Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90results about How to "Meet surface quality requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

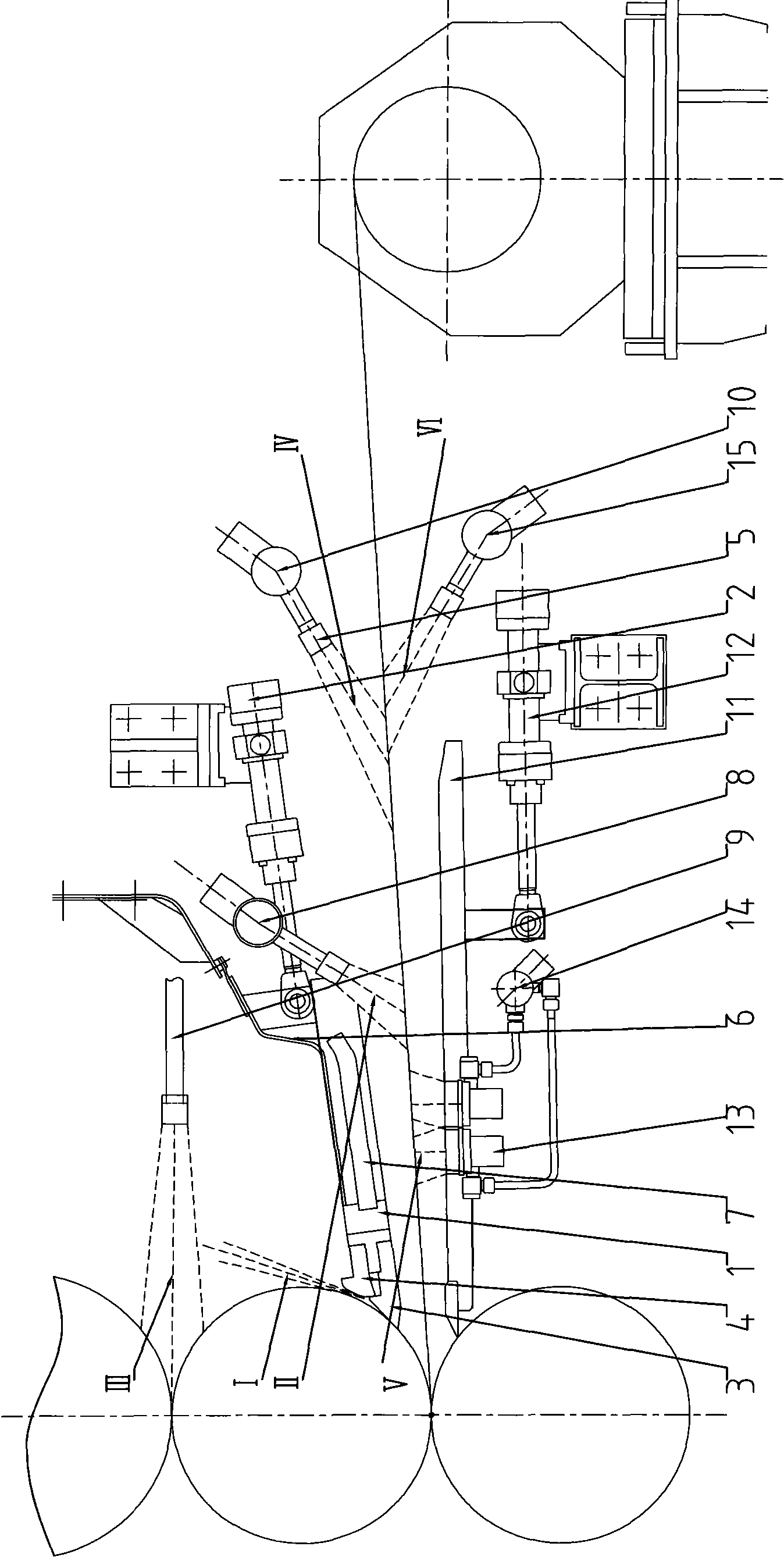

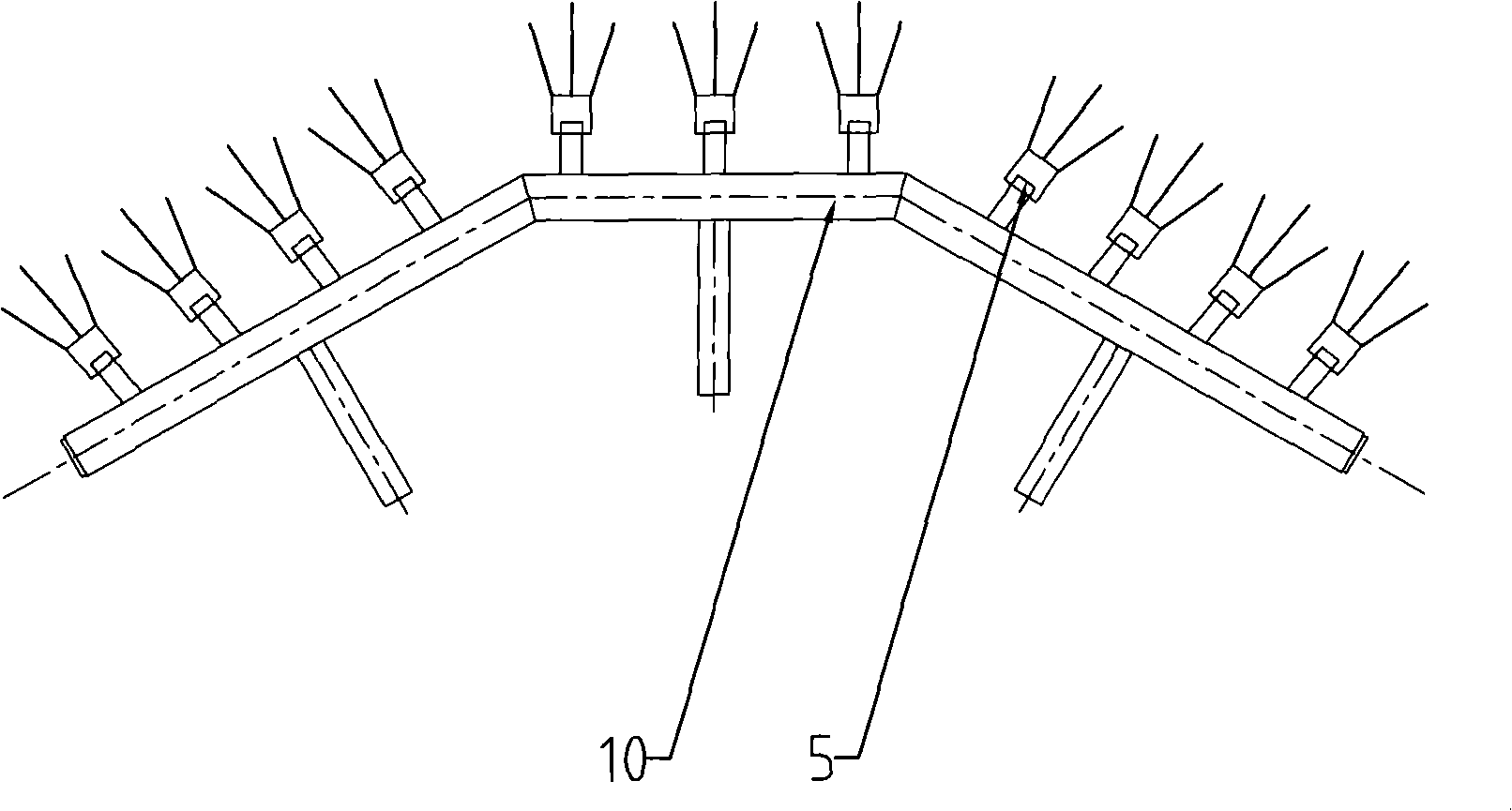

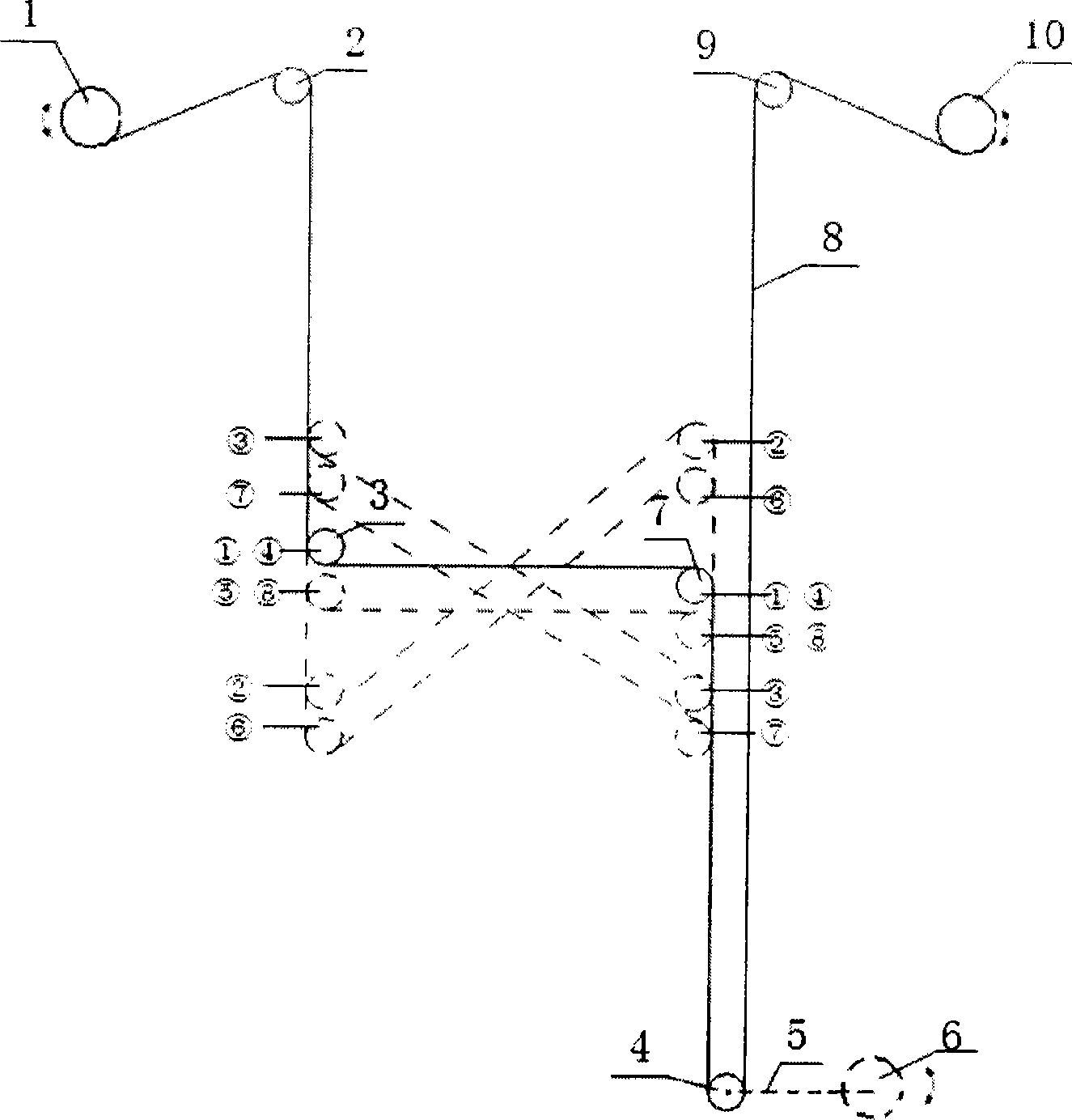

Emulsion cleaning device

InactiveCN101780485AEasy to cleanMeet surface quality requirementsWork treatment devicesMetal rolling arrangementsEmulsionEconomic benefits

The invention relates to an emulsion cleaning device, which consists of an air curtain purging device for an upper anti-wrap guide plate of a rolling mill, a purging device for the middle of the upper part of a strip, a roll gap purging device, a purging device for the upper part of the strip, a lower anti-wrap guide plate suction device, and a purging device for the edge of the lower surface of the strip. By the combination action of a series of strip surface purging, roll gap purging, sucking, edge purging and the like, the strip surface emulsion purging effect is very obvious and the residual oil amount on the surface of the strip can completely meet the requirement of the user for the surface quality of the finished strip. By the emulsion cleaning device, the surface quality of the product is improved and the economic benefit of the user is increased. The emulsion cleaning device not only has very good application effect in a cold continuous rolling mill, but also can have wide application in a plurality of sets such as a single-stand reversing cold mill, a double stand reversing cold rolling mill, a planisher and the like, can be greatly popularized and used in the cold rolling industry and brings convenience and benefits for more users.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

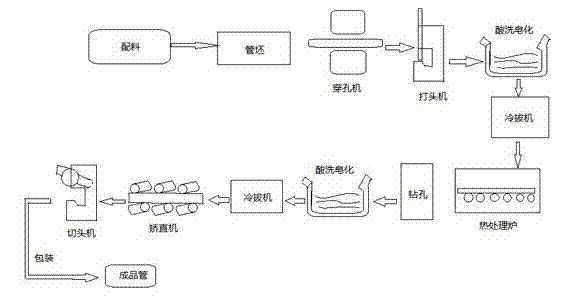

Manufacturing method of vehicle seamless steel tubes

The invention relates to a manufacturing method of vehicle seamless steel tubes. Surface quality of finished products can be improved through twice phosphorus acid saponification processing and secondary cold drawing processing; during manufacturing, external and internal quality of the products can be guaranteed through twice test, performance index of the steel tubes with the tensile strength larger than or equal to 500Mpa and extension larger then or equal to 10% and internal and external surface roughness smaller than or equal to 0.4 micrometers can be achieved by directly using saw cutting without heat treatment and mechanical machining, requirements of the steel tubes of vehicle parts on strength, toughness and surface quality are met, and meanwhile, technical requirement of processing-free steel tube parent materials of the vehicle parts can be met.

