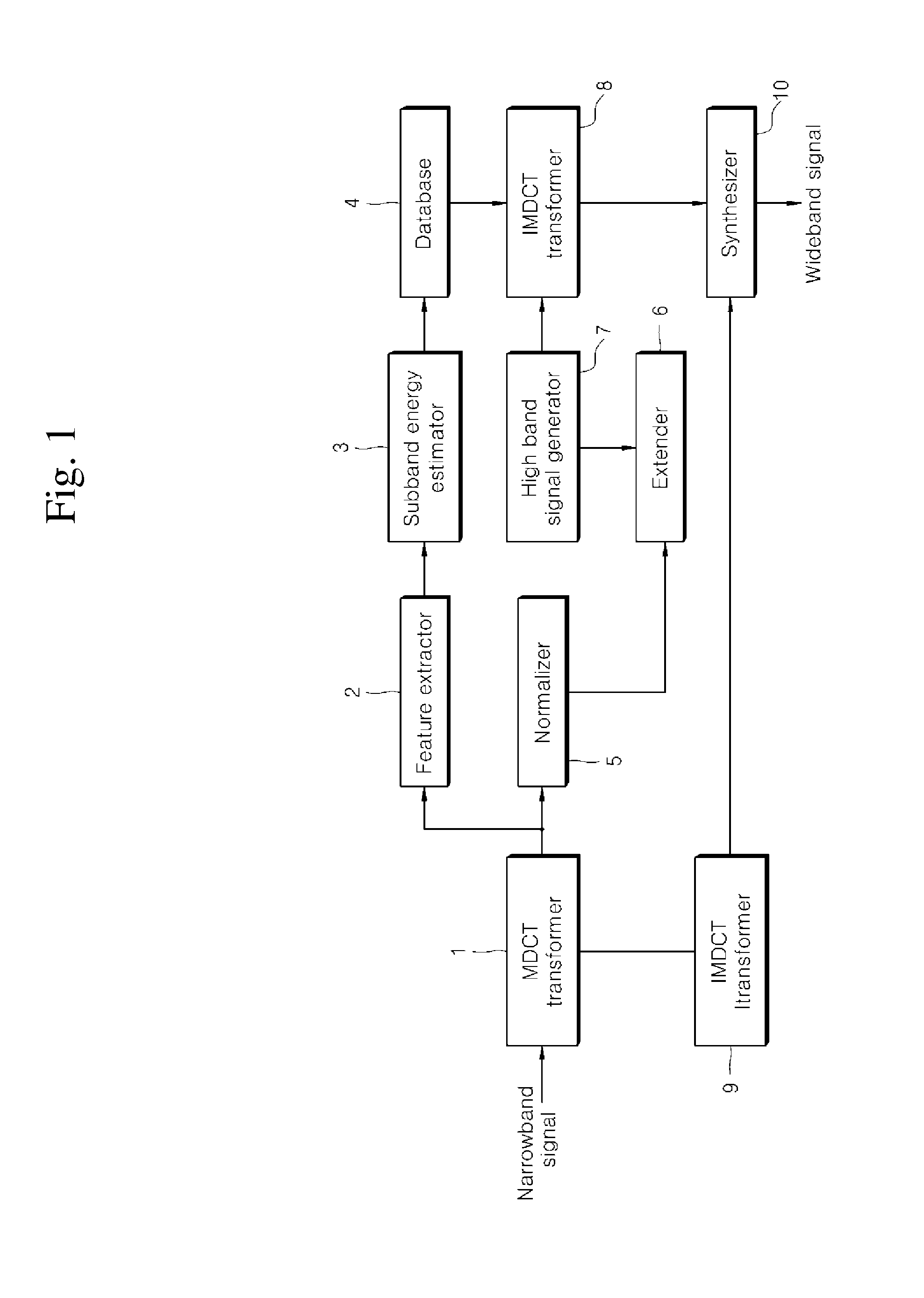

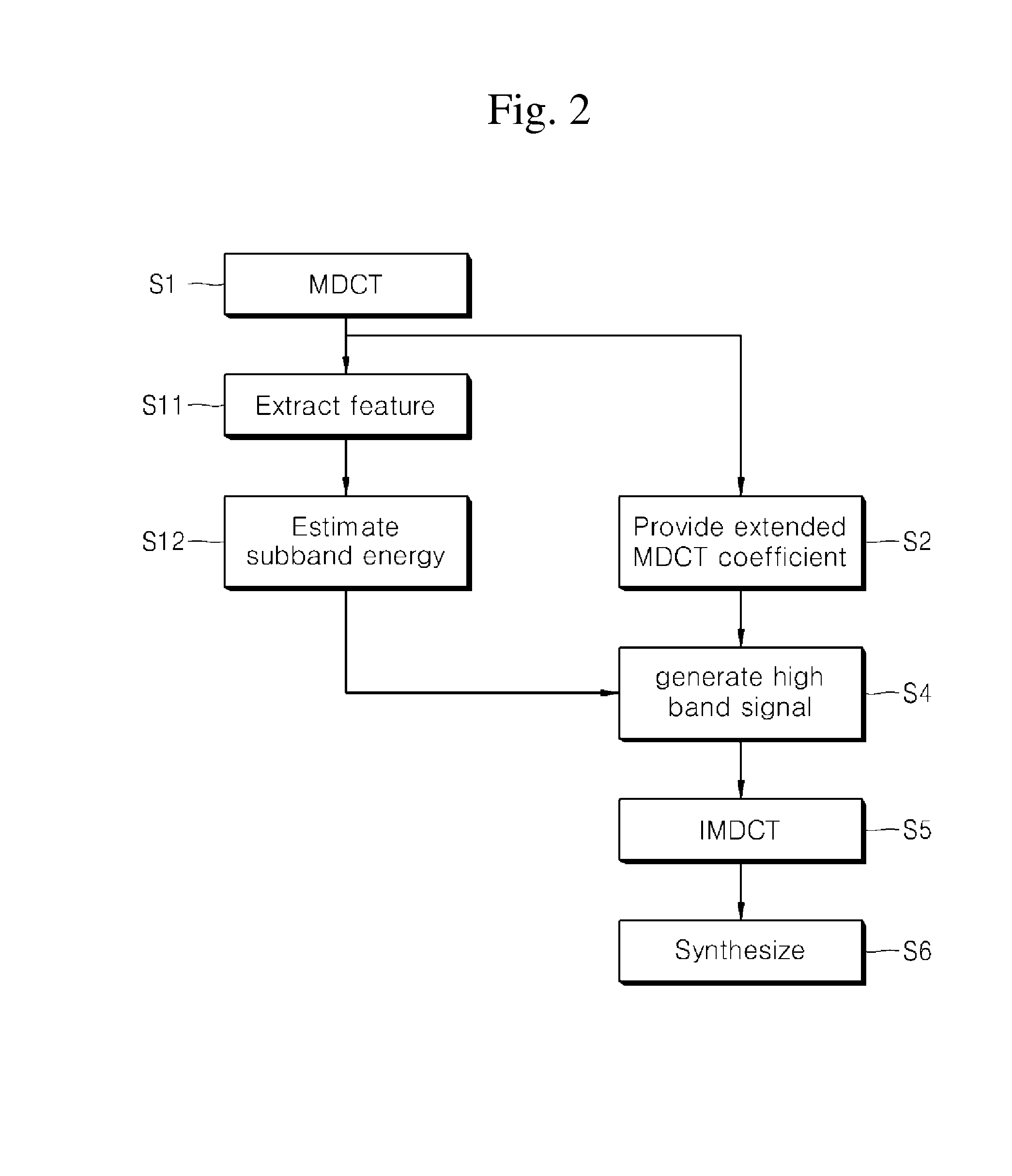

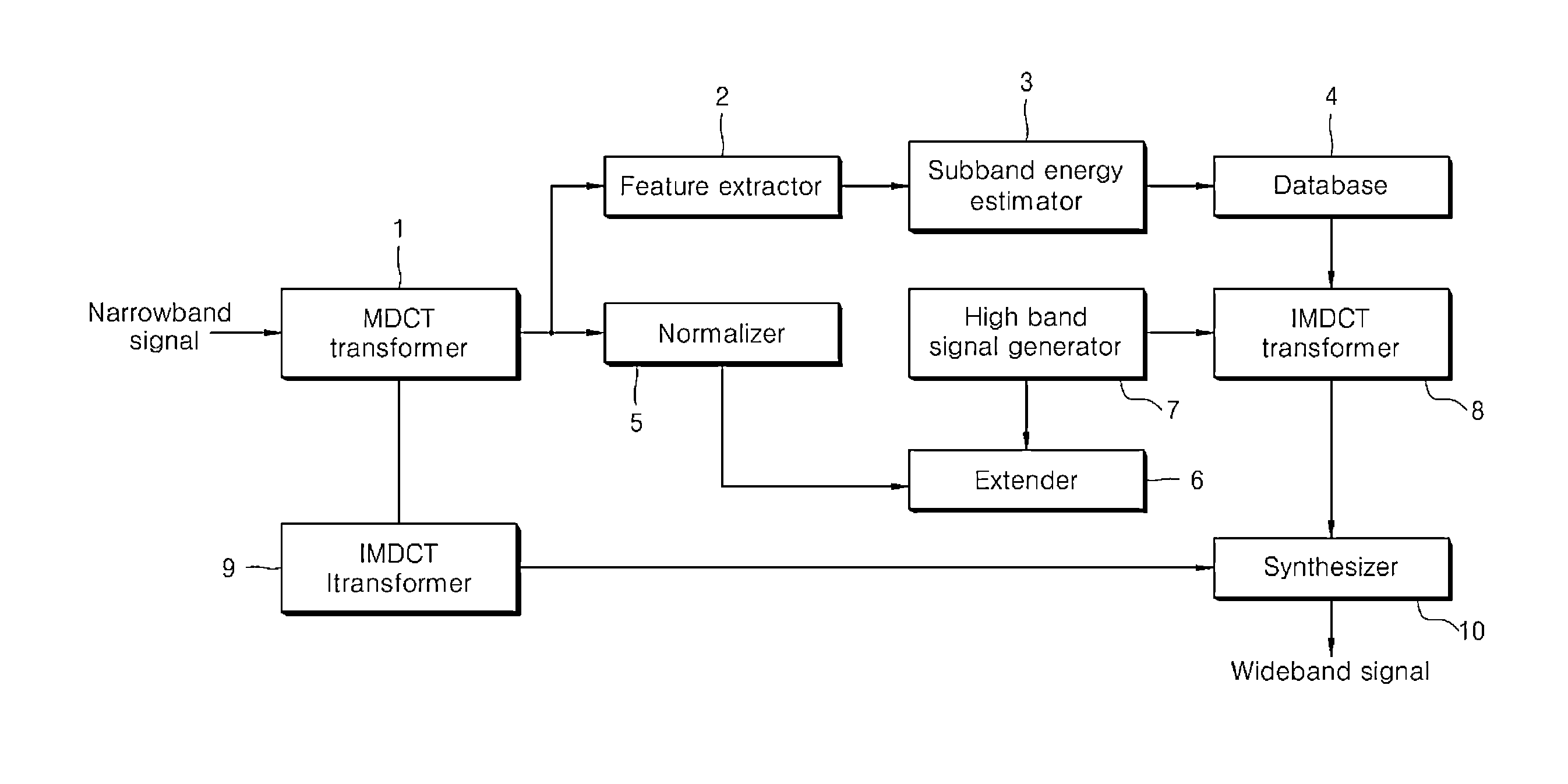

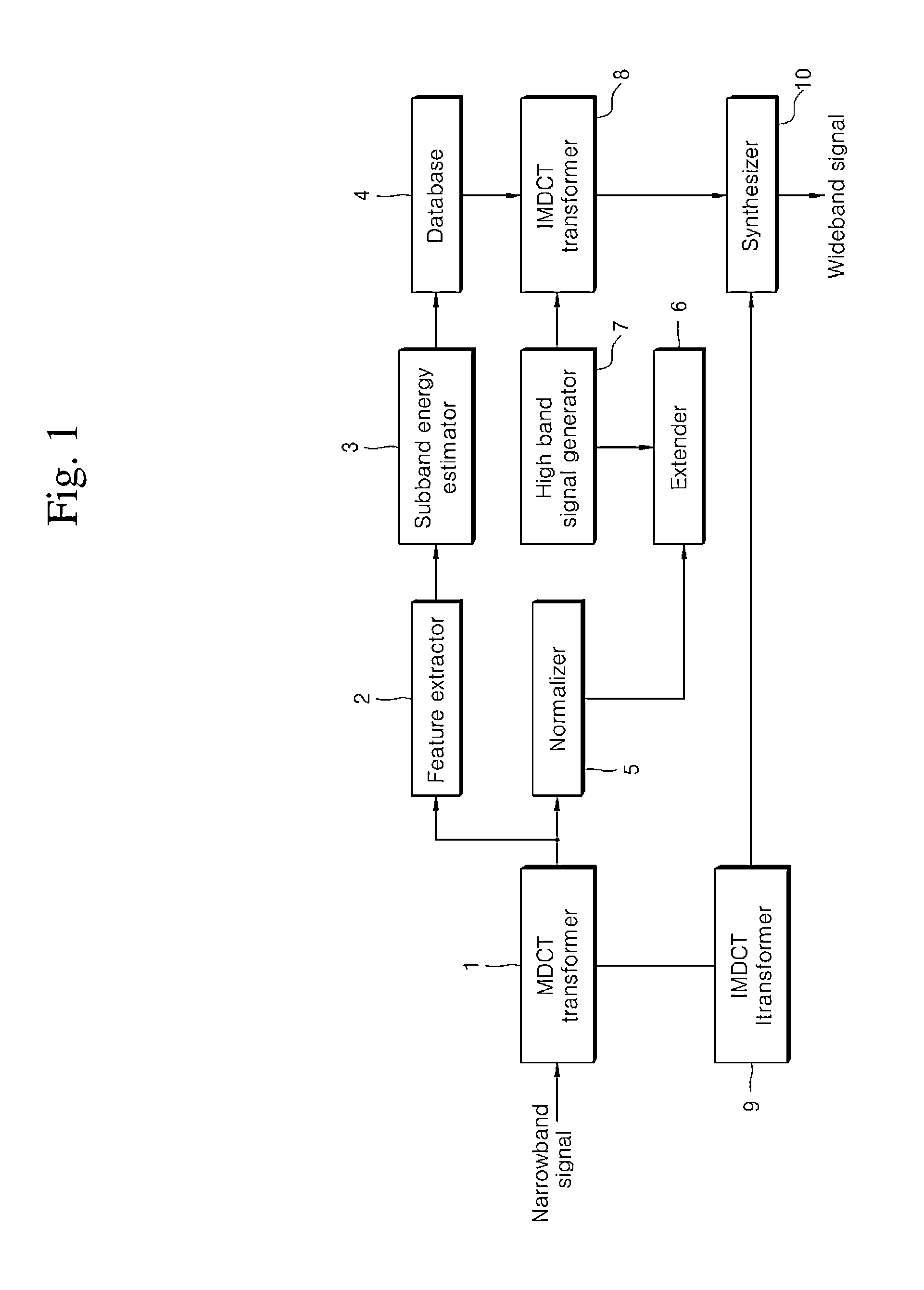

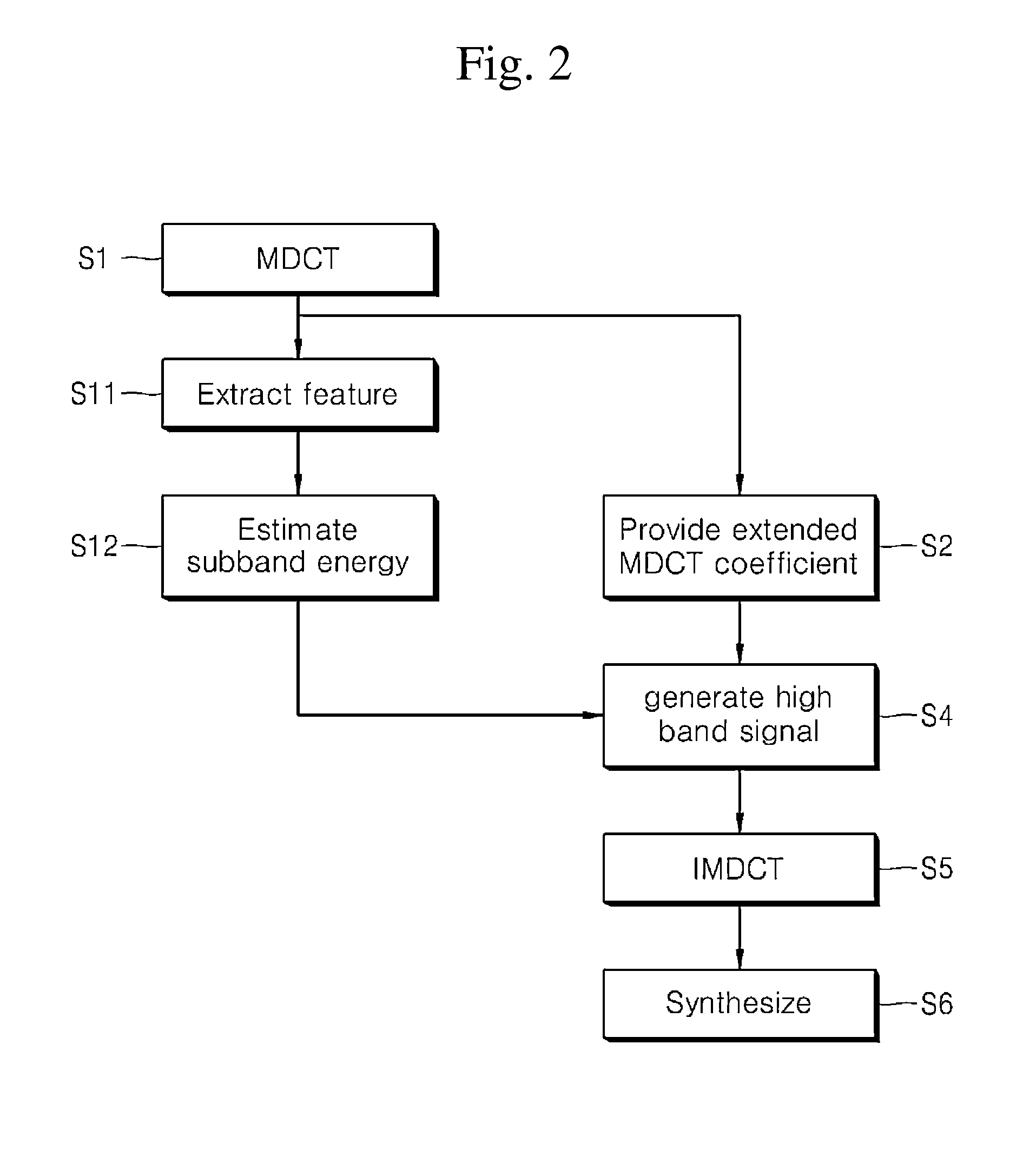

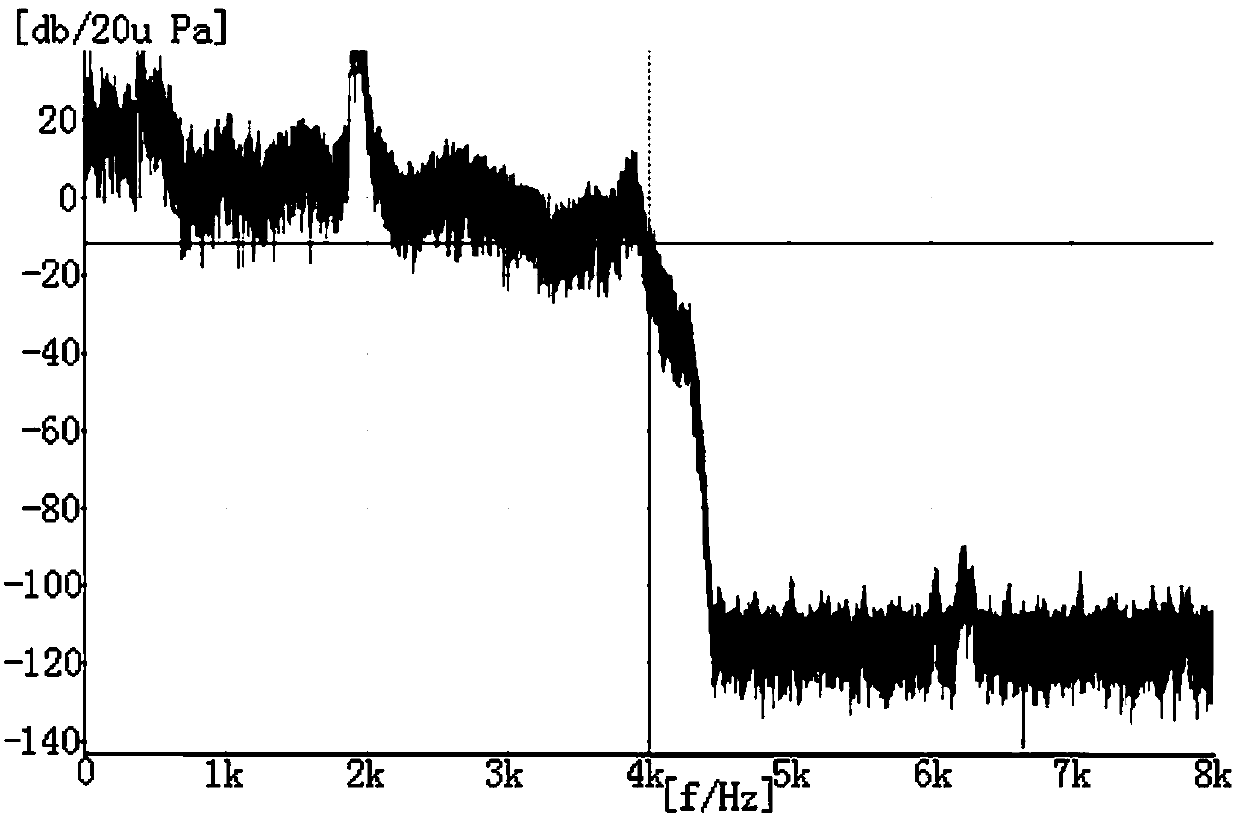

Apparatus and method for extending bandwidth of sound signal

ActiveUS20150112692A1High bandwidthHigh quality call serviceSpeech analysisHide markov modelTransformer

Disclosed is an apparatus for extending a bandwidth of a sound signal. The apparatus includes a database that stores predetermined training information as a result of at least one of Gaussian mixture model (GMM) training and hidden Markov model (HMM) training; a modified discrete cosine transform (MDCT) transformer that transforms a first band signal through MDCT, a feature extractor that extracts a feature parameter of the first band signal from an MDCT coefficient output from the MDCT transformer; an extender that provides an extended MDCT coefficient for a second band signal based on the MDCT coefficient of the first band signal output from the MDCT transformer, a subband energy estimator that estimates subband energy of the second band signal with reference to information stored in the database based on the feature parameter.

Owner:GWANGJU INST OF SCI & TECH

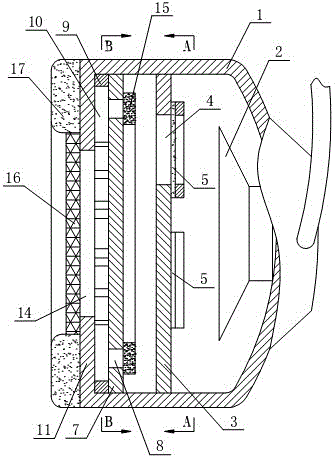

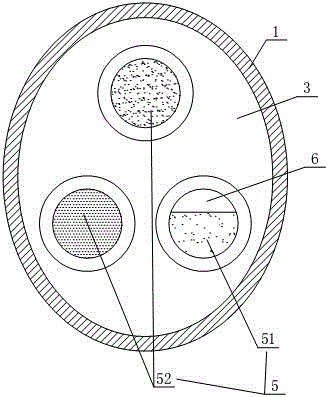

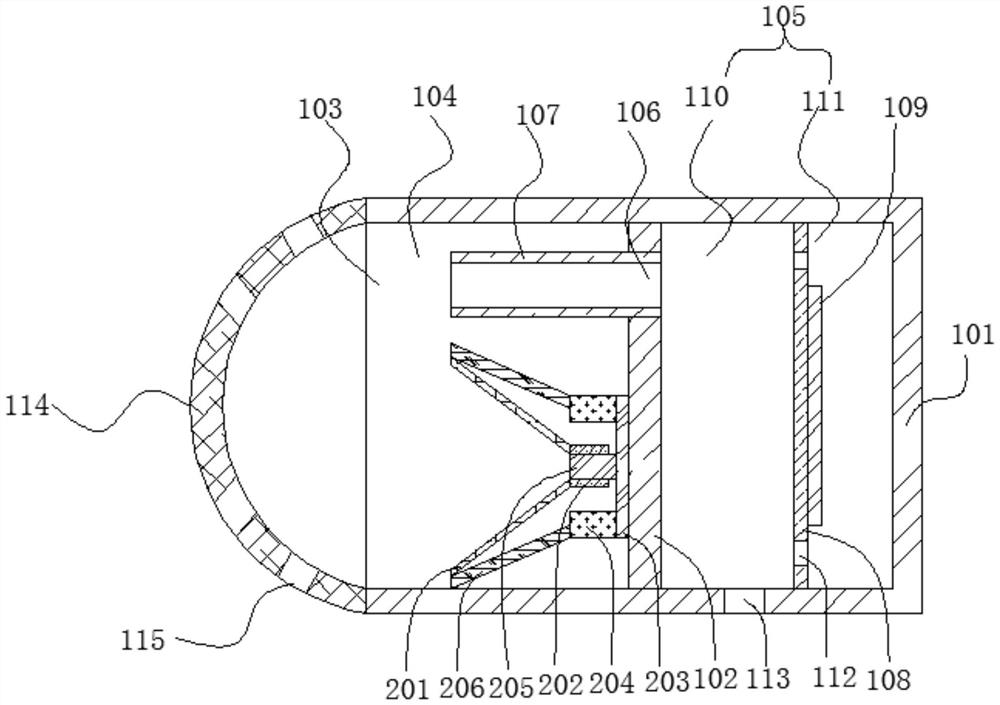

Moving coil piezoelectric compound loudspeaker

ActiveCN105979449AGood bassSoft voiceFrequency/directions obtaining arrangementsPiezo-electric polymer transducersLoudspeakerSound quality

The invention relates to the technical field of loudspeakers, and especially relates to a moving coil piezoelectric compound loudspeaker. The moving coil piezoelectric compound loudspeaker comprises a shell and a supporting plate; the shell is provided with a sound outlet; the supporting plate