Large-gap back-chipping-free welding process for I-shaped groove of middle thick plate

A welding process and large gap technology, which is applied in welding equipment, plasma welding equipment, welding/welding/cutting items, etc., can solve the problems of large cutting quality assembly gap, failure to meet quality requirements, unqualified welding quality, etc., to achieve assembly The effect of large gap, high welding production efficiency and stable welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In view of the situation in the prior art that the plasma cutting quality of medium and thick plates is not high, there is a natural groove, the assembly gap is large, and the quality of the weld seam is required to be a first-class weld, the present invention proposes a type I groove suitable for medium and thick plates. The welding method with large gaps and unclear roots, the basic process is S-M-S (SAW-MAG-SAW), that is, solid wire gas shielded welding (MAG), front submerged arc welding (SAW), and back submerged arc welding (SAW).

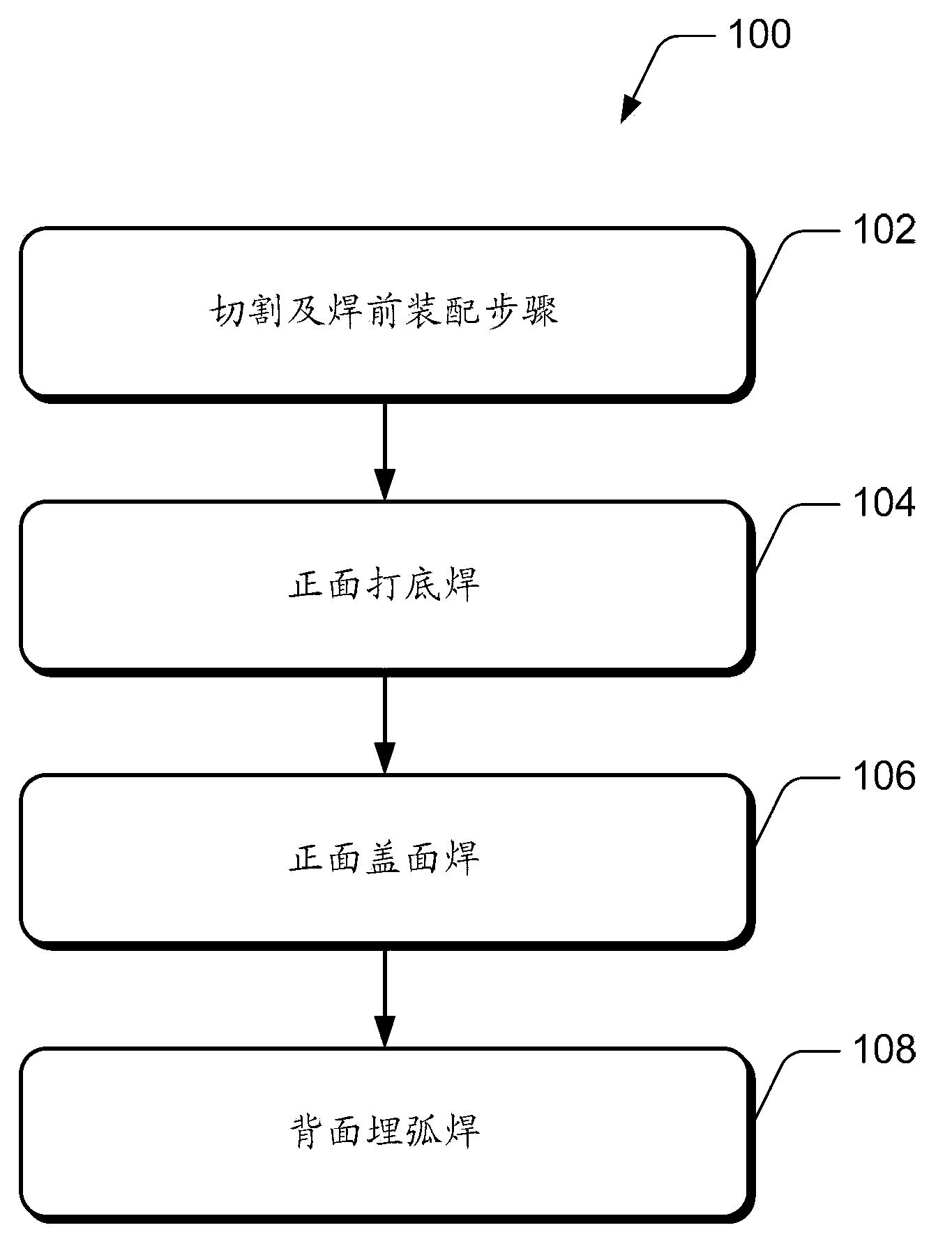

[0024] refer to figure 1 As shown, the present invention discloses a welding process 100 of type I groove of medium and thick plate with large gap and unclear root, including the following steps:

