Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Efficiently form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chip manufacturing method

ActiveUS20150343559A1Efficiently formGlass reforming apparatusGlass severing apparatusLight beamUltrasonic vibration

A chip having a desired shape is formed from a platelike workpiece. The chip manufacturing method includes a shield tunnel forming step of applying a pulsed laser beam to the workpiece from a focusing unit included in a pulsed laser beam applying unit along the contour of the chip to be formed, with the focal point of the pulsed laser beam set at a predetermined depth from the upper surface of the workpiece, thereby forming a plurality of shield tunnels inside the workpiece along the contour of the chip to be formed. Each shield tunnel has a fine hole and an amorphous region formed around the fine hole for shielding the fine hole. In a chip forming step, ultrasonic vibration is applied to the workpiece to break the contour of the chip where the shield tunnels have been formed, thereby forming the chip from the workpiece.

Owner:DISCO CORP

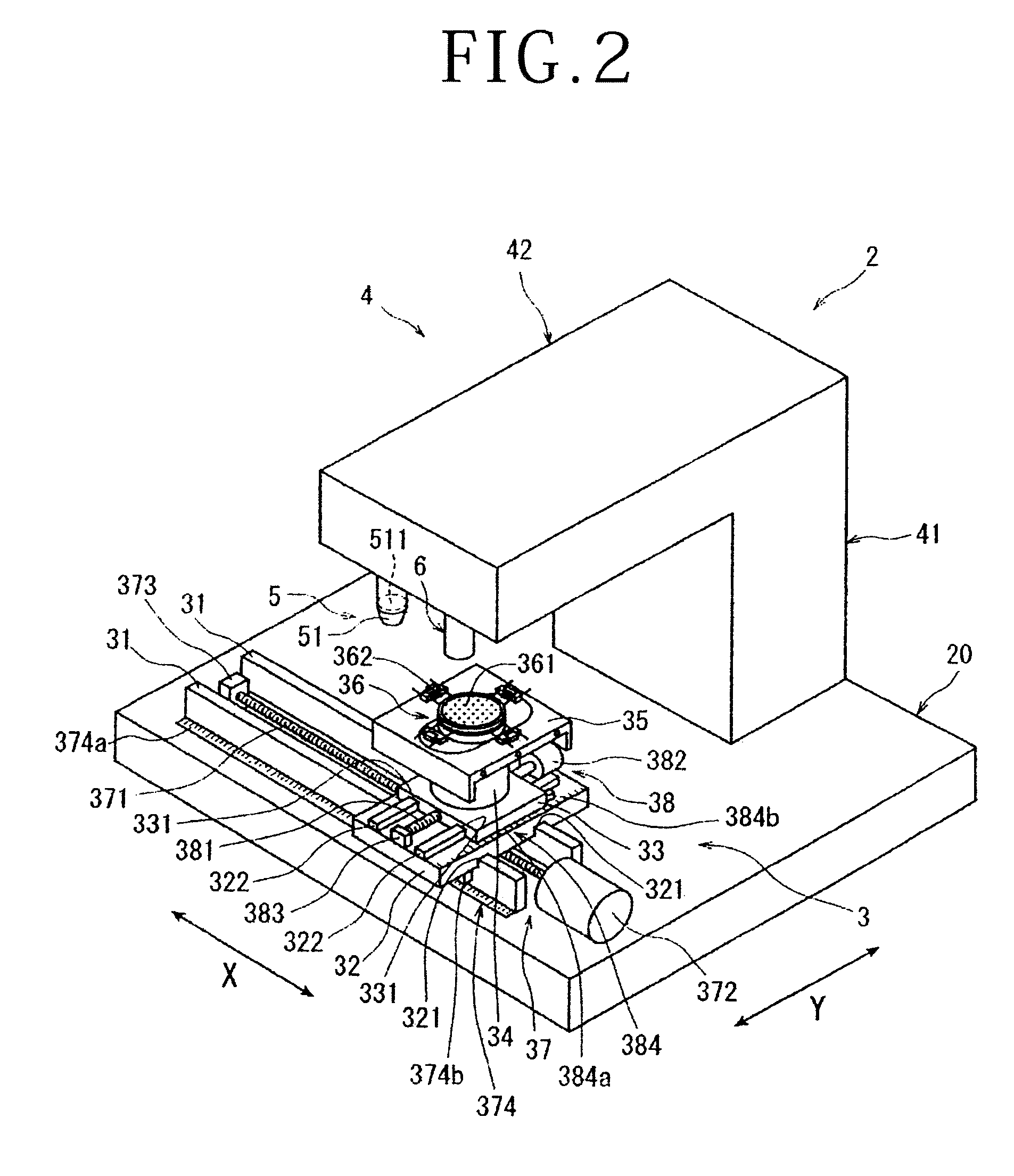

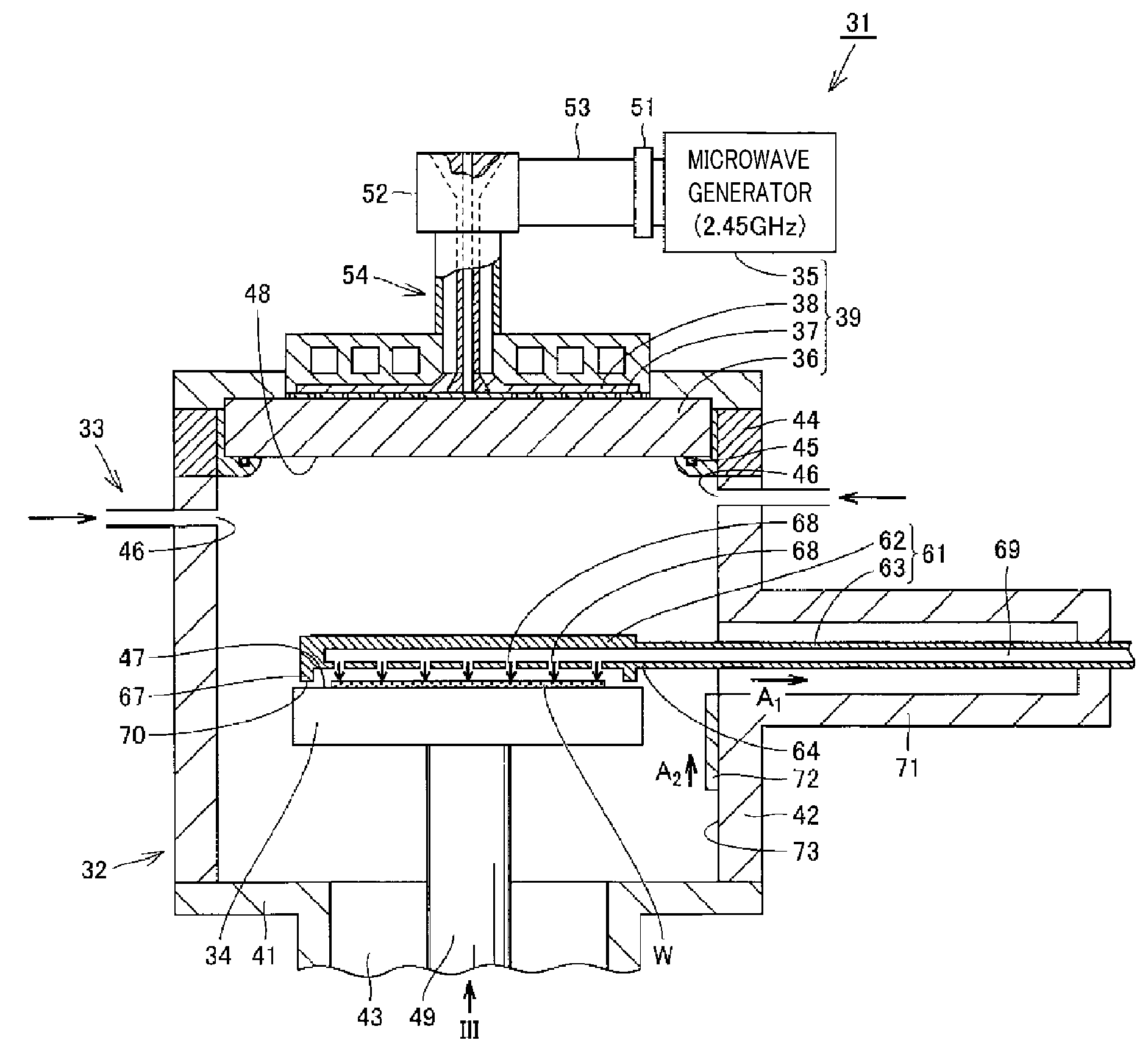

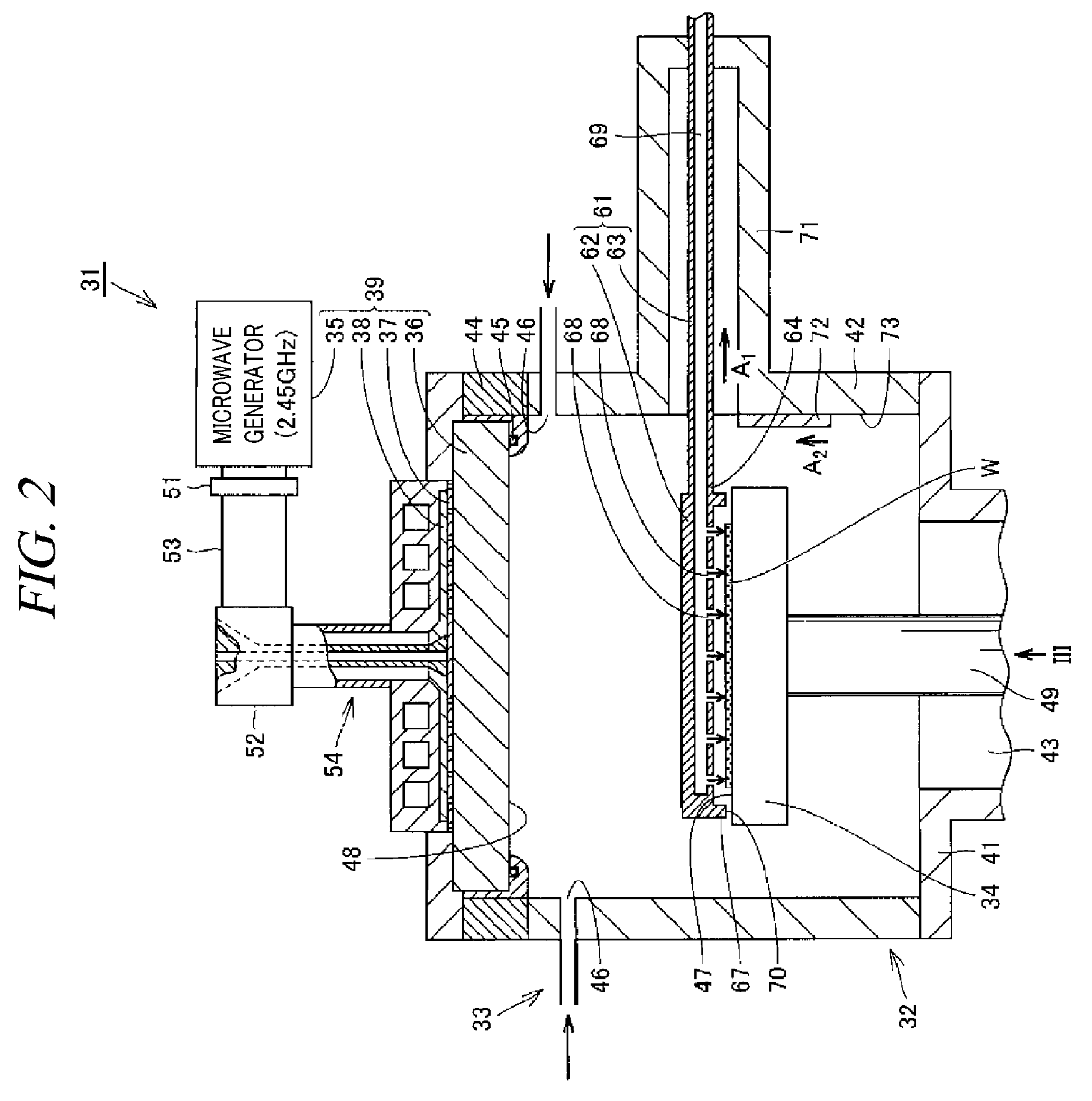

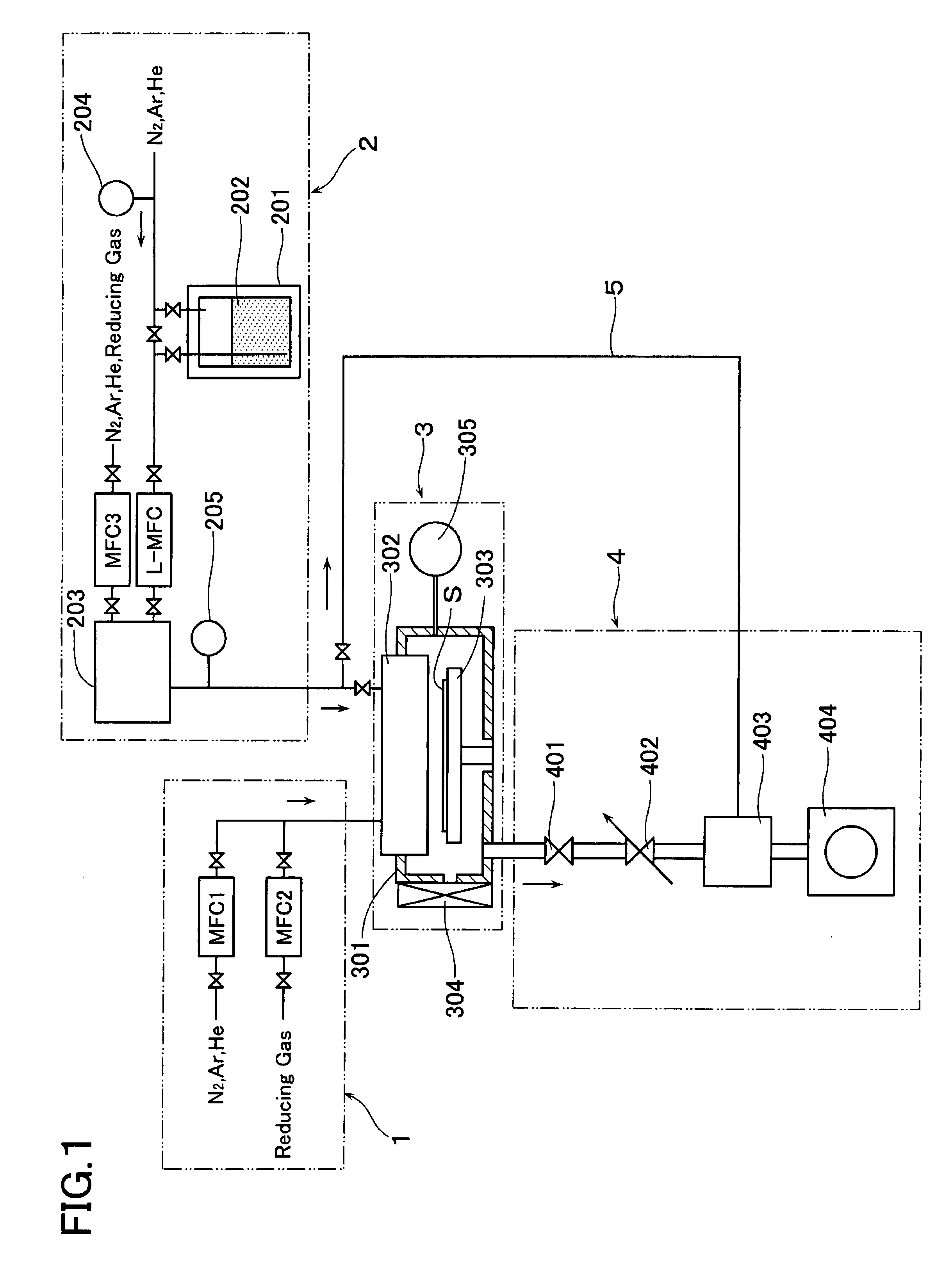

Plasma processing apparatus and gas supply device for plasma processing apparatus

ActiveUS20120186521A1Reduce supply amountEfficiently formSemiconductor/solid-state device manufacturingChemical vapor deposition coatingForming gasPlasma processing

A plasma processing apparatus 31 includes a processing chamber 32; a gas supply unit 33 for supplying a plasma processing gas into a processing chamber 32; a mounting table 34 configured to hold the target substrate W thereon; a plasma generating device 39 configured to generate plasma within the processing chamber 32; and a gas supply device 61. The gas supply device 61 includes a head unit 62 configured to move between a first position above the mounting table 34 and a second position different from the first position and to supply a gas, and the head unit 62 is configured to supply a film forming gas to a small-volume region formed between the mounting table 34 and the head unit 62 when the head unit 62 is positioned at the first position and to adsorb the film forming gas on the target substrate W.

