Welding robot

A welding robot and welder technology, which is applied in welding equipment, manipulators, arc welding equipment, etc., can solve the problems of weld seam tracking not being able to function effectively, effort, error, etc., to achieve efficient tracking and prevent human errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

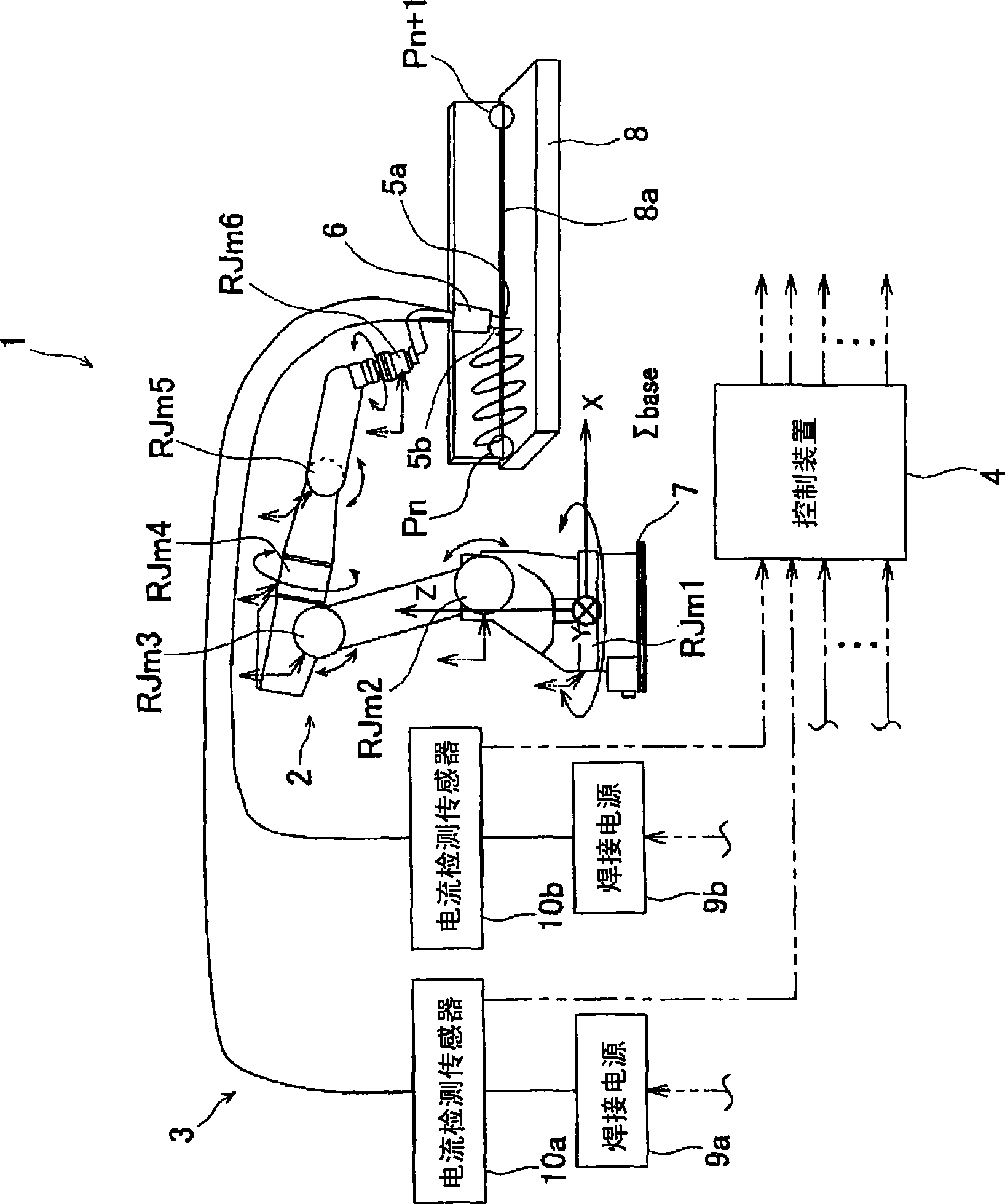

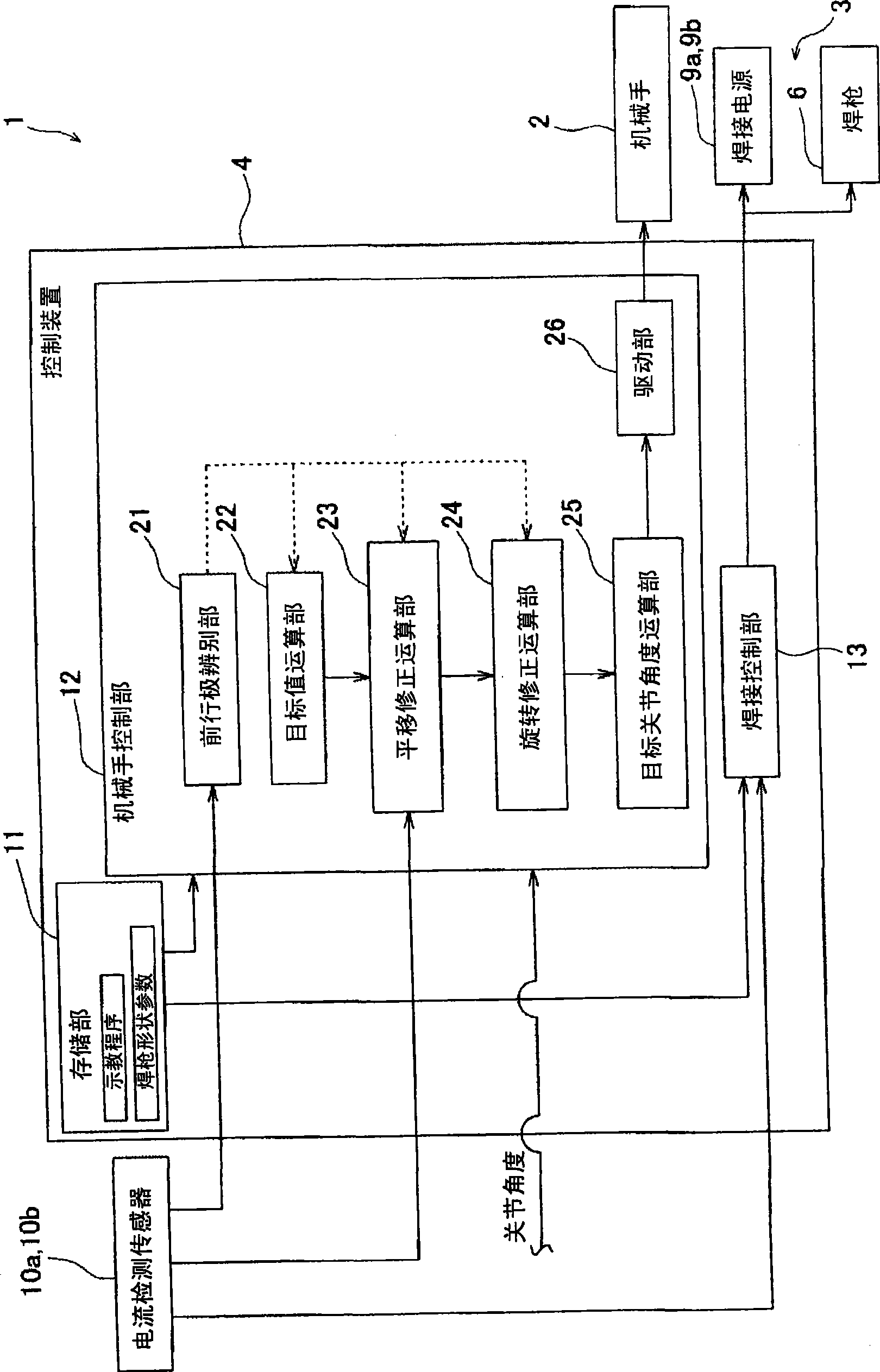

[0066] figure 1 The shown welding robot 1 according to the first embodiment of the present invention includes a manipulator 2 , a welder 3 , and a control device 4 . This welding robot 1 automatically welds a workpiece (object to be welded) 8 along a welding joint 8a.

