Device and method for preparing magnesium alloy semi-solid blank through repetitive upsetting-extrusion deformation and isothermal annealing

A technology of isothermal annealing and magnesium alloy, which is applied in the field of devices for preparing magnesium alloy semi-solid blanks by warm annealing, can solve the problems of high process cost, large blank shape change, and low production efficiency, and achieve high mechanical properties, small forming force, The effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

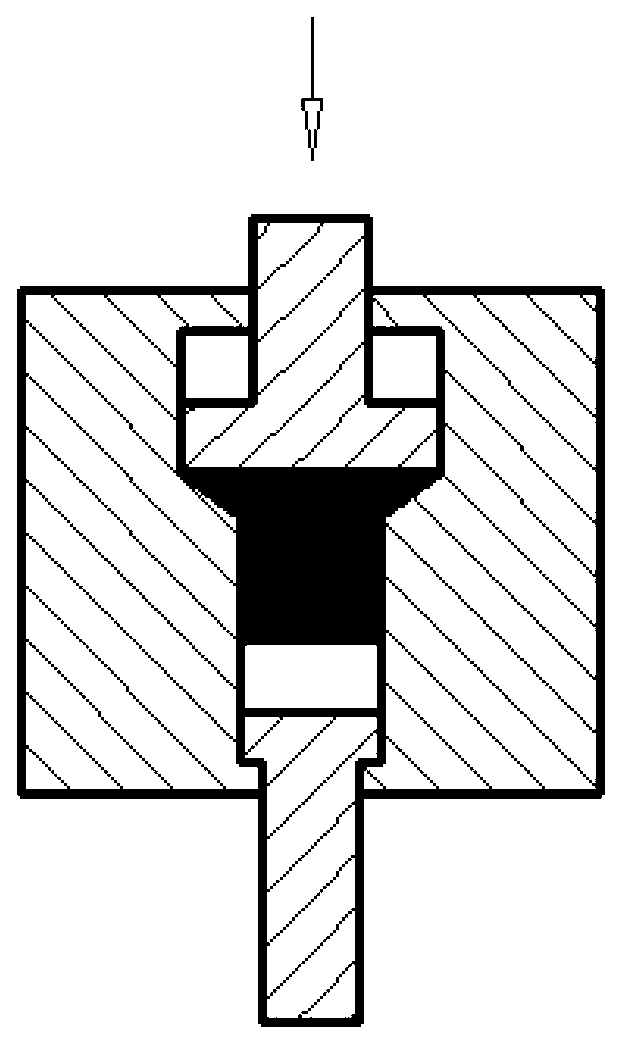

[0028] Specific Embodiment 1: In this embodiment, the reciprocating upsetting extrusion deformation-isothermal annealing device for preparing a magnesium alloy semi-solid billet consists of an upper template 1, an upper backing plate 2, an upper pressing sleeve 3, an upsetting punch 4, an upper pressing plate 5, and a die The pre-tightening sleeve 6, the die 7, the extrusion punch 9, the lower pressing plate 10, the lower pressing sleeve 11, the lower backing plate 12 and the lower template 13; the die 7 is provided with a cavity, and the die pre-tightening sleeve 6 sets On the outer circle of the die 7, the upper platen 5 is connected to the upper surface of the die 7 and the die pre-tightening sleeve 6 respectively, and the lower pressing plate 10 is connected to the lower surface of the die 7 and the die pre-tightening sleeve 6 respectively. One end of the upsetting punch 4 is inserted into the upper part of the cavity, and the other end of the upsetting punch 4 is fixed in ...

specific Embodiment approach 2

[0030] Specific embodiment 2: The method of reciprocating upsetting extrusion deformation-isothermal annealing to prepare magnesium alloy semi-solid billet in this embodiment is implemented through the following steps:

[0031] 1. Machining the as-cast magnesium alloy billet into a cylindrical bar;

[0032] 2. Lubricate the cylindrical bar, and then put it into the cavity of the device for preparing magnesium alloy semi-solid billet through reciprocating upsetting extrusion deformation-isothermal annealing, and heat the cylindrical bar to the upsetting temperature;

[0033] 3. The upsetting cylindrical bar is deformed through the upsetting punch until it fills the cavity. After the upsetting punch is reset, the device is turned over and reciprocated for extrusion deformation-isothermal annealing to prepare a magnesium alloy semi-solid billet, and then through extrusion The punch moves downward to extrude the cylindrical bar until it fills the cavity, and performs the upsetting...

specific Embodiment approach 3

[0040]Embodiment 3: This embodiment is different from Embodiment 2 in that the material of the magnesium alloy is AZ91D magnesium alloy, AZ61 magnesium alloy, ZK60 magnesium alloy, AZ31 magnesium alloy or AM60 magnesium alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com