Owner:泰州双马节能科技有限公司

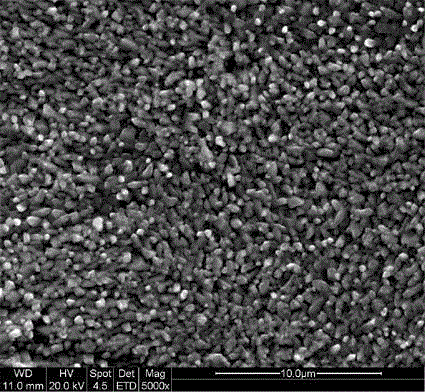

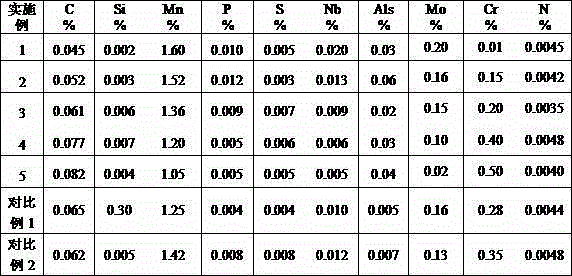

450 MPa-level zinc-plated dual-phase steel for sedan and production method thereof

ActiveCN105369135AUniform surface color without defectsUniform color without defectsHot-dipping/immersion processesBall impactLevels zinc

450 MPa-level zinc-plated dual-phase steel for a sedan comprises components in percentage by weight as follows: 0.04%-0.09% of C, smaller than or equal to 0.01% of Si, 1.0%-2.0% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.010% of S, 0.01%-0.08% of Als, 0.01%-0.30% of Mo, 0.01%-1.0% of Cr, 0.001%-0.03% of Nb and smaller than or equal to 0.005% of N. The production steps comprise heating of a casting blank after smelting, refining and continuous casting; finish rolling; reeling; cold rolling after acid pickling; hot galvanizing; finishing. The mechanical properties of a product are shown as follows: the yield strength is 260-320 MPa, the tensile strength is 470-510 MPa, the elongation percentage is 28%-33%, and the n value is 0.17-0.19; the product has good platability, the surface of a plating has uniform glossiness and doesn't have defects, an inhibition layer is continuous and compact, the adhesion of the zinc-plated layer reaches the first level of ball impacting, the bending test proves that the zinc-plated layer and base steel are qualified, and surface quality requirements of an intermediate car for a high-strength structural part and an outer covering part can be met.

