Die in alloy blade precision forging process

A precision forging and mold technology, which is applied in the field of high-temperature alloy blade precision forging, can solve the problems such as the need to improve the process route of the wool forming method, the uniformity of the structure and the difficulty of coarse grains, etc., to improve the mechanical properties and performance, and the direction of the streamline reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

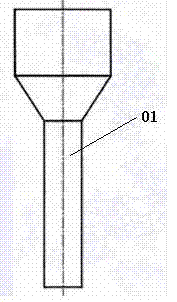

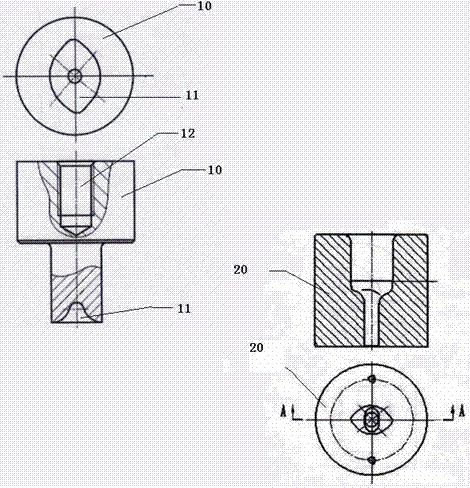

[0011] The content of the present invention will be specifically described below in conjunction with accompanying drawings 1 to 4 and embodiments.

[0012] Such as figure 1 As shown, the extruding rod die is composed of the ejector rod 1, the ejector rod guide sleeve 2, the cushion block 3, the insert block 4, the extrusion cylinder 5, the punch 6 and the like.

[0013] In a preferred embodiment of the present invention, the ejector rod 1 includes a thick rod part, and its length is defined as L w , the thick rod part cooperates with the ejector rod holder 7, and the ejector rod 1 also includes a thin rod part, which cooperates with the ejector rod sleeve 2; the ejector rod guide sleeve 2 is provided with a small end, and its length is defined as L x , the push rod guide sleeve 2 is also provided with a large end, which is matched with the pad 3. In the preferred embodiment of the present invention, the cross section of the push rod guide sleeve 2 is T-shaped.

[0014] The e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com