Owner:TOKYO ELECTRON LTD

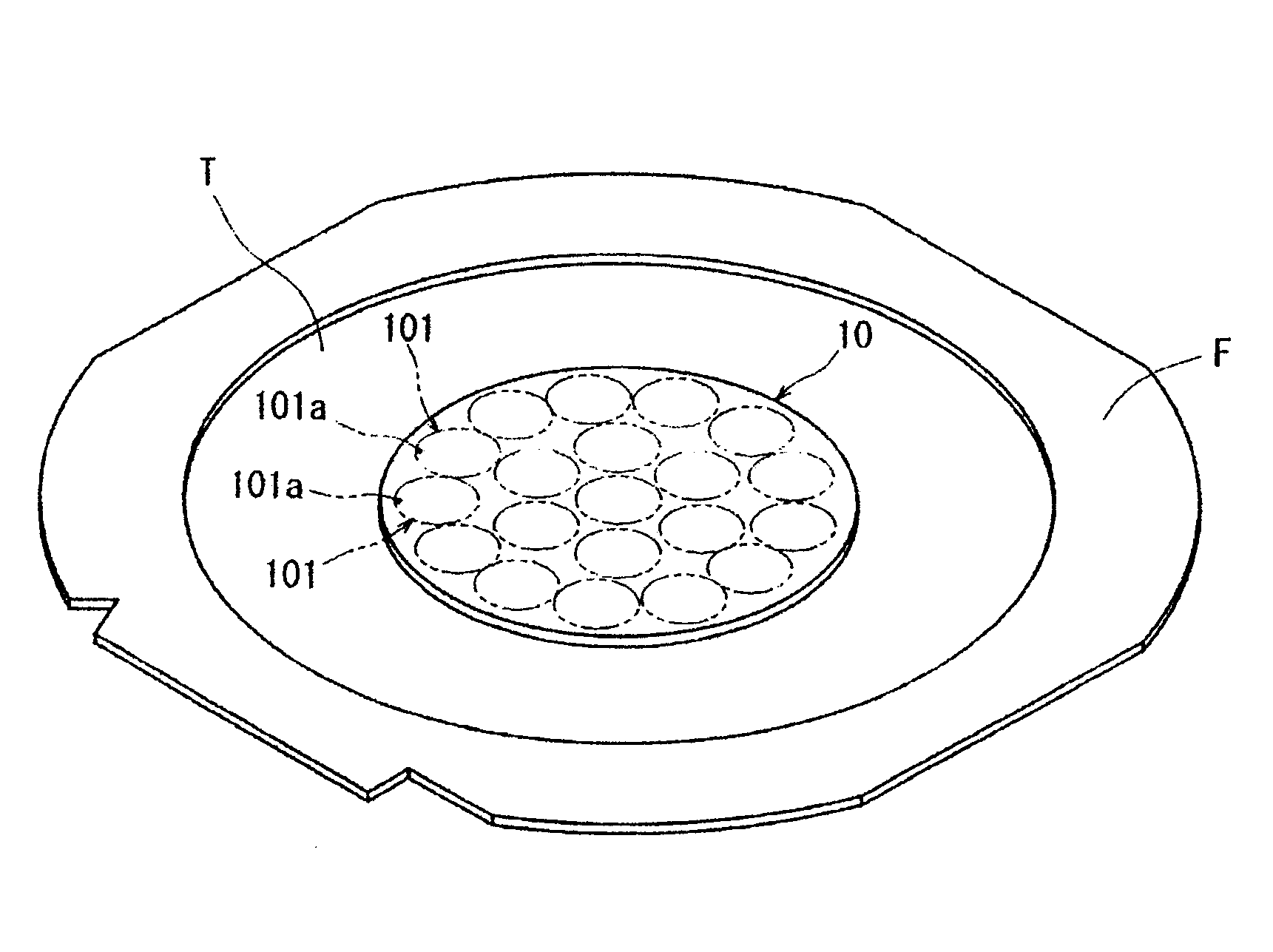

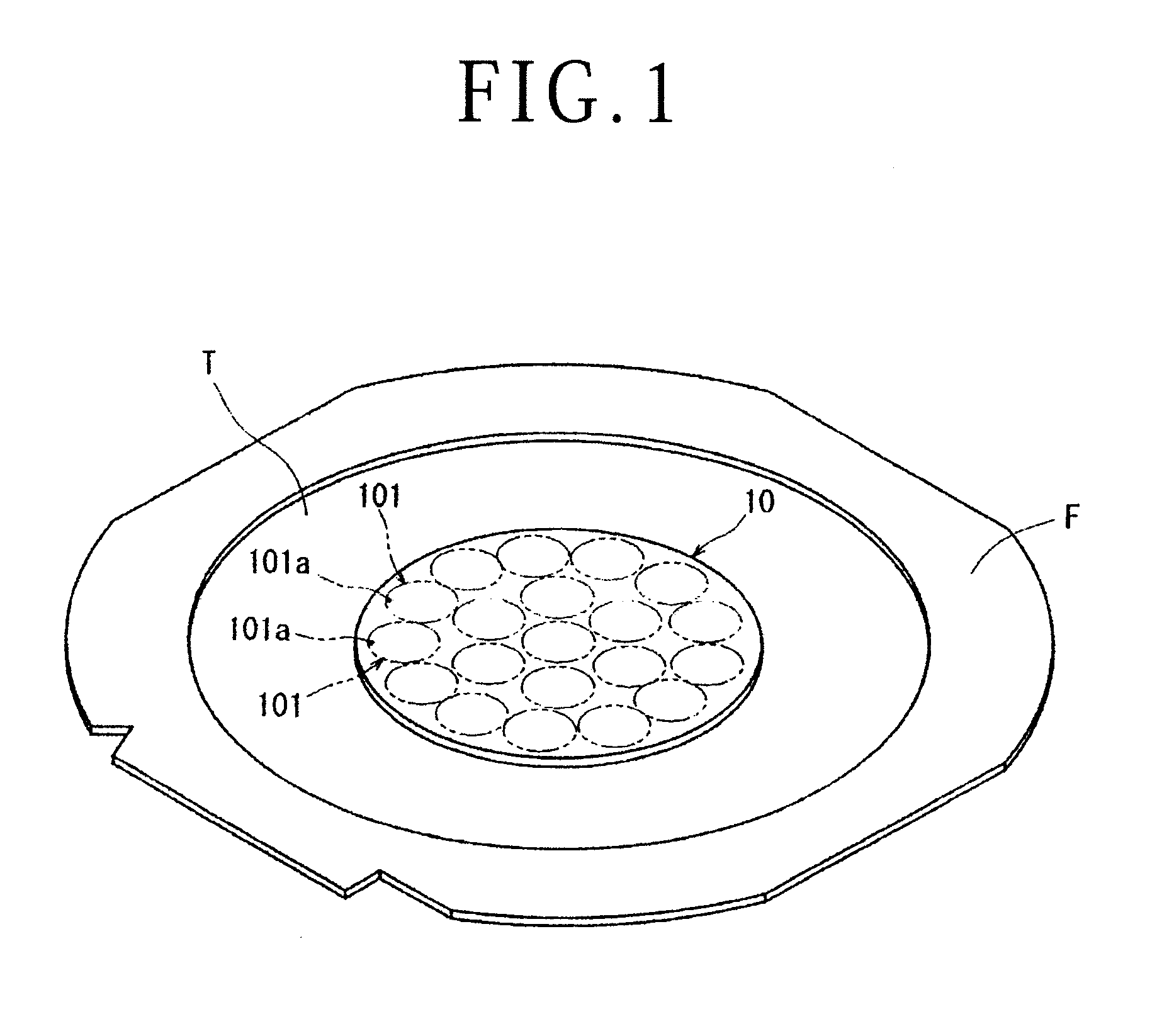

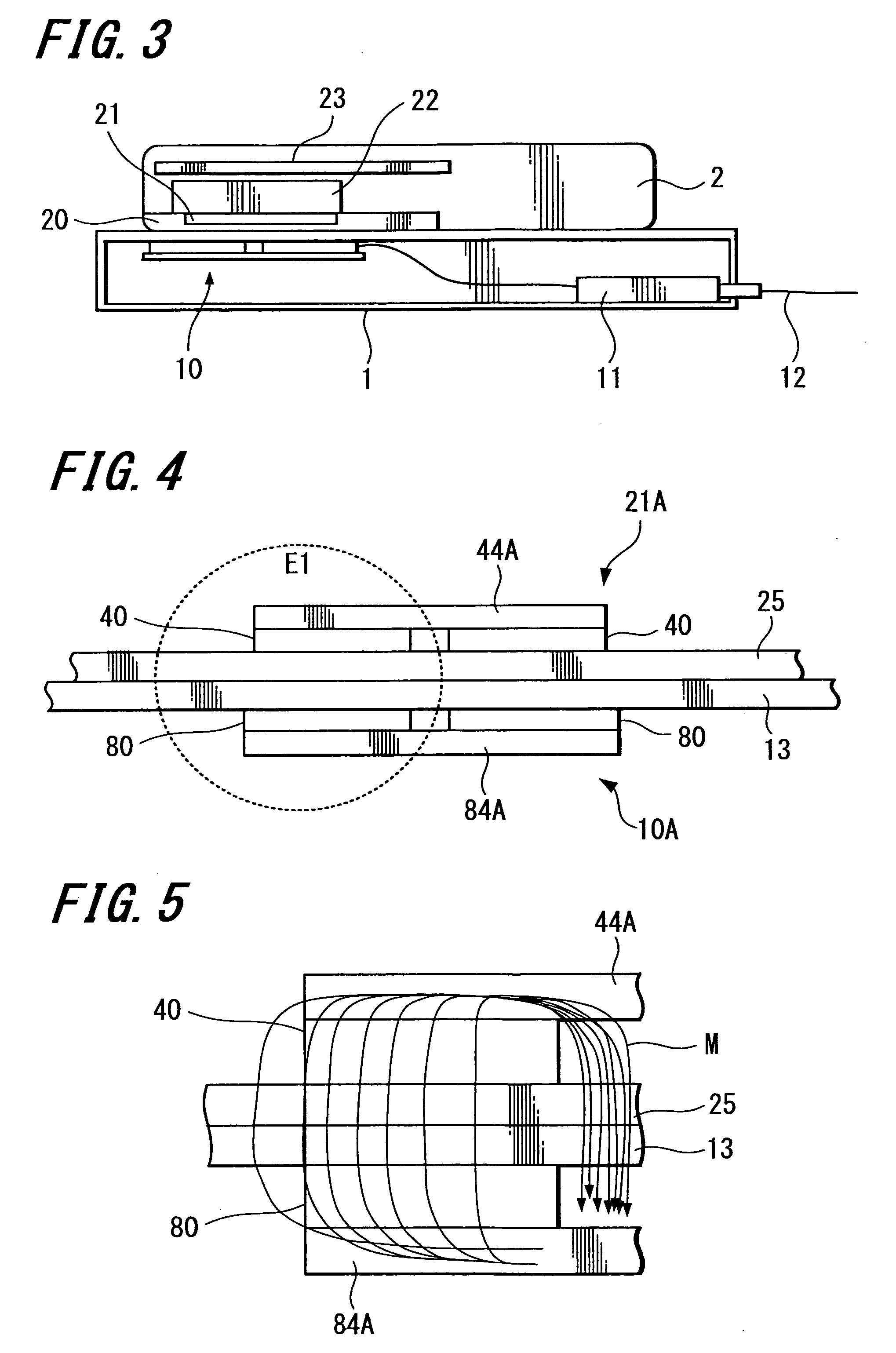

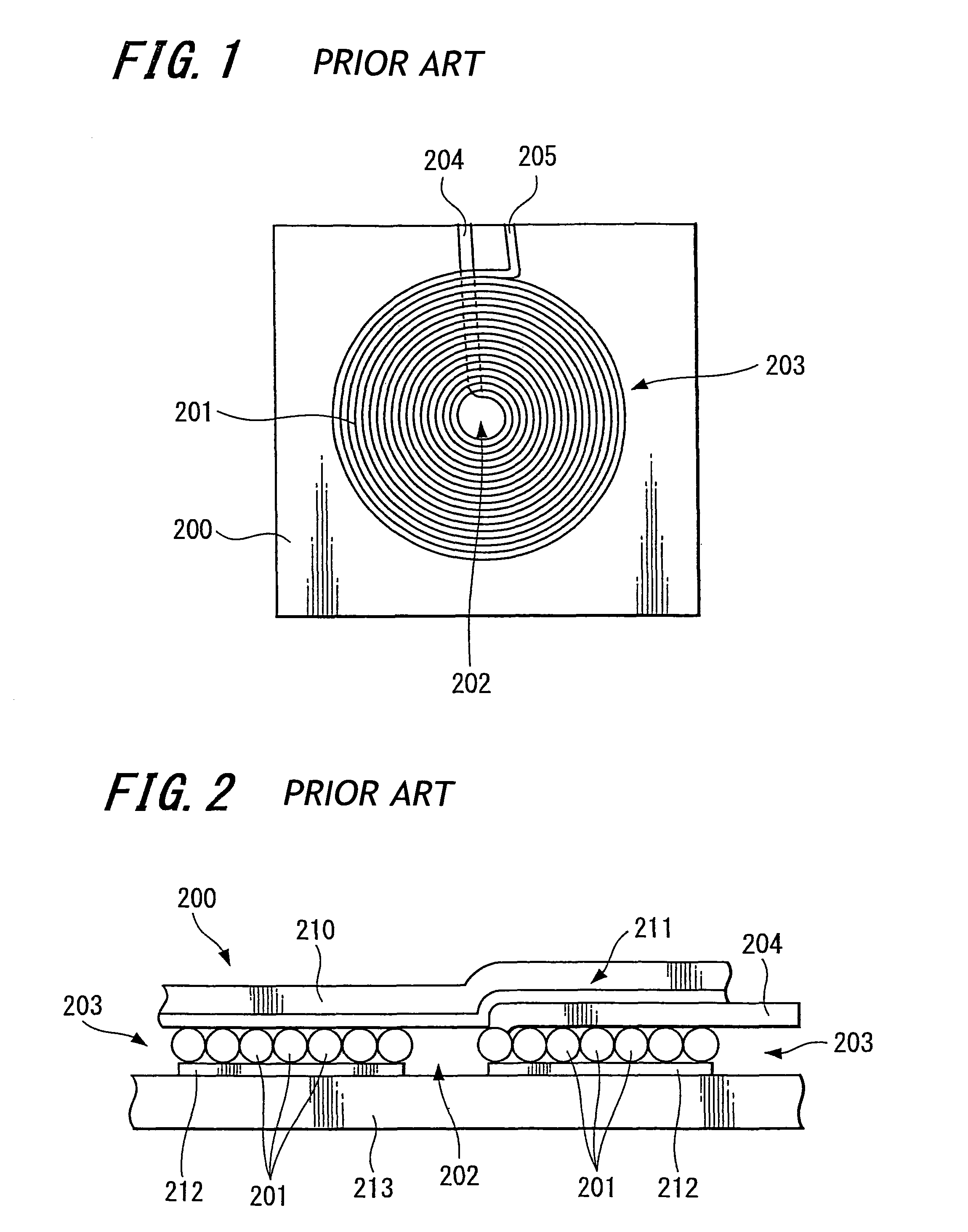

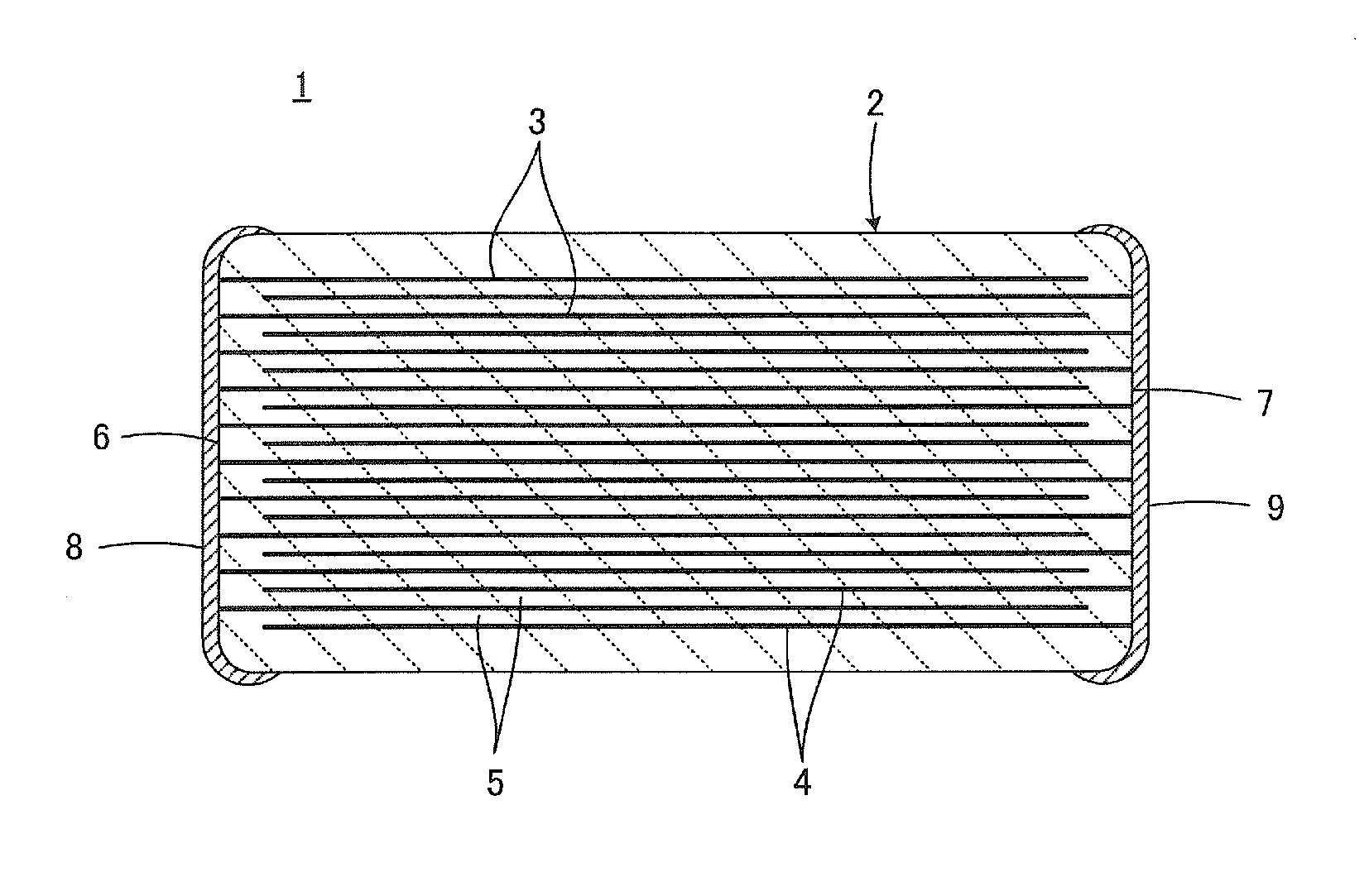

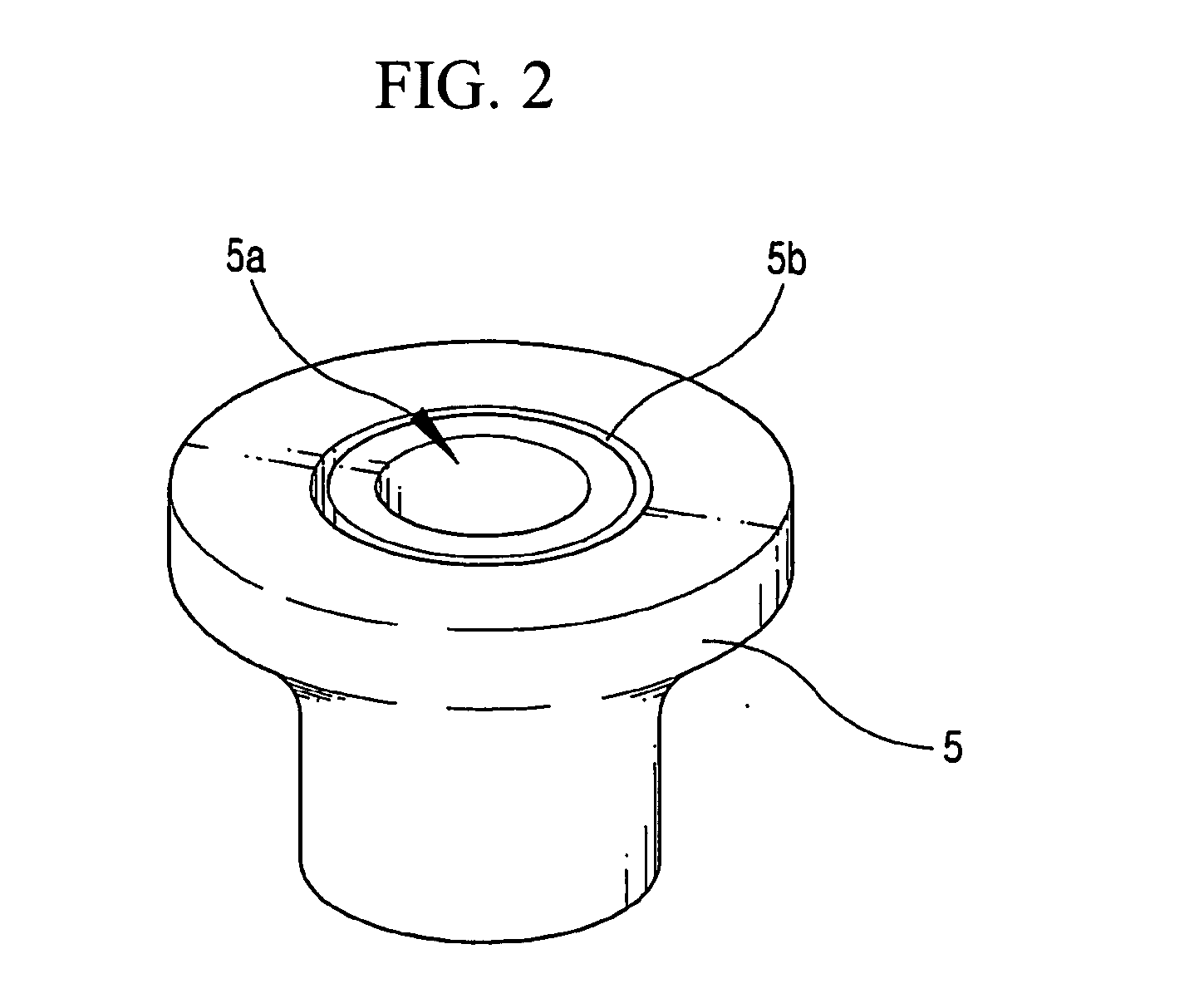

Noncontact power-transmission coil, portable terminal and terminal charging device, planar coil magnetic layer formation device, and magnetic layer formation method

ActiveUS20080164844A1Efficiently formedImprove efficiencyCircuit authenticationTransformers/inductances coils/windings/connectionsElectric power transmissionElectrical conductor

Owner:SONY MOBILE COMM INC +1

System and method for an interactive mobile-optimized icon-based profile display and associated public figure social network functionality

InactiveUS20120290979A1Efficient identificationEfficiently formAdvertisementsServices signallingGraphicsPersonalization

An icon-based interactive public figure profile, search, status update delivery, and matching system and method configured within open and exclusive public figure social network platforms and technologies enabling a public figure and fan to generate a personalized interactive icon-based profile representing icon profile elements optimized for display and functionality on mobile devices. The icon profile system utilizes and integrates selected personalized icon profile elements and associated data for searching, compatibility matching, invitations, services, advertisements, communities, and calendar functions. In public figure social network environments icon elements and exclusive celebrity social environments are unitized to aggregate fans based on a selected icon profile element and in further environments automatically compare and report compatibility between all unknown users which vastly improves social network functionality.