Owner:武汉钢铁有限公司

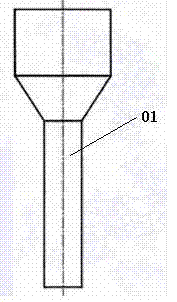

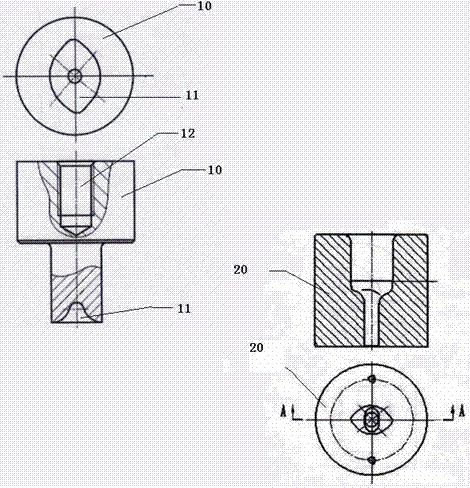

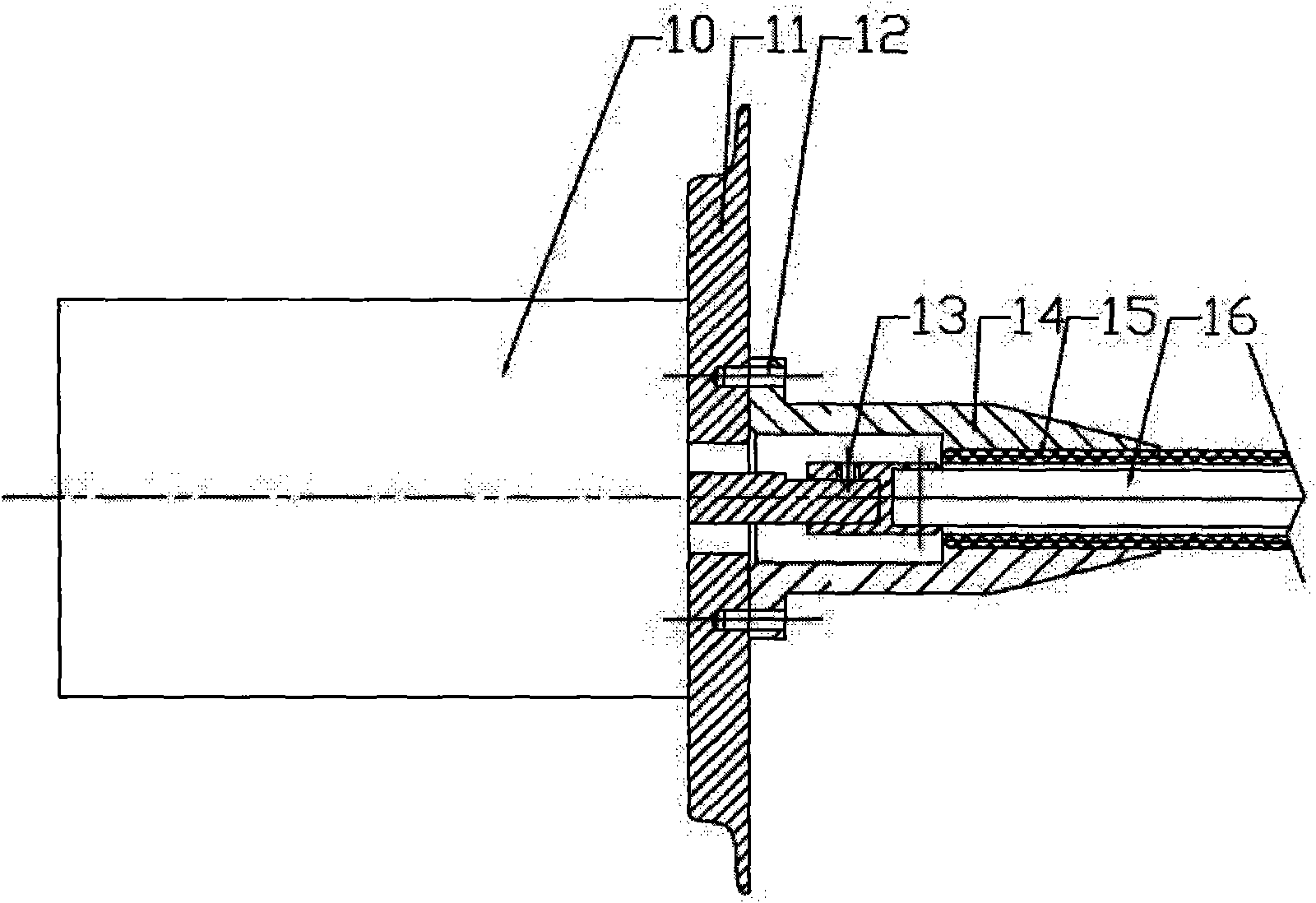

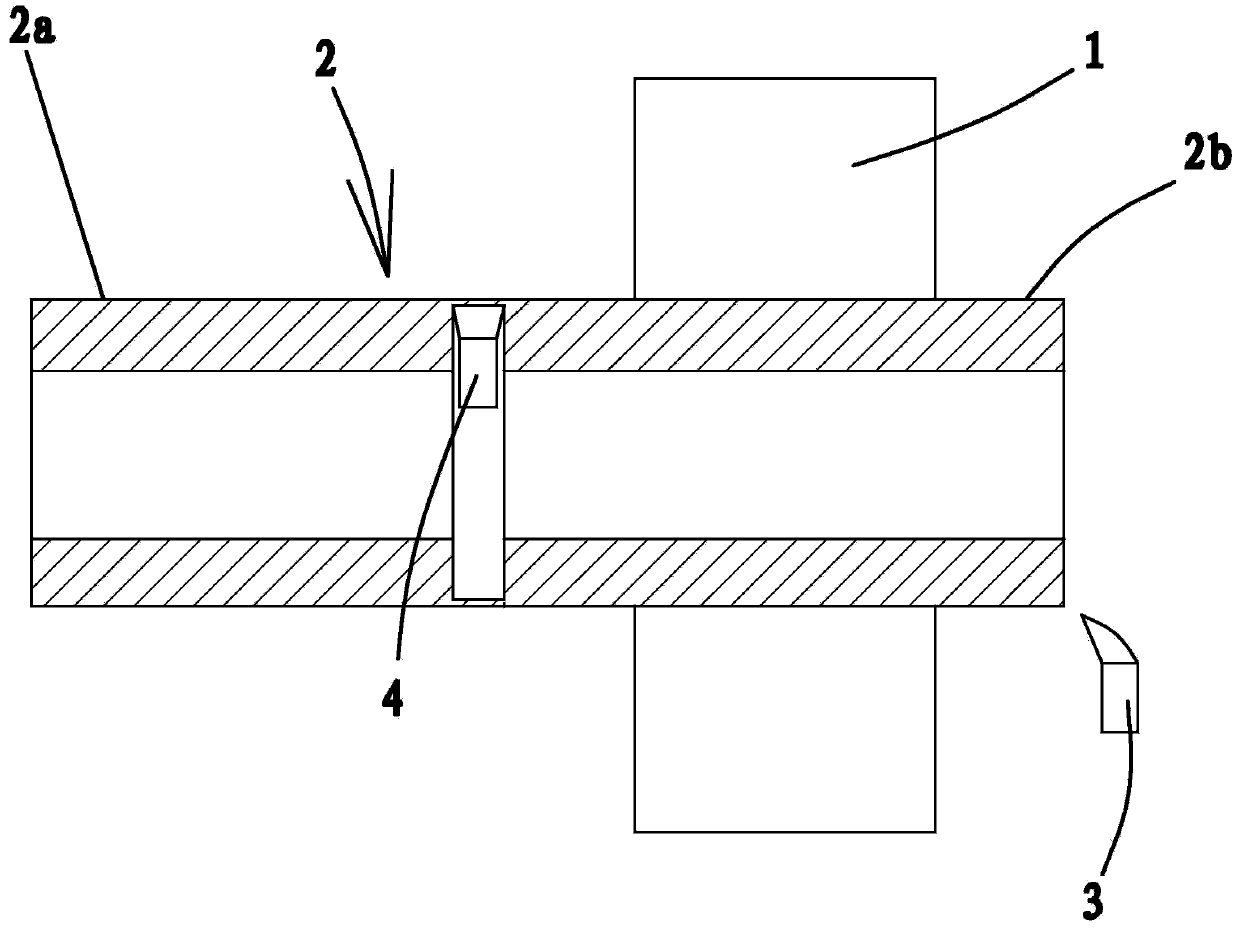

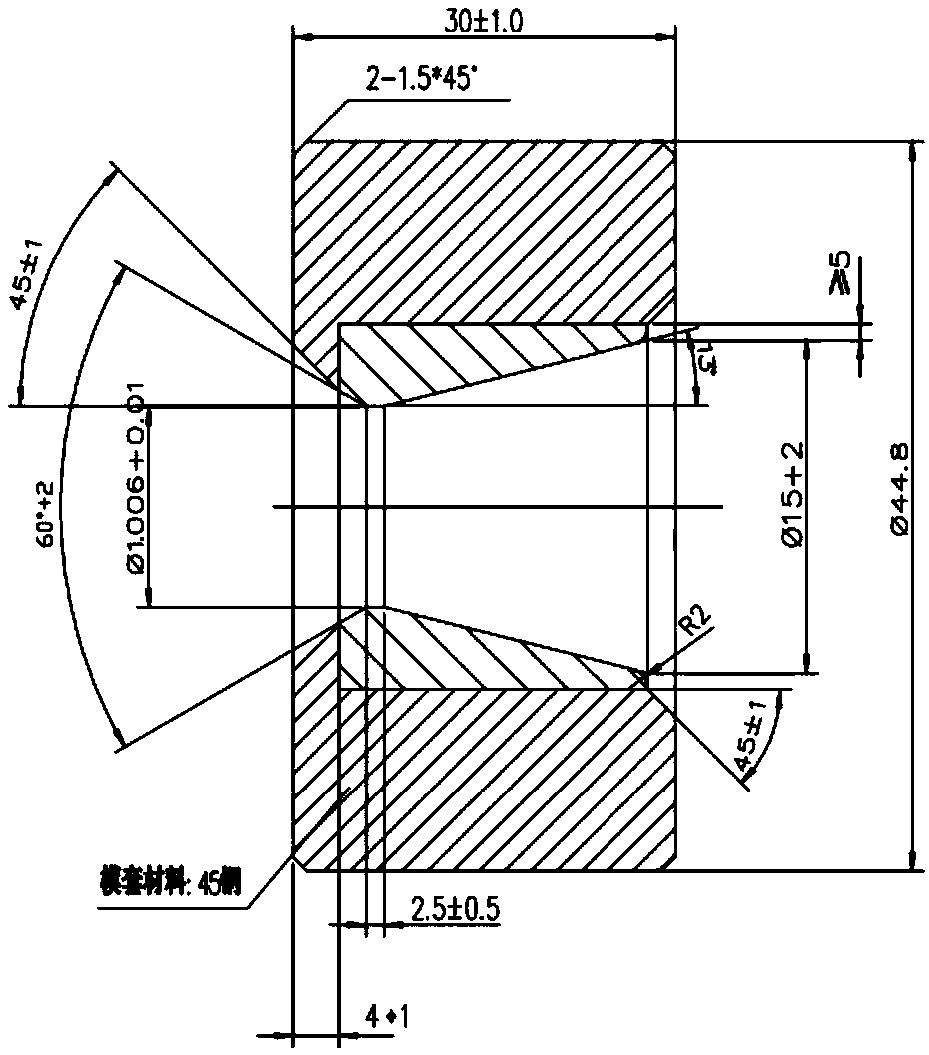

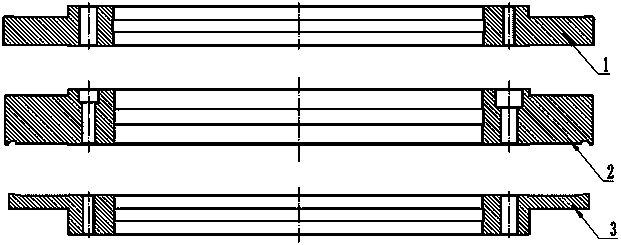

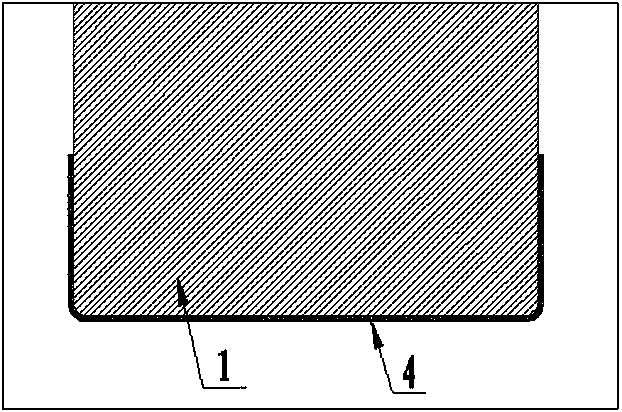

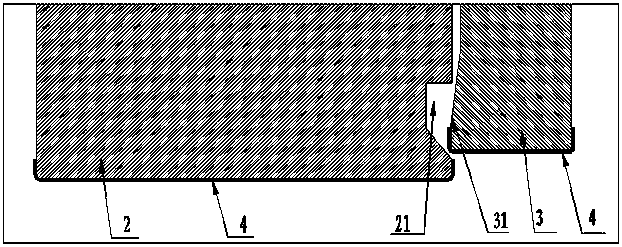

Die in alloy blade precision forging process

InactiveCN102310154AImprove mechanical propertiesEasy to useForging/hammering/pressing machinesAlloyMechanical property

The invention provides a die in an alloy blade precision forging process, and particularly provides a rod squeezing die and a forging die. The die is characterized in that the rod squeezing die comprises an ejector rod (1), an ejector rod guide sleeve (2), a cushion block (3), an insert (4), a squeezing cylinder (5) and a punch head (6); and the forging die comprises a male die (10) and a female die (20). The blanking die squeezing die and forging die are adopted for blanking so as to realize precision forging with the blade singe-face allowance of 0.3-0.7mm, the requirements of a cold rolling process on processing allowance, size precision and surface quality of forge pieces are met, the metal streamline direction of a blade body is reasonable, and the mechanical properties and the use performance of the blade are improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

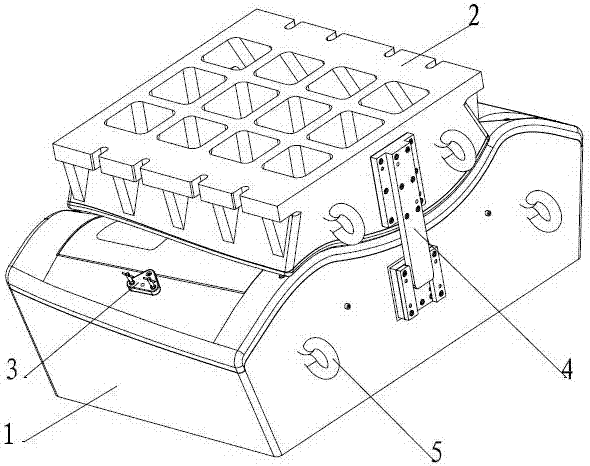

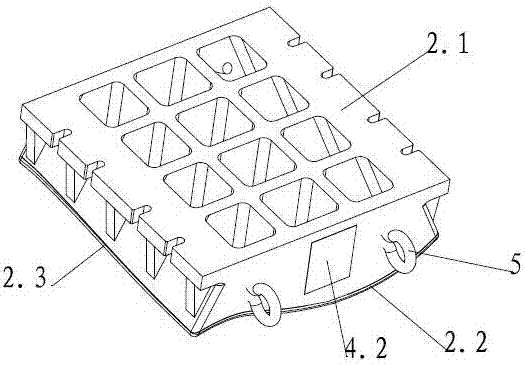

Stretch forming die with composite structure and manufacturing method of stretch forming die

ActiveCN107413948ATotal light weightExtended service lifeShaping toolsEngineeringMechanical engineering

The invention relates to the field of airplane metal envelope manufacturing, in particular to a stretch forming die with a composite structure and a manufacturing method of the stretch forming die. The stretch forming die comprises an upper die assembly and a lower die assembly, the upper die assembly is connected with the lower die assembly through a guiding positioning device assembly, the upper die assembly is located above the lower die assembly, a hole making device assembly of an envelope part positioning hole is arranged on the upper surface of the lower die assembly, and at least two earring-shaped hooks are arranged on the side face of the lower die assembly. The stretch forming die is provided with a lower die and an upper die , and the upper die and the lower die have the composite structural characteristic, a base body of the stretch forming die adopts a cast aluminum material and is provided with lightening grooves and reinforced ribs so that the total weight of the stretch forming die can be lightened obviously. Dovetail grooves which are distributed in a latticed mode on the molded surface of the cast aluminum base body can firmly hold machinable resin, and effectively prevent a machinable resin layer from cracking and falling down, and the service life of the stretch forming die is prolonged.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

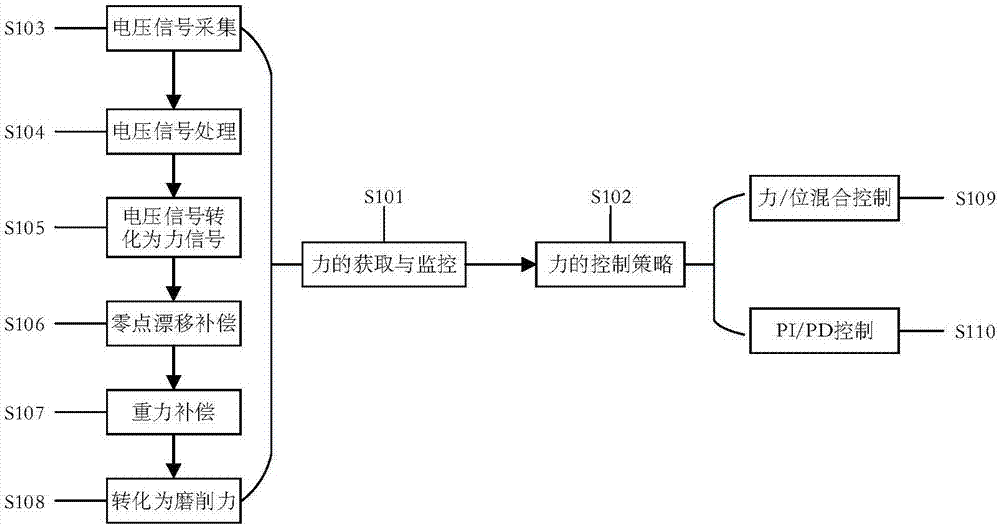

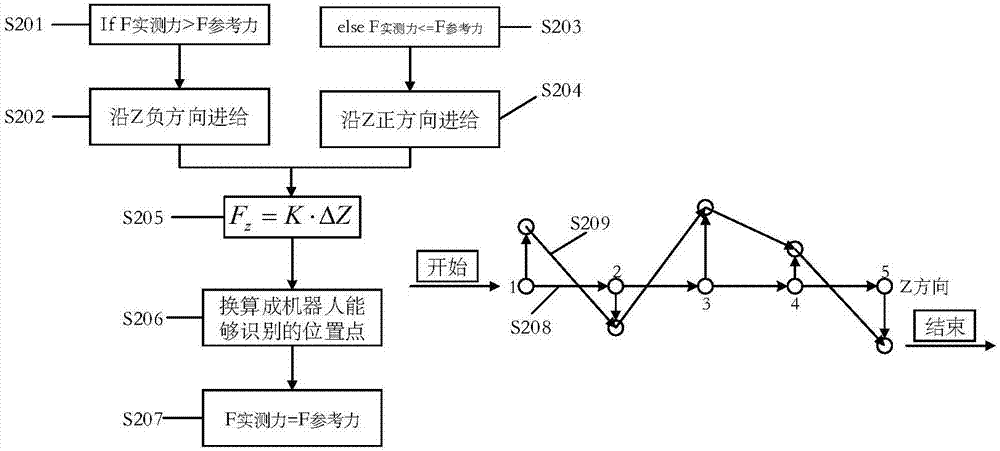

Force control method for robotic abrasive belt grinding machining for blade

ActiveCN107962480AUniform removalImprove grinding efficiencyBelt grinding machinesGrinding feed controlConstant forcePosition control

The invention discloses a force control method for robotic abrasive belt grinding machining for a blade. The force control method for robotic abrasive belt grinding machining for the blade comprises the following steps: modulation and processing for voltage signals; compensation for a converted force; and a force control strategy. The modulation and processing for the voltage signals comprises thefollowing steps: acquiring the voltage signals of six channels of a sensor; carrying out software filtering on the acquired voltage signals; and converting the filtered voltage signals to force signals. The compensation for the converted force comprises the own zero drift compensation of the sensor and gravity compensation for a robotic end load. The force control strategy comprises hybrid force-position control and PI / PD control. The force control method for robotic abrasive belt grinding machining for the blade is capable of increasing the efficiency of the grinding machining, avoiding thecase of low consistency of manual grinding machining, realizing constant-force grinding machining, and keeping a uniform and consistent removal amount of a surface material, thereby improving the surface consistency of the blade while improving the machining accuracy and surface quality.

Owner:HUAZHONG UNIV OF SCI & TECH

Portable ultrasonic auxiliary spark sedimentation repairing and polishing integrated device and process thereof

ActiveCN102019531ALower acquisition costsPrevent electrode stickingArc welding apparatusCeramicPre stressing

The invention relates to a portable ultrasonic auxiliary spark sedimentation repairing and polishing integrated device and a process thereof. The device comprises an air supply system for creating a protective atmosphere for sedimentation repairing, a power supply, a control box, an ultrasonic auxiliary spark sedimentation repairing and polishing integrated element, a workpiece chuck and a tool electrode, wherein the ultrasonic auxiliary spark sedimentation repairing and polishing integrated element comprises a shell, a spindle and an ultrasonic vibrator; the ultrasonic vibrator comprises a rear matching cover, two electrode plates of the ultrasonic vibrator, two piezoelectric ceramics, an insulation sleeve, an amplitude transformer, a pre-stress bolt and a electrode chuck. The device of the invention is portable and multifunctional, can repair the failure surfaces of module and parts through the ultrasonic spark sedimentation repairing, can improve the surface quality of the repaired sedimentation layer by ultrasonic polishing, can locally strengthen the surfaces of the module and parts through ultrasonic spark sedimentation and can remove surplus materials of the surfaces of the module and parts through reversed polarity spark processing. The portable ultrasonic auxiliary spark sedimentation repairing and polishing integrated processing method of the invention is simple in operation, is convenient and is practical.

