Hydraulic control system of crane and winch device of crane

A technology of hydraulic control system and hoisting device, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of complex structure, miscalculation and high price of pressure memory valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

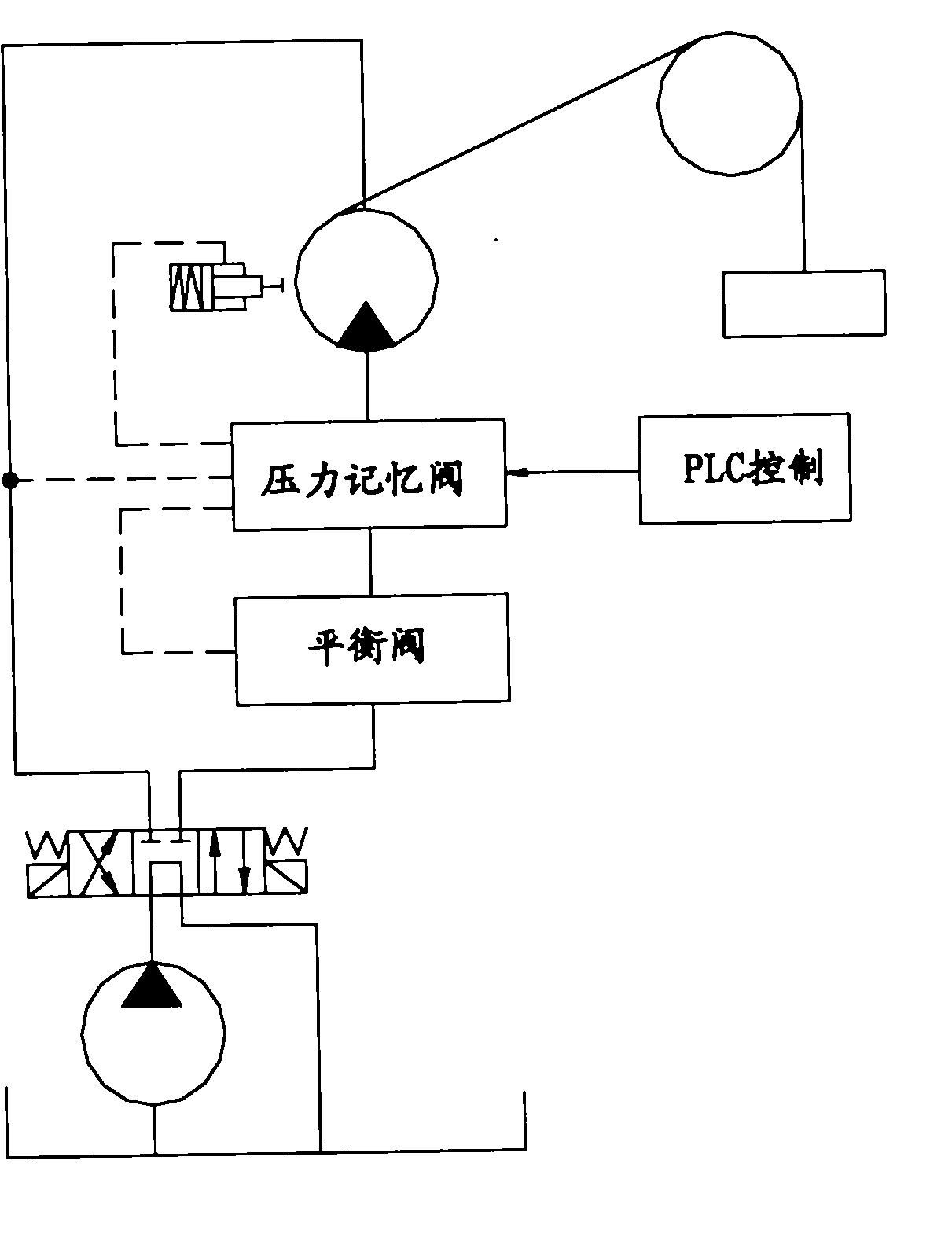

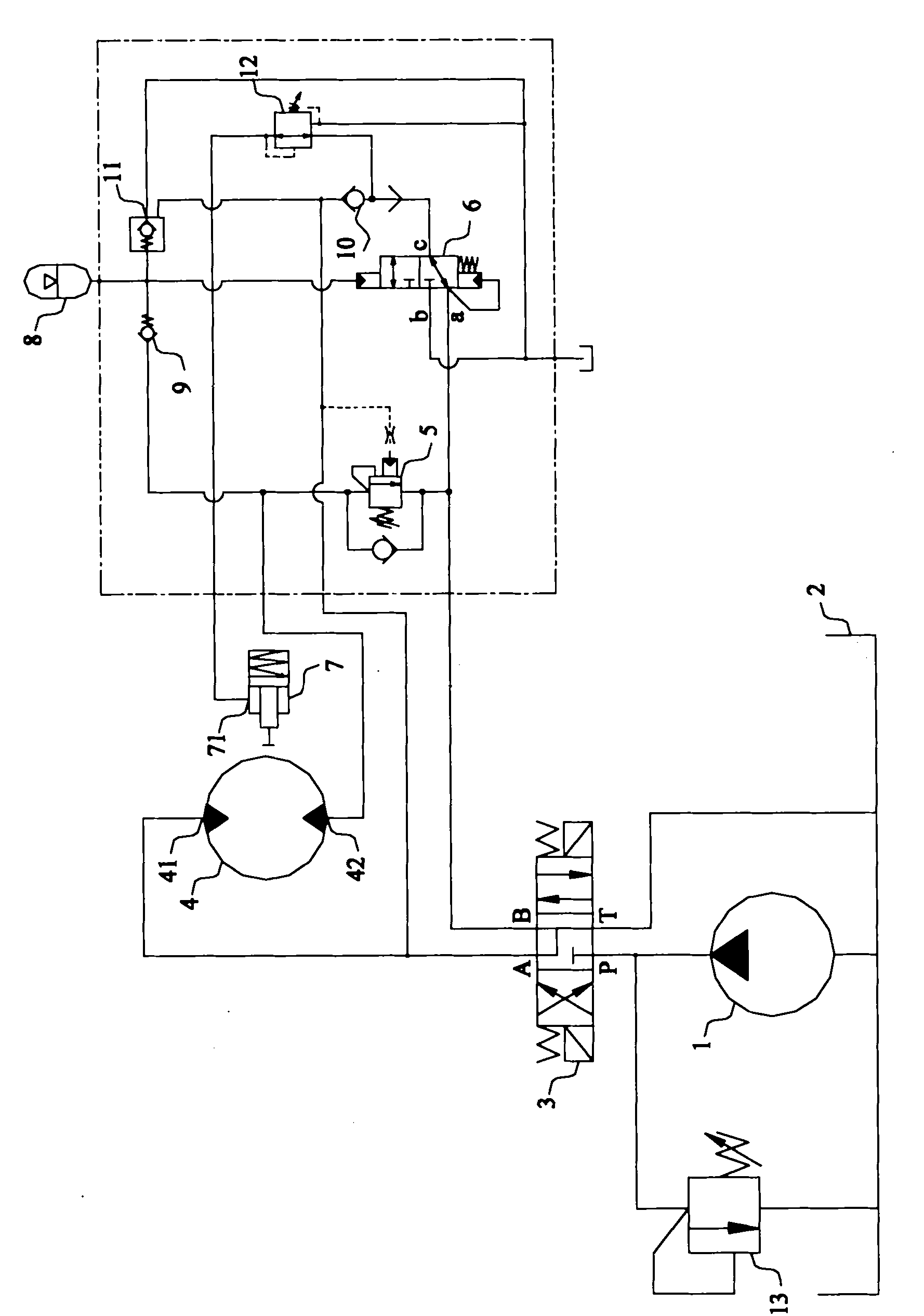

[0027] The core of the present invention is to provide a hydraulic control system for the hoisting device. From the perspective of stabilizing the opening pressure of the brake, the working pressure of the system is memorized through the hydraulic pressure memory device; the system is improved on the basis of effectively reducing the manufacturing cost. Reliability of work.