is arranged at the inside of the shell; the supporting plate separates the shell into a moving coil cavity and a piezoelectric cavity; the moving coil cavity is communicated with the sound outlet; the inside of the moving coil cavity is provided with a moving coil unit; the inside of the piezoelectric cavity is provided with a piezoelectric vibrator; the supporting plate is provided with a sound guide hole; and the piezoelectric cavity is communicated with the moving coil cavity through the sound guide hole. According to the moving coil piezoelectric compound loudspeaker provided by the invention, the piezoelectric vibrator is added on the basis of an original moving-coil loudspeaker, and the piezoelectric vibrator compensates the sound effect and sound quality of the moving-coil loudspeaker at high frequency, so that the moving coil unit and the piezoelectric vibrator vibrate and produce a sound simultaneously to form a resonance, so as to widen the frequency response range and improve listening experience of users.

Owner:常州市武进晶丰电子有限公司

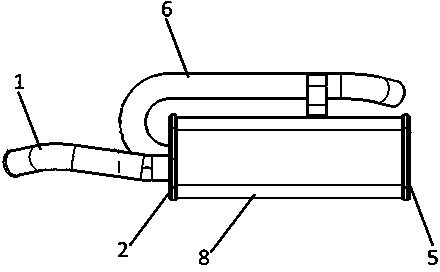

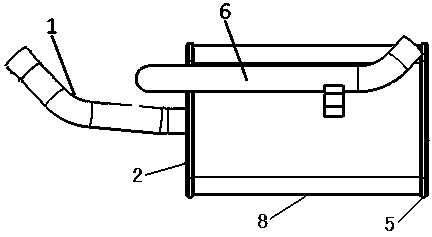

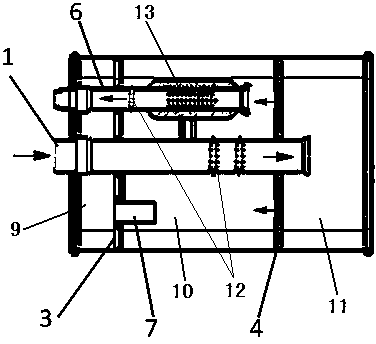

Rear-arranged main silencer

InactiveCN104141522AIncrease the lengthEliminate standing wavesSilencing apparatusMachines/enginesEngineering

The invention discloses a rear-arranged main silencer which comprises a cylinder, an air inlet pipe, an air outlet pipe, a front end cover and a rear end cover. A first partition plate and a second partition plate are sequentially arranged on the inner edge of the cylinder in the longitudinal direction of the cylinder and sequentially divide the cylinder into a first cavity, a second cavity and a third cavity. The outlet end of the air inlet pipe extends into the third cavity from the front end cover of the cylinder. The air inlet end of the air outlet pipe is communicated