Owner:广州市联合科技发展有限公司

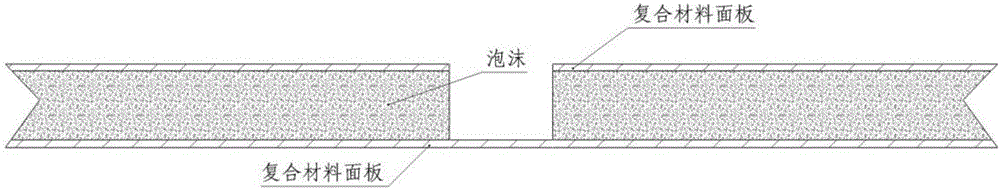

Repairing method of airplane composite material foam interlayer structure

PendingCN106628240AMeet surface quality requirementsEasy to operateAircraft maintainanceEngineeringOblique angle

The invention relates to a repairing method of an airplane composite material foam interlayer structure. The repairing method comprises the following steps that 1, foam and a panel on the damaged portion are removed, and the panel is grinded; 2, a sticking patch is produced by laying a lower panel, and foam is cut and repaired; 3, the sticking patch is glued to the lower portion of the lower panel and supported through a backer board; 4, an upper panel is grinded to form an oblique angle of a certain degree; 5, a glue film is laid on the upper surface of the lower panel; and 6, repairing layers are laid and pasted to the upper panel, the boundary of the first layer needs to be larger than that of the damaged portion, and steps are reserved between every two adjacent repairing layers. The method is easy to implement and can be flexibly applied, the strength and rigidity of the airplane foam interlayer structure can restore, bumping is avoided, and rigidity is uniform.

Owner:R&D INST OF CHINA AVIATION IND GENERAL AIRCRAFT

Method capable of removing head transverse fold lines of low-carbon steel hot rolling pickle sheet

ActiveCN111151578AHigh yield strengthImprove surface qualityRoll force/gap control deviceWork cooling devicesEngineeringHigh surface

The invention relates to the field of steel rolling, in particular to a method capable of removing head transverse fold lines of a low-carbon steel hot rolling pickle sheet. Through curling temperature and head centralized cooling manner combination and limiting of laminar flow cooling speeds, the yield strength of a low-carbon steel hot steel strip can be improved, generation of the transverse fold lines in the leveling process can be thoroughly reduced, the surface quality of the hot rolling pickle sheet can be improved, and the high surface quality needs of the hot rolling pickle sheet canbe met.

Owner:HEBEI IRON AND STEEL

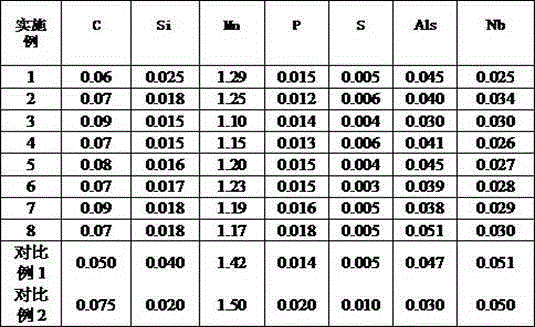

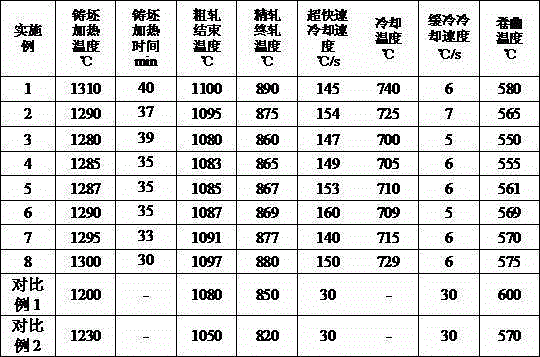

Coated steel used for 500 MPa grade automobile girder and ultrafast-cooling production method of coated steel

Coated steel used for a 500 MPa grade automobile girder comprises, by weight, 0.06-0.09% of C, not more than 0.025% of Si, 1.10%-1.29% of Mn, not more than 0.015% of P, not more than 0.006% of S, 0.020%-0.060% of Als and 0.025%-0.034% of Nb. The production method includes the steps that argon blowing is conducted in an argon station after converter smelting is conducted; casting blanks are heated after tapping is conducted and the blanks are formed through continuous casting; staged hot rolling is conducted; laminar cooling is conducted in a variable-speed cooling manner; reeling is conducted; and finishing and subsequence procedures are conducted. Under the design of low alloy components, ultrafast cooling and staged cooling are adopted, the produced coated steel used for the girder has excellent surface quality and platability, hot galvanizing production can be directly conducted, the denting resistance and coating adhesive force of steel plates are further improved, and good surface quality is achieved.

Owner:武汉钢铁有限公司

Lithium niobate crystal polishing solution and preparation method thereof

ActiveCN101857775AThe preparation method is simple and easyMeet surface quality requirementsPolishing compositions with abrasivesAlcoholActive agent

The invention discloses lithium niobate crystal polishing solution and a preparation method thereof. The lithium niobate crystal polishing solution is characterized by comprising the following components in percentage by weight: 5 to 50 percent of silicon dioxide, 0.5 to 5 percent of pH regulator, 0.02 to 2 percent of ether alcohol active agent, 0.5 to 5 percent of oxidant, 0.1 to 10 percent of dispersant and the balance of deionized water, wherein the silicon dioxide is added in a state of silicon sol or the silicon sol of the silicon dioxide is used as mother solution for preparing the polishing solution. The polishing solution has the advantages of simple operation, convenient preparation, strong chemical action, high polishing efficiency, low surface roughness and no scratch, and is special for lithium niobate crystals.

Owner:BEIJING GRISH HITECH

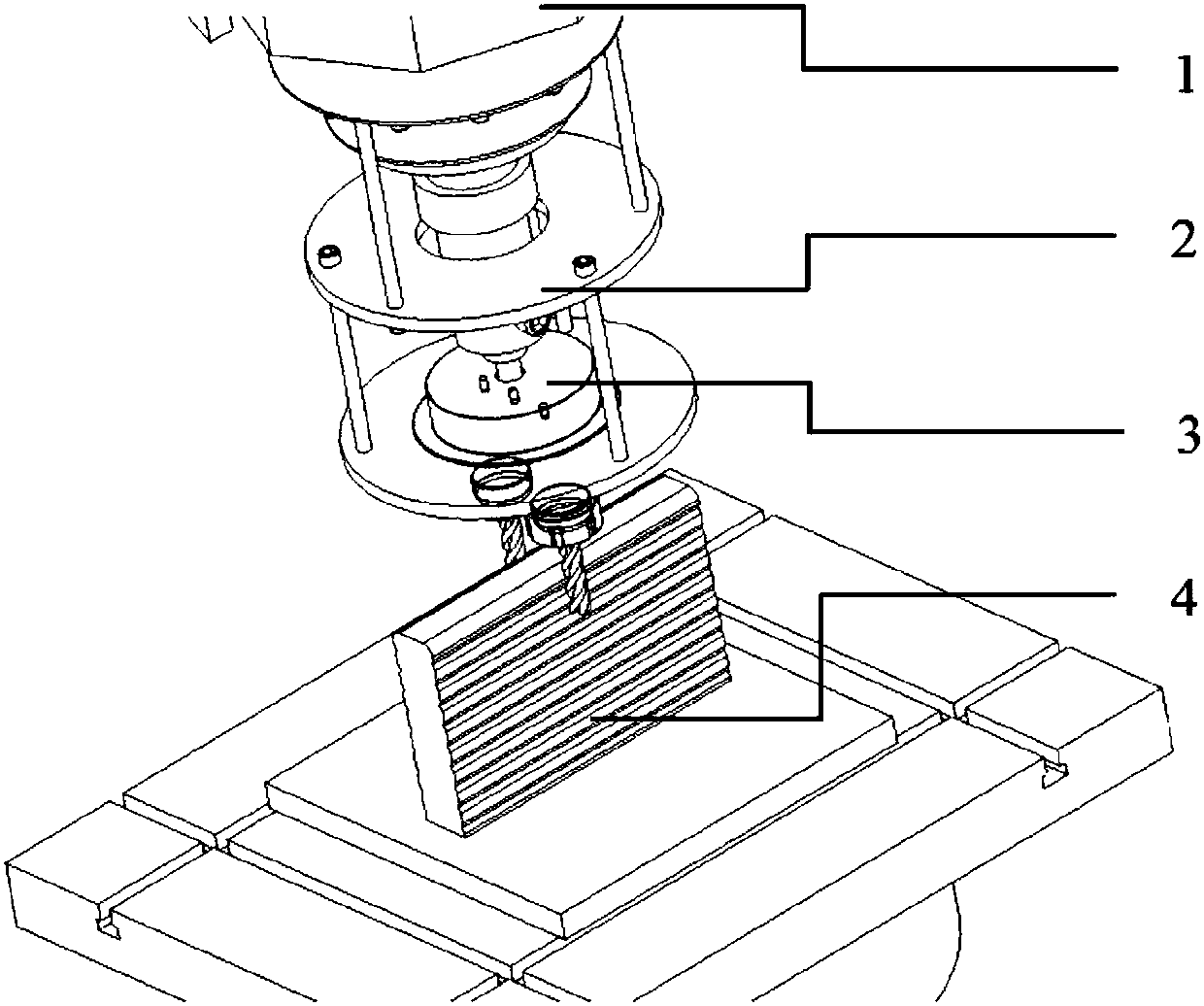

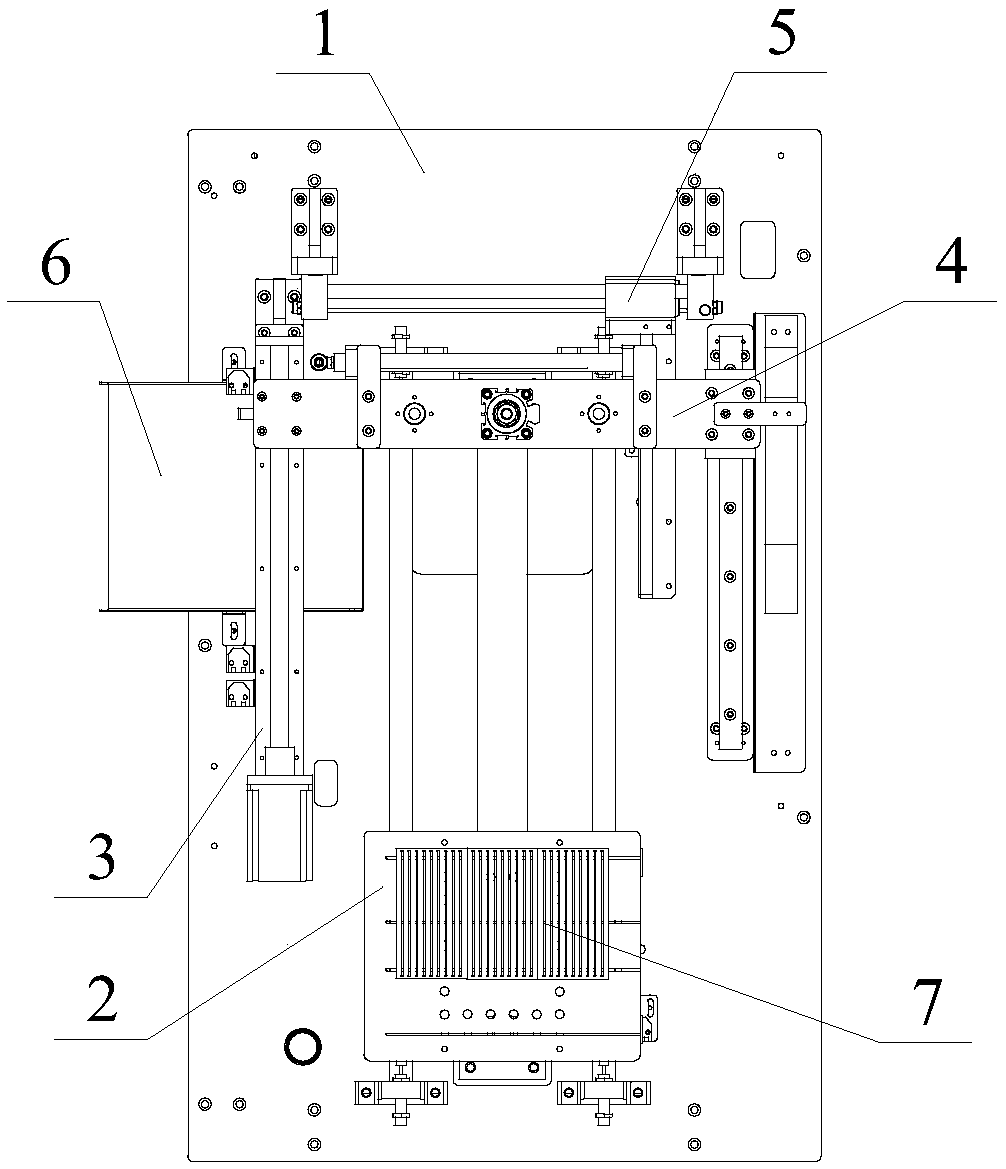

Robot milling double-shaft compound cutter device and method

ActiveCN107855569ASimple structureEasy to installMilling machinesMilling equipment detailsGear driveMilling cutter

The invention relates to a robot milling double-shaft compound cutter device and a method, and belongs to the field of cold and hot compound working in machining. The device consists of a robot driving unit, a connecting bracket, a compound cutter device and a machined workpiece. The compound cutter device comprises a robot connecting shaft, an upper cover, a bearing, a gear set, a shank, a springchuck, milling cutters and a shank cap. The robot driving unit drives the milling cutters in the compound cutter device to rotate to machine the machined workpiece. The robot driving unit is fixedlyconnected with the robot connecting shaft of the compound cutter device to drive a driving gear. The driving gear drives two driven gears to oppositely rotate, so that the two milling cutters are driven to oppositely rotate to realize synchronous milling of double shafts by double side surfaces of the machined workpiece. The device is simple in structure, convenient to install and lower in cost, and replaces the milling cutters to change the side surface sizes of the machined workpiece, namely the thickness of a wall, so as to achieve the machining precision and the surface quality requirements.