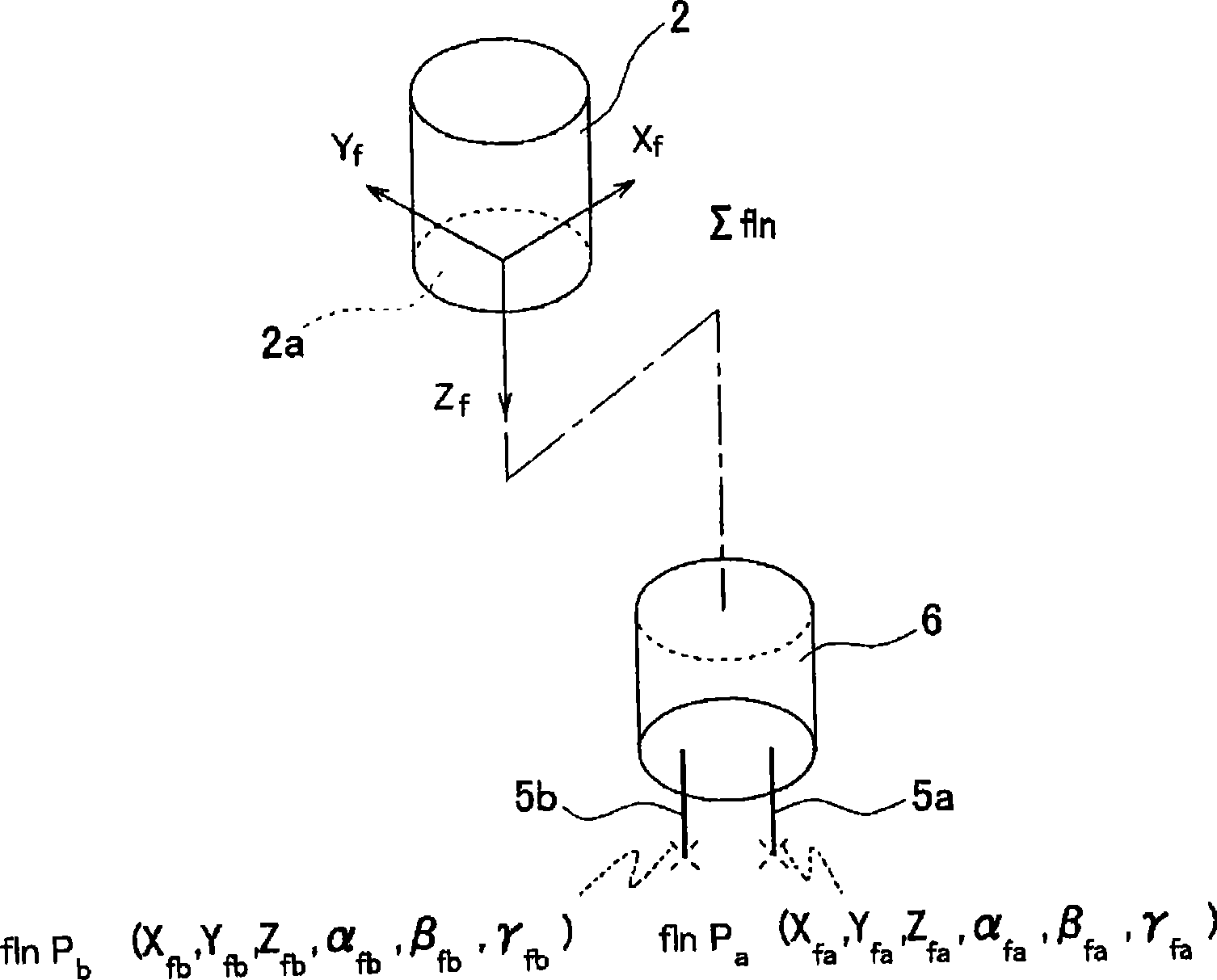

[0067] On the flange surface 2a at the front end of the manipulator 2 (refer to image 3 ) is mounted with a pair of arc electrodes (hereinafter, simply referred to as "electrodes") 5a, 5b made of copper wires, and a tandem type torch 6 is attached. The manipulator 2 changes the position and posture of the welding torch 6 in three-dimensional space. Manipulator 2 has six rotary joints, namely RJm1, RJm2, RJm3, RJm4, RJm5, RJm6. The revolving joints RJm1 to RJm6 are connected by a link, and the bottommost revolving joint RJm1 is attached to the pedestal 7 . Each of the revolving joints RJm1 to RJm6 includes an angle sensor for detecting a motor joint angle J ( J1 , J2 , J3 , J4 , J5 , J6 ) for rotational dr...

no. 2 approach

[0120] Such as Figure 10 and Figure 11 The shown welding robot 1 of the second embodiment of the present invention is provided with alternative current detection sensors 10a, 10b (refer to figure 2 and figure 1 ) of the optical sensor 100. The optical sensor 100 includes: a condenser 101 ; and a light receiving sensor 102 . In addition, in the present embodiment, the forward electrode can be known in advance (hereinafter, the electrode 5 a is referred to as the forward electrode).

[0121] Such as Figure 12A and Figure 12B The shown control of the manipulator 2 by the control device 4 is the same as that of the first embodiment in that after moving to the welding start position Pn and starting welding (steps S12-1, S12-2), the target of the forward electrode 5a The calculation of the value Plead(t) uses the calculation of the primary correction target value Plead(t)' using the translation correction amount ΔP(t), and the secondary correction target value Plead(t)" ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com