Integral forming method of large size thin-walled titanium alloy cylindrical part without welding line

A kind of overall forming, titanium alloy technology, applied in the direction of furnace type, furnace, heat treatment furnace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

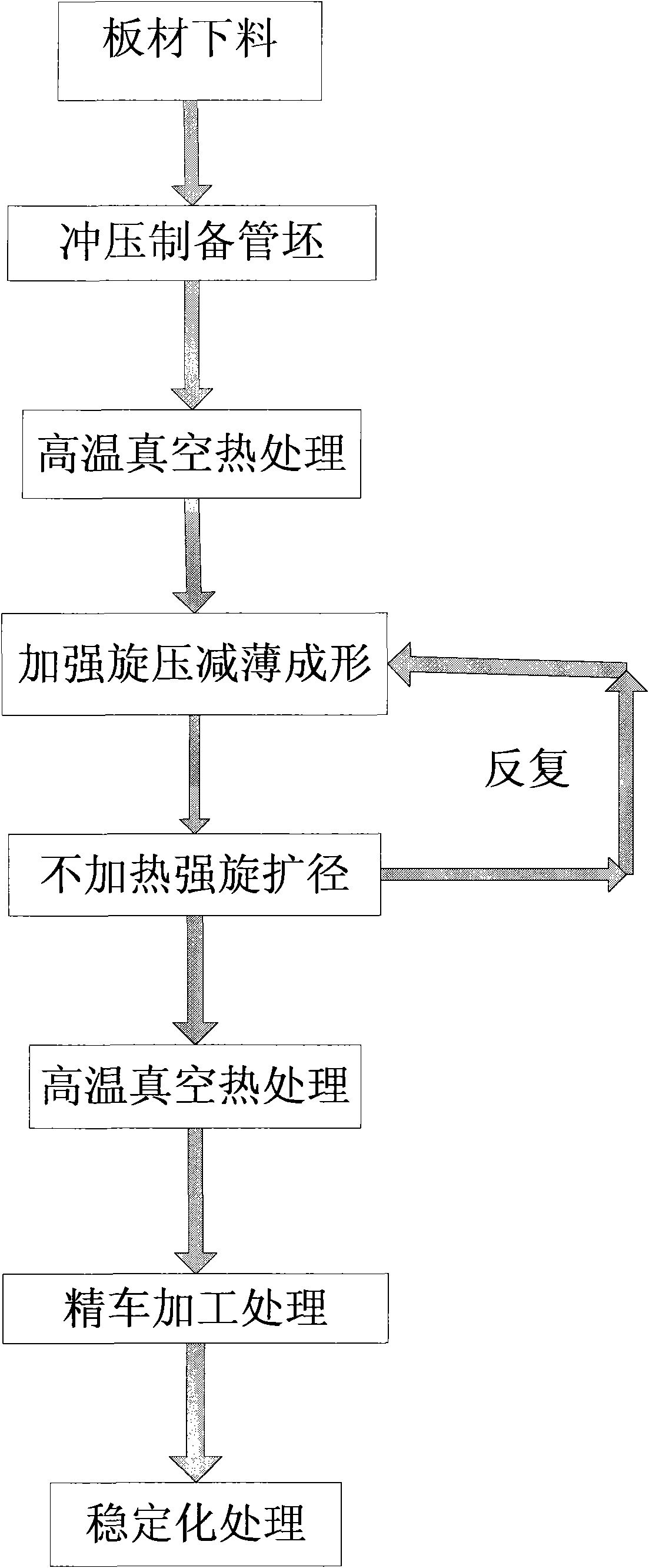

[0025] Adopt the method of the present invention to make the overall forming method of the large-scale thin-walled titanium alloy cylindrical part with 600 mm in diameter, 400 mm in length and 2 mm in wall thickness, such as figure 1 As shown, the specific steps are as follows:

[0026] (1) Plate blanking: adopt the existing technology to calculate the required diameter of the titanium alloy plate according to the size of the prepared pipe, and then process the titanium alloy plate into a circular plate blank;

[0027] (2) Stamping to prepare tube blanks: Coat the round plate blank with a glass powder coating of 0.05 mm to prevent titanium alloy oxidation and hydrogen absorption, then put the circular plate blank into a heating furnace and heat it to 800 ° C, take it out and immediately punch and stretch it , Stop stamping when the blank temperature is lower than 700°C, and then repeat the above heating stamping process 3 times until a cylindrical tube blank is prepared.

[0...

Embodiment 2

[0041] Adopt the method of the present invention to make the overall forming method of the large-scale thin-walled titanium alloy cylindrical part with a diameter of 400mm, a length of 200mm, and a wall thickness of 1mm, and the specific steps are as follows:

[0042] (1) Plate blanking: adopt the existing technology to calculate the required diameter of the titanium alloy plate according to the size of the prepared pipe, and then process the titanium alloy plate into a circular plate blank;

[0043] (2) Stamping to prepare the tube blank: Coat the disc blank with a glass powder coating of 0.1mm to prevent titanium alloy oxidation and hydrogen absorption, then put the disc blank into a heating furnace and heat it to 700°C, take it out and immediately punch and stretch it , Stop stamping when the blank temperature is lower than 600°C, repeat the above-mentioned heating stamping process twice until a cylindrical tube blank is prepared.

[0044] (3) High-temperature vacuum heat t...

Embodiment 3

[0052] Adopt the method of the present invention to make the overall forming method of the large-scale thin-walled titanium alloy cylindrical part with 800mm in diameter, 500mm in length, and 7mm in wall thickness, and the specific steps are as follows:

[0053] (1) Plate blanking: adopt the existing technology to calculate the required diameter of the titanium alloy plate according to the size of the prepared pipe, and then process the titanium alloy plate into a circular plate blank;

[0054] (2) Stamping to prepare tube blanks: Coat 0.08 mm of glass powder coating to prevent titanium alloy oxidation and hydrogen absorption on the circular plate blanks, then put the circular plate blanks into a heating furnace and heat them to 900 ° C, take them out and stamp them immediately , Stop stamping when the blank temperature is lower than 700°C, and repeat the above-mentioned heating stamping process 7 times until a cylindrical tube blank is prepared.

[0055] (3) High-temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com