Owner:BEIJING UNIV OF TECH

A PCB automatic derusting machine

InactiveCN108890497AEfficient rust removalImprove rust removal efficiencyGrinding machinesGrinding feedersMaterial resourcesEngineering

The invention discloses a PCB automatic derusting machine, which comprises a frame, wherein a feeding unit, a support moving unit, a derusting unit, a pushing unit and a discharging bin are arranged on the frame; The rust removing unit is arranged on the support moving unit, the rust removing unit is arranged above the feed unit to remove rust from the PCB board on the feed unit, The pushing unitis arranged behind the rust removing unit to push out the PCB board on the feeding unit from the feeding unit, the discharge bin is arranged on one side of the supporting mobile unit, and the PCB board enters the discharge bin after being pushed out from the feeding unit. The automatic rust remover of the PCB board of the invention has the advantages of reasonable functional division, simple structure and convenient operation, is not limited by the site, improves the rust removing and cleaning efficiency, strengthens the surface of the board, is favorable for maintenance, loading and unloading, saves manpower and material resources, and improves the working efficiency.

Owner:俞斌

Oil-water-soluble diamond grinding paste and preparation method thereof

InactiveCN104531066AEvenly dispersedImprove stabilityOther chemical processesPolishing compositions with abrasivesWater solubleOil water

The invention relates to an oil-water-soluble diamond grinding paste which is prepared from the following raw materials by weight percentage: 5 to 20% of diamond micro-powder, 25 to 50% of grease, 20 to 50% of a dispersing agent, 3 to 10% of a water-soluble surfactant and 3 to 10% of an oil-soluble surfactant. The oil-water-soluble diamond grinding paste provided by the invention can ensure the grinding and polishing rate and meet the surface quality requirement, and is easily cleaned.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

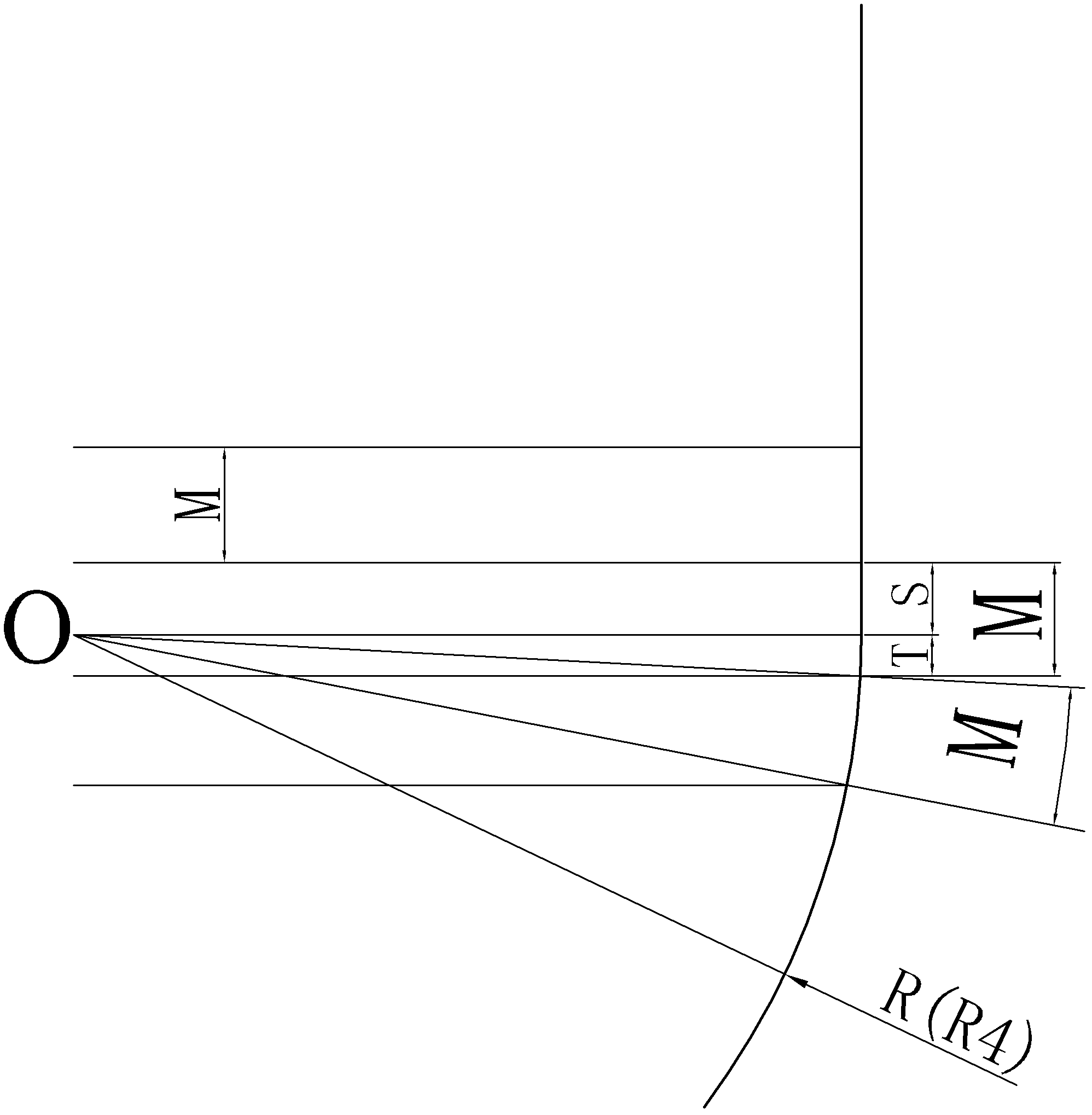

Cavity machining track planning method based on numerical control operation system

ActiveCN102354156AConsistent surface qualityConsistent machined surface qualityProgramme controlComputer controlNumerical controlOperational system

The invention discloses a cavity machining track planning method based on a numerical control operation system, relates to a cavity machining track planning method, and aims to solve the problem of surface quality and roughness inconsistence in machining a diccavity of the cavity by using the traditional machining method. The cavity machining track planning method based on the numerical control operation system has the key technical points as follows: a machining track number of times n is used as a set condition variable, a track distance step value can be changed through changing the machining track number of times n by only deducing an overall length formula of combined line segments; the overall length of the combined line segments is equal to the sum of the length of a straight line segment and an arc segment, a step value of a projection of a track distance on the combined line segments can be solved through dividing a set track number by the overall length of the combined line segments, the projection distance of the track distance on the straight line segment part is the solved step value, and the distance projection between two tracks at a combined part of the straight line segment and the arc segment in the combined line segments is composed of a small segment of straight line segment and a small segment of arc segment together, so that a length formula of the small segment of straight line segment and the small segment of arc segment is deduced. By using the method provided by the invention, the precision for precision machining of the slotting of an edge-chamfering cavity is consistent.

Owner:HARBIN TURBINE +1

Galvanized dual-phase steel for 500 MPa class car and production method

ActiveCN105401071AUniform color without defectsSuppression of continuous densificationHot-dipping/immersion processesPunchingZinc

A galvanized dual-phase steel for a 500 MPa class car comprises the following components in percentage by weight: 0.04-0.09% of C, smaller than or equal to 0.01% of Si, 1.0-2.0% of Mn, smaller than or equal to 0.015 of P, smaller than or equal to 0.010% of S, 0.01-0.08% of Als, 0.01-0.30% of Mo or 0.02-0.9% of Cr, 0.001-0.03% of Nb and smaller than or equal to 0.005% of N. The production method comprises the following production steps: heating of casting blanks after smelting, refining and continuous casting, finish rolling, reeling, cold rolling after acid pickling, hot galvanizing, and finishing. According to the mechanical properties of the product, yield strength is 295-365 MPa, tensile strength is 515-558 MPa, ductility is 25-30%, and n value is 0.165-0.18; and platability of the product is good, the surface of a plating layer is uniform in color and does not have defects, an inhibition layer is continuous and compact, the adhesive force of a zinc layer reaches level-one standard of ball punching, bending test on the zinc layer and a steel base is qualified, and requirements of intermediate cars on surface quality of high-strength structures and outer covering parts can be met.

Owner:武汉钢铁有限公司

Steel plate rust removing mechanism

ActiveCN110900408AImprove stabilityWide range of useGrinding carriagesGrinding drivesSteel platesMaterial resources

The invention relates to a steel plate rust removing mechanism, which includes a fixing table, and a group consisting of a steel plate guiding device, a steel plate conveying and positioning device, asteel plate rust removing device, and a steel plate rust and dust removing device that are arranged on the fixing table. Steel ball brushes are distributed on the surfaces of a roller and a conveyingroller. The rust on both sides of the steel plate can be removed simultaneously, which greatly improves the rust removal efficiency of the steel plate. The steel ball brushes are spirally wound around the surfaces of the roller and the conveying roller, thereby not only cleaning the rust layer and the sticking substances on the surface of the steel plate, but also making the steel plate reach a certain surface quality requirement. The steel plate rust removing mechanism is not subject to sites, has high degree of automation, high efficiency of rust removal, is easy to maintain and install, saves manpower and material resources, and improves work efficiency.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

Automatic extracting device used in fine blanking

InactiveCN102601258AAutomatic pick-up implementationRealize automatic separationStripping-off devicesPunchingControl system

The invention discloses an automatic extracting device used in fine blanking, which comprises an extracting arm, a driving device of the extracting arm, a part slideway, a waste slideway, a part conveyor belt and a waste conveyor belt. The extracting arm is used for extracting parts and wastes from a fine blanking working area. The driving device is connected with a driving controller which is connected with a machine tool control system. The part slideway and the waste slideway are used for transferring extracted parts and wastes from the fine blanking working area to a part collecting device and a waste collecting device respectively. The part conveyor belt and the waste conveyor belt are used for transferring extracted parts and wastes from the part slideway and the waste slideway to the part collecting device and the waste collecting device respectively. The automatic extracting device is capable of realizing automatic extracting of fine blanking parts after punching and automatic separating the parts from the wastes, and accordingly, bumping of the parts is avoided, the surface quality demands of the parts are met, yield is enhanced, and labor cost is reduced greatly.

Owner:SUZHOU DONGFENG FINEBLANKING ENG

Manufacturing process of high-strength circular-drawing six-angle steel

InactiveCN110125194AImprove processing efficiencyMeet the needs of deformationDrawing diesExtrusion cleaning devicesLubricationOxide

The invention discloses a manufacturing process of high-strength circular-drawing six-angle steel. The manufacturing process route sequentially comprises the steps of preparation of a blank material,surface cleaning, tip rolling, annealing and solid solution, blank lubrication, cold drawing, straightening, polishing and quality inspection and packaging, wherein a lubricant used for lubricating the blank material is a mixture of liquid paraffin, metal nano-powder and graphene oxide, the diameter of a die hole of a cold-drawing die is 6-14 mm, and the width of a diameter-fixed belt is 5-8 mm. According to the manufacturing process, cold drawing is adopted after surface lubrication treatment, so that the machining efficiency is improved, and the industrial amplification production requirements are met; and meanwhile, the cold drawing die hole is reasonably set, so that the deformation requirement is met, the drawing force is small, drawing is stable, the deformation is uniform, the drawing die is uniformly abraded, the size and the surface smoothness of a cold drawing material are ensured, then the cold-drawn steel has relatively high surface smoothness, and the requirement for the surface quality of the cold-drawn steel in the aerospace industry is met.