Owner:DEVECKA JOHN

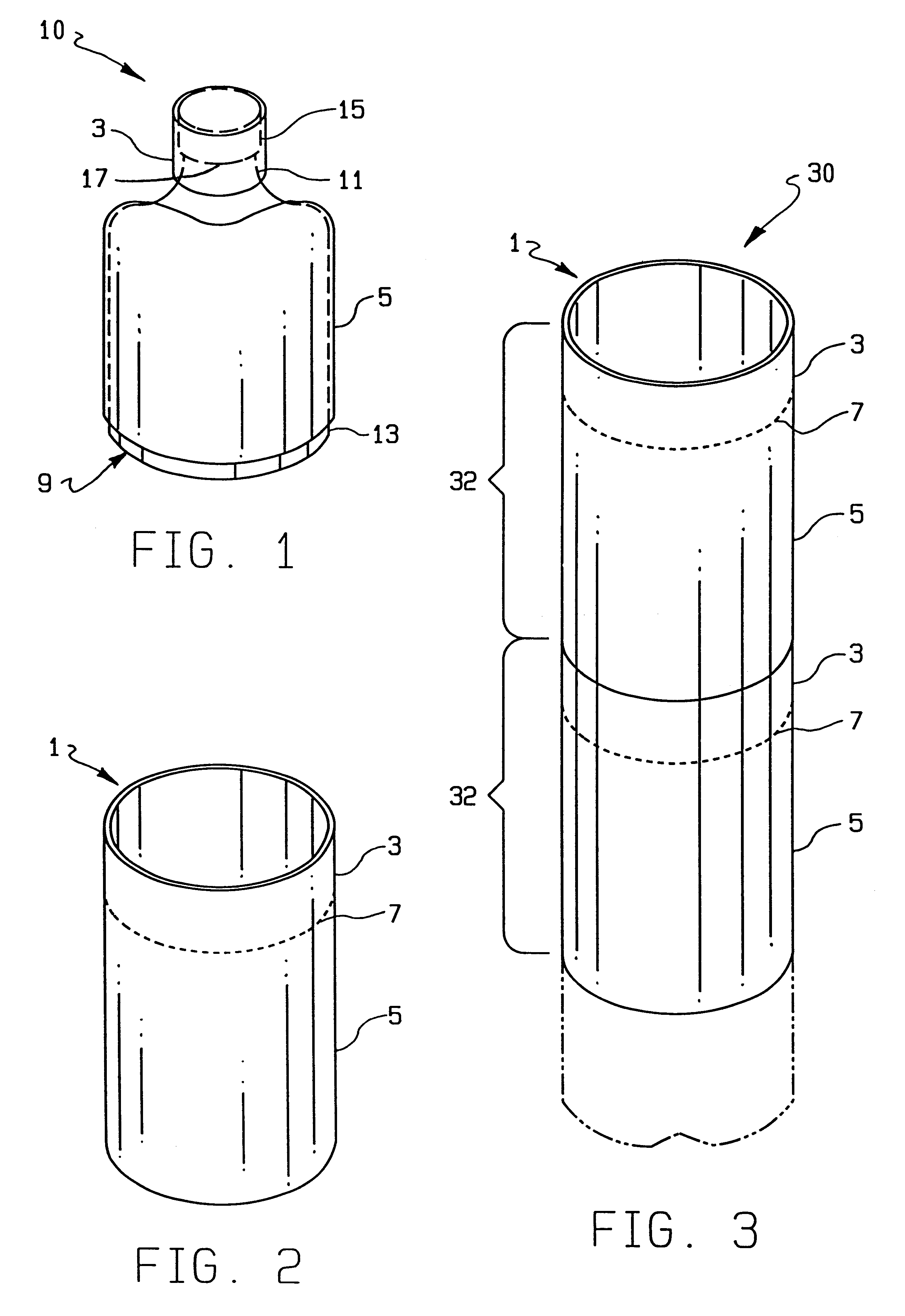

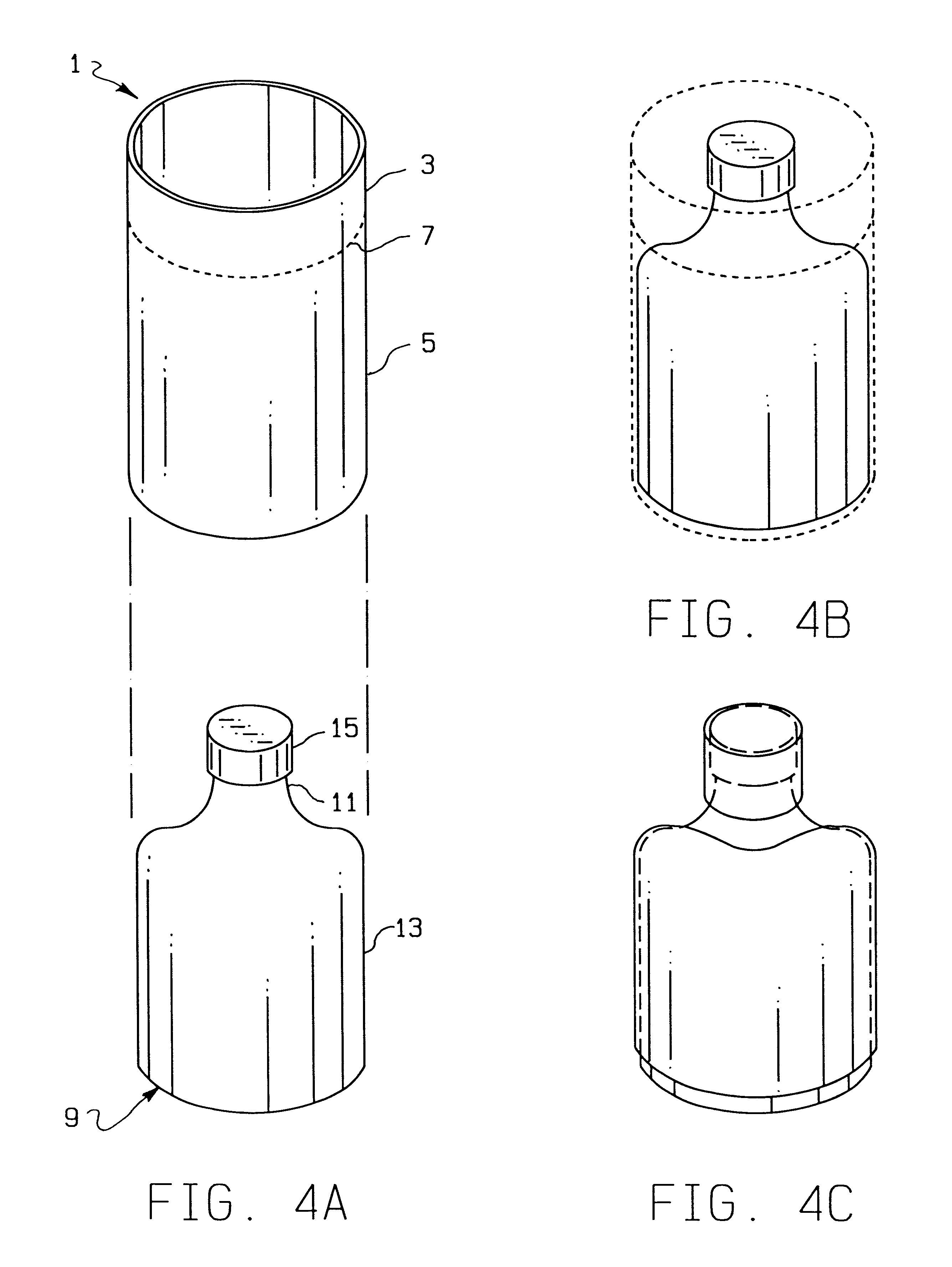

Method for shrink-wrapping containers and articles obtained thereby

InactiveUS6296129B1Efficiently formEfficient methodCapsClosure using stoppersHeat-shrinkable sleeveShrink wrap

Owner:FUJI SEAL INTERNATIONAL INC

Three-dimensional fabricating apparatus and method of fabricate three-dimensional shaped object

ActiveUS20160107387A1Little time differenceShorten the timeConfectionerySweetmeatsLayer thicknessMaterial supply

A three-dimensional fabricating apparatus has a table on which a powder material is stacked in a layered manner, and a shaping unit which includes a powder material supply device supplying the powder material onto a top surface of the table by every predetermined layer thickness and a binder liquid supply device ejecting a binder liquid to the powder material supplied onto the top surface of the table. The powder material supply device of the shaping unit is movable in one direction in a state adjacent to the top surface of the table and is capable of supplying the powder material onto the top surface of the table at a predetermined supply width while moving the powder material supply device. The binder liquid supply device is capable of moving in the same direction as the powder material supply device in a state adjacent to the top surface of the table.