with the second cavity. The portion, located in the second cavity, of the air inlet pipe is provided with an air hole. The second partition plate is provided with an air hole so that the second cavity and the third cavity can be communicated. The first partition plate is provided with a middle pipe so that the second cavity and the first cavity can be communicated. On the premise of not increasing the volume for exhausting and silencing, second-order noise of an exhaust port can be effectively lowered.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

a kind of earphone

The invention relates to an earphone, which comprises a housing and a horn built in the rear of the housing. The inner cavity of the housing at the front of the horn forms a front cavity, and a first partition is arranged in the front cavity. There are three sound holes and each sound hole is covered with a diaphragm, and the diaphragm on at least one sound hole is a half-diaphragm with a gap; the front cavity is also provided with a second partition near the sound outlet end. The spacer ring is provided with a plurality of through holes on the position close to the peripheral edge of the second partition; the peripheral edge of the second partition front side is provided with an annular retaining edge, and the inner ring wall of the annular retaining edge is fixed at intervals with A plurality of unit partitions, each unit partition divides the space between the second partition and the front end wall of the front cavity into a plurality of unit cavities located in the periphery and a central cavity located in the center and communicated with each unit cavity, the front cavity A sound outlet communicating with the above-mentioned central cavity is opened on the front end wall. The invention has simple structure and delicate design, can produce ideal sound effects and can reduce damage to human ears.