Owner:江油华冶特材有限公司

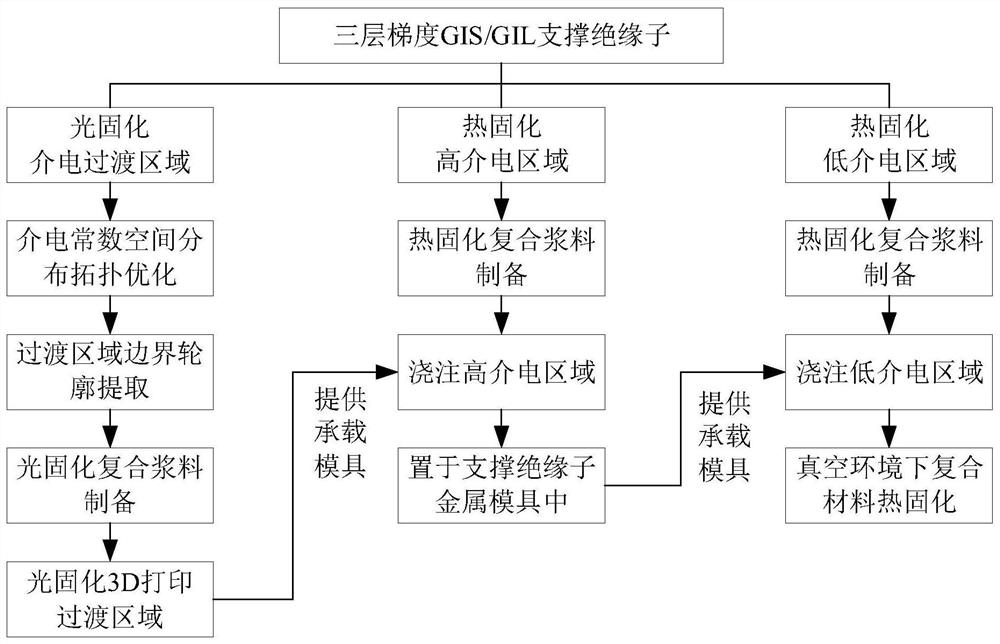

Preparation method of three-layer gradient GIS/GIL supporting insulator

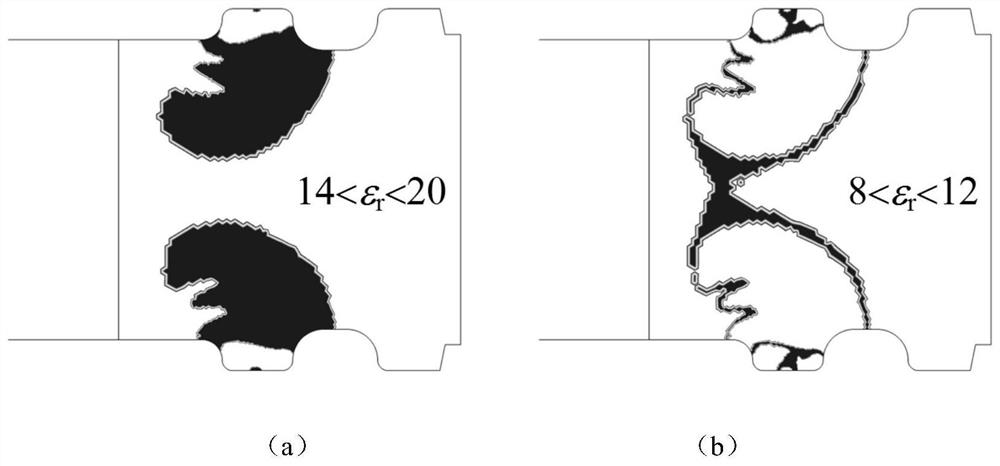

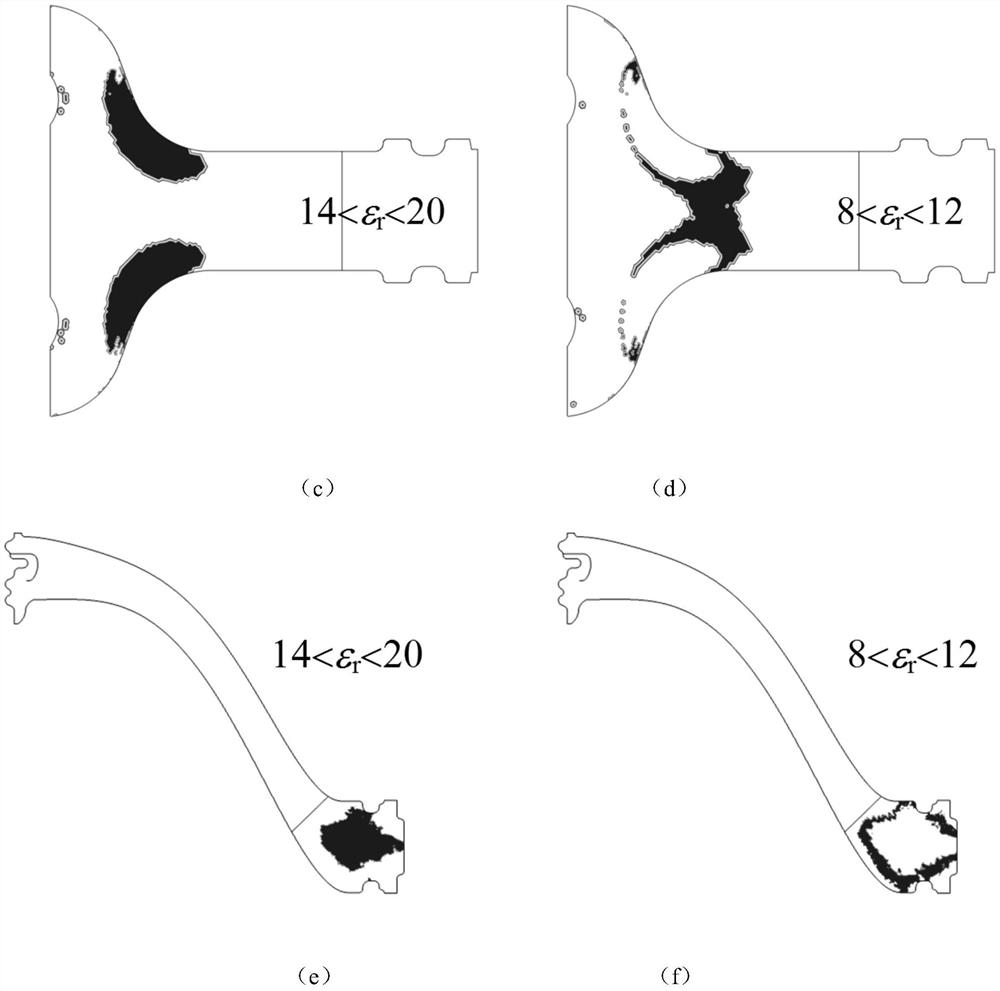

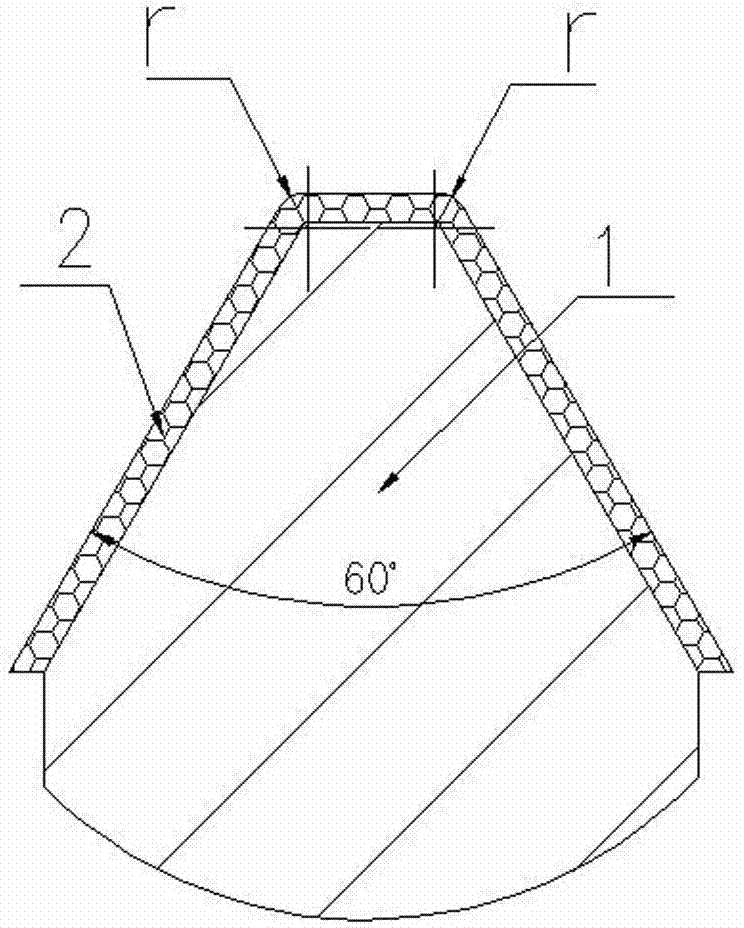

ActiveCN113284684AGuaranteed mechanical strengthImprove electrical strengthAdditive manufacturing apparatusAdditive manufacturing with liquidsDielectricMetal mold

The invention discloses a preparation method of a three-layer gradient GIS / GIL supporting insulator, which aims at reducing the electric field intensity of an insulator along a surface or a local region as an optimization target, and solves the optimal spatial distribution of a dielectric constant in the supporting insulator by using a variable density algorithm. According to the optimization result, the dielectric constant change area is divided into a dielectric constant transition area and a high dielectric area, the combination contour of the dielectric constant transition area is extracted, and then a hollow dielectric constant transition area with a support and a resin sprue gate is generated through photocuring 3D printing; a thermocurable high-dielectric composite material is prepared by adopting a high-dielectric filler / polymer blending mode, and then the high-dielectric composite material is poured into the dielectric constant transition area and integrally put into a metal mold for fixing; and a thermocurable high-dielectric composite material is prepared in a low-dielectric filler / polymer blending mode, then the thermocurable high-dielectric composite material is poured into a metal mold, and the three-layer gradient GIS / GIL supporting insulator can be obtained after curing is completed in vacuum.

Owner:XI AN JIAOTONG UNIV

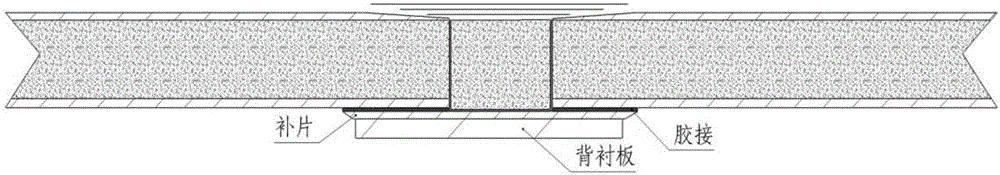

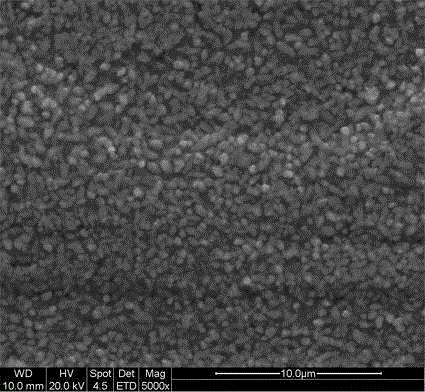

Production process of high-performance 6061 aluminum alloy for cell phone card slot and key materials

InactiveCN109536792AImprove metallographic structureImprove the ratio of ingredientsSolution treatmentMetal machining

The invention belongs to the technical field of aluminum alloy metal machining and discloses a production process of a high-performance 6061 aluminum alloy for cell phone card slot and key materials.According to the production process, a high-performance 6061 aluminum alloy plate is obtained through the steps of smelting and casting, homogenization treatment, machining face-milling, hot rolling,cold rolling to the finished product thickness, solution treatment and quenching at a continuous quenching line, manual aging treatment and the like, the tensile strength Rm of the high-performance 6061 aluminum alloy plate reaches 300 MPa or above, the hardness HV of the high-performance 6061 aluminum alloy plate reaches 90 or above, and on the one hand, the high-performance 6061 aluminum alloy plate has good machining performance and can be suitable for early CNC machining of the cell phone card slot and key materials; and on the other hand, the high-performance 6061 aluminum alloy plate hasgood anodic oxidation performance, can be oxidized into various bright colors and thus is quite attractive, a layer of uniform and luster-consistent protecting film is formed on the surfaces of the materials after oxidation, the hardness and abrasion resistance of a cell phone card slot and keys are greatly improved, and the service life of a product is prolonged.

Owner:郑州明泰实业有限公司

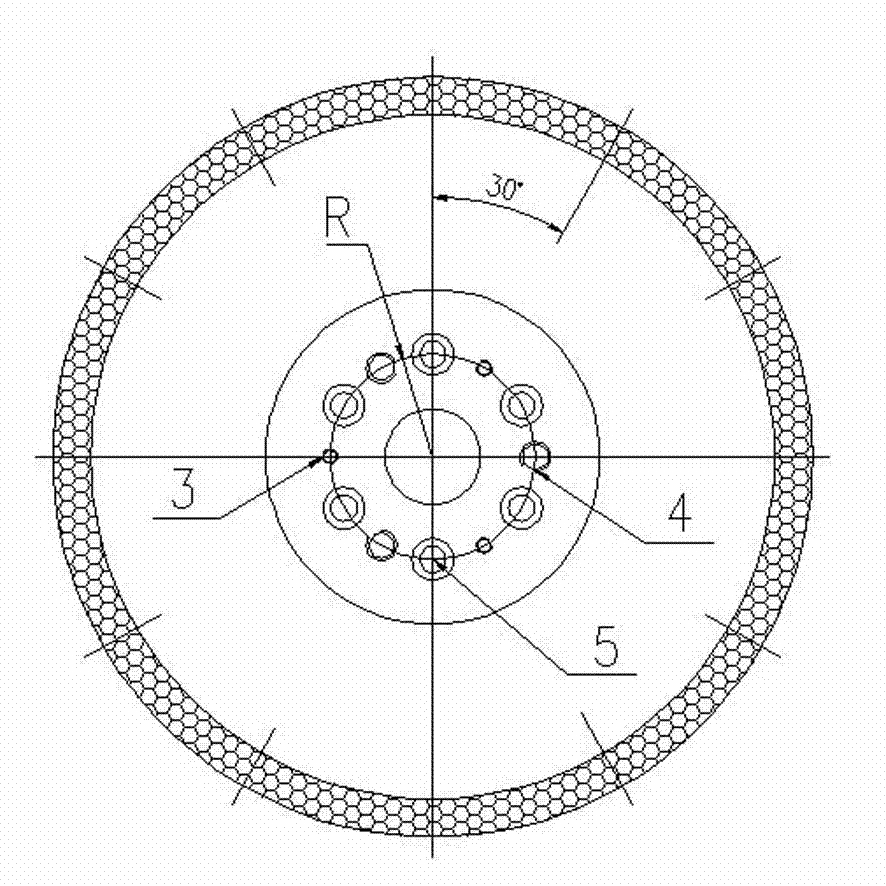

Electroplating CBN grinding wheel for efficient and precise gear profile grinding and manufacturing method of electroplating CBN grinding wheel for efficient and precise gear profile grinding