Owner:CMET

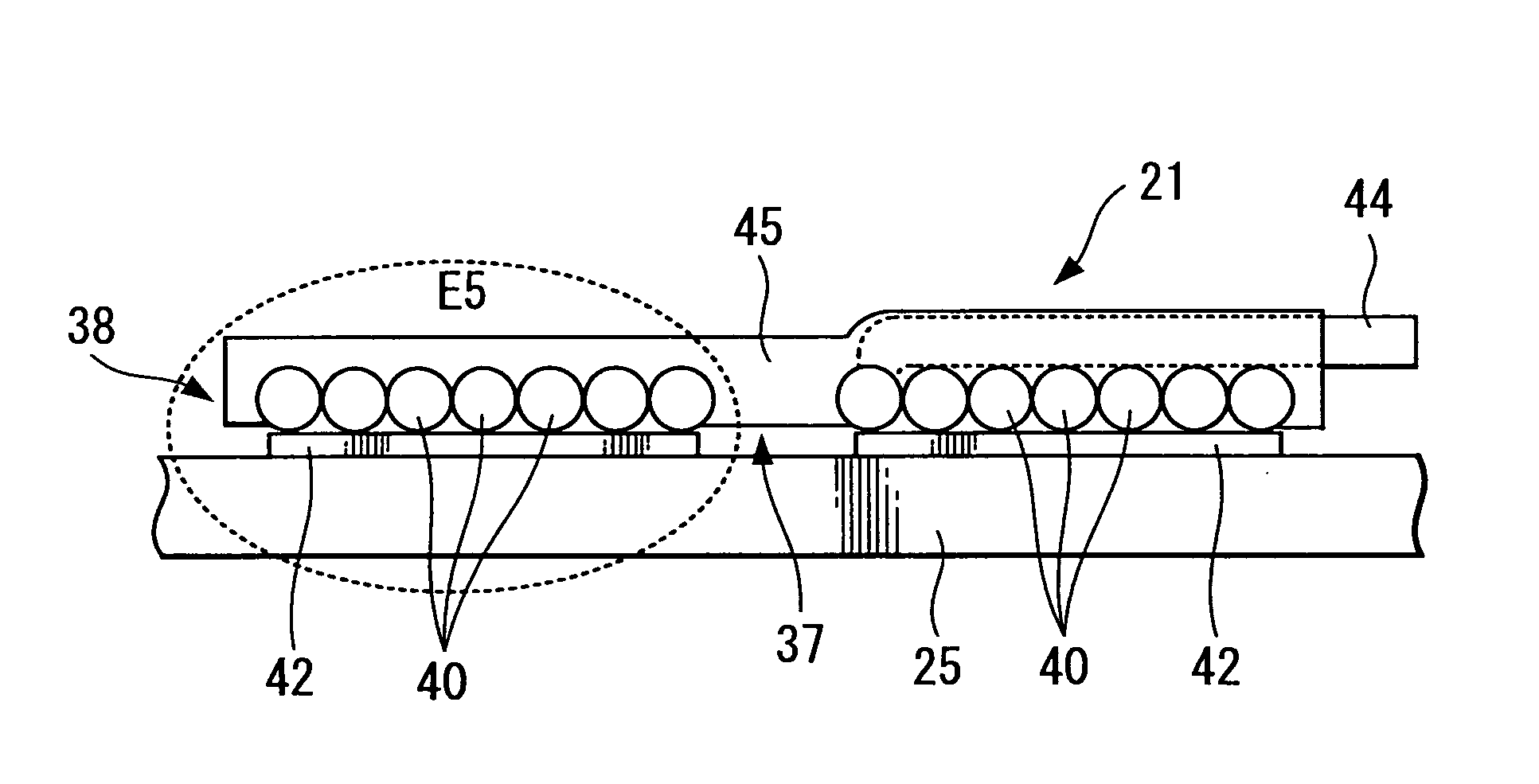

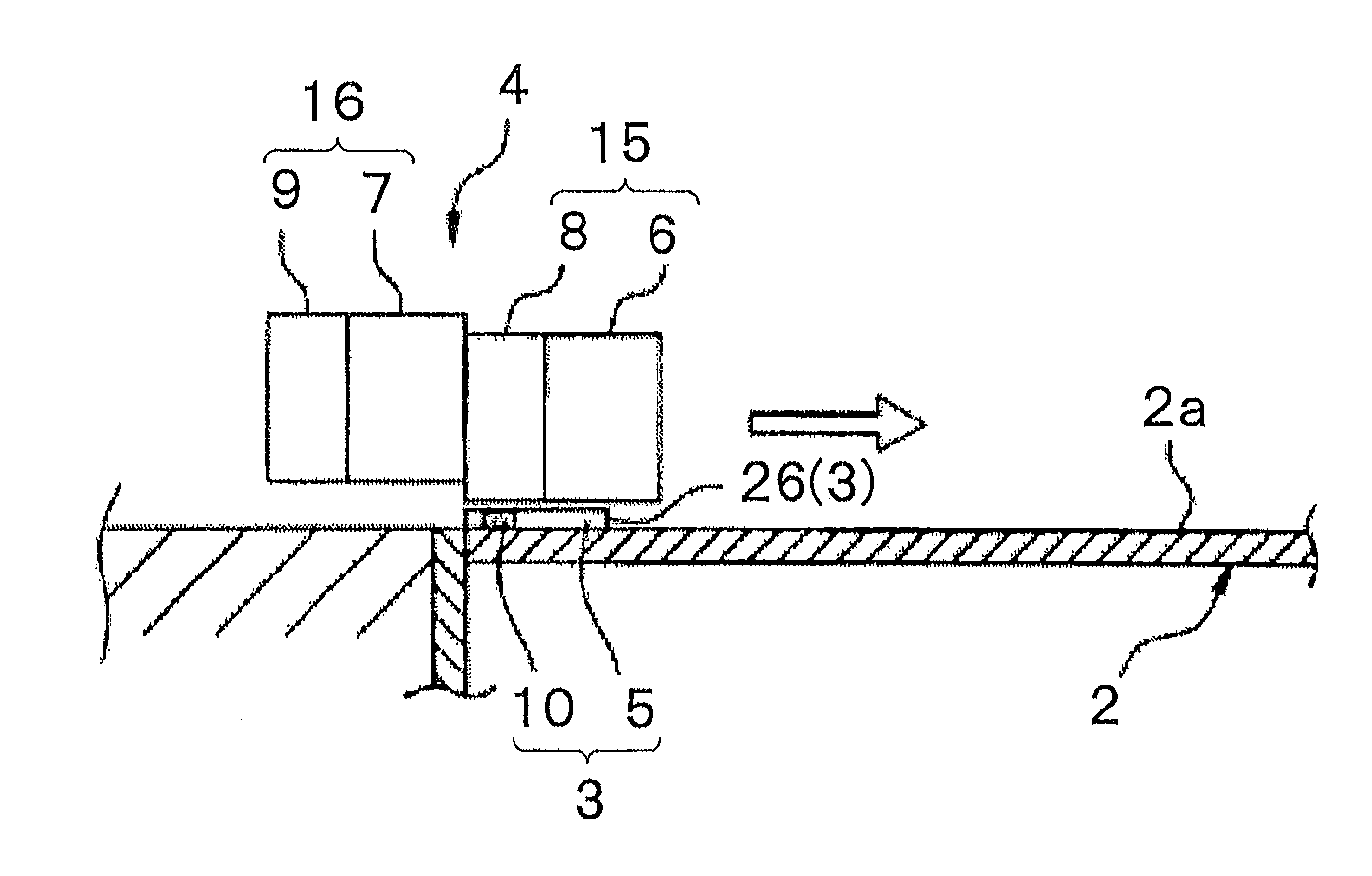

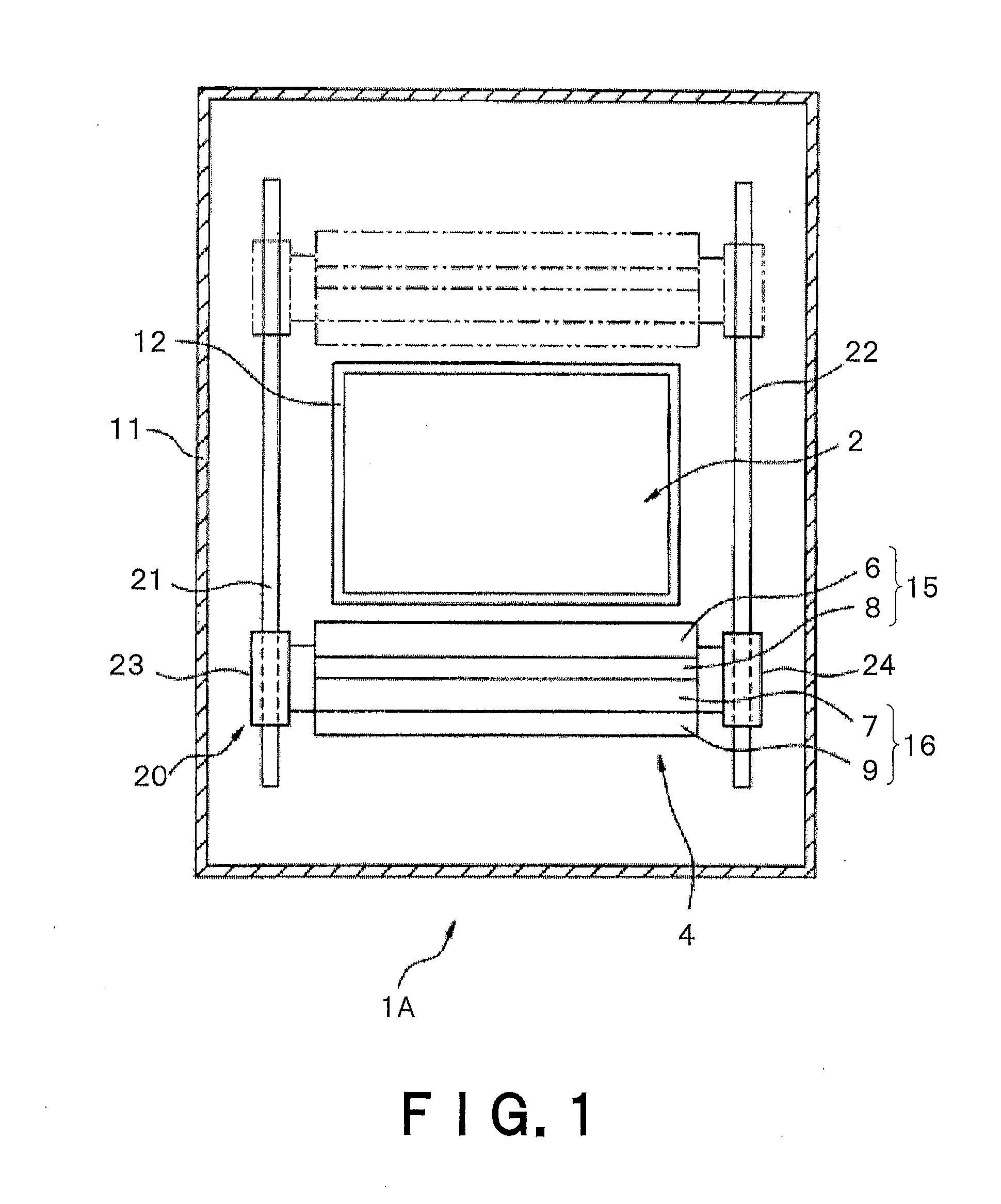

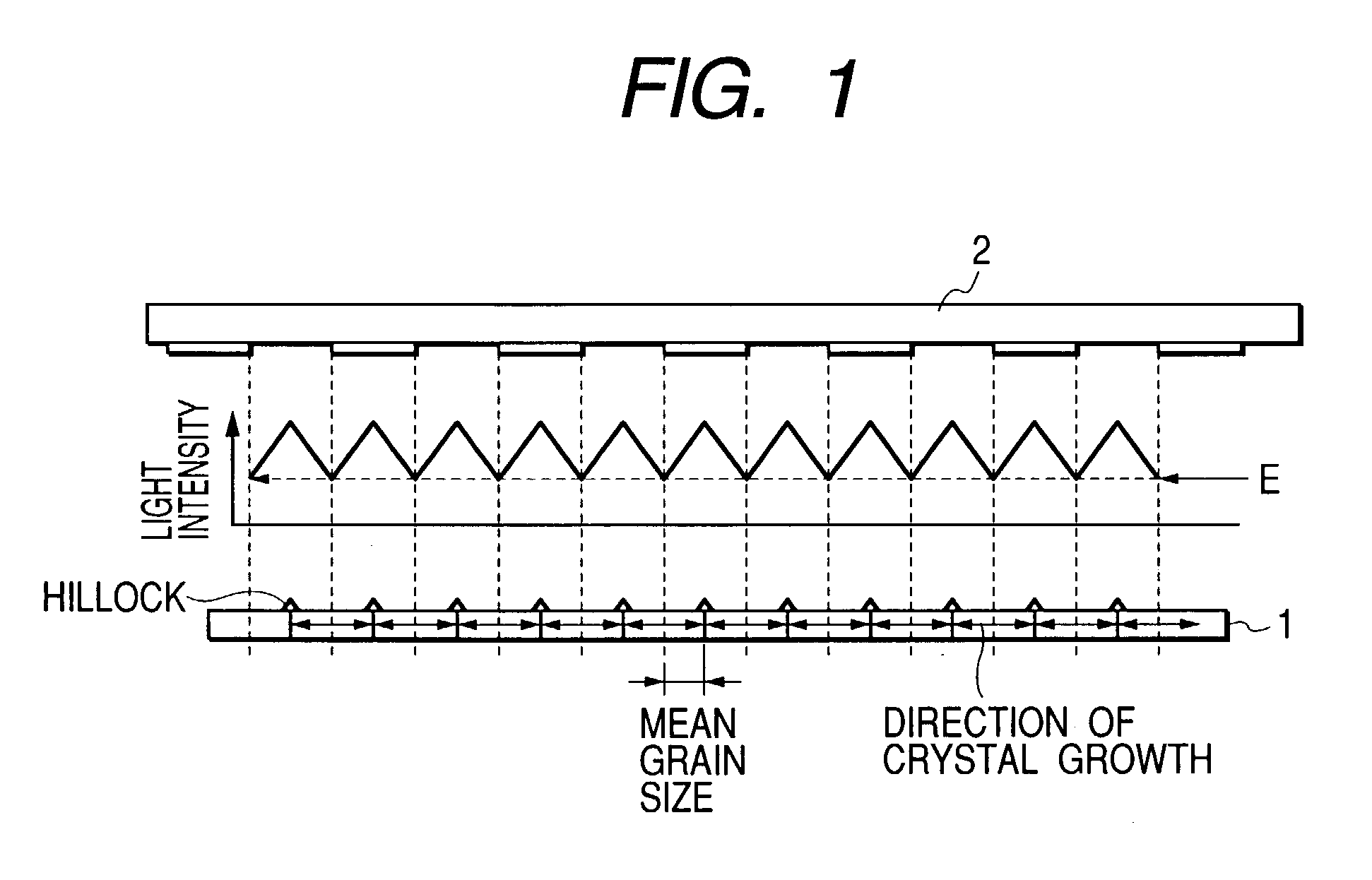

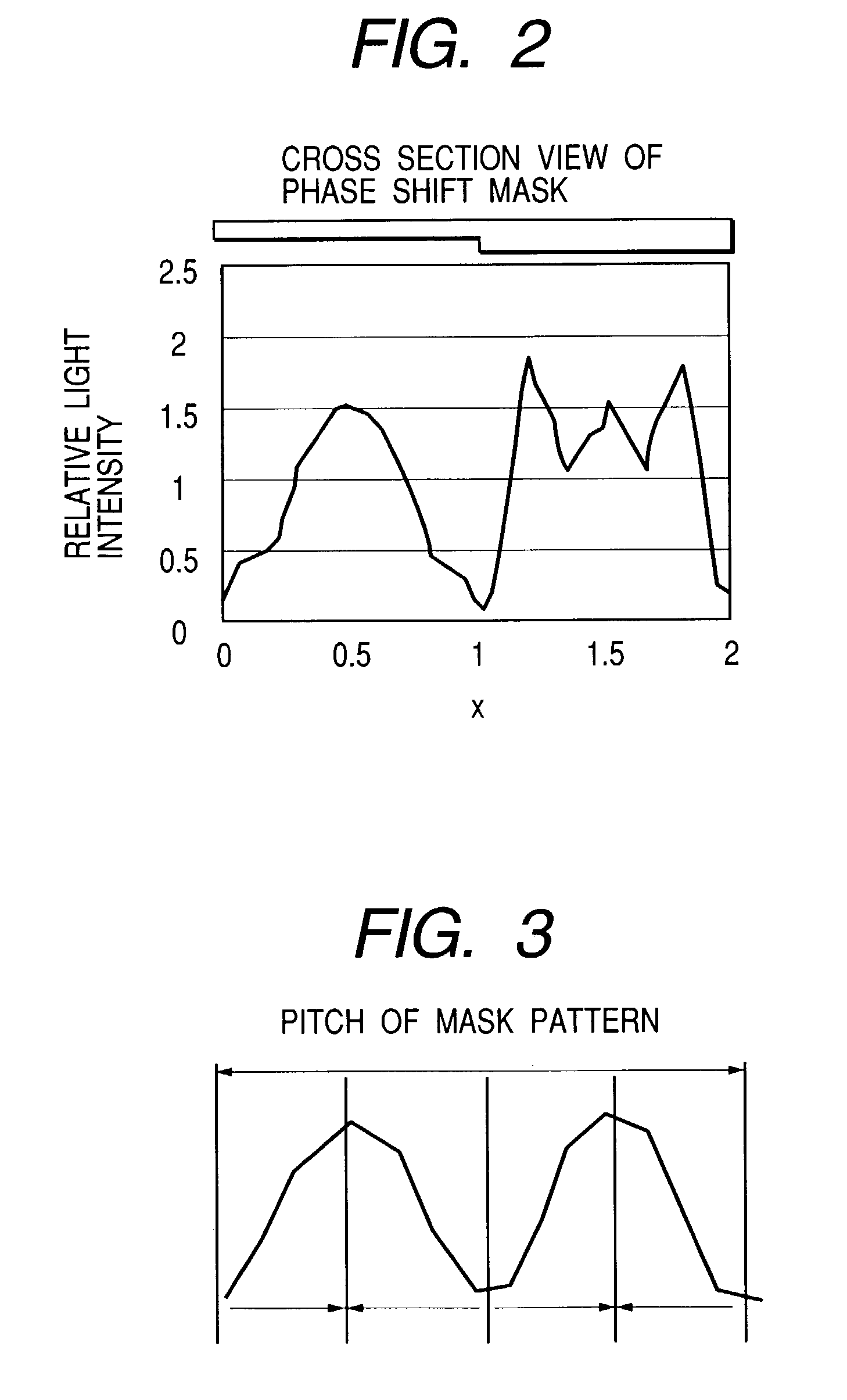

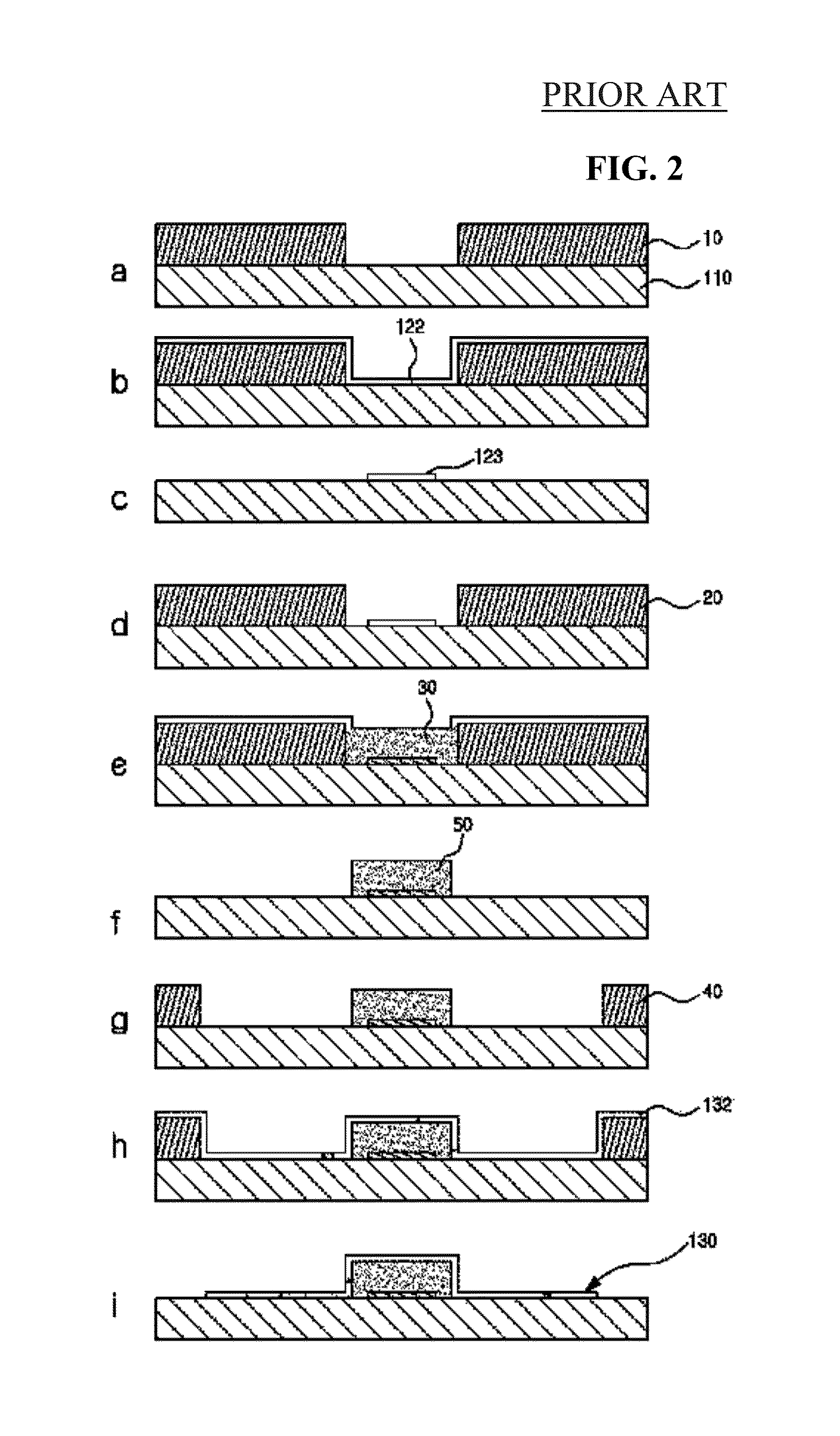

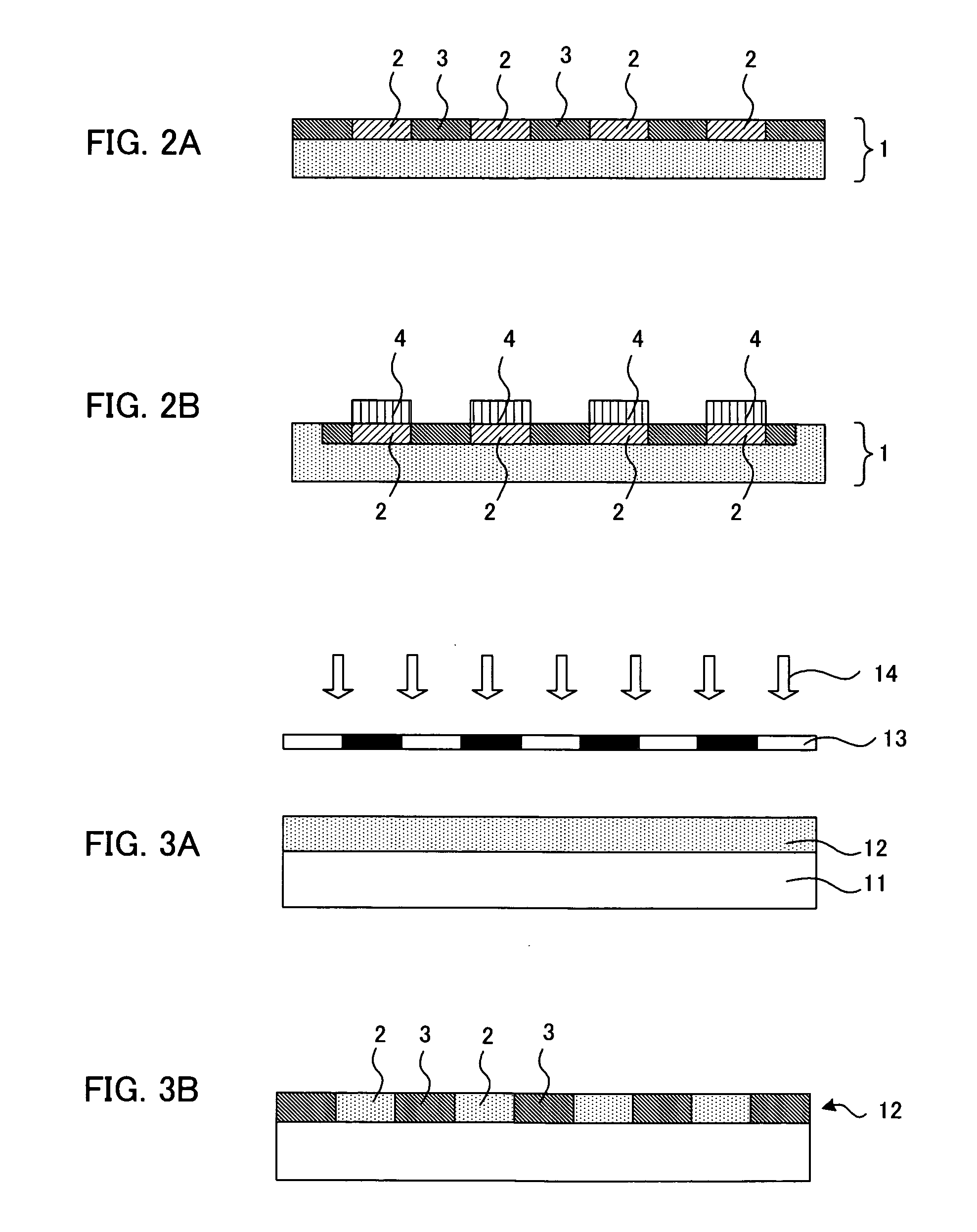

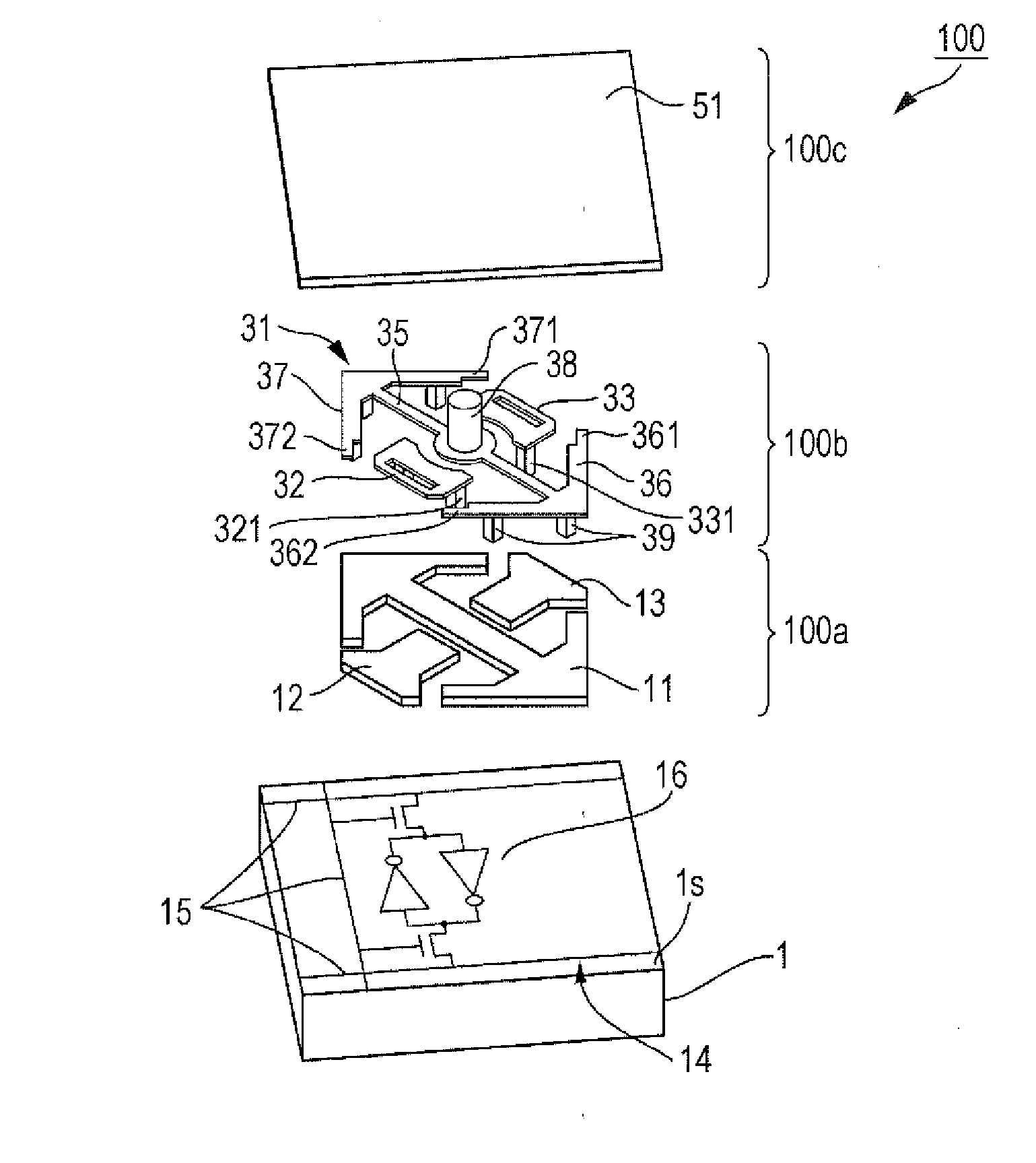

Semiconductor thin film and process for production thereof

ActiveUS7022183B2Efficiently formEfficiently formedTransistorPolycrystalline material growthSemiconductorPulsed laser

To improve the laser annealing process for polycrystallizing amorphous silicon to form silicon thin films having large crystal particle diameters at a high throughput, the present invention is directed to a process of crystallization by irradiation of a semiconductor thin film formed on a substrate with pulsed laser light. The process comprises having a means to shape laser light into a linear beam and a means to periodically and spatially modulate the intensity of pulsed laser in the direction of the long axis of the linear beam by passing through a phase-shifting stripy pattern perpendicular to the long axis, and collectively forming for each shot a polycrystalline film composed of crystals which have grown in a certain direction over the entire region irradiated with the linear beam.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

