Manufacturing method of vehicle seamless steel tubes

A technology of seamless steel pipe and manufacturing method, which is applied to the manufacturing field of special steel pipe for auto parts, can solve the problems of reducing production efficiency, no requirement for surface roughness, and increasing production cost, so as to reduce production cost, improve surface quality, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

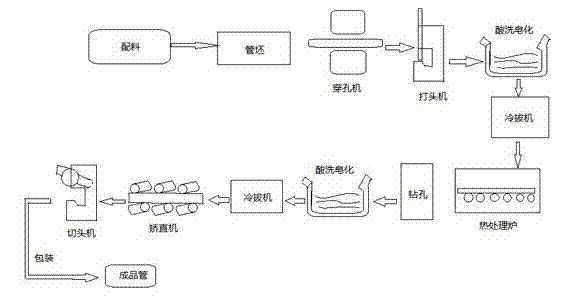

[0030] Such as figure 1 Said, the method includes the following steps:

[0031] Step 1: round tube forming;

[0032] Put the ingredients into the pipe-making mold, and after smelting, heat processing and cooling, the tube blank is formed;

[0033] Step 2: perforation treatment;

[0034] Cut the tube blank with a cutting device, set the cutting according to the required length of the auto parts, and then transport it to the heating device through the conveyor frame for full heating after cutting. The heating temperature is controlled within the range of 1220°C to 1230°C. The temperature is controlled by the automatic temperature closed-loop control system, and the capillary is heated to prepare for perforation. Heating can transform the capillary into a material with sufficient plasticity and low deformation resistance. During the heating process, the structure and properties of the steel can be improved, and the tube blank is released Finally, it needs to pass through t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com