Robot welding line tracking deviation compensation method

A compensation method and robot technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., to achieve the effect of ensuring stability and good molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

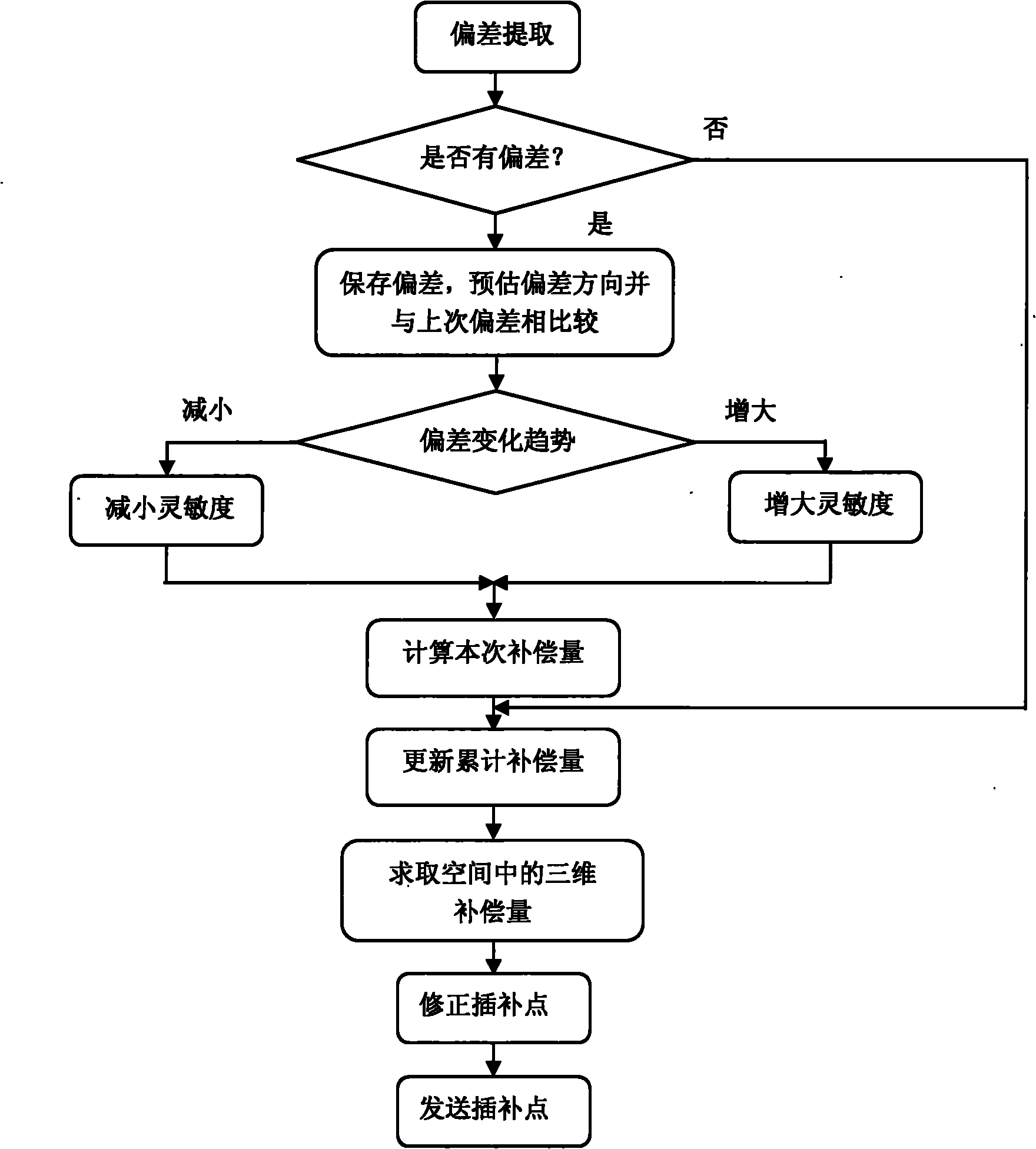

[0025] The concrete structure of the present invention will be described in detail below with reference to accompanying drawing:

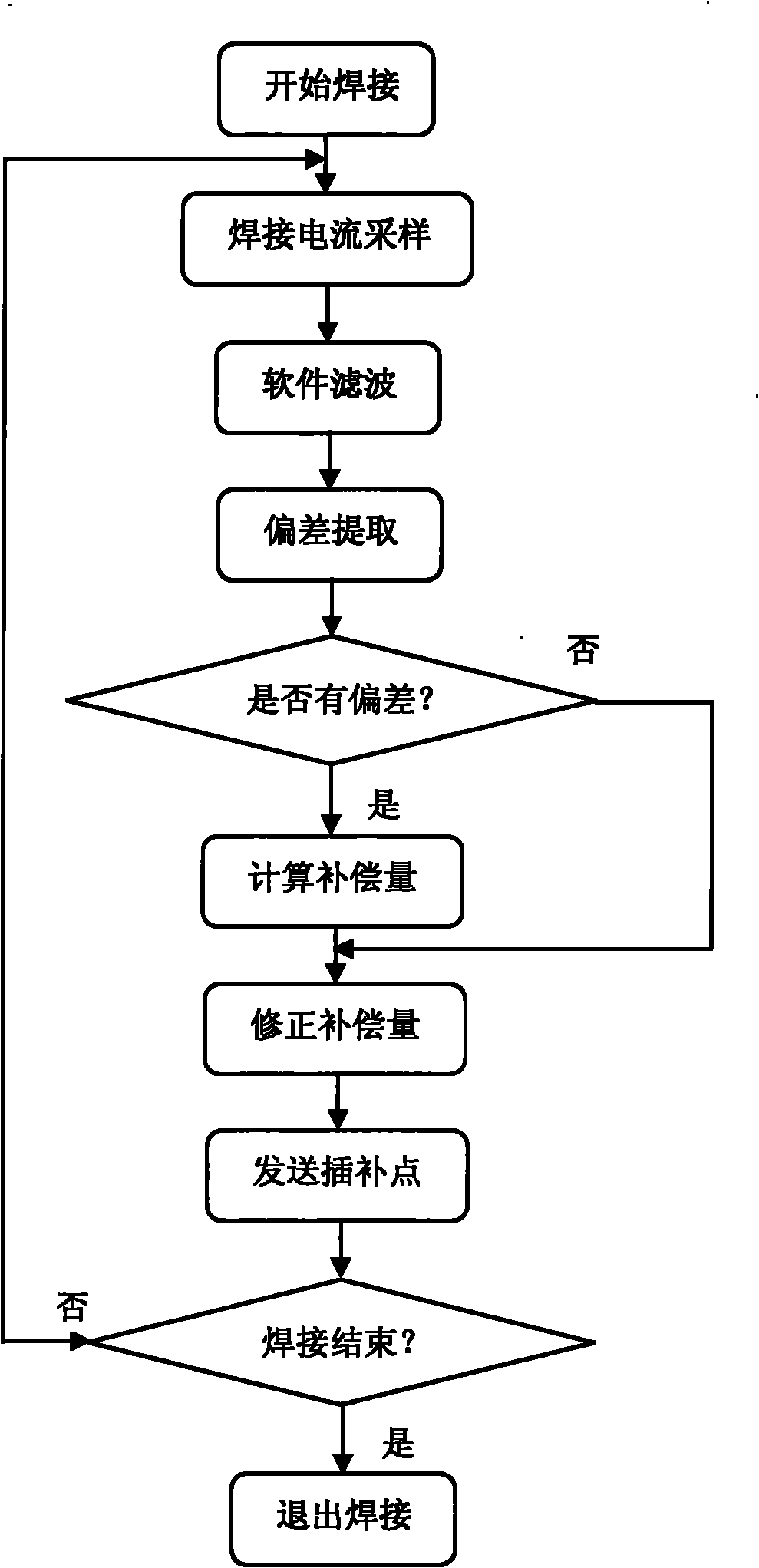

[0026] A robot seam tracking device includes an arc sensor, a signal processing module, and a seam deviation correction module. The arc sensor is used to detect welding current, and the seam deviation correction module is used to compensate the track deviation of the weld seam. Wherein, the trajectory deviation compensation method includes the following steps:

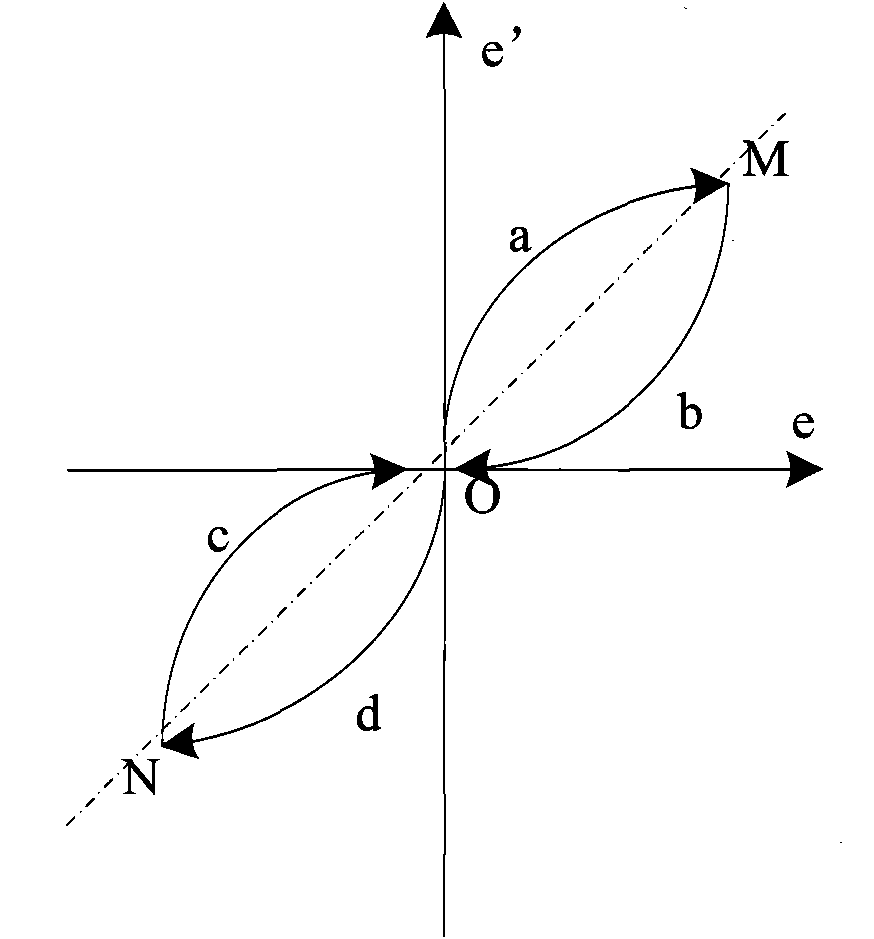

[0027] as attached figure 1 , 2 Shown: Step 1: Start welding, the arc sensor detects the current welding current immediately, the signal processing module samples the welding current detected by the arc sensor, and filters the collected welding current data. In this embodiment, a digital filter combining local mean filtering and improved sliding median filtering is designed through experiments. Experiments show that the filter can better filter out the interference signal in the welding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com