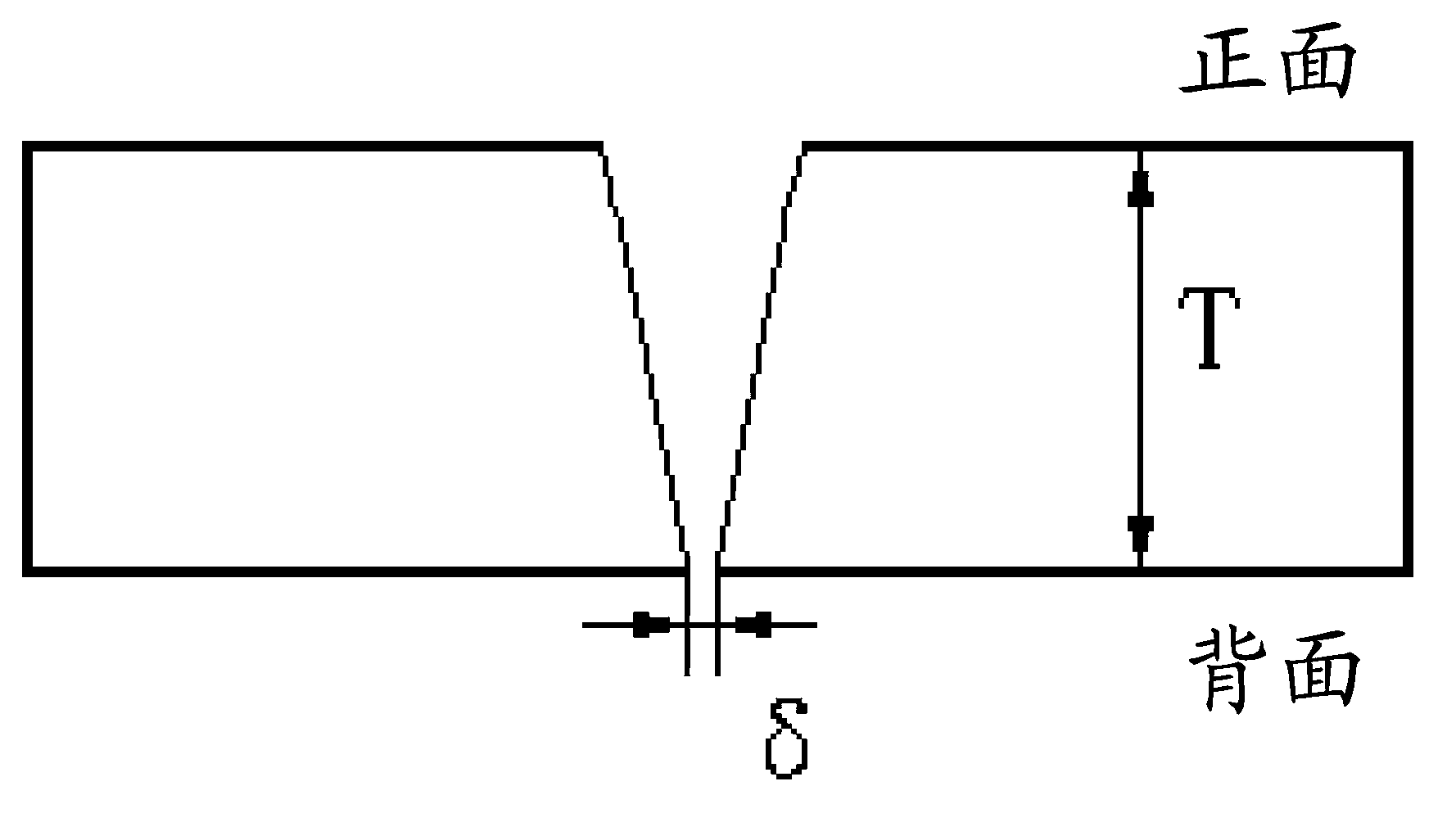

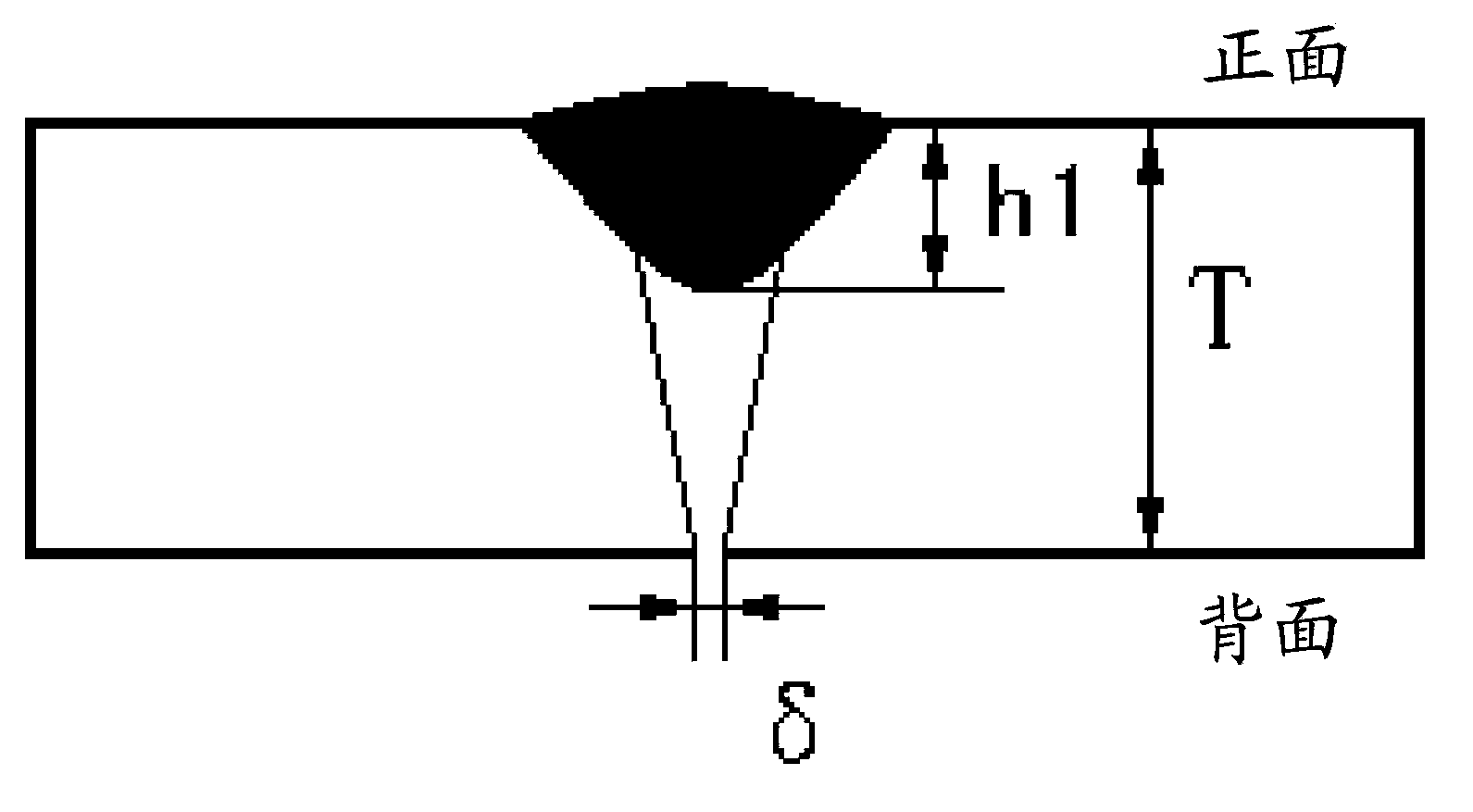

[0025] 102. Cutting and pre-weld assembly steps. Use plasma to cut medium-thick plates, assemble medium-thick plates to form I-shaped grooves, the gap at the root of the groove δ is less than or equal to 3mm, and the gap at the front of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com