[0028] Hereinafter, this embodiment will be described in detail with reference to the drawings in the specification.

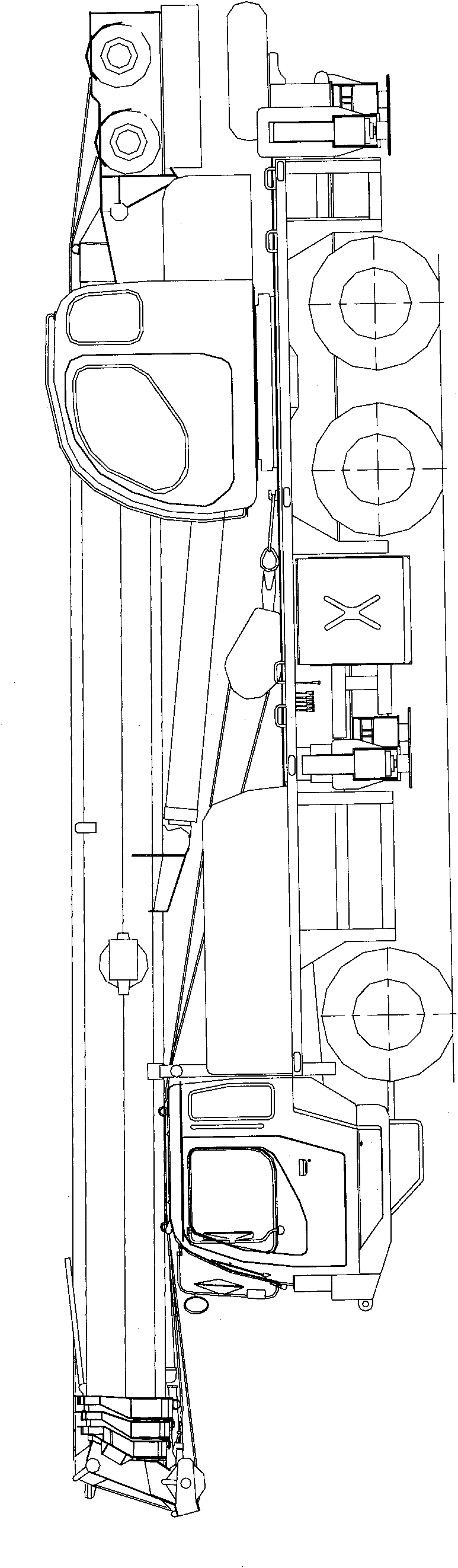

[0029] See figure 1 This figure is a schematic diagram of the overall structure of the crane in this embodiment.

[0030] It should be noted that the main functional components of the crane, such as the traveling system, power system, boom system, hoisting system, and electrical system, are completely the same as the prior art. Those skilled in the art do not need to pay creative labor based on the prior art. It can be achieved, so I won't repeat it here.

[0031] The hoist of the crane is drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com