Owner:李翰林

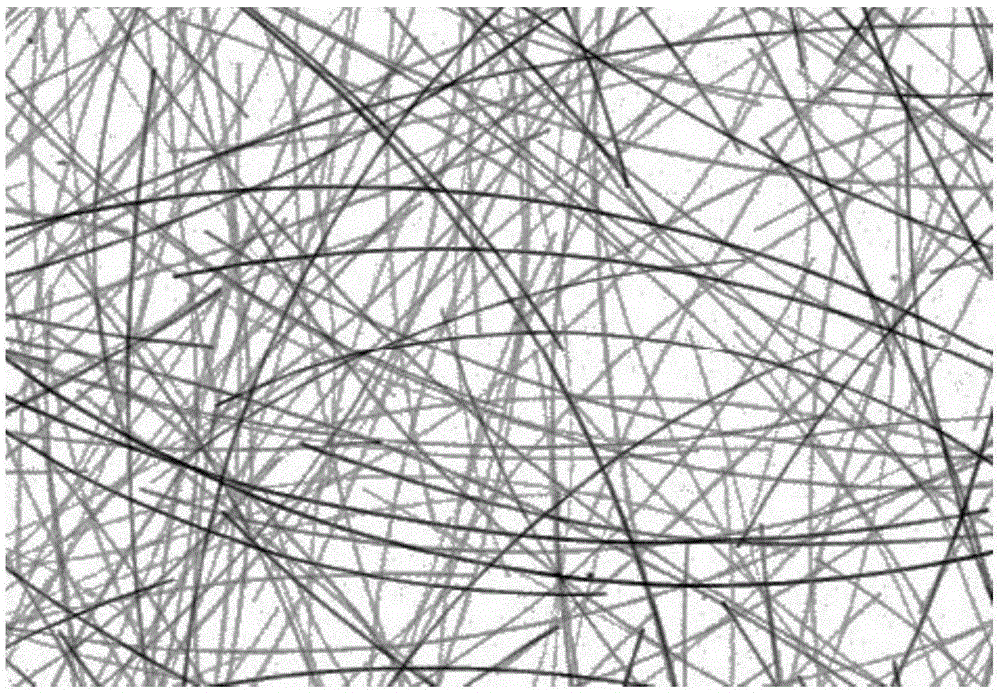

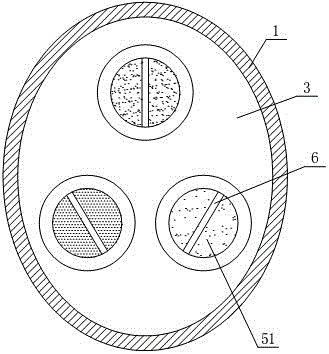

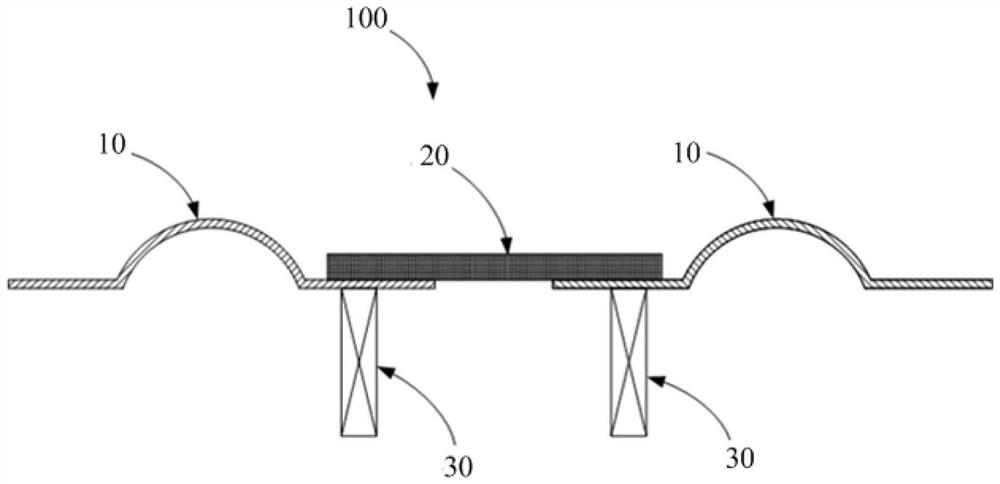

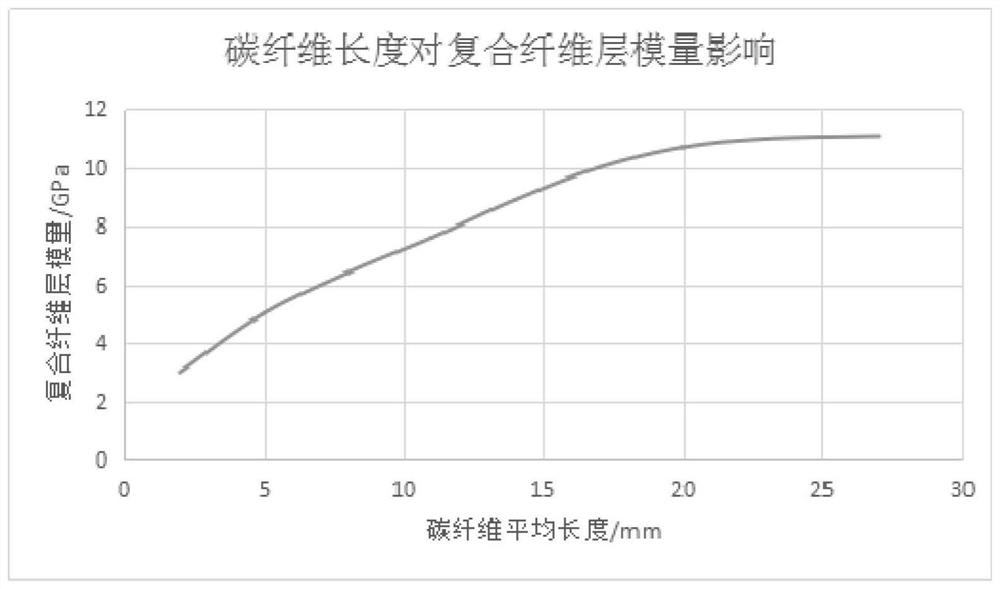

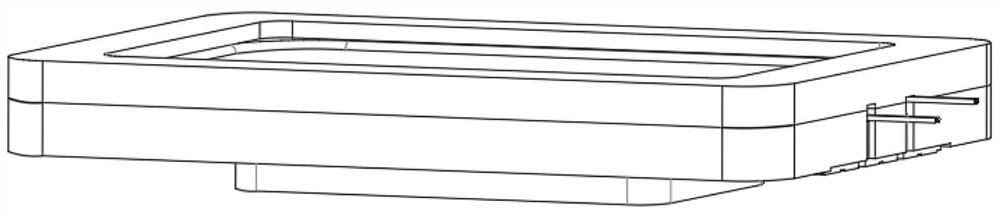

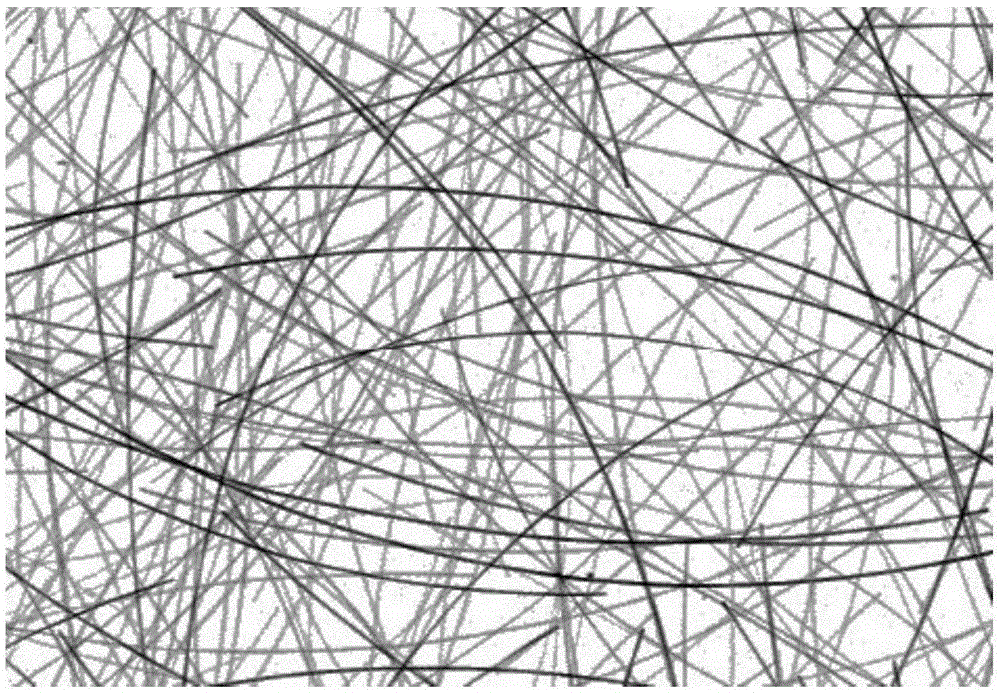

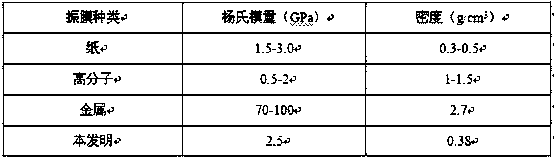

Vibration plate and sound production device

PendingCN113709636AHigh modulusLow densityFibre diaphragmsPolymeric diaphragmsCarbon fibersSound production

The invention discloses a vibration plate and a sound production device. The vibration plate comprises at least one composite fiber layer and at least one foaming body material layer, the at least one composite fiber layer and the at least one foaming body material layer are arranged in a stacked mode, and composite fibers in the composite fiber layer comprise carbon fibers. According to the technical scheme, the modulus of the vibration plate can be improved, and the frequency response range of the vibration plate is widened.