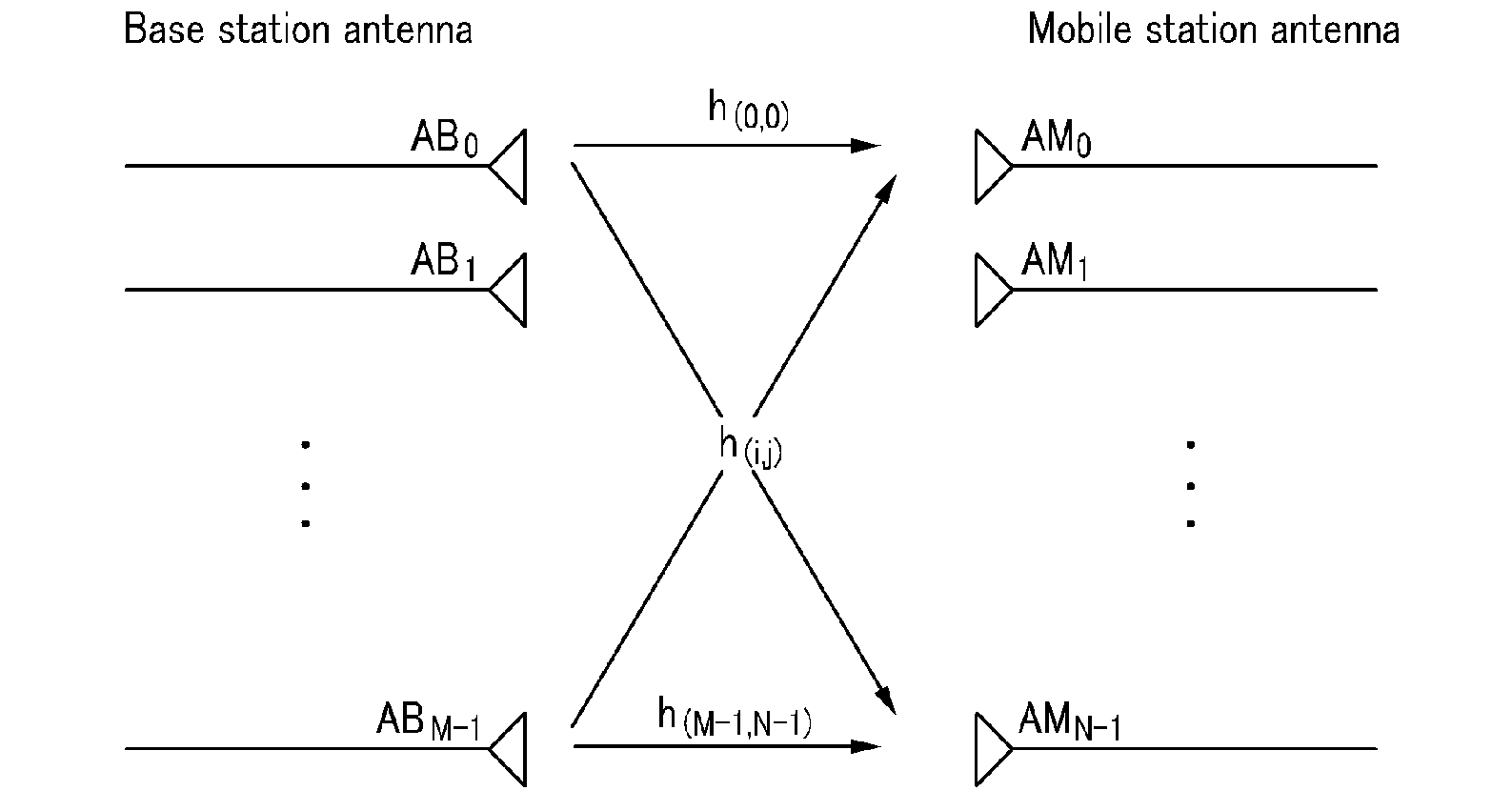

Beamforming method using multiple antennas

InactiveUS20100265853A1Increased power consumptionEfficiently formTime-division multiplexRadio transmissionMultiple antennaBase station antennas

A mobile station includes a plurality of mobile station antennas that receive at least one independent training signal from a plurality of base station antennas, and estimates a downlink channel formed by each of a plurality of base station antennas and each of the mobile station antennas by using the at least one independent training signal. The mobile station generates a beam vector by using the downlink channel, and forms transmission beams in the plurality of mobile station antennas for transmitting a signal to an uplink.

Owner:SAMSUNG ELECTRONICS CO LTD +1

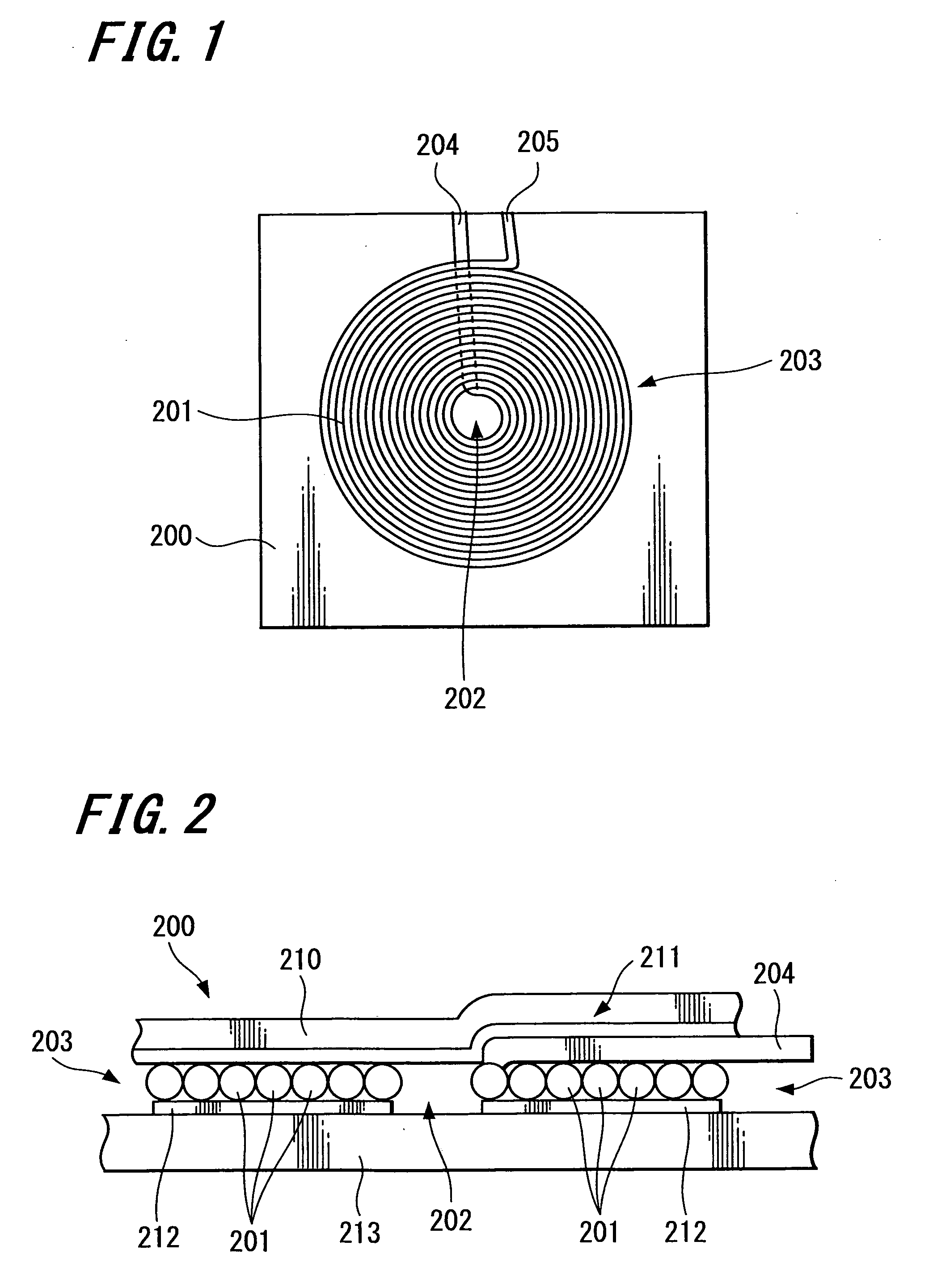

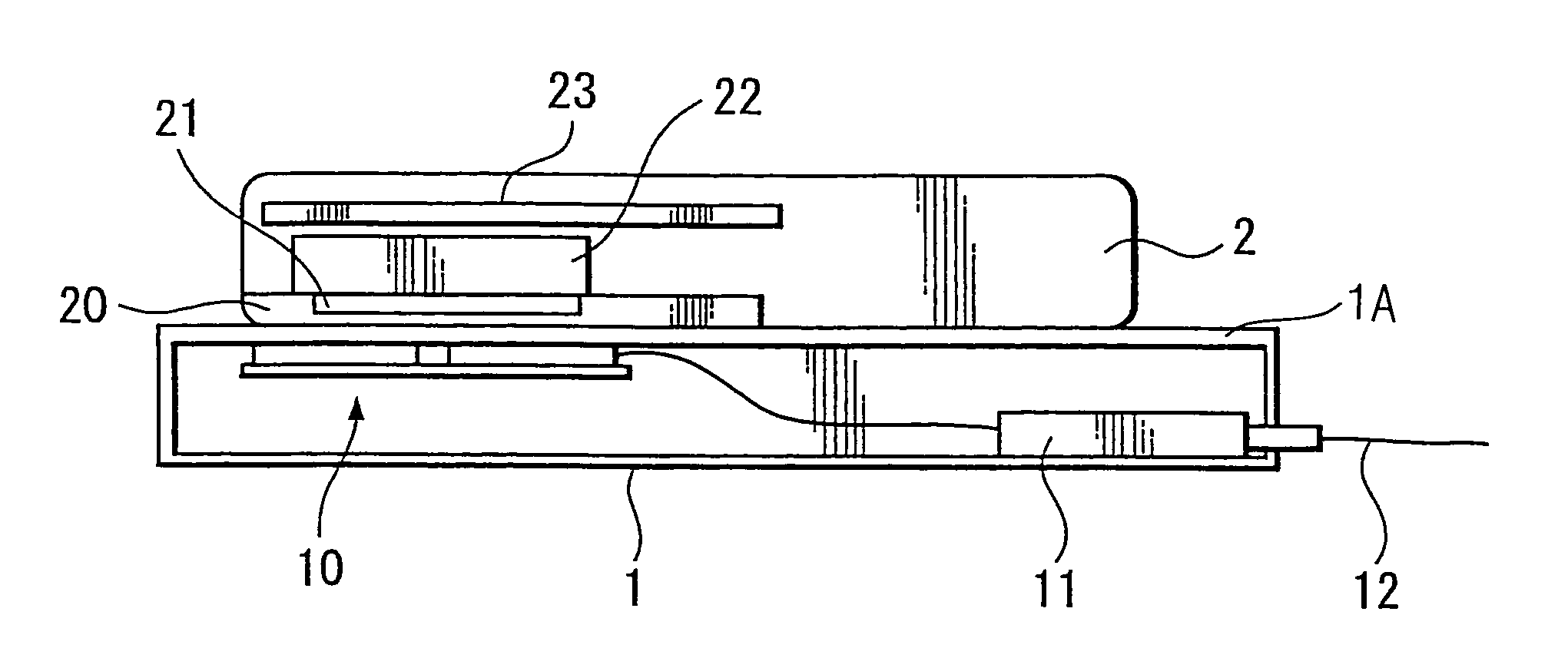

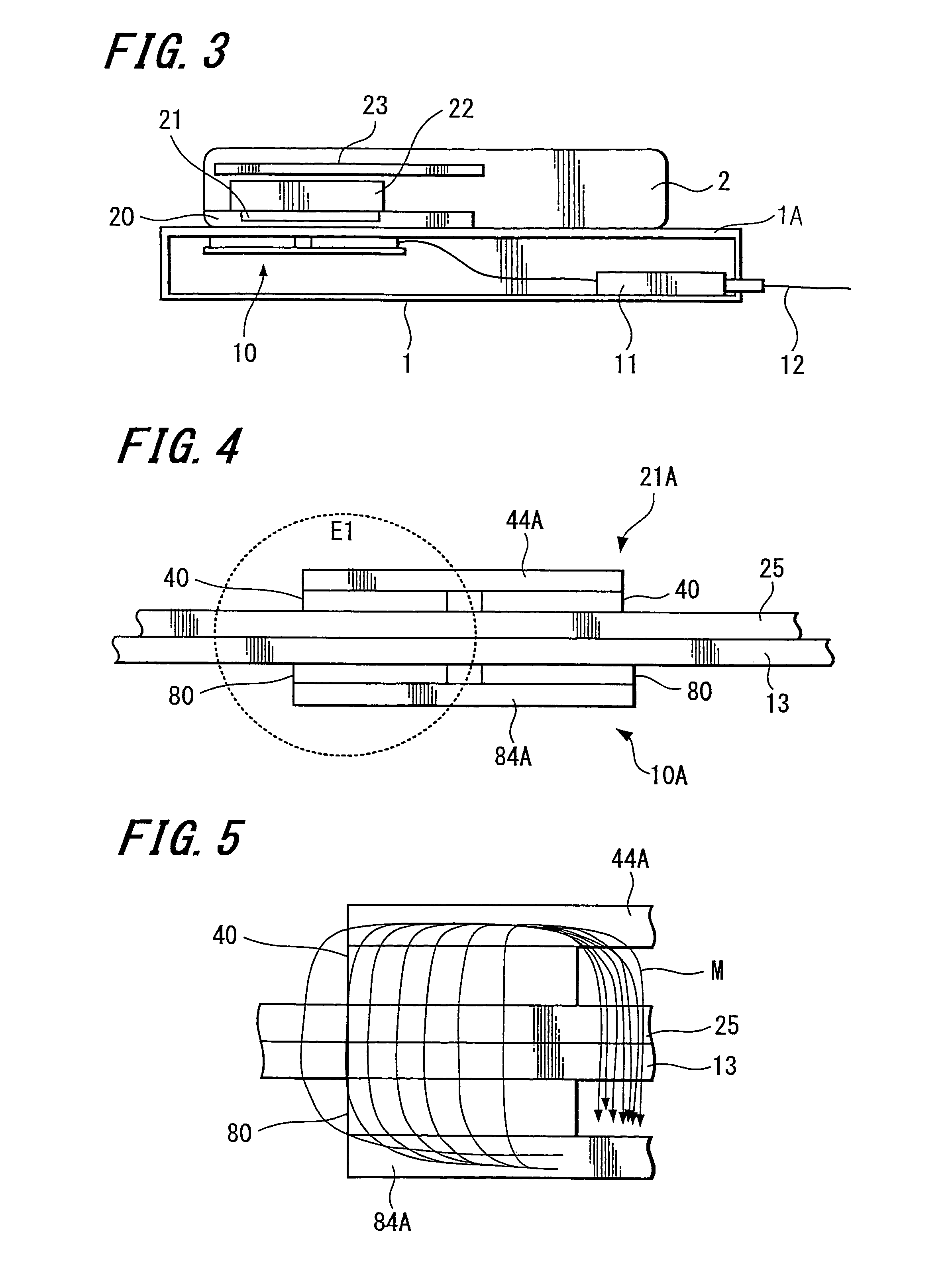

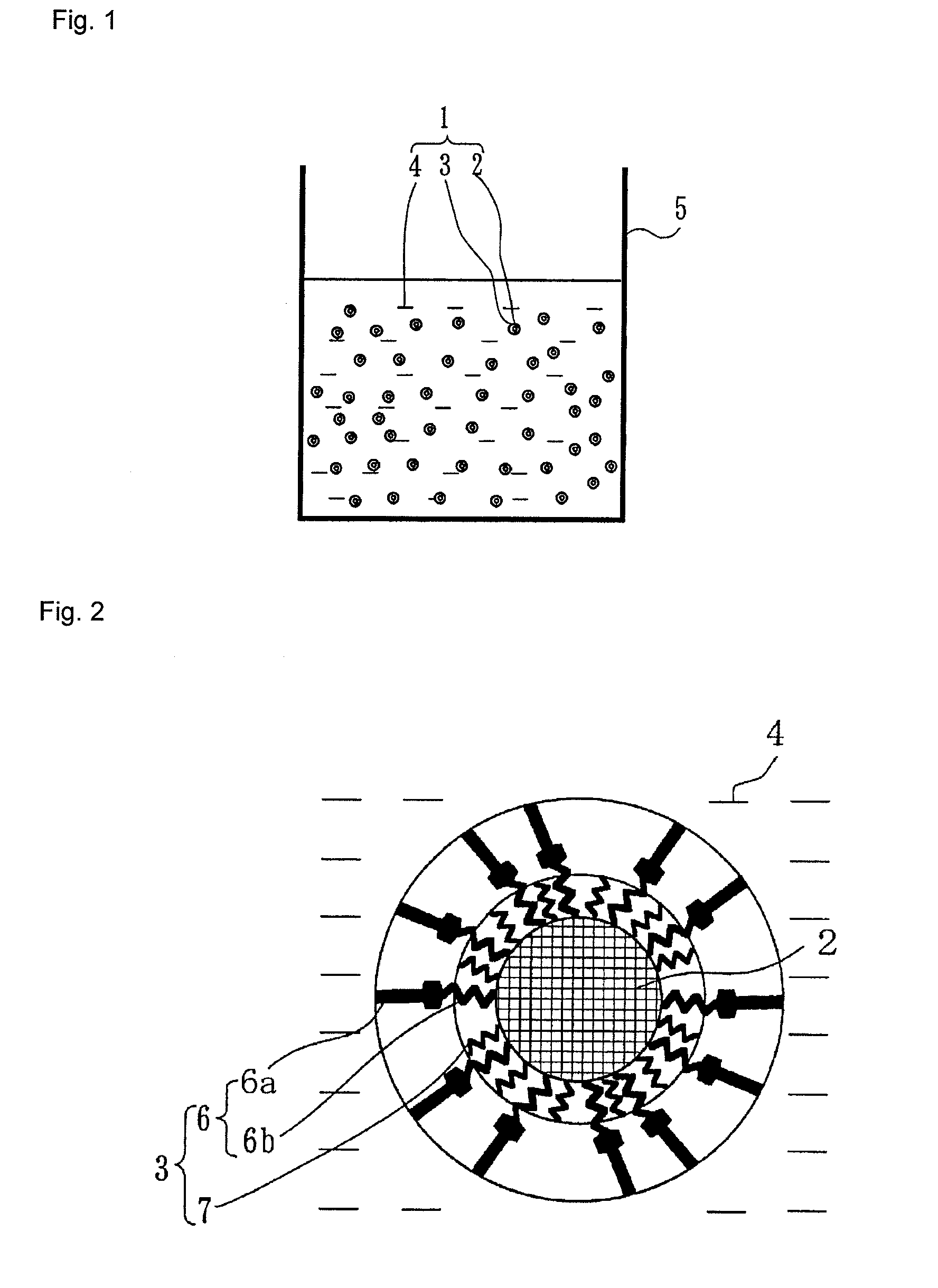

Noncontact power-transmission coil, portable terminal and terminal charging device, planar coil magnetic layer formation device, and magnetic layer formation method

ActiveUS8072304B2Reduce thicknessEfficiently formCircuit authenticationTransformers/inductances coils/windings/connectionsElectric power transmissionElectrical conductor

A noncontact power-transmission coil is provided. The noncontact power-transmission coil includes a planar coil and a magnetic layer. The planar coil is formed by winding a linear conductor in a spiral shape substantially in a single plane. The magnetic layer is formed by applying a liquid-form magnetic solution in which magnetic particles are mixed with a binder solvent, so as to cover one planar portion of the planar coil and a side-face portion of the planar coil.