ActiveCN103878705AImprove mass distributionIncrease limit speedBonded abrasive wheelsIsosceles trapezoidAdsorptive membrane

The invention relates to an electroplating CBN grinding wheel for efficient and precise gear profile grinding. The electroplating CBN grinding wheel comprises a dish-shaped base body and a material grinding area at the edge of the dish-shaped base body, the mass of the material grinding area is 4%-15% of the total mass of the base body, the cross-section of a material grinding layer on the material grinding area is in an isosceles trapezoid shape, and the upper bottom and the two lateral edges are chamfered. A manufacturing method of the electroplating CBN grinding wheel includes the steps of firstly machining the base body of the grinding wheel, and then sequentially conducting negative and positive pole alternative electrochemistry oil removing, clamp and electrostatic adsorption film insulation assembling, negative and positive pole alternative electrolytic treatment, ballistic method preplating, grinding material assembling, thickening and grinding wheel electroplating on the base body of the grinding wheel. The using linear velocity of the electroplating CBN grinding wheel can achieve 250 m / s, and the grinding feeding amount achieves 4 m / min-10 m / min and is much higher than that of a common grinding wheel. The roughness Ra can achieve 0.4 micrometers, the surface quality requirement of a workpiece can be met, and gear efficient and precise gear profile grinding can be successfully achieved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

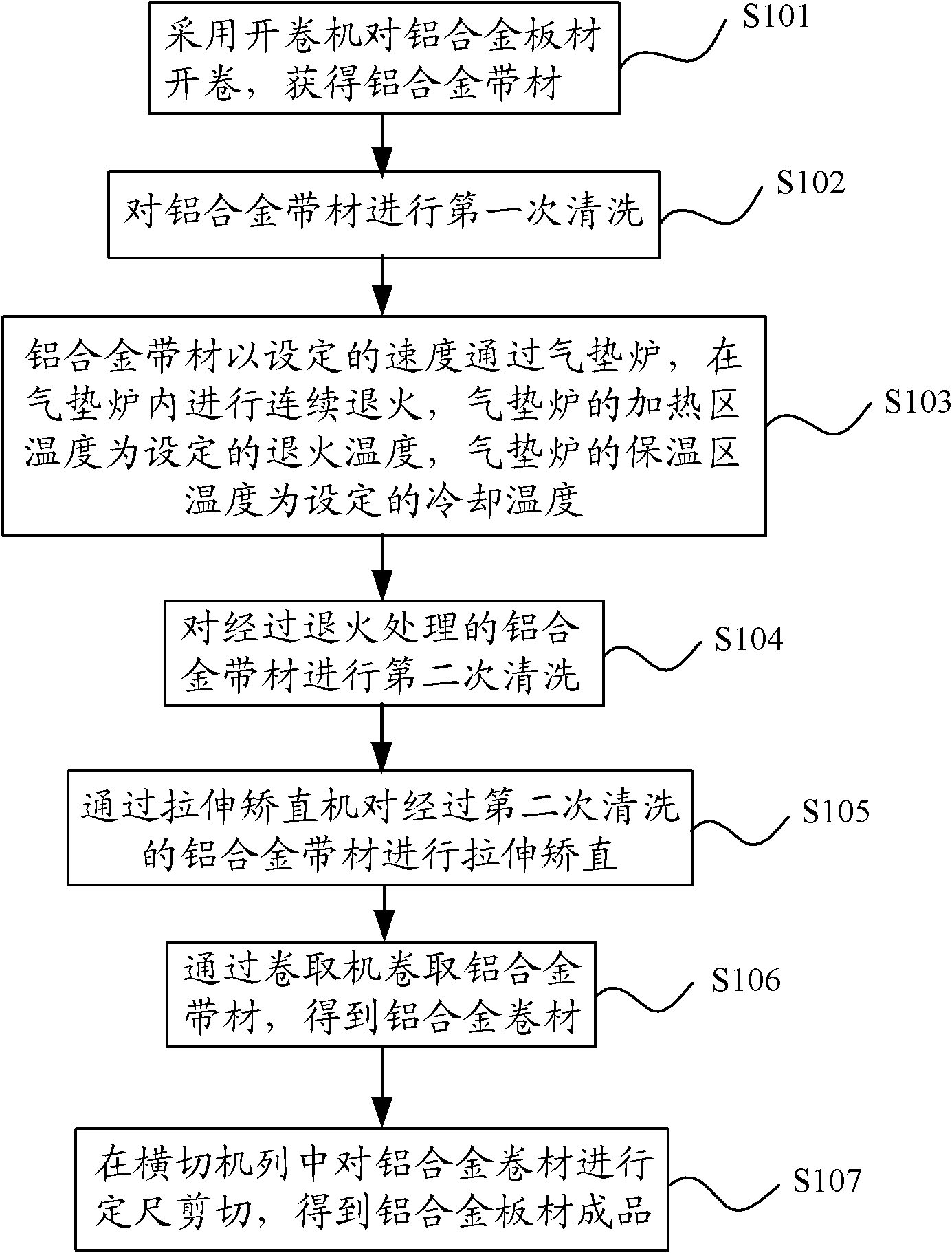

Production method and system of aluminum alloy plates

InactiveCN102424905AReduce oil pollutionReduces aluminum ash residueProcess efficiency improvementContinuous annealingCooling temperature

The invention provides a production method of aluminum alloy plates, comprising the following steps of: decoiling aluminum alloy plates by a decoiler to obtain aluminum alloy tapes; cleaning the aluminum alloy tapes for the first time; enabling the aluminum alloy tapes to pass through an air cushion furnace at a set speed, performing continuous annealing in the air cushion furnace, wherein the temperature of a heating section of the air cushion furnace is a set annealing temperature, and the temperature of a holding section of the air cushion furnace is a set cooling temperature; cleaning the aluminum alloy tapes for the second time; performing stretch leveling on the aluminum alloy tapes by a stretcher leveler; coiling the aluminum alloy tapes by a coiler to obtain aluminum alloy coils; and cutting the aluminum alloy coils to length in a transverse cutting unit to obtain finished products of aluminum alloy plates. The production method of aluminum alloy plates reduces scratches, oil stain and aluminum ash residue on the surfaces of the aluminum alloy plates, and meets the requirements on surface quality of aluminum alloy plates for electrommunication control cabinets. The invention also provides a production system of the aluminum alloy plates.

Owner:SOUTHWEST ALUMINUM GRP

Turning cutting off method for rod-shaped workpieces

ActiveCN103464785AAvoid issues with glitchesMeet surface quality requirementsEngineeringMachine tool

The invention provides a turning cutting off method for rod-shaped workpieces and belongs to the mechanical technology field. The turning cutting off method for the rod-shaped workpieces solves the problem that cut surfaces of finished products have burrs during rod-shaped workpieces machining through the prior art. The turning cutting off method for the rod-shaped workpieces comprises A material loading and B cutting off; in the material loading, one ends of workpieces to be cut are finished product ends and the other ends are excess material ends, the finished product ends of the workpieces to be cut are clamped to chucks of a lathe, and the excess material ends of the workpieces are arranged on the external sides of the chucks; in the cutting off, the chucks of the lathe rotate, the workpieces to be cut are cut off through a common turning method, obtained finished workpieces after cutting off are clamped to the chucks of the lathe, the excess material ends of the workpieces to be cut fall off, and cutting tools continue feeding to perform turning on burrs at cutting surfaces of finished product ends. According to the turning cutting off method for the rod-shaped workpieces, the finished product ends of the workpieces are clamped and cut off, the cut surfaces of the finished product ends are free of burrs, the problem that the burrs are formed on the finished product ends due to the fact that the excess ends are clamped is avoided, and the problem that low product accuracy caused by twice clamping is avoided.

Owner:浙江海德曼智能装备股份有限公司

Manufacturing method of Mg-based composite wallboard profile

The invention relates to a manufacturing method of an Mg-based composite wallboard profile. The manufacturing method aims to solve the problems that in an existing manufacturing method of the wallboard profile, jamming occurs easily in the extrusion process and the profile is high in bending degree and twisting degree. The manufacturing method comprises the steps of smelting raw materials in a smelting furnace, adding SiC particles, making a Mg-based composite flat cast bar through casting, cutting off the flat cast bar, removing an oxide skin through turning, carrying out homogenizing annealing, extruding an annealed Mg-based composite flat cast ingot, heating the Mg-based composite wallboard profile to 150 DEG C to 180 DEG C, carrying out tension straightening, and cutting away the head end and the tail end. The bending degree of the Mg-based composite wallboard profile obtained through the manufacturing method is smaller than 1.5 mm per meter, the twisting degree of any part of the profile around the longitudinal axis is not larger than 1.5 degrees per meter, and jamming will not occur in the extrusion process.

Owner:HEILONGJIANG INST OF TECH

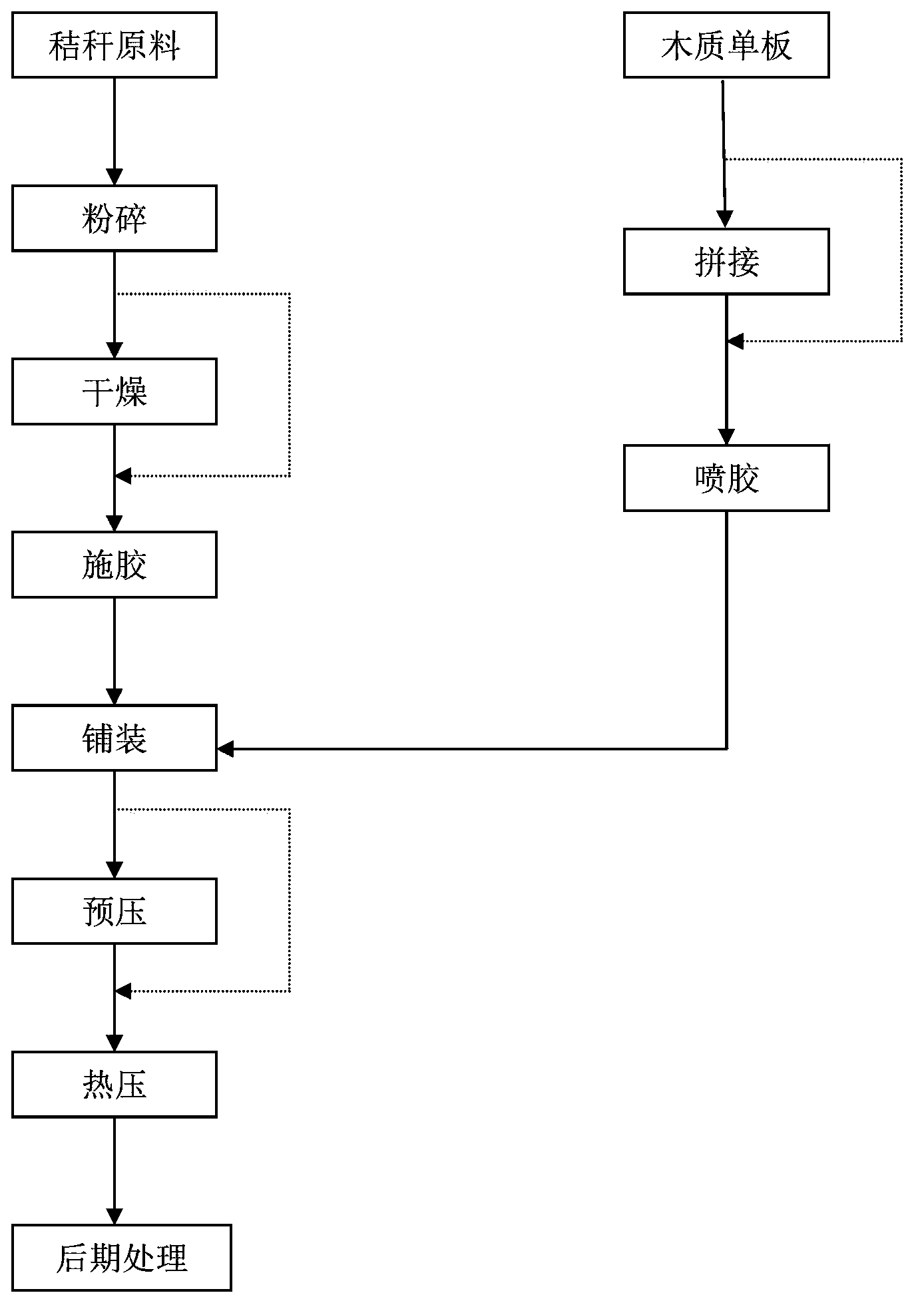

One-time formed methanal-free compound panel and processing technique

InactiveCN103978537AUniform and dense structureImprove processing performanceLaminationWood working apparatusBiomassEngineering

The invention relates to a one-time formed methanal-free compound panel and a processing technique. The one-time formed methanal-free compound panel is characterized in that wood veneers are arranged on a bottom layer and a surface layer of the panel; a homogeneous crop straw layer or homogeneous forestry waste biomass layer is arranged as a middle layer; the bottom layer, the surface layer and the middle layer are at a time pressed and formed. According to the one-time formed methanal-free compound panel and the processing technique, three layers of structures are at a time pressed and formed, so that the space between every two layers is more compact and the layering phenomenon is difficult to occur. The processing technique is simpler.