Owner:GOERTEK INC

a speaker

ActiveCN112261559BExtend the effective frequency rangeHigh frequencyElectrical transducersNonlinear distortionSound film

The invention relates to a loudspeaker and belongs to the technical field of loudspeakers. Including a mesh cover, a bracket and a U cup, the mesh cover and the bracket are matched and connected to each other to form a whole, the U cup is clamped at the bottom of the bracket, a sound membrane is installed in the mesh cover, and the bottom surface of the sound membrane is provided with A rectangular piezoelectric ceramic sheet, the bottom of the piezoelectric ceramic sheet is cemented with a grooved voice coil that runs through up and down, and a rectangular U-cup mounting port is also opened on the bottom surface of the bracket, and the U-cup mounting port is snap-fitted and installed. U cup, the top surface of the U cup is also provided with a magnetic slot for installing the washer, the top surface of the washer is provided with a secondary magnetic slot, and a secondary magnet is glued and installed inside the secondary magnetic slot. There is also a main magnet glued to the bottom surface of the company, and the bottom surface of the main magnet is glued in the magnetic groove of the U cup. The loudspeaker of the invention solves the problem of difficult assembly of the loudspeaker, simultaneously solves the technical problems of magnetic flux leakage and nonlinear distortion, and has low production cost, high production efficiency, high finished product qualification rate and excellent acoustic performance.

Owner:常州诚铭电子科技有限公司

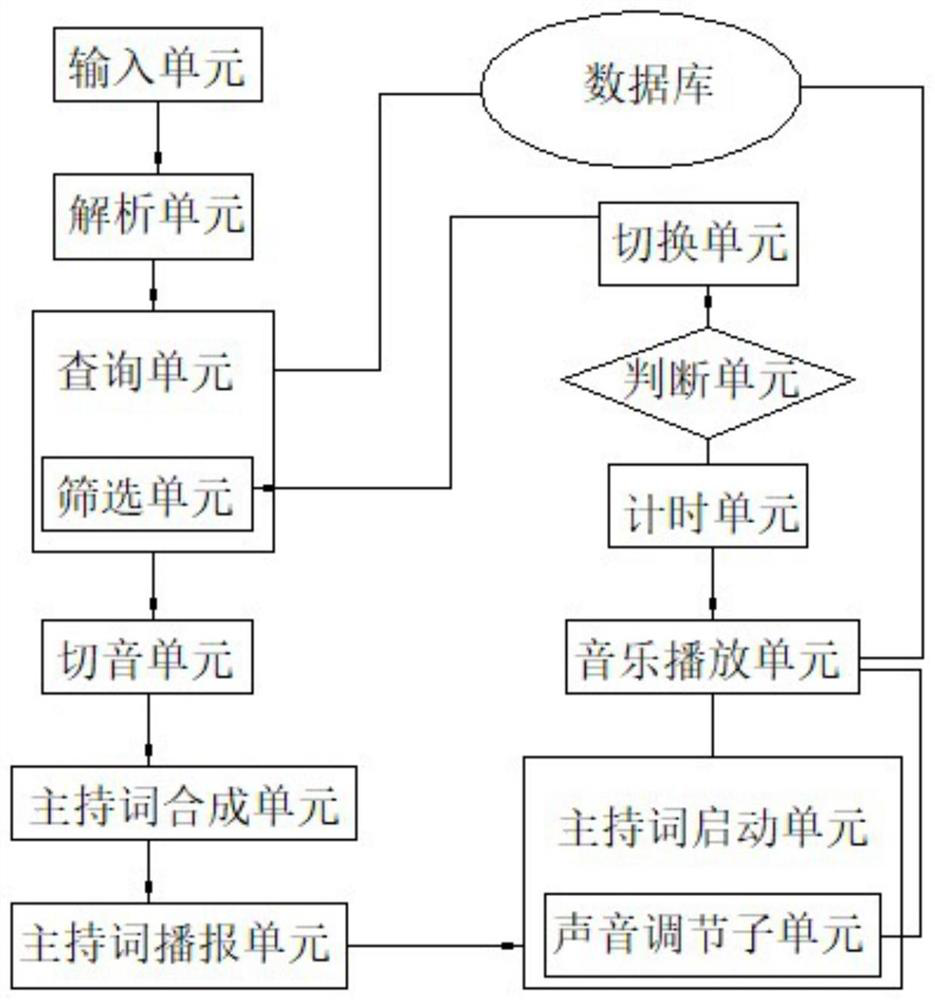

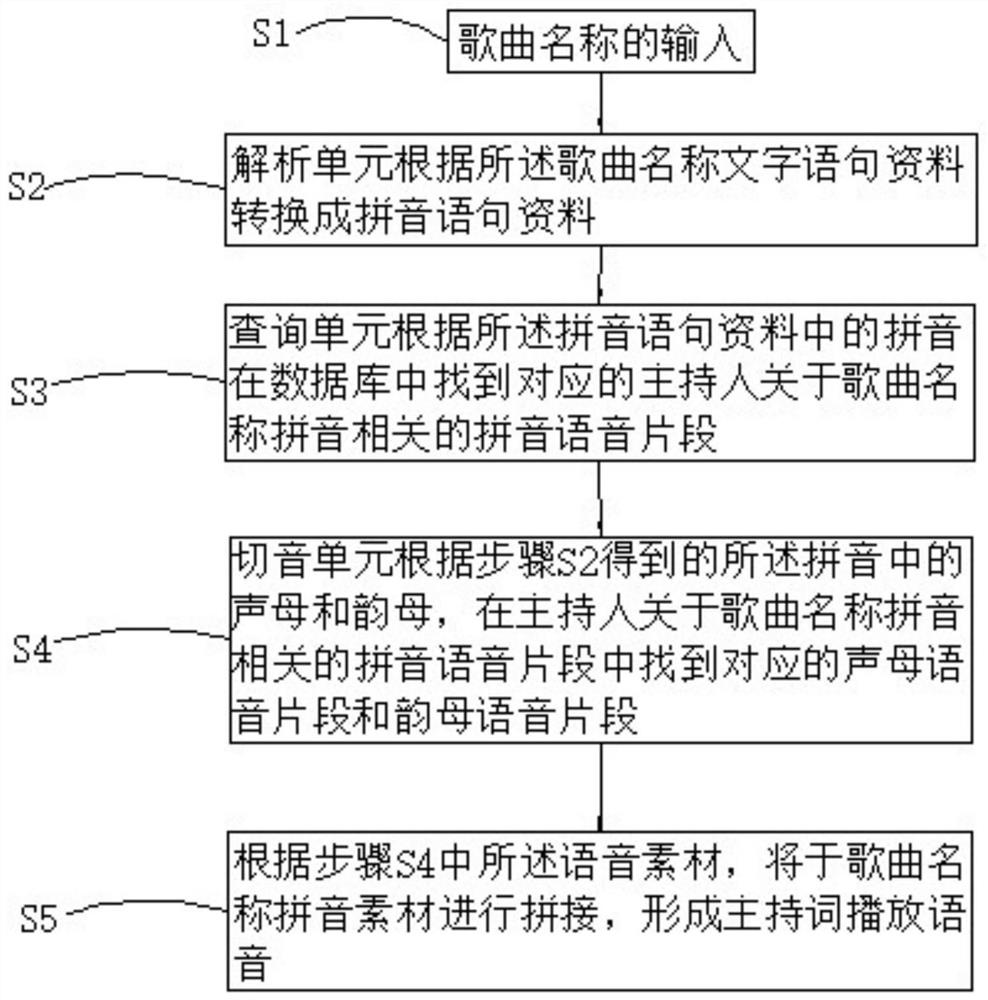

Radio station intelligent anchor music program system

ActiveCN111564153BMeet needsSoft voiceNatural language data processingSpeech synthesisTelecommunicationsMusic festival

The invention discloses an intelligent anchor music program system of a radio station, which comprises an input unit, an analysis unit, a sound cutting unit, a host word synthesis unit, an host word broadcast unit, a host word start unit, a music playing unit, a timing unit, a judging unit, Switching unit and database, the intelligent anchor music program system of this radio station divides the massive sound program material of the anchor by collecting professional anchor voices, then reorganizes and recreates, and finally becomes an AI anchor. According to the needs of the program, the AI anchor can use tens of thousands of There is no way to introduce a song, and it will not be repeated. The voice of the host can perfectly connect the songs before and after the broadcast period through voice splicing technology, and finally form a professional music program, replacing the real host, and meeting the needs of the radio station for excellent hosts. At the same time, it also provides multiple options for attracting listeners during the period when the station is purely playing music.

Owner:湖南声广科技有限公司

Gasoline exhaust silencer

InactiveCN106401699AEffective absorptionReduce noiseExhaust apparatusSilencing apparatusGasolineEngineering

The invention discloses a gasoline exhaust silencer. The silencer comprises a casing as well as a front outer baffle and a back outer baffle which are located at the front end and the back end of the casing to seal the casing; four inner baffles are arranged inside the casing; an inner cavity of the casing is divided by each inner baffle into five chambers; at least 60 air holes are formed in each inner baffle; an air inlet is formed in the middle of the casing; the outer layer of the air inlet in the middle of the casing is sleeved with a reinforcing plate outer layer; air outlet inner pipes are inserted in two ends of the casing; at least 250 air holes are formed in the middle of each air outlet inner pipe; and sound absorbing layers are arranged on outer walls of the air holes in the middles of the air outlet inner pipes. The silencer is reasonable in structure, has the relatively good silencing effect at the temperature and under the pressure of a working air flow in the required frequency range, the sound is reduced by 1-2 db at the rated rotating speed, and the power loss is reduced by 0.3%.

