Forming process of aluminum alloy pipe and aluminum alloy pipe

A technology of aluminum alloy tube and forming process, which is applied in the forming process of aluminum alloy tube and the field of aluminum alloy tube, which can solve the problem that the surface brightness of aluminum alloy tube is difficult to adapt to high-precision special devices, the surface roughness of aluminum alloy tube is high, and the performance of strengthening layer Problems such as uneven layers can be achieved to improve surface quality and performance, excellent comprehensive mechanical properties, and reduce surface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] A forming process of an aluminum alloy tube, comprising the following steps:

[0088] Extrude through the die first to get the aluminum alloy tube billet, then pass through the die, use the outer mold and the inner film to reversely extrude the wall thickness of the aluminum alloy tube billet, and before the reverse extrusion, the outer surface of the tube billet Evenly apply a layer of lubricant to reduce the diameter and wall thickness of the tube blank, and initially obtain an aluminum alloy tube with precise dimensions;

[0089] Then clean it. After cleaning, use the heat treatment high-temperature walk-in furnace to perform rapid annealing in the temperature range. The annealing temperature in the high-temperature range is 420°C for 10 minutes, and rapid cooling with water mist is performed to soften the aluminum alloy. After complete annealing, use The outer mold is cold drawn separately to reduce the outer diameter.

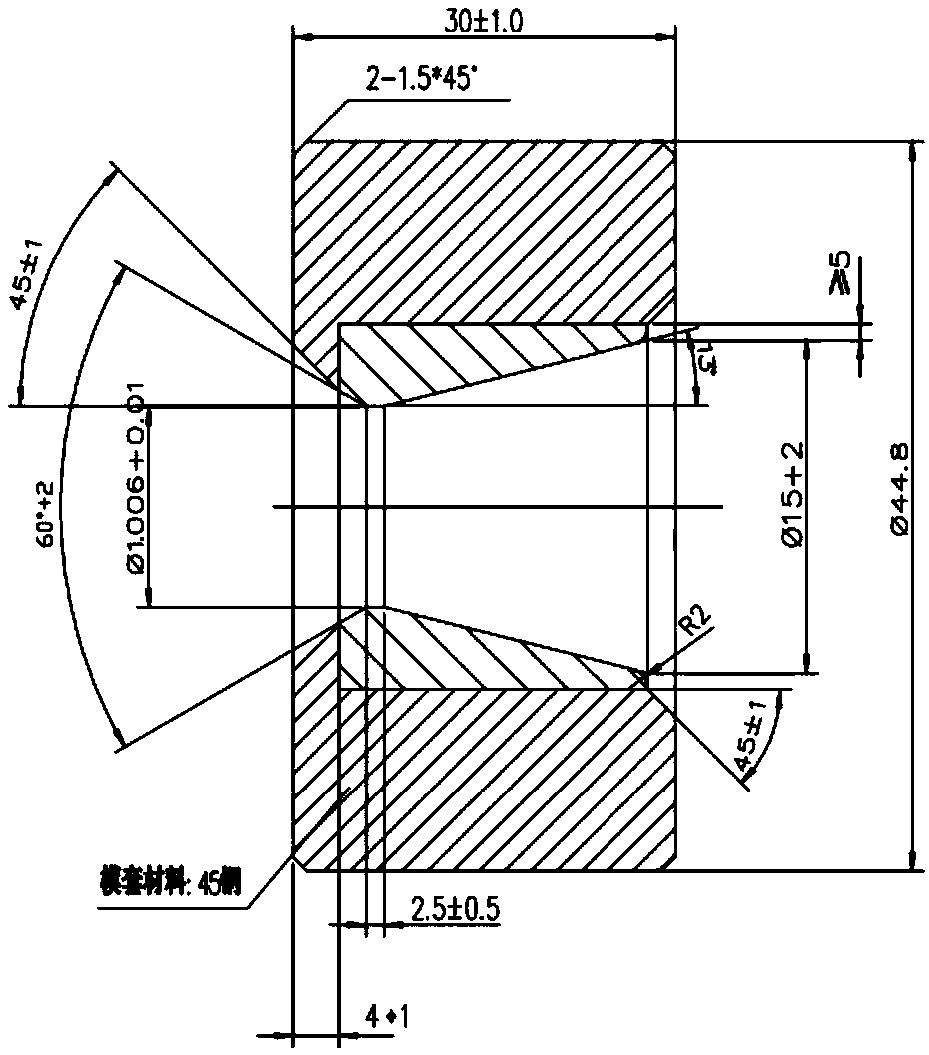

[0090] Among them, the outer model used is a...

Embodiment 2

[0092] A forming process of an aluminum alloy tube, comprising the following steps:

[0093] Extrude through the die first to get the aluminum alloy tube billet, then pass through the die, use the outer mold and the inner film to reversely extrude the wall thickness of the aluminum alloy tube billet, and before the reverse extrusion, the outer surface of the tube billet Evenly apply a layer of lubricant to reduce the diameter and wall thickness of the tube blank, and initially obtain an aluminum alloy tube with precise dimensions;

[0094] Then clean, after cleaning, use heat treatment high-temperature walk-in furnace to perform rapid annealing in the temperature range. The annealing temperature in the high-temperature range is 450°C for 15 minutes, and rapid cooling with water mist is performed to soften the aluminum alloy. After complete annealing, use The outer mold is cold drawn separately to reduce the outer diameter.

[0095] Wherein, the making material of outer mold is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com