Owner:SONY MOBILE COMM INC +1

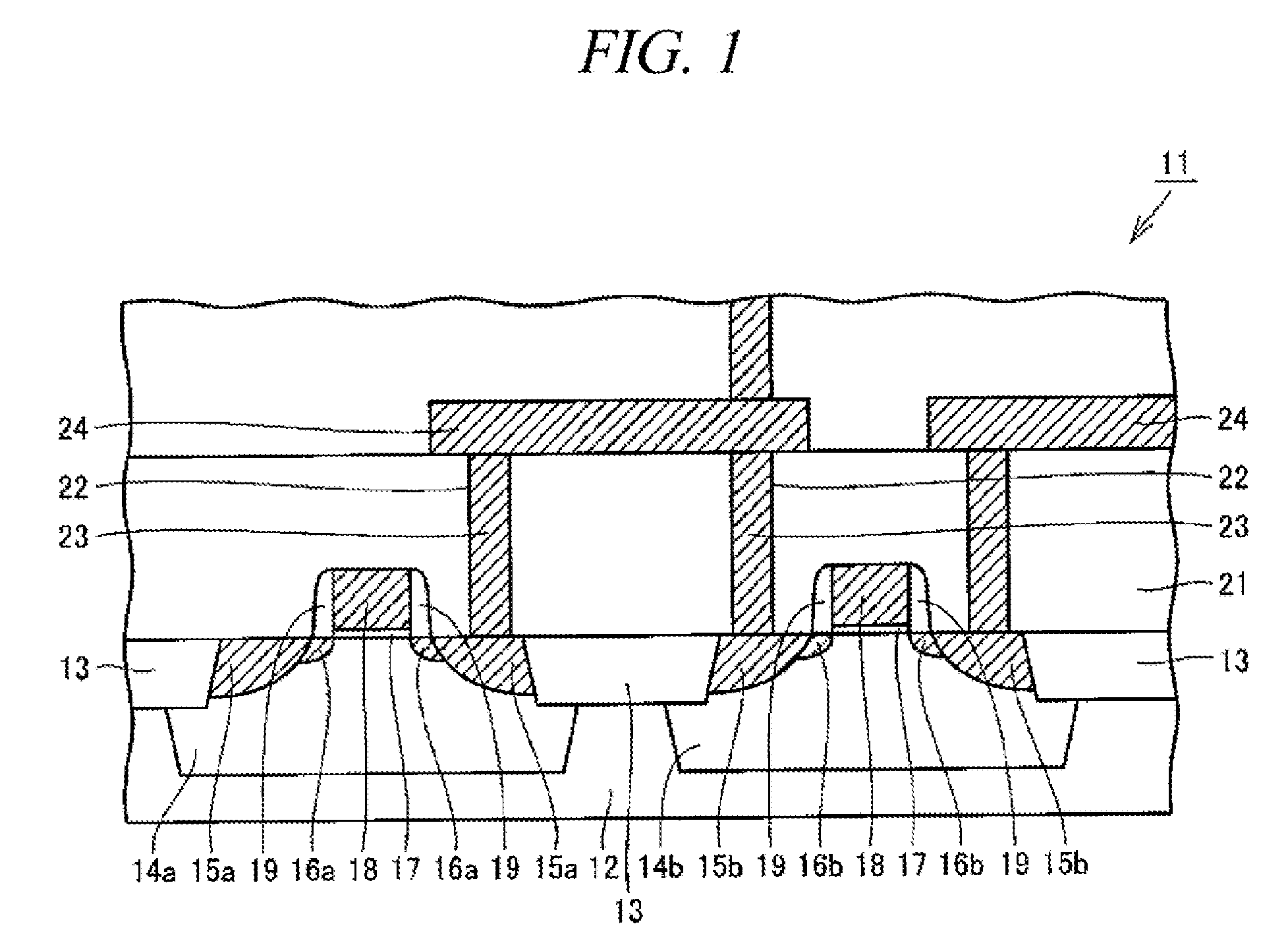

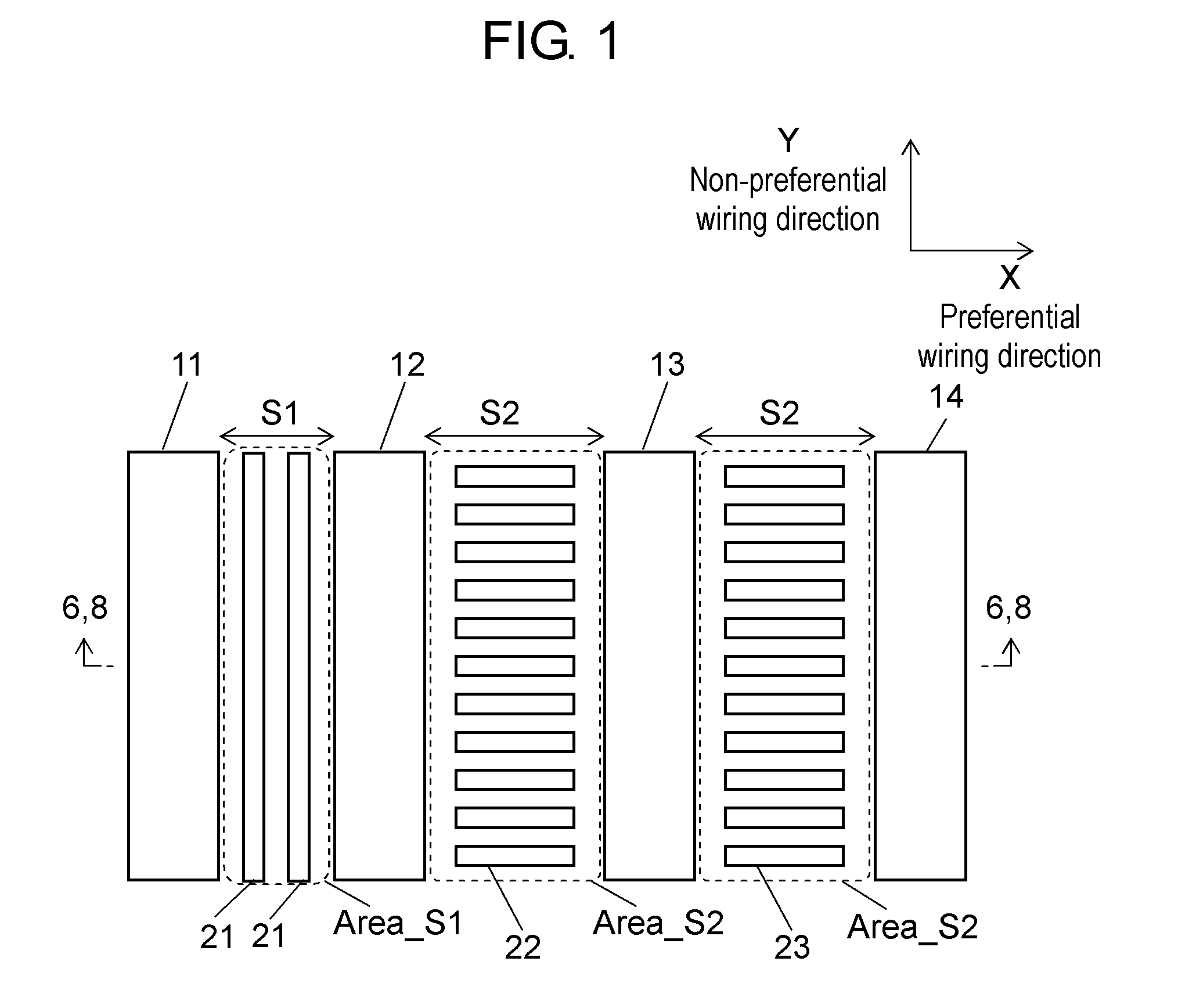

Semiconductor device

ActiveUS20120139101A1Efficiently formGrowth inhibitionSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceSemiconductor

Disclosed is a semiconductor device having a multilayer wiring structure, in which a dummy pattern is formed in a wiring void with favorable manufacturing efficiency. In a semiconductor device having a multilayer wiring structure, dummy pattern (21) is formed in relatively narrow wiring void (Area_S1) so as to extend in a direction different from that of dummy patterns (22, 23) formed in relatively wide wiring void (Area_S2).

Owner:PANASONIC CORP

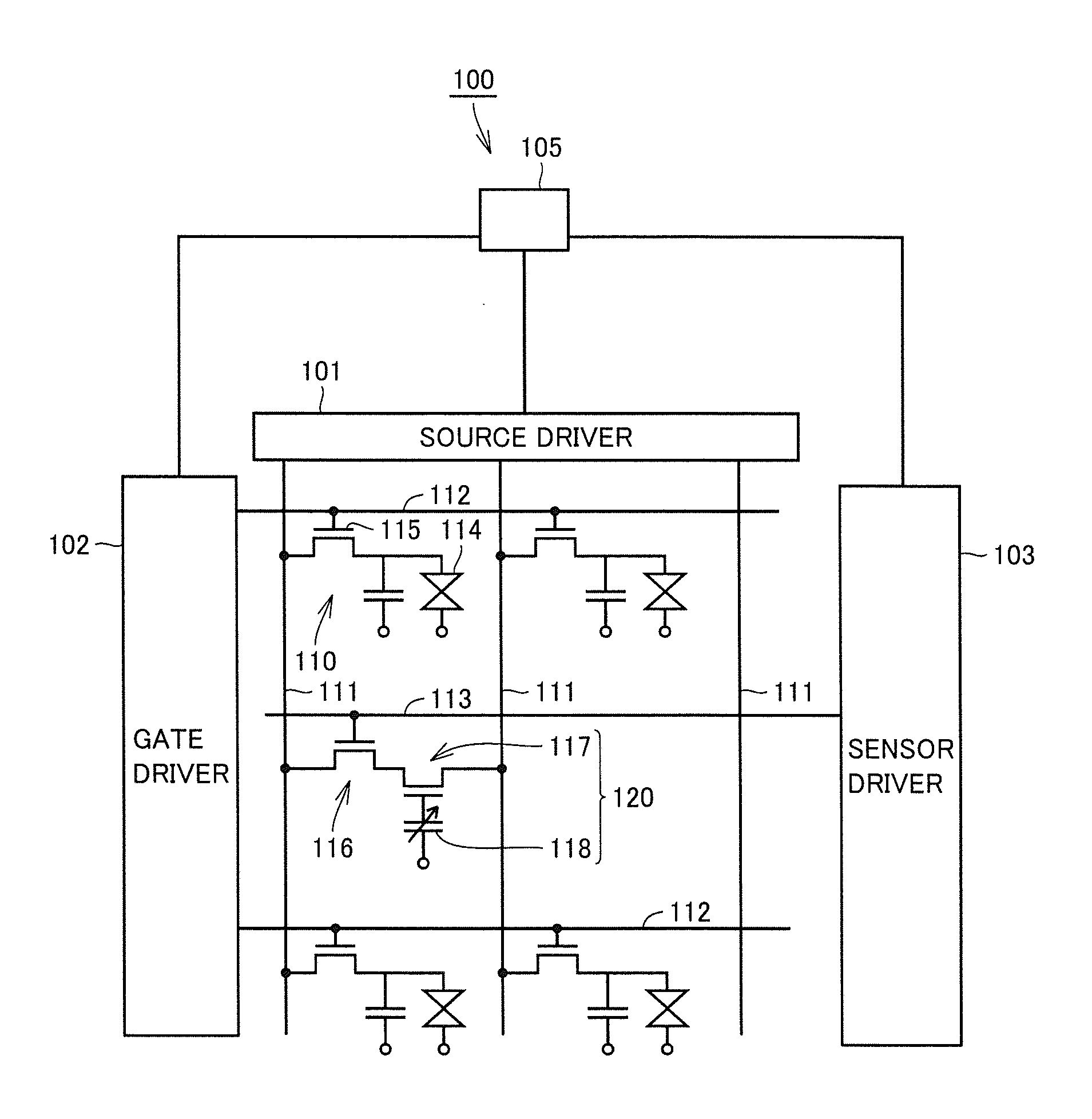

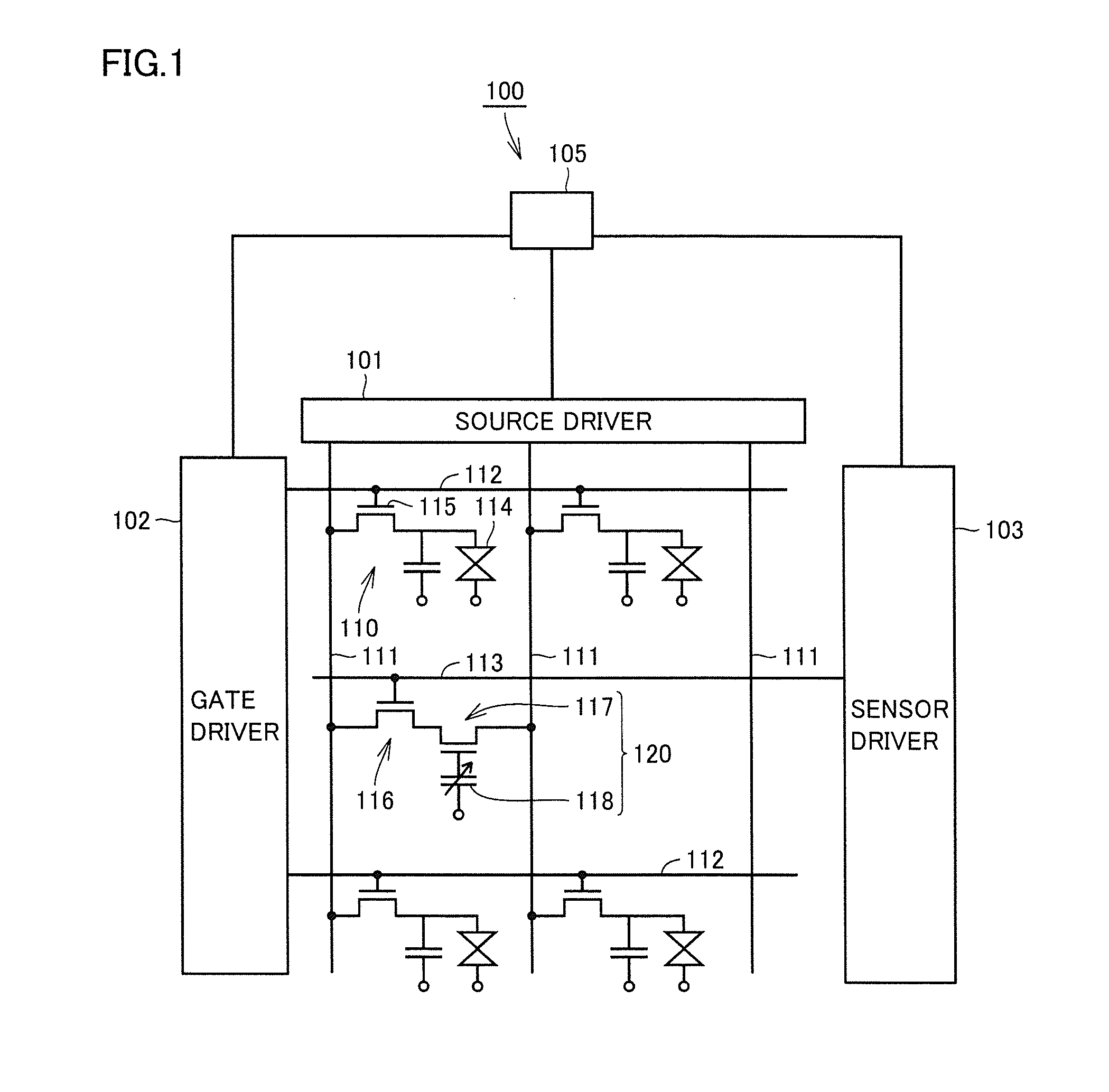

Pressure detecting device and method for manufacturing the same, display device and method for manufacturing the same, and TFT substrate with pressure detecting device

InactiveUS20130020573A1Efficiently formEfficiently formedSolid-state devicesForce measurementEngineeringDisplay device

A pressure detecting device includes a glass substrate as a substrate, a lower electrode arranged on the glass substrate, an upper electrode spaced apart from the lower electrode and facing the lower electrode, the upper electrode having holes as one or more through-openings, and a source line as a change extracting wiring for detecting a change in electrical state caused by the upper electrode receiving pressure to deflect toward the lower electrode.

Owner:SHARP KK

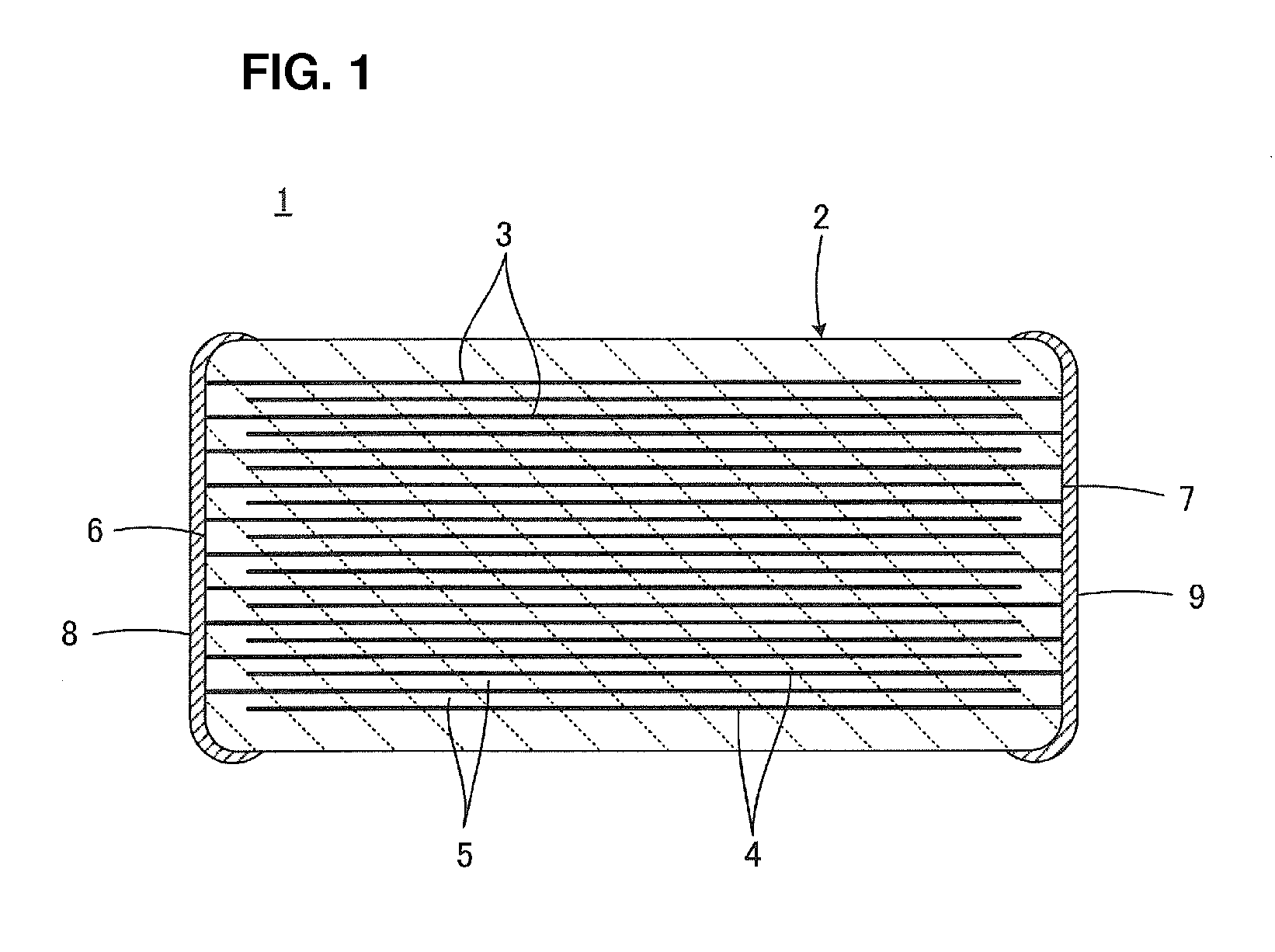

Laminate type electronic component and manufacturing method therefor

ActiveUS20120161576A1Efficiently formFixed capacitor electrodesPiezoelectric/electrostriction/magnetostriction machinesElectronic componentElectron

In a method of manufacturing a laminate type electronic component, while the distance between adjacent exposed ends of a plurality of internal electrodes is adjusted preferably to be about 50 μm or less, a plurality of conductive particles composed of Pd, Pt, Cu, Au, or Ag are provided on the surface of a component main body. The conductive particles have an average particle size of about 0.1 nm to about 100 nm, which are distributed in island-shaped configurations over the entire surface of the component main body, while the average distance between the respective conductive particles is adjusted to fall within the range of about 10 nm to about 100 nm. The component main body is subjected to electrolytic plating such that plating growth develops in and around a region including the respective exposed ends of the plurality of internal electrodes.

Owner:MURATA MFG CO LTD

Ultrafine zinc oxide particle dispersion solution, method for producing the ultrafine zinc oxide particle dispersion solution, and zinc oxide thin film

ActiveUS20110036268A1Narrow particle size distributionEfficiently formMaterial nanotechnologyCosmetic preparationsSolventSide chain

In an ultrafine ZnO particle dispersion, ultrafine ZnO particles are dispersed and float in a hydrophobic solvent while being surrounded by a surfactant composed of a primary surfactants such as polyoxyethylene nonylphenyl ether, and a secondary surfactant such as 1-octanol. The ultrafine ZnO particles have an average particle diameter D50 of 10 nm or less and a ratio of the standard deviation σ to the average particle diameter D50, σ / D50, of 0.2 or less. The average particle diameter D50 of the ultrafine ZnO particles can be controlled by changing the side chain length of the hydrophilic group of the primary surfactant. A ZnO thin film produced by using this dispersion solution has a ratio of a maximum emission intensity in a visible region to a maximum emission intensity in a ultraviolet region, P1 / P2, of 0.2 or less. Thereby, an ultrafine ZnO particle dispersion solution in which ultrafine ZnO particles having a very narrow width of particle size distribution and being in nanometer level with an average particle diameter of 10 nm or less are present in a monodispersed state, and a ZnO thin film produced by using this are realized.