Owner:湖南长丰汽车零部件有限责任公司

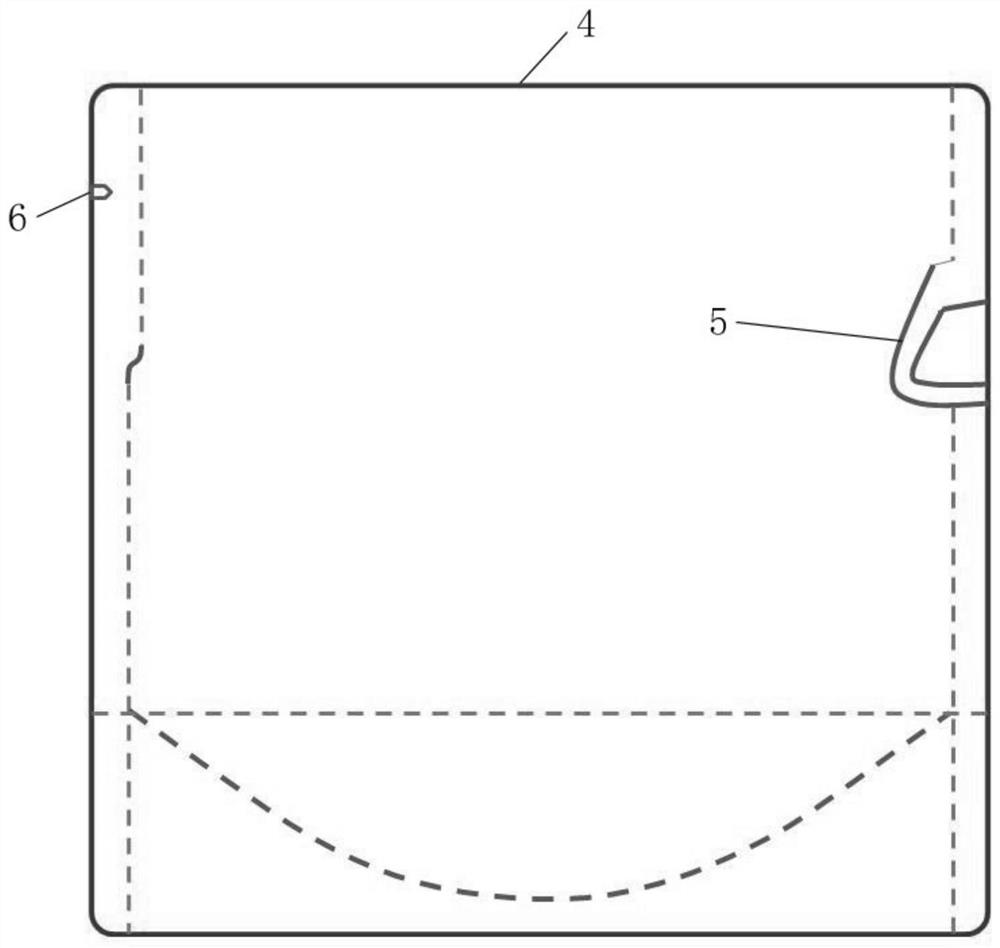

A microwave heating exhaust packaging bag

Owner:SHANGHAI TOPPAN CO LTD

Apparatus and method for extending bandwidth of sound signal

ActiveUS9460733B2High bandwidthImprove call qualitySpeech analysisFeature extractionHide markov model

Disclosed is an apparatus for extending a bandwidth of a sound signal. The apparatus includes a database that stores predetermined training information as a result of at least one of Gaussian mixture model (GMM) training and hidden Markov model (HMM) training; a modified discrete cosine transform (MDCT) transformer that transforms a first band signal through MDCT, a feature extractor that extracts a feature parameter of the first band signal from an MDCT coefficient output from the MDCT transformer; an extender that provides an extended MDCT coefficient for a second band signal based on the MDCT coefficient of the first band signal output from the MDCT transformer, a subband energy estimator that estimates subband energy of the second band signal with reference to information stored in the database based on the feature parameter.

Owner:GWANGJU INST OF SCI & TECH

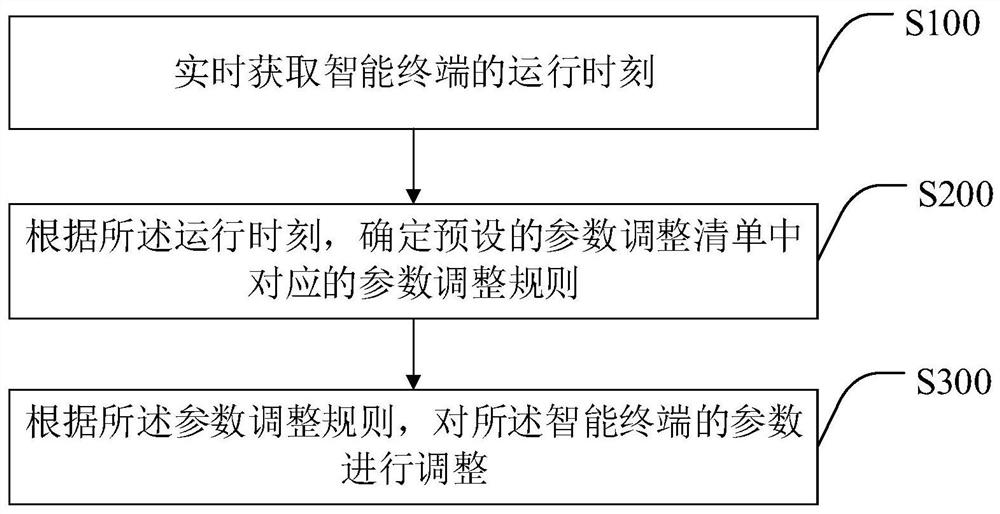

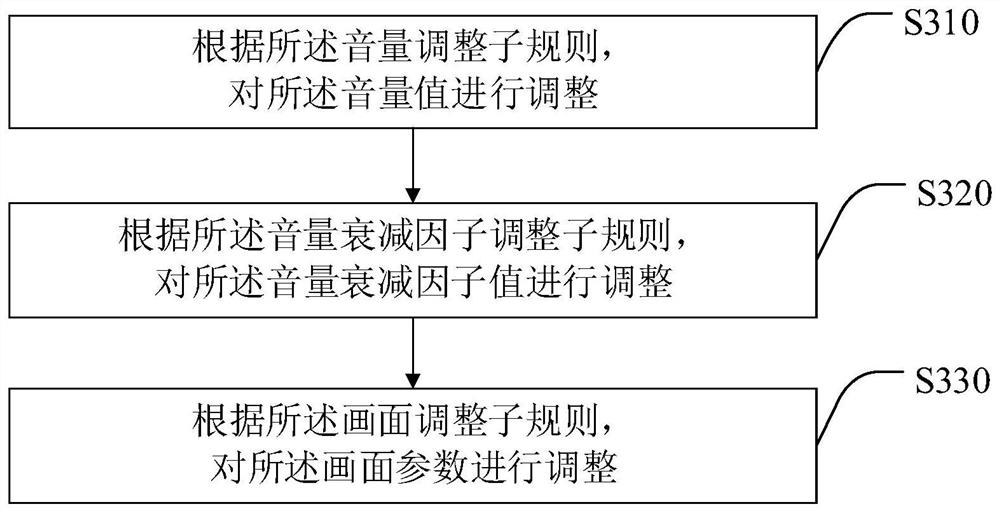

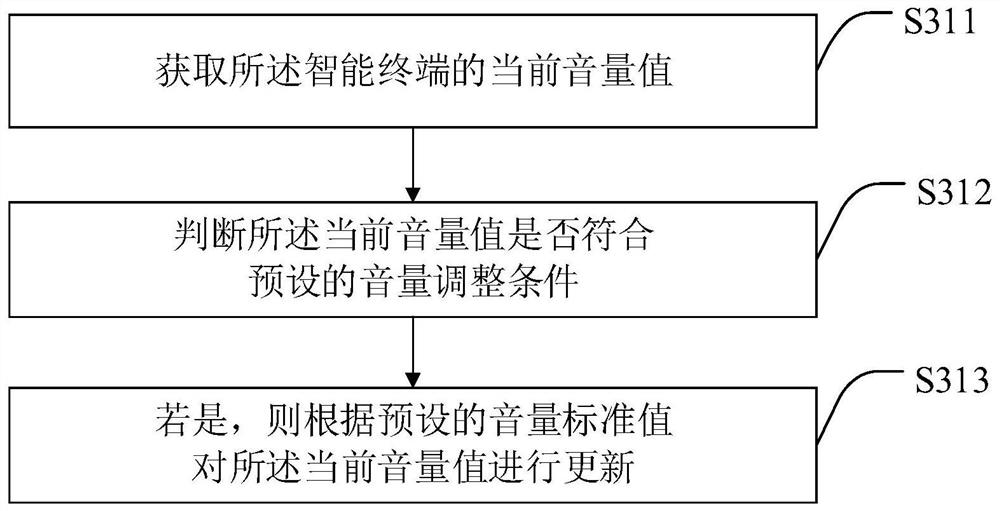

Parameter adjustment method, intelligent terminal and storage medium

PendingCN114339387AReduce the hassle of manually adjusting parametersSoft voiceSound input/outputSelective content distributionReal-time computingIndustrial engineering

The invention discloses a parameter adjustment method, an intelligent terminal and a storage medium. The method comprises the following steps: acquiring a running moment of the intelligent terminal in real time; determining a corresponding parameter adjustment rule in a preset parameter adjustment list according to the operation moment; and adjusting the parameters of the intelligent terminal according to the parameter adjustment rule. Parameters can be automatically adjusted according to different times, and the trouble of manually adjusting the parameters by a user is reduced.

