Water-based ion battery plate manufacturing process

A technology of ion battery and manufacturing process, which is applied in the direction of electrode manufacturing, electrode rolling/calendering, etc., which can solve the problems of plate thickness not greater than 1mm, low material utilization rate, and non-recyclability, etc., so as to achieve easy control of surface density and thickness , high material utilization and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

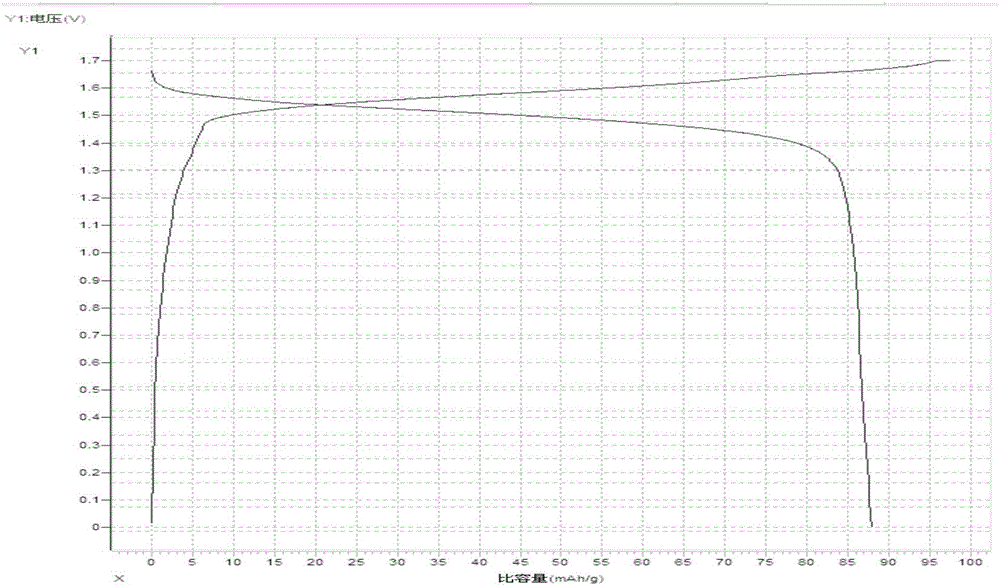

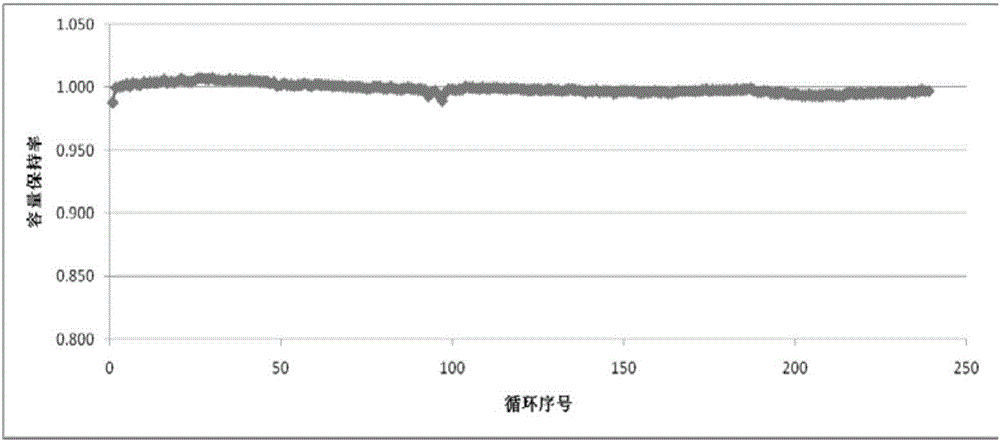

[0016] A water-based ion battery plate manufacturing process, including the selection steps: (1) mixing materials, adding 3.5g lithium manganate, 1gSP, 0.5g PTFE into the mixer, then adding 3g deionized water, stirring and mixing evenly; (2) Once rolling, transfer the uniformly mixed raw material powder to a rolling machine, and roll it into a sheet, with a rolling thickness of 2mm; (3) Drying, transfer the sheet to a drying oven for drying, and the drying temperature is 100°C , the drying time is 6 hours; the purpose of drying is to remove the moisture in the sheet, which can improve the compaction of the sheet and avoid sticking to the roll when the sheet is processed very thin; (4) Secondary rolling, the dried sheet The material is rolled again, and the rolling thickness is 0.1mm; the second rolling is to make the sheet into the required thickness and surface density; (5) punching, punching the rolled sheet into a diameter of 16mm disc; (6) Pressing, pressing the die-cut di...

Embodiment 2

[0018] A water-based ion battery plate manufacturing process, including the selection steps: (1) Mixing materials, adding 7g lithium iron phosphate, 1gSP, 1g KS-6, 1g PTFE into the stirrer, and then 8g deionized water, stirring and mixing (2) Once rolling, transfer the uniformly mixed raw material powder to a rolling machine, and roll it into a sheet, with a rolling thickness of 10mm; (3) Drying, transfer the sheet to a drying oven for drying, and the drying temperature 100°C, drying time 8 h; (4) Secondary rolling, rolling the dried sheet again, with a rolling thickness of 9mm; (5) Die-cutting, punching the rolled sheet into edges A square piece with a length of 40mm; (6) Pressing, pressing the punched square piece with a side length of 40mm and a square stainless steel strip with a side length of 40mm on a roller press, and adjusting the thickness to 9mm.

Embodiment 3

[0020] A water-based ion battery plate manufacturing process, which includes the selection steps: (1) mixing materials, adding 6g sodium titanium phosphate, 2gSP, 1.5g PTFE, 0.5g SBR into the stirrer, and then 3g deionized water, stirring and mixing (2) Once rolling, transfer the uniformly mixed raw material powder to a roller press, and roll it into a sheet, with a rolling thickness of 4mm; (3) Drying, transfer the sheet to a drying oven for drying, and the drying temperature 80°C, drying time 8 h; (4) secondary rolling, rolling the dried sheet again, the rolling thickness is 0.5mm; (5) punching, punching the rolled sheet into A disc with a diameter of 18mm; (6) Pressing, the die-cut disc with a diameter of 18mm and a titanium mesh with a diameter of 18mm are pressed together on a roller press, and the thickness is adjusted to 0.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com