Robot milling double-shaft compound cutter device and method

A compound tool and robot technology, applied in the direction of milling machines, milling machine equipment, manufacturing tools, etc., can solve the problems of step effect, size error, increased cost, etc., and achieve the effect of fewer components, convenient speed adjustment, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

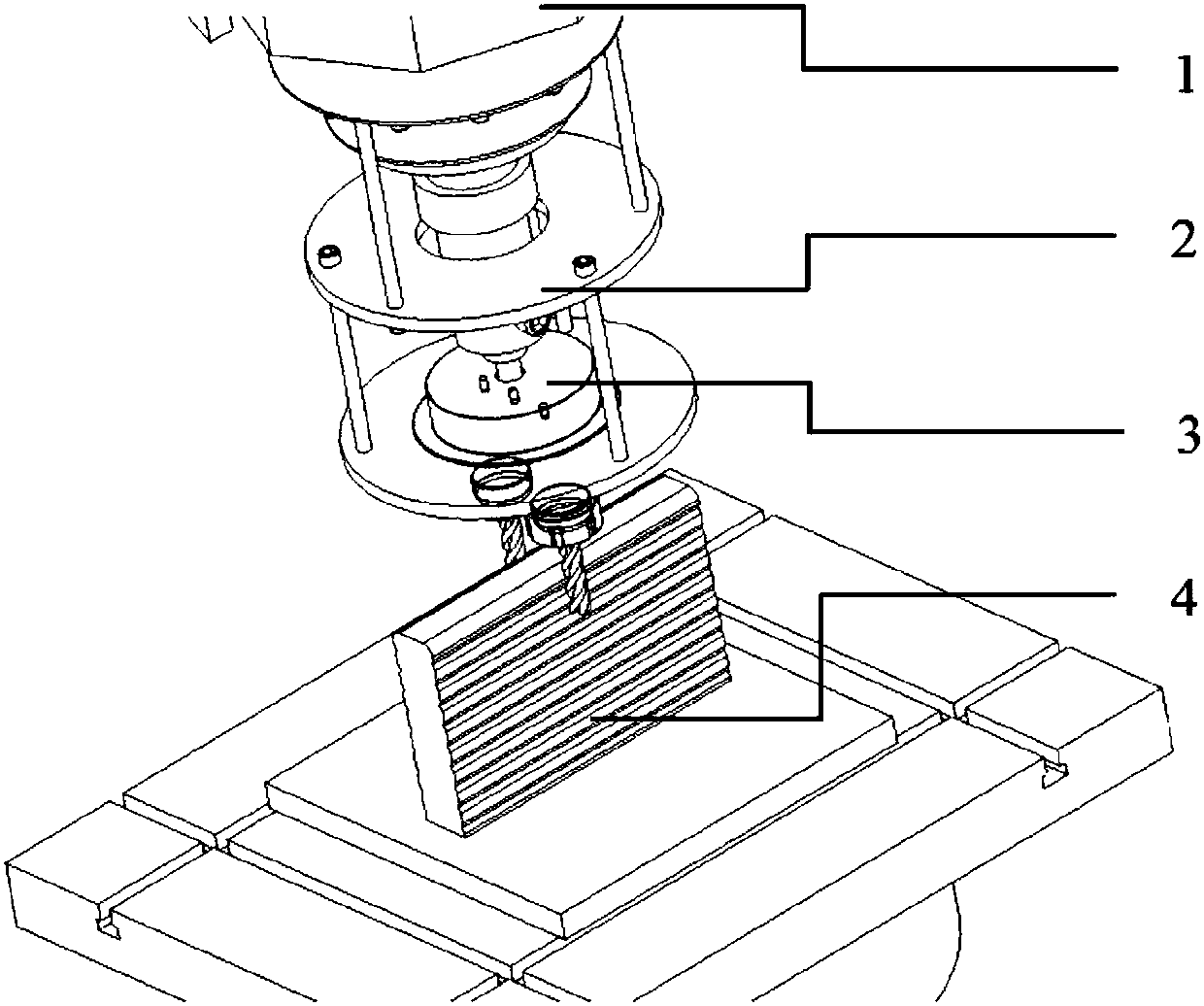

[0035] In this example, figure 1 It is a schematic diagram of the structure of the milling compound tool device. Such as figure 1 As shown, the robot milling two-axis compound tool device is composed of a robot drive unit, a connecting bracket, a compound tool device and a workpiece to be processed. Wherein, the connecting bracket is composed of bolts, an upper cover plate, a supporting plate and a lower cover plate.

[0036] The composite cutter device is connected to the robot drive unit through the connecting bracket, and the robot drive unit drives the dual-axis cutter system of the composite cutter device to rotate, thereby realizing double-sided simultaneous cutting on the side of the thin-walled wall. The rotation speed and rotation direction of the tool can be adjusted through the robot drive unit and the robot control system. The connecting bracket supports the compound cutter device, and the whole device is connected and fixed to the flange plate of the end joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com