Owner:MURATA MFG CO LTD

Method for manufacturing group iii nitride compound semiconductor light-emitting device, group iii nitride compound semiconductor light-emitting device, and lamp

ActiveUS20100051980A1Good uniformityEfficiently formVacuum evaporation coatingSputtering coatingSurface layerCompound semiconductor

A method for manufacturing a Group III nitride semiconductor light-emitting device according to the present invention, comprising forming, on a substrate, a semiconductor layer comprised of a Group III nitride compound semiconductor containing Ga as a Group III element by a sputtering method, wherein during the formation of the semiconductor layer, sputtering is performed under the condition where at least the surface layer of a sputtering target comprised of Ga is liquefied.

Owner:TOYODA GOSEI CO LTD

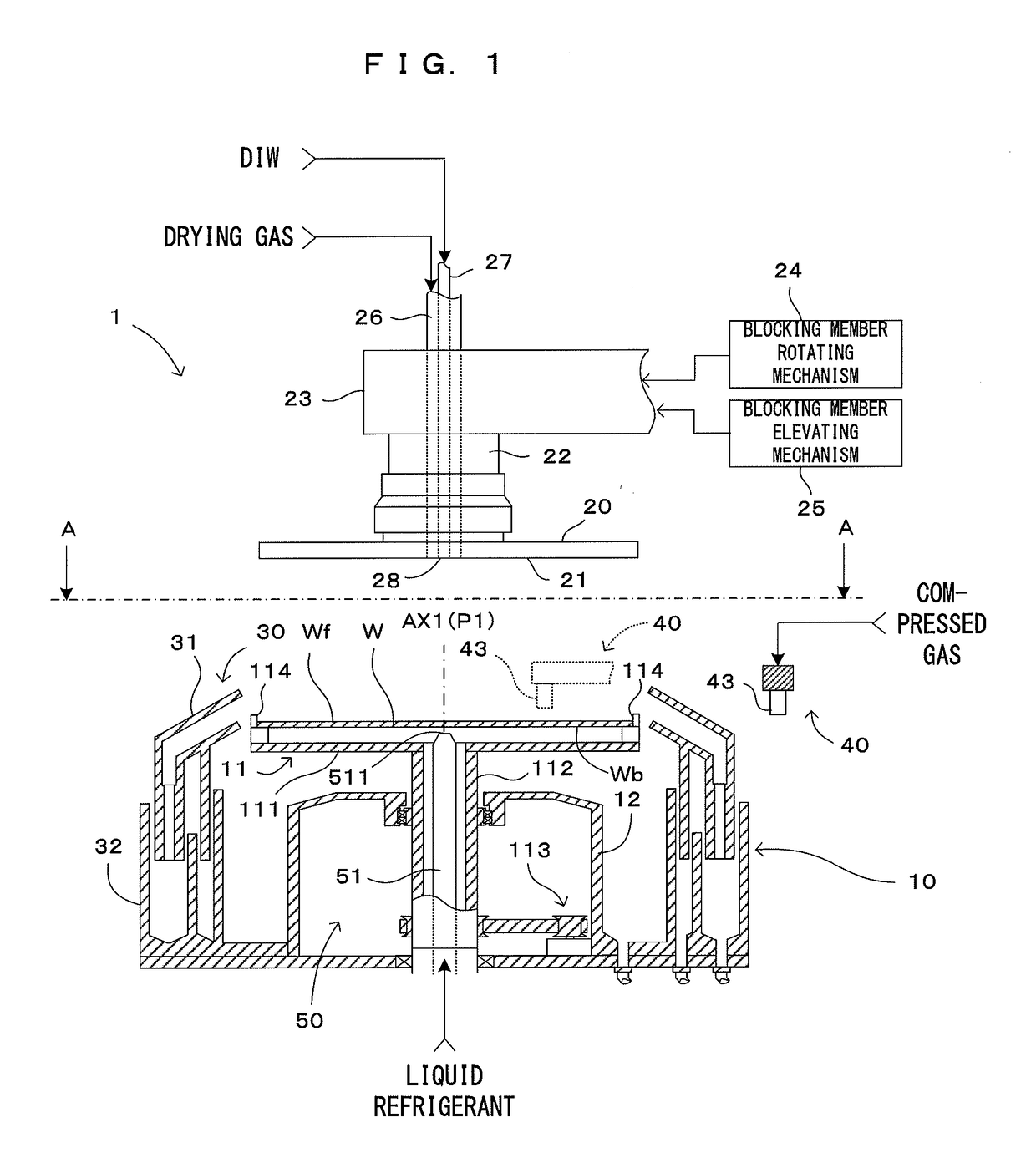

Substrate processing apparatus and substrate processing method

ActiveUS20170213725A1Efficiently formShort timeSolid-state devicesPhotomechanical apparatusRefrigerantProduct gas

A substrate processing apparatus comprises: a first solidifier and a second solidifier. The first solidifier solidifies a liquid to be solidified adhering to a front surface of a substrate by supplying a liquid refrigerant to a back surface of the substrate at a first position. The second solidifier solidifies the liquid to be solidified by at least one of a first cooling mechanism and a second cooling mechanism. The first cooling mechanism cools the liquid to be solidified by supplying a gas refrigerant toward the substrate at a second position more distant from a center of rotation of the substrate in a radial direction than the first position. The second cooling mechanism cools the liquid to be solidified by bringing a processing surface into contact with the liquid to be solidified at the second position.

Owner:SCREEN HLDG CO LTD

Controller for solid state disk which controls access to memory bank

ActiveUS20110276740A1Reduce delaysAvoid difficult choicesMemory architecture accessing/allocationMemory adressing/allocation/relocationMemory bankEngineering

A controller for a solid state disk is provided. The controller includes a storage module to store an index of at least one idle bank among a plurality of memory banks, and a control module to control an access to the at least one idle bank using the stored index. Here, the access to the at least one idle bank may be controlled based on a state of a channel corresponding to each of the at least one idle bank.

Owner:KIOXIA CORP

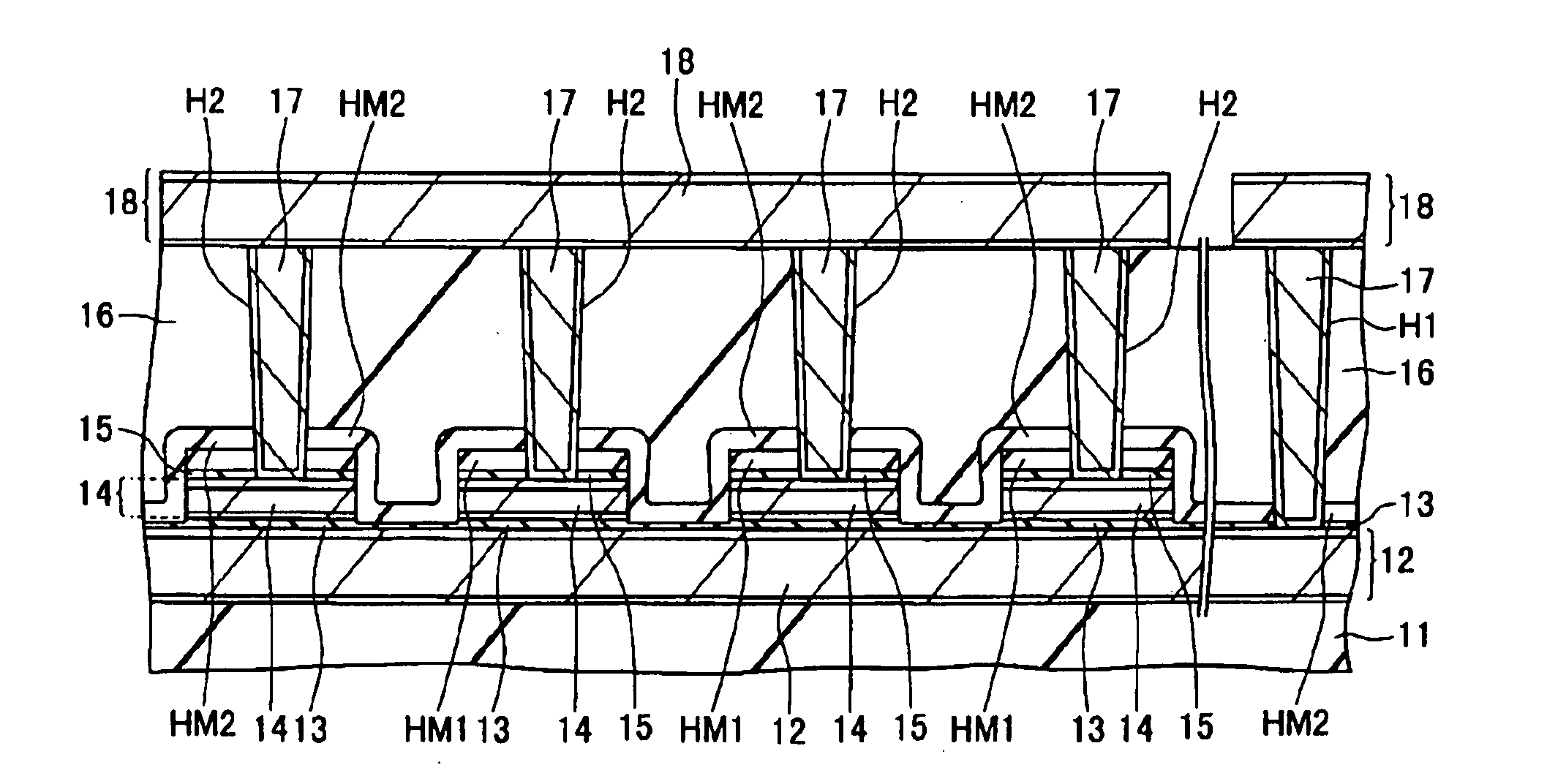

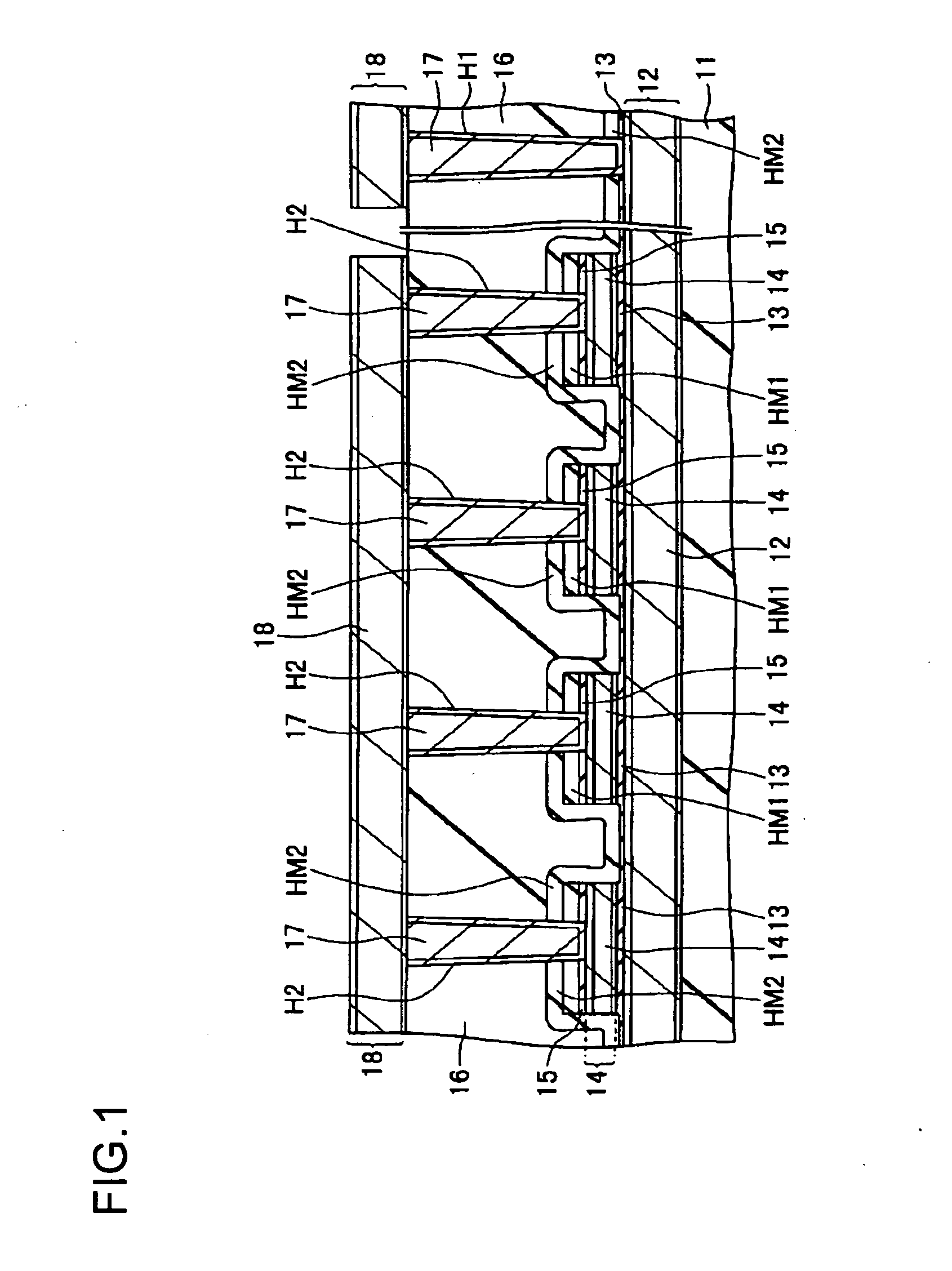

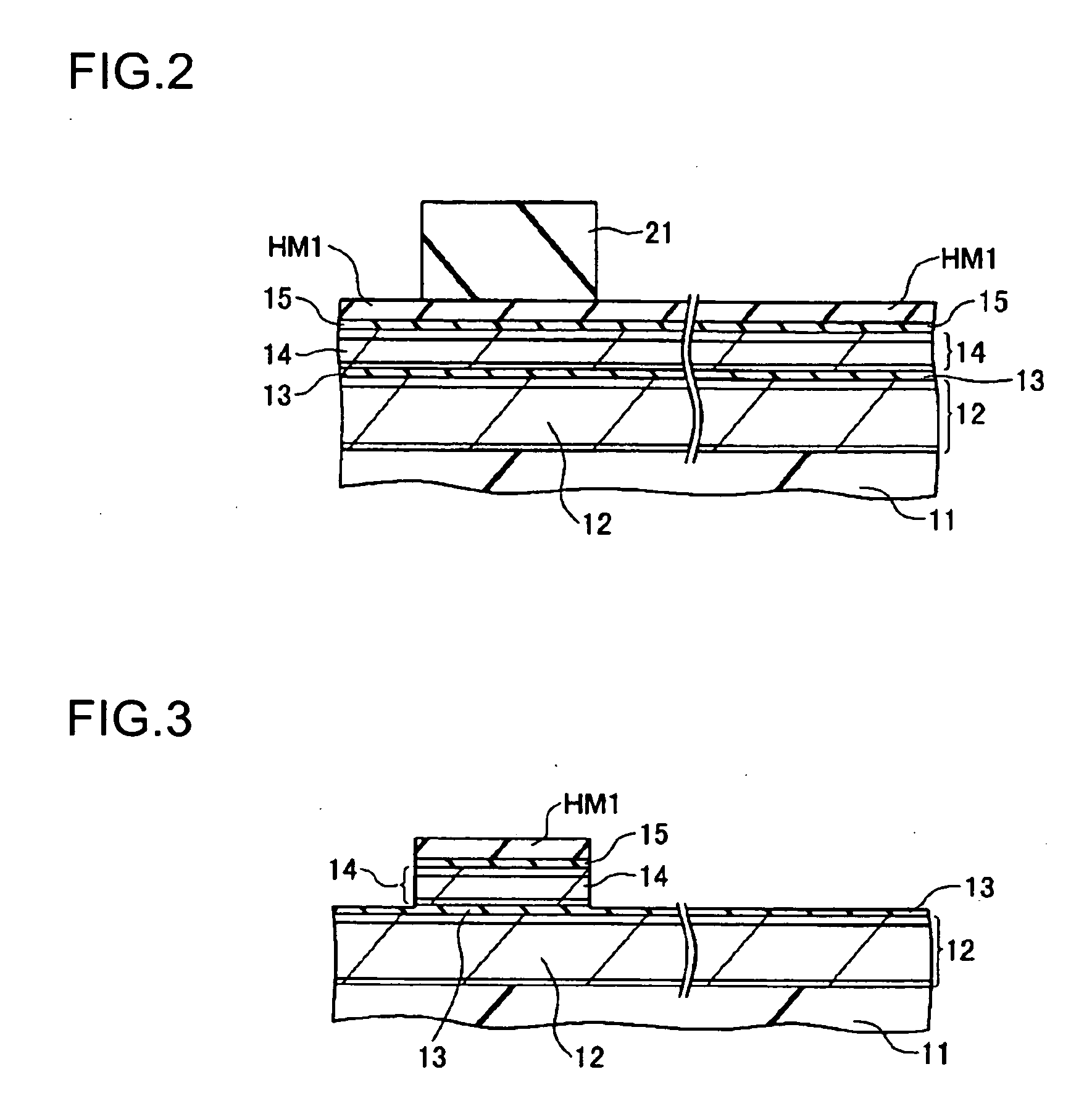

Semiconductor device and method of manufacturing the same

InactiveUS20050020025A1Reduce layer thicknessEfficiently formedSemiconductor/solid-state device detailsSolid-state devicesDevice materialProtection layer

A semiconductor device including an MIM capacitor is provided. A first metal wiring layer is patterned together with a first hard mask member and forms a lower capacitor electrode. A second metal wiring layer is formed on the first metal wiring layer with a capacitor insulating film therebetween and is patterned together with a protection layer and a second hard mask member which remains under the first hard mask member. The second metal wiring layer forms a plurality of upper capacitor electrodes. A third metal wiring layer connected with the first or second metal wiring layer is patterned on an insulating film. The third metal wiring layer includes a connection with a plug wiring member provided within a first or second contact hole.

