Emulsion cleaning device

A cleaning device and emulsion technology, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems that have not been solved well, the emulsion is cleaned, the residual oil is too large, and the structural Compact, space-saving, clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

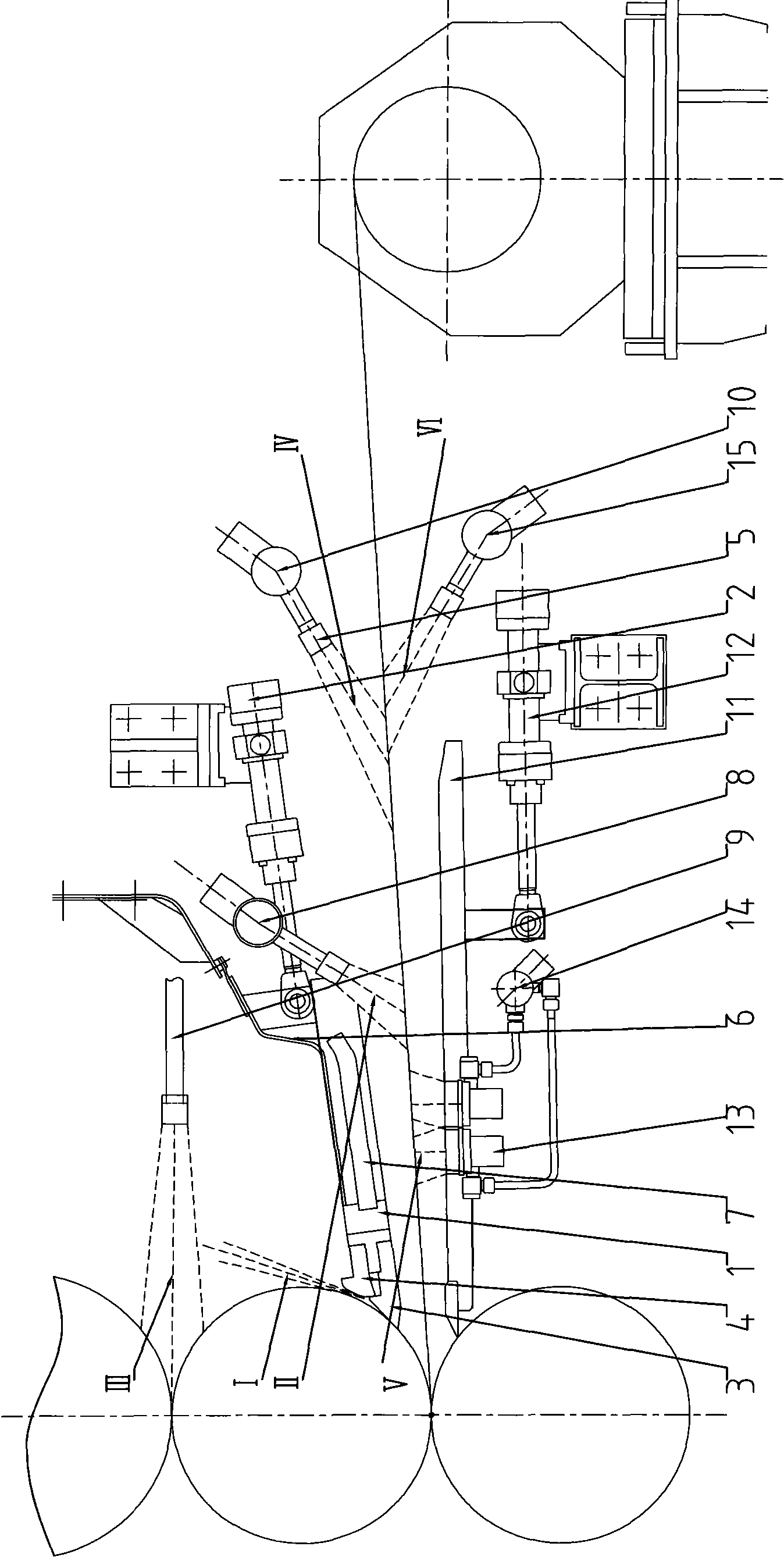

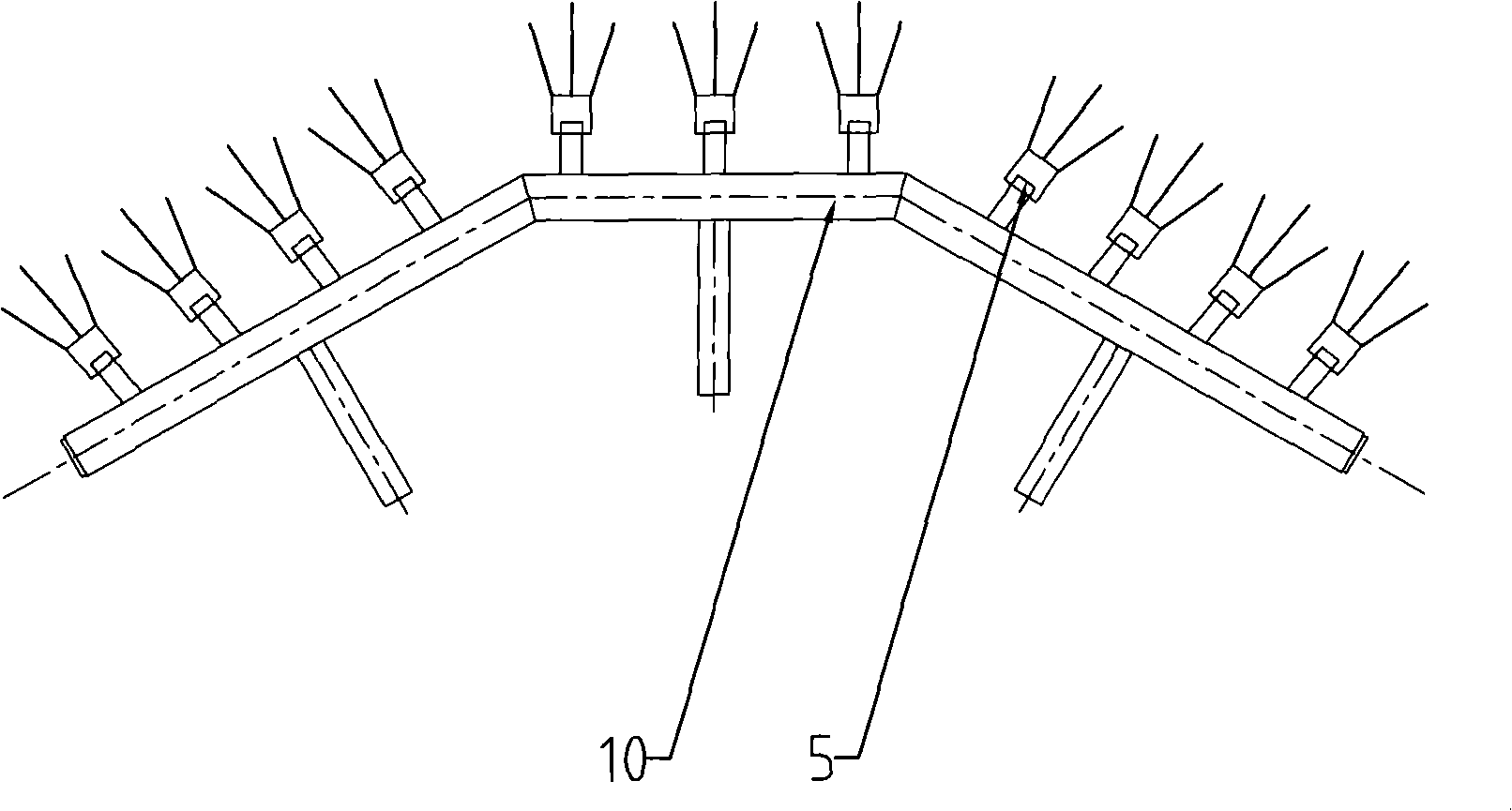

[0020] Specific examples of the present invention are attached figure 1 Shown is a front view of an emulsion removal device, which is mainly composed of an upper anti-winding guide plate purging device 16, an upper middle strip purging device 17, a roll gap purging device 18, a strip upper purging device 19, a lower anti-winding The guide plate suction device 20, the lower surface of the strip and the edge purge device 21 are composed of several parts.

[0021] as attached figure 1 As shown, the position of the upper anti-winding guide plate 1 is controlled by two hydraulic cylinders 2, and the tail of one of the hydraulic cylinders 2 is equipped with a built-in displacement sensor. To achieve accurate positioning, the distance between the tip of the shovel head 3 and the roll is 0.2-0.5mm, the front part of the upper anti-winding guide plate 1 is a box, the shovel head 3 is at the front end of the box, and a line is reserved between the shovel head 3 and the pressure plate 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com