Owner:SHENZHEN TCL NEW-TECH CO LTD

A kind of automobile meter housing and backlight assembly

ActiveCN104442400BPrecise alignmentIngenious ideaVehicle interior lightingData displayDriver circuit

The invention discloses an automobile instrument shell and a backlight module. The backlight module comprises an anti-surge circuit, a buzzer drive circuit, a comprehensive data display circuit, a backlight adjustable circuit, an expansion indication lamp drive circuit, an anti-static device and a CPU. The output end of the anti-surge circuit is connected with the power input end of the CPU, the power input end of the buzzer drive circuit, the power input end of the comprehensive data display circuit, the power input end of the backlight adjustable circuit and the power input end of the expansion indication lamp drive circuit. The signal output end of the comprehensive data display circuit is connected with the signal input end of the backlight adjustable circuit, the buzzer signal output end of the comprehensive data display circuit is connected with the signal input end of the buzzer drive circuit, the indication lamp signal output end of the comprehensive data display circuit is connected with the signal input end of the expansion indication lamp drive circuit, and the signal output end of the expansion indication lamp drive circuit is connected with the signal input end of the backlight adjustable circuit.

Owner:CHONGQING YAZAKI METER

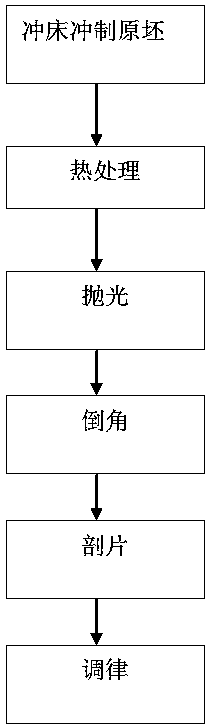

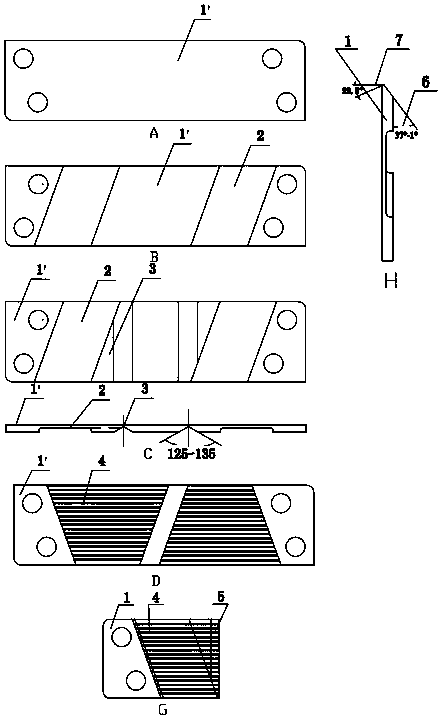

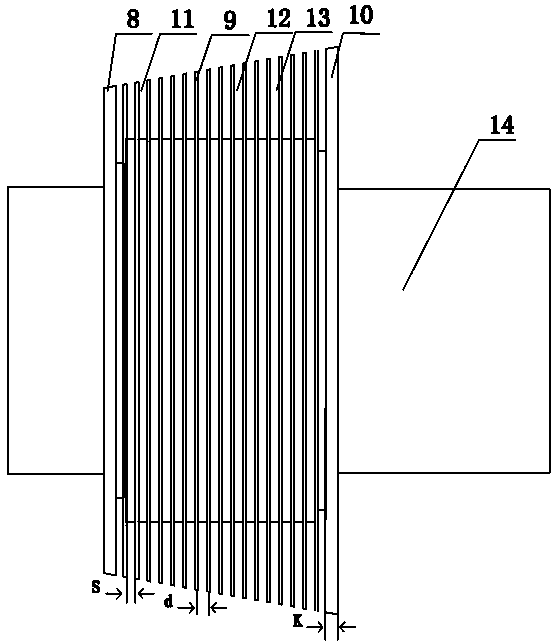

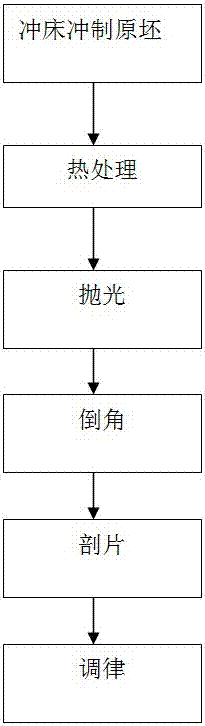

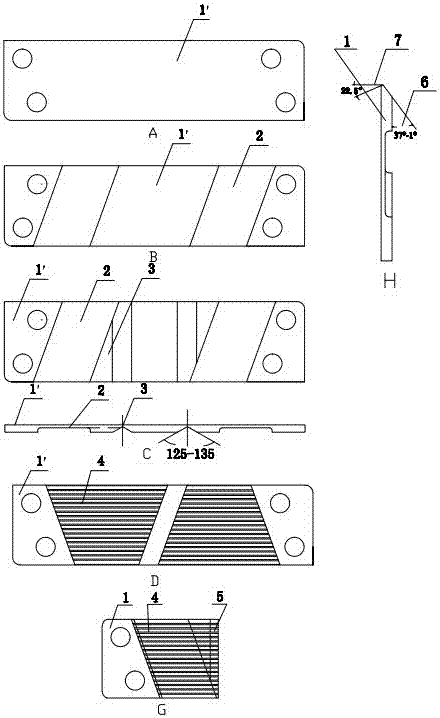

Processing technology and special tool for music bell vibrating piece

ActiveCN107322069BEasy to processThe solution will not changeMilling cuttersAutomatic musical instrumentsPolyesterProduction rate

Disclosed is a music bell vibrating plate machining technology and a special tool. The music bell vibrating plate machining technology comprises the following steps that traditional polyester grinding wheel cutting machining is replaced with special tool combined milling cutters, firstly, cutting machining is conducted on a vibrating plate blank, then heat treatment is conducted on the vibrating plate blank, traditional machining procedures of a vibrating plate is changed radically, and the difficult problem that after plate cutting, the heat treatment is conducted, and all voice keys are easy to deform in the heat treatment process is solved. According to the music bell vibrating plate machining technology, by adopting a technology method that the double-plate integrated vibrating plate blank is punched by a punching machine and machined, cutting machining is conducted on the double-plate integrated vibrating plate blank by adopting the combined milling cutters, all the voice keys and chamfering areas are machined, it is ensured that the width of a cutting seam is 0.25 millimeter, the precision of the center distances of all the voice keys reaches 0.9+-0.005 millimeter, the rigidity of the vibrating plate is always kept 54+-1 degrees, each set of combined milling cutter can machine and produce 2-3 ten thousand vibrating plates, frequent replacement of tools is reduced, the work efficiency is improved, the precision of products and the stability of quality are ensured, voice of the vibrating plate is soft, pleasant to the ear and standard, and the quality and productivity of music bells are improved greatly.

Owner:王正尧

Music bell vibrating plate machining technology and special tool

ActiveCN107322069AEasy to processThe solution will not changeMilling cuttersAutomatic musical instrumentsProduction ratePolyester

Disclosed is a music bell vibrating plate machining technology and a special tool. The music bell vibrating plate machining technology comprises the following steps that traditional polyester grinding wheel cutting machining is replaced with special tool combined milling cutters, firstly, cutting machining is conducted on a vibrating plate blank, then heat treatment is conducted on the vibrating plate blank, traditional machining procedures of a vibrating plate is changed radically, and the difficult problem that after plate cutting, the heat treatment is conducted, and all voice keys are easy to deform in the heat treatment process is solved. According to the music bell vibrating plate machining technology, by adopting a technology method that the double-plate integrated vibrating plate blank is punched by a punching machine and machined, cutting machining is conducted on the double-plate integrated vibrating plate blank by adopting the combined milling cutters, all the voice keys and chamfering areas are machined, it is ensured that the width of a cutting seam is 0.25 millimeter, the precision of the center distances of all the voice keys reaches 0.9+-0.005 millimeter, the rigidity of the vibrating plate is always kept 54+-1 degrees, each set of combined milling cutter can machine and produce 2-3 ten thousand vibrating plates, frequent replacement of tools is reduced, the work efficiency is improved, the precision of products and the stability of quality are ensured, voice of the vibrating plate is soft, pleasant to the ear and standard, and the quality and productivity of music bells are improved greatly.

Owner:王正尧

Loudspeaker with better sound effect

The invention relates to a loudspeaker with a better sound effect. The loudspeaker is characterized by comprising a loudspeaker main body and a flexible elastic vibrating diaphragm which is arranged on the outer edge of a horn opening of the louderspeaker. The flexible elastic vibrating diaphragm is additionally arranged, so that on the one hand, the vibrating diaphragm can reduce the vibration of the loudspeaker main body, on the other hand, the vibration of the vibrating diaphragm can enhance a bass effect and improves the curve between the alto voice and the high pitch, and then the loudspeaker makes a soft sound.