Owner:富朗投资管理集团(香港)有限公司

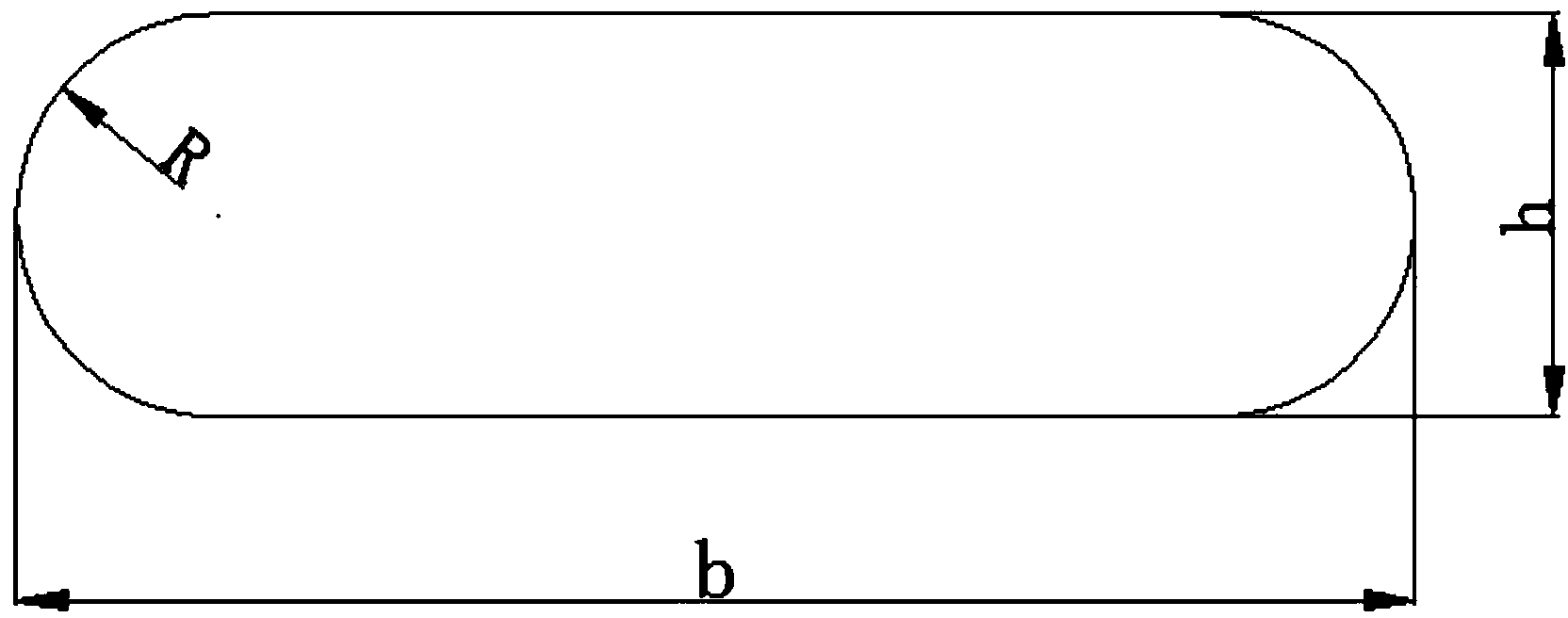

Forming process of aluminum alloy pipe and aluminum alloy pipe

InactiveCN109433851AQuality improvementEasy to useDrawing diesFurnace typesMechanical propertyForming processes

The invention belongs to the technical field of aluminum alloy pipe processing, and relates to a forming process of an aluminum alloy pipe and the aluminum alloy pipe. The forming process of the aluminum alloy pipe comprises the following steps that an aluminum alloy raw material is extruded to obtain an aluminum alloy pipe blank; the obtained aluminum alloy pipe blank is drawn, and then annealingtreatment is carried out; and after the obtained aluminum alloy pipe blank is completed annealed, cold drawing is carried out again, the deformation amount of the outer diameter of the pipe in the cold drawing process is less than 5%, and thus a finished product of the aluminum alloy pipe is obtained. According to the forming process of the aluminum alloy pipe and the aluminum alloy pipe, the process is simple, the implementation is easy, and the surface quality and service performance of the material can be simultaneously increased on the premise of not changing the mechanical properties ofthe material.

Owner:南通长海铝业有限公司

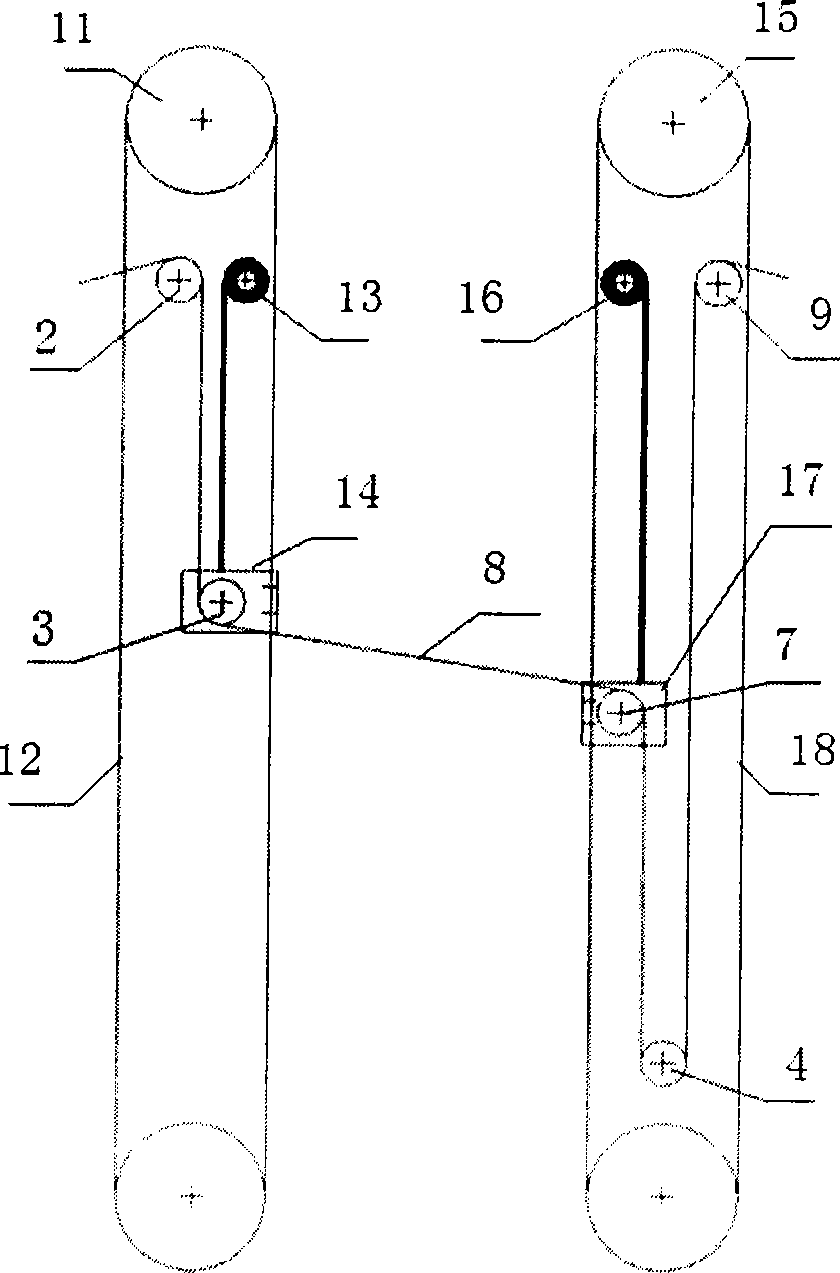

Differential wire conveyor for diamond wire saw cutter

InactiveCN104290208AMeet surface quality requirementsSmall cutting forceFine working devicesStone-like material working toolsDiamond wire sawElectric machinery

The invention discloses a differential wire conveyor for a diamond wire saw cutter. The differential wire conveyor comprises two pay-off (take-up) drums, two wire guide wheels, two differential wheels and a tension wheel. By reasonably setting the turning direction and speed of two variable frequency adjustable-speed motors, the differential wheels are driven to move up and down in different directions, a diamond saw wire between the differential wheels moves in a cutting path with reciprocating cross diagonal motion and slow downward feed, and traditional parallel linear feed cutting is replaced with the cross diagonal cutting of the diamond saw wire. The differential wire conveyor has the advantages that crisp and hard material can be cut stably, cut surfaces are smooth, and processed surface quality is significantly improved.

Owner:TAIZHOU POLYTECHNIC COLLEGE +1

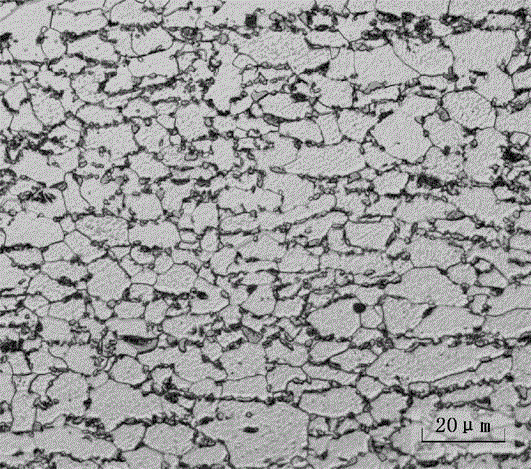

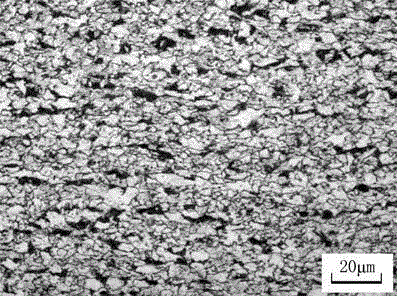

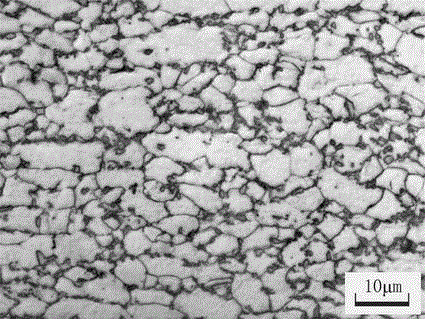

Nano hardness measurement method for multiphase molybdenum alloy

ActiveCN110686951ASolve the problem of nano hardness measurementAccurate measurementPreparing sample for investigationInvestigating material hardnessAlloyHardness

The invention discloses a nano hardness measurement method for multiphase molybdenum alloy. The method comprises the following steps: step one, carrying out cutting to obtain a multiphase molybdenum alloy sample; step two, grinding the multi-phase molybdenum alloy sample, carrying out electrolytic polishing, and then carrying out cleaning and drying; step three, fixing the cleaned and dried multiphase molybdenum alloy s determining the position of the multiphase molybdenum alloy sample ample on a sample table of a nanoindentor; and step four, calibrating the nanoindentor on which the multiphase molybdenum alloy sample is fixed, determining the position of the multiphase molybdenum alloy sample, acquiring three-dimensional morphology distribution of the surface of the multiphase molybdenumalloy sample and locating positions of different phases, and then selecting a point to carry out nano hardness measurement. According to the invention, the positions of different phases are directly distinguished in three-dimensional morphology distribution of the surface of the multiphase molybdenum alloy sample by using electrolytic corrosion rate differences of different phases in the multiphase molybdenum alloy sample to realize accurate measurement of the nanometer hardness of the multiphase molybdenum alloy, so that problems that the multiphase molybdenum alloy sample is too high in hardness and difficult to polish, and the different phases are difficult to distinguish in the prior art are solved.

Owner:CHANGAN UNIV

Combined plating CBN grinding wheel for camshaft grinding and manufacturing method thereof

ActiveCN109551383AMeet surface quality requirementsNo burnsBonded abrasive wheelsGrinding devicesSurface roughnessEngineering

The invention discloses a combined plating CBN grinding wheel for camshaft grinding and a manufacturing method thereof, belonging to the technical field of design and manufacture of abrasive grindingtools. The combined plating CBN grinding wheel for camshaft grinding comprises a camshaft and a combined plating CBN grinding wheel sleeving a main shaft for grinding different parts of the camshaft;one side, far away from the combined plating CBN grinding wheel, of the camshaft is abutted against a guide wheel; the combined plating CBN grinding wheel comprises a grinding wheel for grinding big end excircle and end face, a grinding wheel for grinding big end excircle journal and a plurality of grinding wheels for grinding excircle journal; and the molded surfaces of the grinding wheel for grinding big end excircle and end face and the grinding wheel for grinding big end excircle journal are matched. The invention is suitable for one-time grinding of a plurality of excircle journals of thecamshaft, can process a plurality of journals and big end of the camshaft at a time, improves the processing efficiency and ensures the surface roughness of the processed workpiece being smaller thanRz 10.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com