Submicron particle reinforced Ag-based electrical contact material and preparation method thereof

A technology of sub-micron particles and electrical contact materials, applied in contacts, circuits, electrical switches, etc., can solve the problems of many pores and uneven distribution, and achieve the prevention of arc concentration, anti-welding performance and anti-arc ablation The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take the preparation of 5mm thick Ag-WC30-1Cu-1Ni material as an example

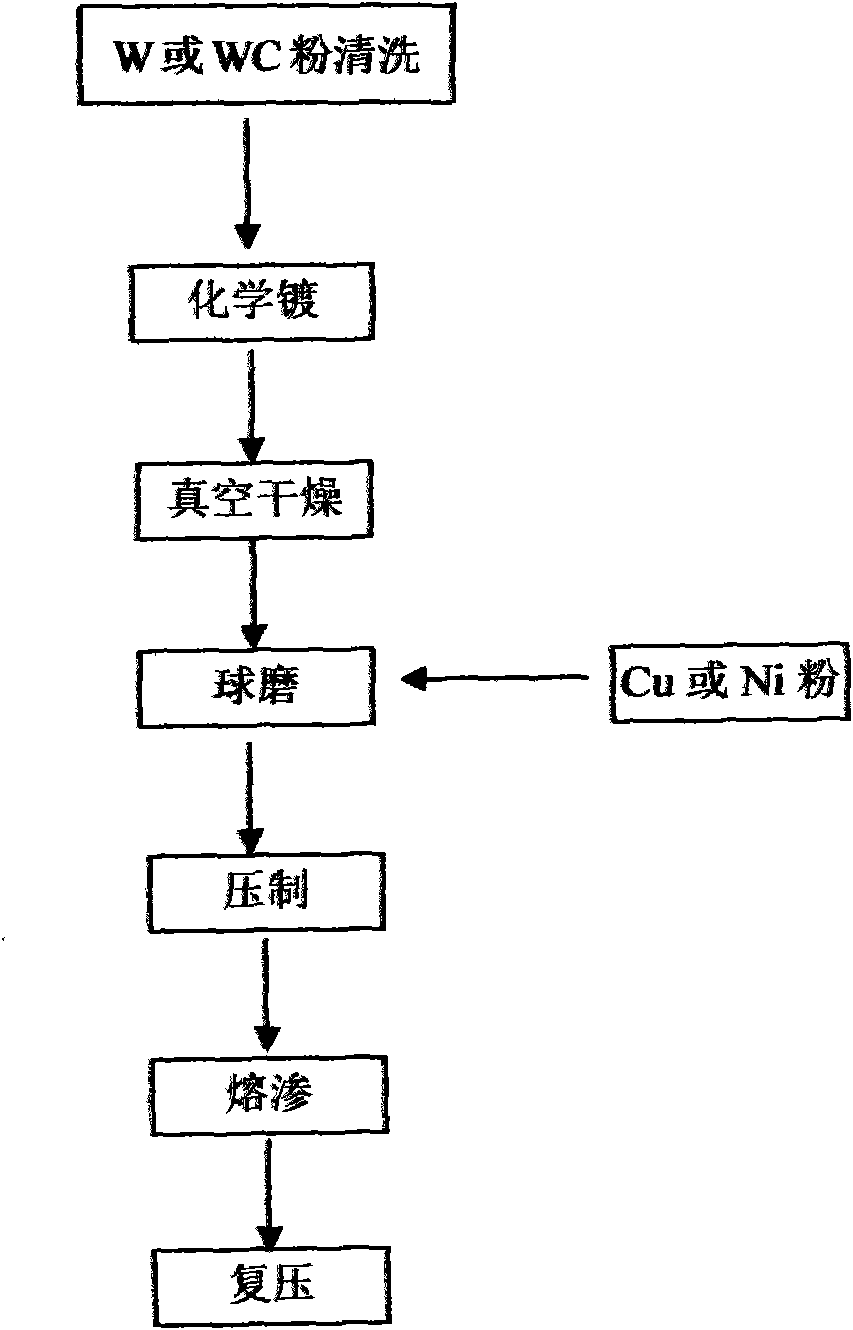

[0034] Such as figure 1 As shown, first 10kg of WC powder (with a particle size of 1 μm) was placed in 5% nitric acid solution, stirred and cleaned for 10 minutes, then washed three times with deionized water and then suction filtered.

[0035] Then implement electroless plating, pour the powder after suction filtration into 500L of hydrazine hydrate solution, the concentration is 3ml / L, adjust the pH value to 8 with ammonia water, stir and ultrasonically vibrate, and simultaneously add 500L of silver nitrate solution with a concentration of 10g / L It is added in the form of spray, the stirring speed is 20 rpm, and the ultrasonic vibration frequency is 15KHz. After the electroless plating is complete, the coated WC powder is obtained by suction filtration, and washed three times with deionized water.

[0036] After vacuum drying, the coated WC powder was placed in vacuum and dried at 100° C. for...

Embodiment 2

[0042] Take the preparation of 10mm Ag-WC80-1Ni material as an example

[0043] Such as figure 1 As shown, firstly, 30kg of WC powder (with a particle size of 0.1 μm) was placed in 20% nitric acid solution, stirred and cleaned for 30 minutes, then washed three times with deionized water and then suction filtered.

[0044]Then implement electroless plating, pour the powder after suction filtration into 500L hydrazine hydrate solution, its concentration is 6ml / L, use ammonia water to adjust the pH value to 10, stir and ultrasonically vibrate, and at the same time, 500L silver nitrate solution with a concentration of 30g / L It is added in the form of spray, the stirring speed is 200 rpm, and the ultrasonic vibration frequency is 50KHz. After the electroless plating is complete, the coated WC powder is obtained by suction filtration, and washed three times with deionized water.

[0045] After vacuum drying, the coated WC powder was placed in vacuum and dried at 150° C. for 24 hou...

Embodiment 3

[0051] Take the preparation of 20mm Ag-WC50-0.1Cu material as an example

[0052] First, 15 kg of WC powder (with a particle size of 0.5 μm) was placed in 10% nitric acid solution, stirred and washed for 10 minutes, then washed three times with deionized water and then suction filtered.

[0053] Then implement electroless plating, pour the powder after suction filtration into 500L hydrazine hydrate solution, its concentration is 4.5ml / L, adjust the pH value to 9 with ammonia water, stir and vibrate ultrasonically. At the same time, 500 L of silver nitrate solution with a concentration of 15 g / L was added in the form of spray, the stirring speed was 100 rpm, and the ultrasonic oscillation frequency was 30 KHz. After the electroless plating is complete, the coated WC powder is obtained by suction filtration, and washed three times with deionized water.

[0054] After vacuum drying, the coated WC powder was placed in vacuum and dried at 100° C. for 24 hours.

[0055] The dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com