Owner:APOLLO ZHUHAI ELECTRONICS

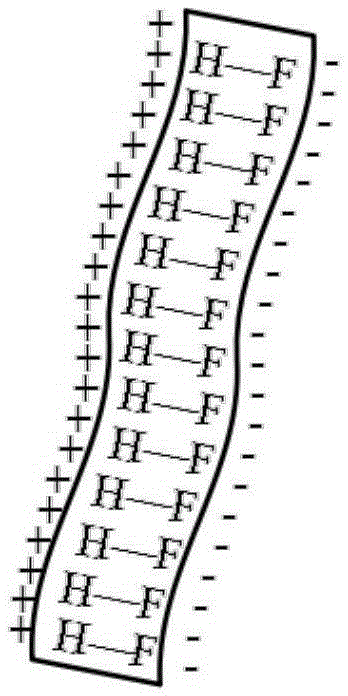

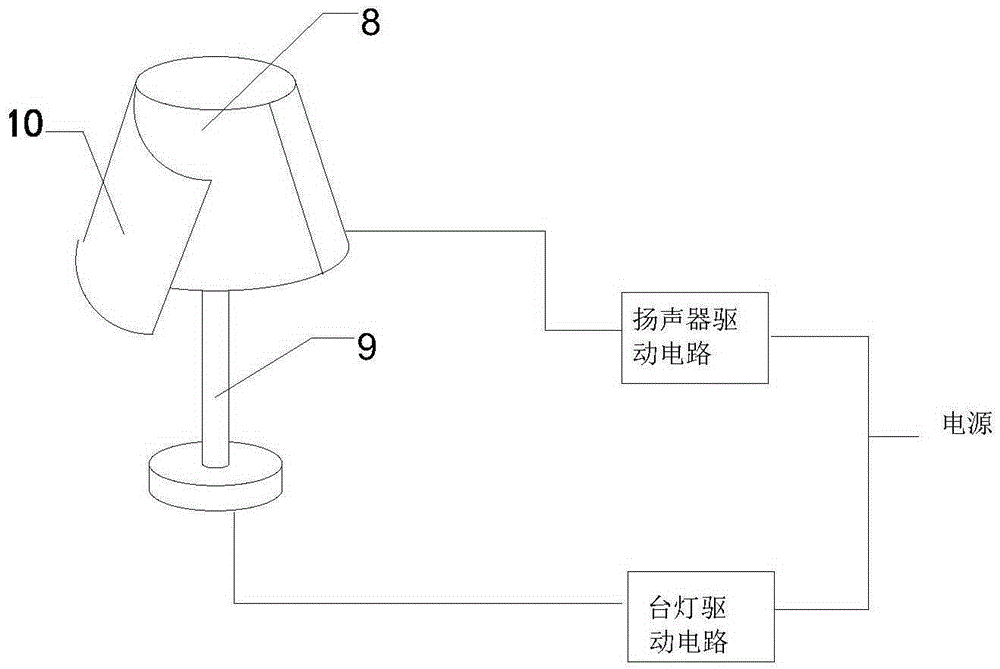

Desk lamp with function of sound equipment

InactiveCN105263092AImprove practicalityAchieve two-in-one integrationElectrical transducersLighting elementsInsulation layerLight guide

The invention discloses a desk lamp with function of sound equipment. The desk lamp comprises a lampshade, a light guide plate in the lampshade, a support and a film loudspeaker. The film loudspeaker is attached to the outer side of the desk lamp, and comprises at least one sounding film, at least one conductive film, at least one insulation layer and at least two conductive terminals, wherein the conductive film coats the sounding film and is made of a nanometer metal line material, the insulation layer is attached to the conductive film, the insulation layer and / or a sound quality improving layer comprise(s) multiple groups of fine processing structures, and the conductive terminals are attached to the conductive film and connected with a loudspeaker drive circuit. The film loudspeaker can be pasted to the external surface, which can be seen, of the desk lamp, or pasted to the internal, which cannot be seen, of the desk lamp, or embedded or placed in the desk lamp; and the practicality of the desk lamp is improved, and the desk lamp is more intelligent.

Owner:李崇

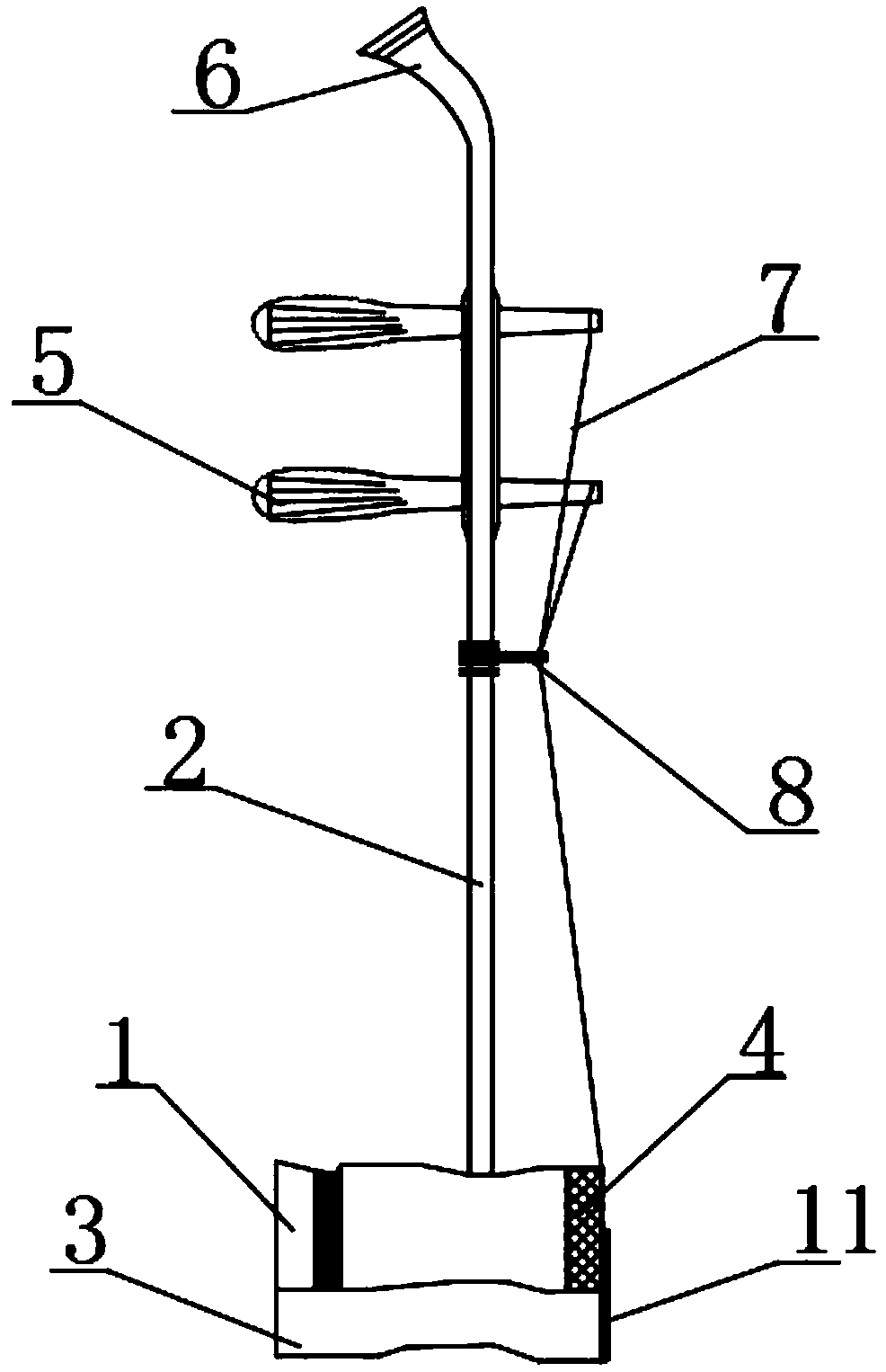

Bamboo erhu

The invention discloses a bamboo erhu. The bamboo erhu comprises a canister, a slim neck, a collect, erhu skin, an erhu shaft, a headstock, a string and a jack thread, wherein the right end of the canister is covered by the erhu skin, the left end of the canister is provided with an opening, the slim neck is arranged at the right end of the canister, a tubular resonance tube is horizontally arranged in the canister, a gap is formed between the periphery of the resonance tube and the inner wall of the canister, the positions, corresponding to the slim neck, of the upper and lower walls of the resonance tube are provided with holes, the slim neck runs through the holes in the upper and lower walls of the resonance tube, the slim neck tightly cooperates with the resonance tube, the left end of the resonance tube is closed, the right end of the resonance tube is provided with an opening, the upper and lower walls of the left end of the resonance tube are provided with amplification holes,the amplification holes in the upper and lower walls are opposite, the amplification holes are of long-strip shapes and arranged in the length direction of the resonance tube, and the erhu is made from bamboo. The bamboo erhu has very soft and smooth, strong resonance, sonorous sound and a good spreading effect.

Owner:贵州新锦竹木制品有限公司

A method for preparing earphone biological diaphragm by using fish bladder glue

ActiveCN109246577BHas sound restoration propertiesBio-diaphragm light weightElectrical transducersVibrating membraneEngineering

The invention discloses a method for preparing a biological vibrating diaphragm of an earphone through bladder glue, belongs to the technical field of earphone diaphragms, and can solve a problem thatconventional earphone diaphragm is liable to cause the distortion, is poor in detail resolution of sound, the types of the earphone vibrating diaphragms made of biological materials are limited and the price is high. The method comprises the five steps: glue preparing, glue hitting, glue liquid extraction, concentration and diaphragm forming. The method is simple in technology, and is low in cost.

Owner:SHANXI UNIV

A sound prompt and alarm system based on a car audio system

Owner:CHERY AUTOMOBILE CO LTD

Dynamic piezoelectric composite speaker

ActiveCN105979449BSimple structureLow priceFrequency/directions obtaining arrangementsPiezo-electric polymer transducersEngineeringSound quality

The invention relates to the technical field of loudspeakers, in particular to a moving-coil piezoelectric composite loudspeaker. The moving coil piezoelectric composite speaker includes a housing and a support plate, the housing is provided with a sound outlet, the support plate is arranged inside the housing, and the support plate separates the housing into dynamic A coil cavity and a piezoelectric cavity, the moving coil cavity communicates with the sound outlet; a moving coil unit is arranged inside the moving coil cavity, and a piezoelectric For the vibrator, the support plate is provided with a sound guide hole, and the piezoelectric cavity communicates with the moving coil cavity through the sound guide hole. In the present invention, the piezoelectric vibrator is added to the original dynamic speaker, and the piezoelectric vibrator is used to compensate the sound effect and sound quality of the dynamic speaker at high frequencies, so that the dynamic unit and the piezoelectric vibrator vibrate and sound at the same time. Resonance is formed to widen the frequency response range and improve the user's listening experience.

Owner:常州市武进晶丰电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com