Owner:SEIKO EPSON CORP

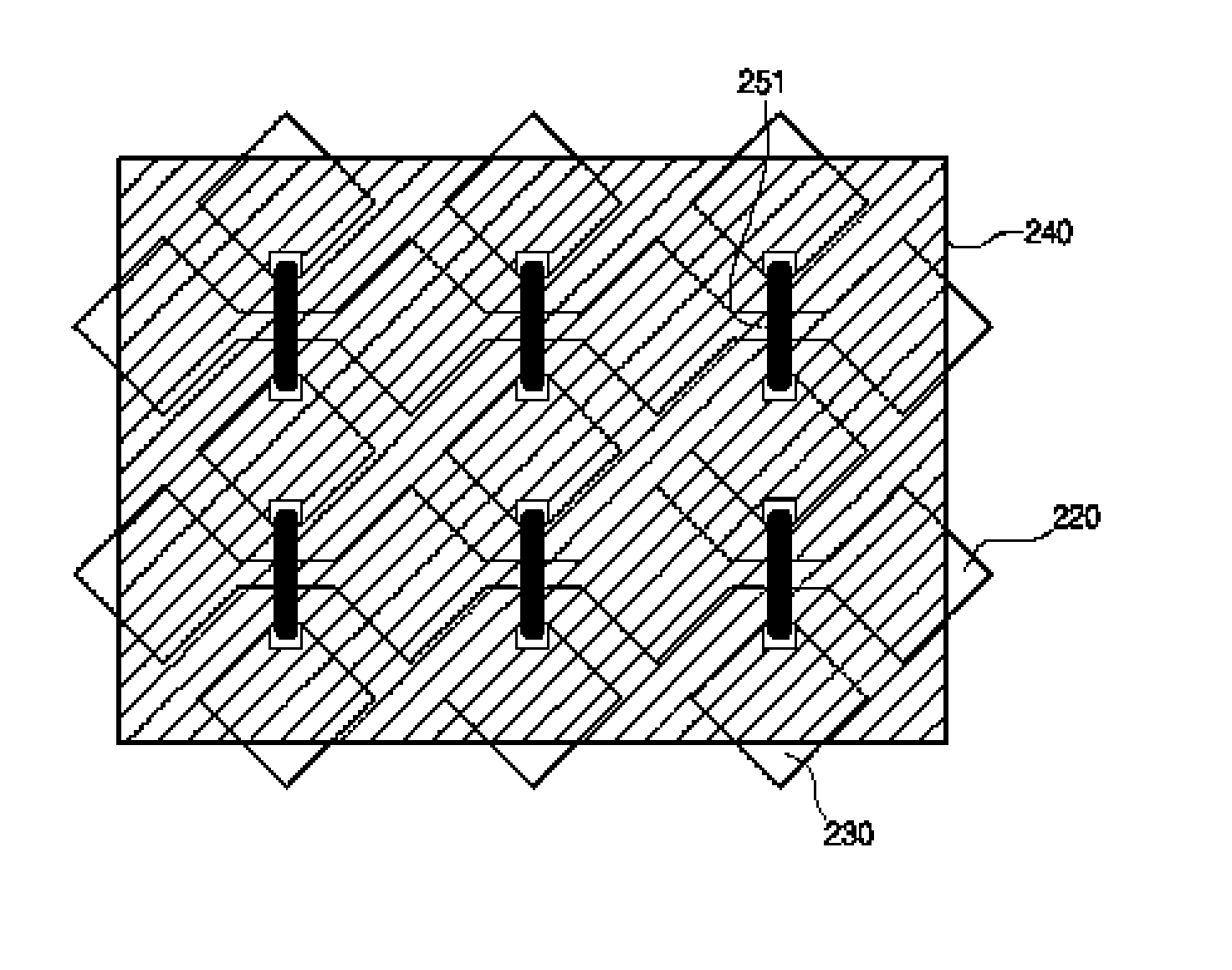

Electrode pattern of touch panel and method of manufacturing the same

InactiveUS20140347579A1Efficiently formReduce thicknessConductive layers on insulating-supportsCable/conductor manufactureTouch panelEngineering

Provided is an electrode panel of a touch panel and a method of manufacturing the same, the method, including: forming a plurality of electrode pattern cells on a substrate to be space apart from each other; forming an insulating layer on the electrode pattern cells; forming a hole on the insulating layer; and forming a bridge electrode and fills the hole with a conductive material.

Owner:LG INNOTEK CO LTD

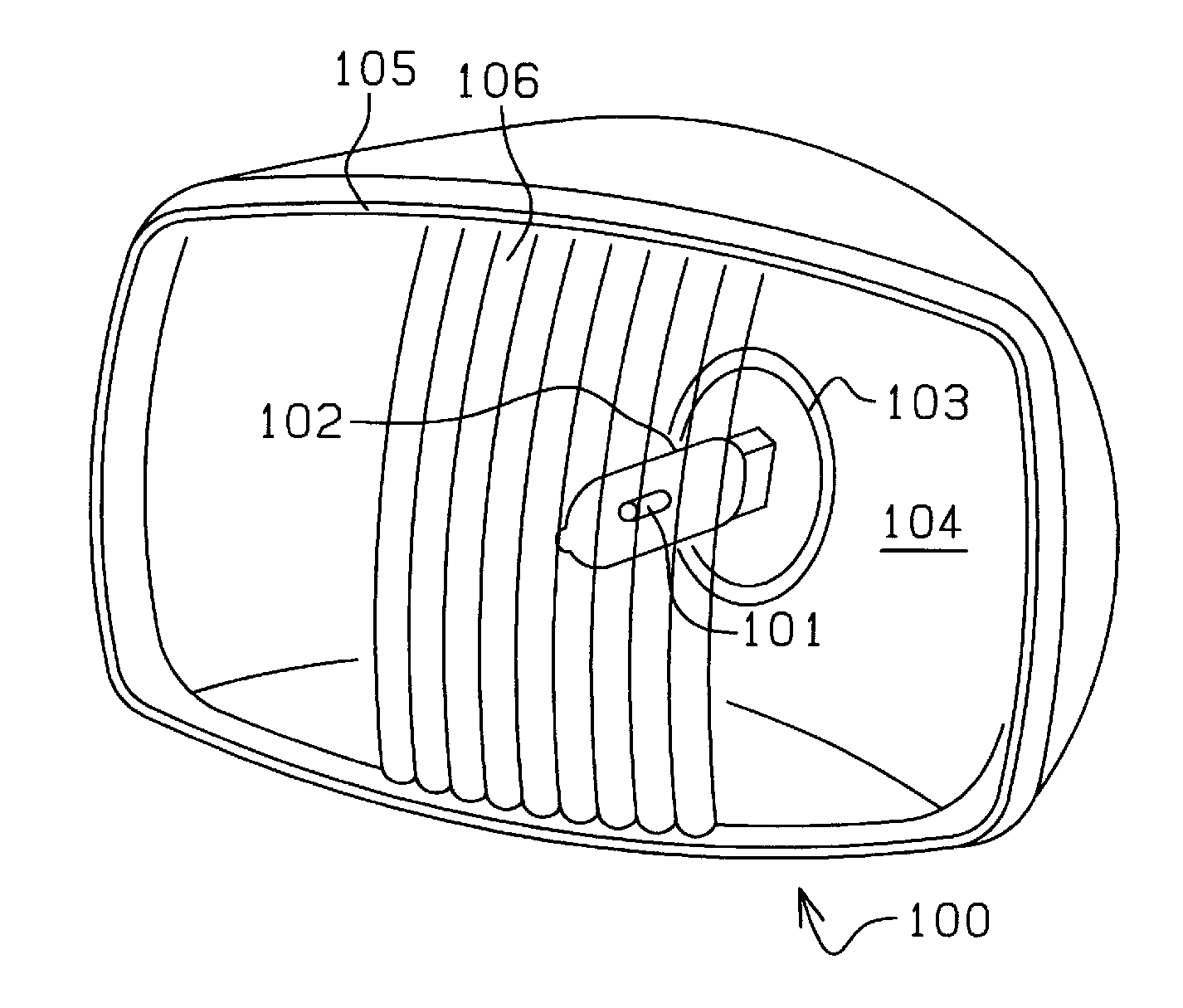

Vehicle light

InactiveUS20070127251A1Efficiently formHigh distance visibilityNon-electric lightingVehicle headlampsOptoelectronicsLight source

A vehicle light can include a light source, a reflector configured to reflect light emitted from the light source in an irradiation direction of a vehicle on which the vehicle light is mounted, and a diffusion plate for diffusion of light and which can irradiate light in the irradiation direction. In this configuration, the diffusion plate can be configured such that light emitted from the light source and light reflected by the reflector enter the diffusion plate and pass therethrough while being refracted. The light is emitted from the diffusion plate in the irradiation direction while being diffused. At the same time, light which is incident on the diffusion plate and is reflected by the diffusion plate is diffused and irradiated in the irradiation direction of the vehicle light. The end portion of the diffusion plate can be bent or curved so as to diffuse the light reflected by the diffusion plate.

Owner:STANLEY ELECTRIC CO LTD

Artificial Blood Vessel and Method for Manufacturing Thereof

InactiveUS20080085544A1Efficiently formEfficiently formedImmobilised enzymesArtificial cell constructsNutrientAdhesion process

An artificial tissue capable of carrying necessary nutrients for maintaining activities of cells and tissues, and a method of manufacturing an artificial blood vessel. A plurality of forms of blood vessels are extracted from an image of a living tissue and made into a blood vessel form image. Each of the blood vessel forms of the blood vessel form image is adjusted and a blood vessel formation pattern is formed. A blood vessel cell culturing pattern of forming is formed, in a cell culturing layer. The blood vessel cell culturing pattern includes: a cell adhesion portion having adhesive properties with a blood vessel cell and formed to the blood vessel formation pattern; and a cell adhesion-inhibiting portion having cell adhesion-inhibiting properties for inhibiting adhesion with a blood vessel cell and formed in an area other than the cell adhesion portion. A blood vessel cell is adhered to the cell adhesion portion, and cultured into a tissue.

Owner:DAI NIPPON PRINTING CO LTD

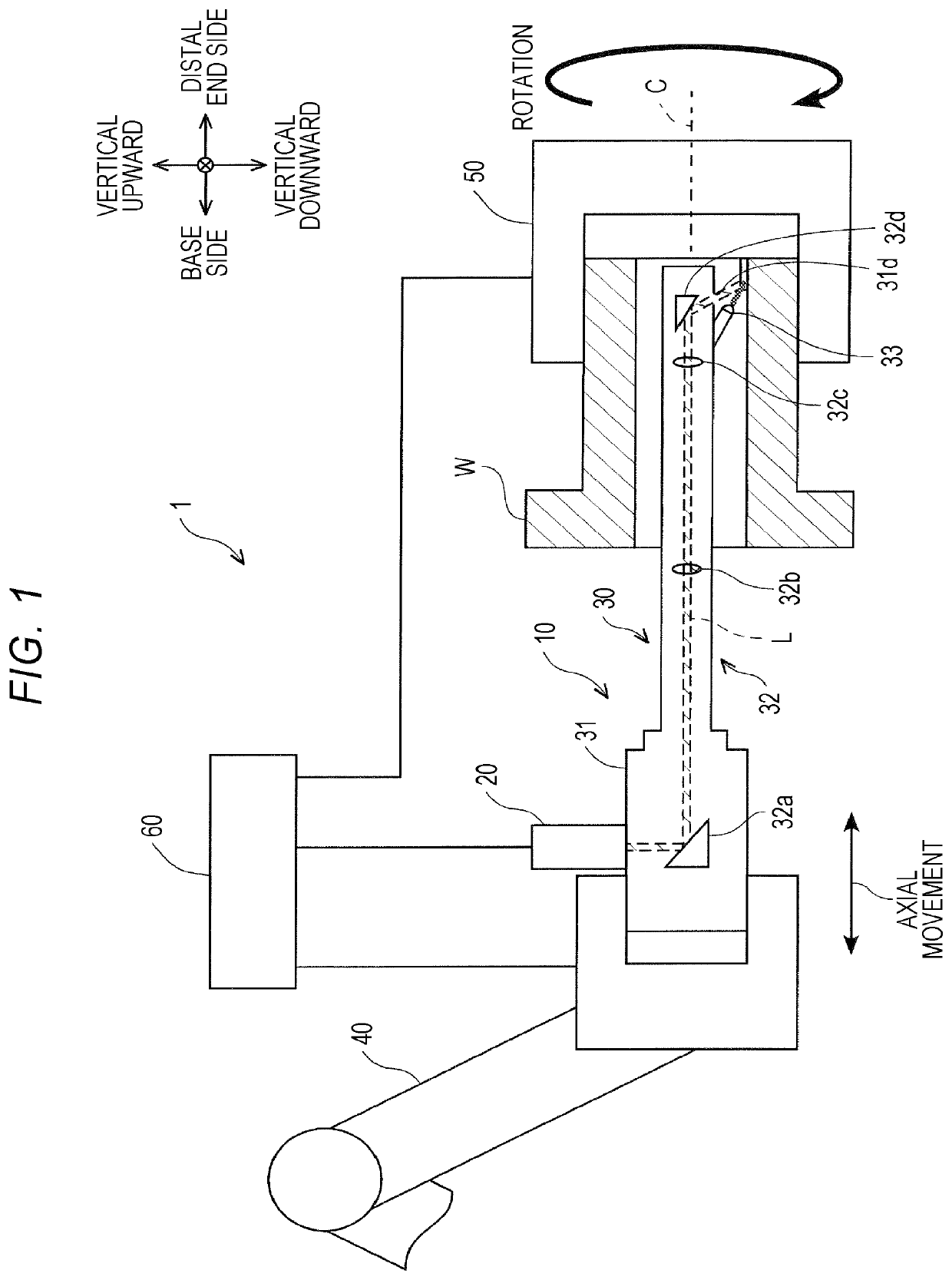

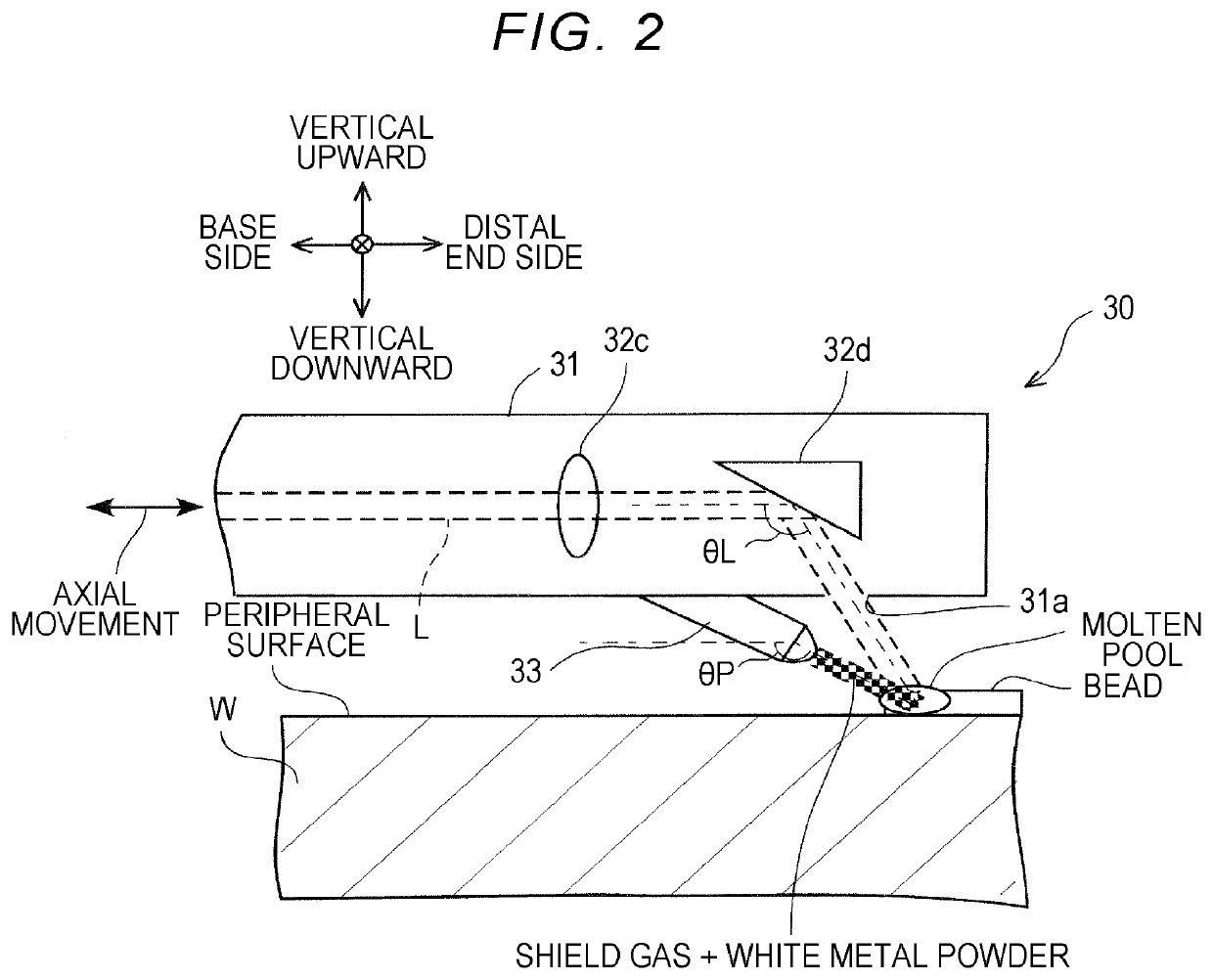

Laser clad layer forming method and laser cladding device

InactiveUS20200248315A1Efficiently formPrevent sagMetallic material coating processesLaser beam welding apparatusAngular rangeEngineering

A laser clad layer forming method includes a partitioning process of partitioning a formation-scheduled portion for a laser clad layer on a peripheral surface of a workpiece into areas; a phase determining process of holding the workpiece such that an axial direction thereof is horizontal and determining a phase of the workpiece such that a direction of a normal to the peripheral surface of the workpiece in one area is within a predetermined angle range with respect to a vertical upward direction; and a forming process of irradiating a powder with a laser beam while supplying the powder to the one area in a state in which the phase of the workpiece is determined and melting the powder to form a bead. The laser clad layer is formed by repeating the phase determining process and the forming process on the areas to form the beads in the whole formation-scheduled portion.

Owner:JTEKT CORP

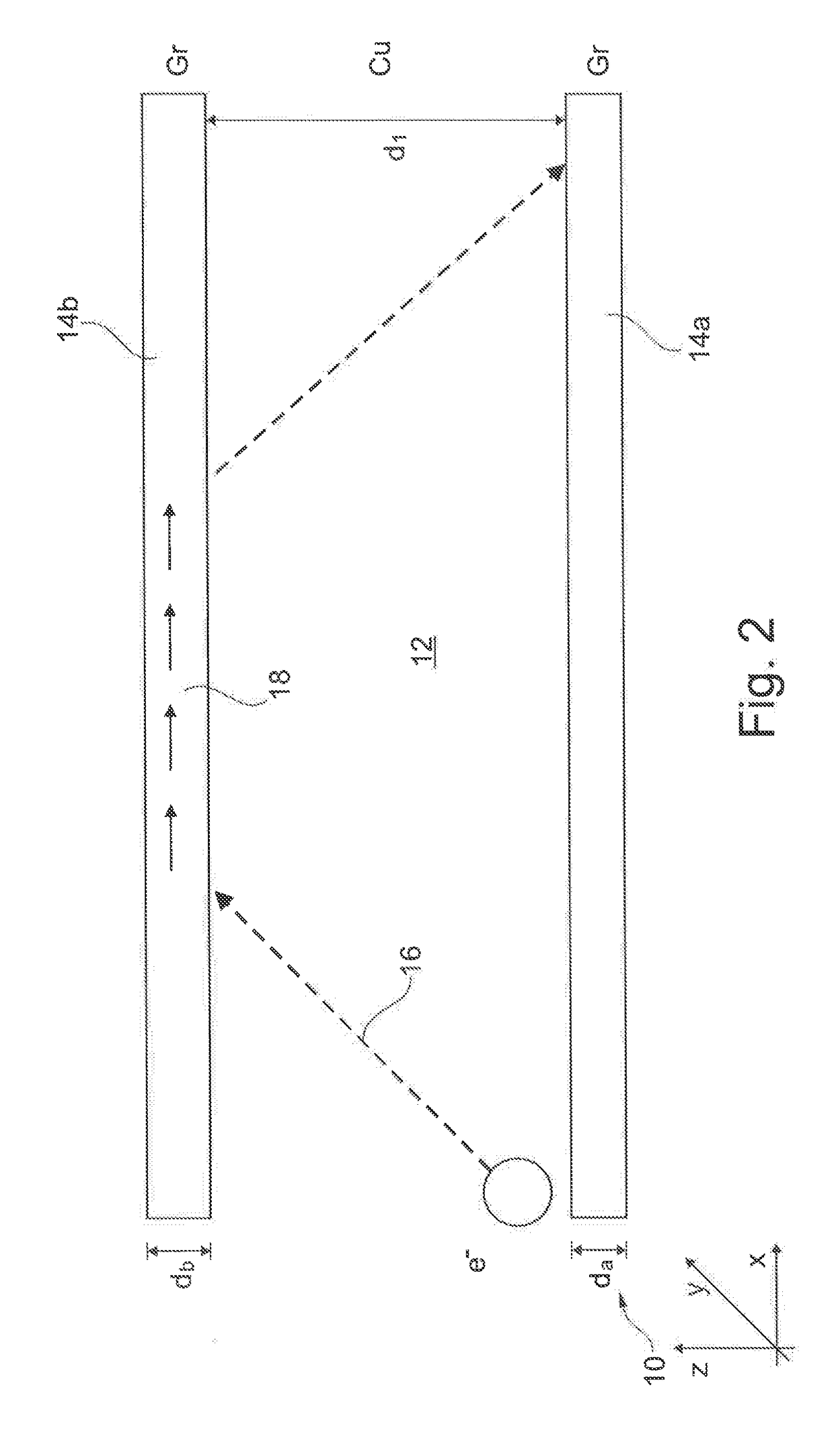

Wire-Drawing Method and System

ActiveUS20190066882A1Simple technologyEfficiently formDrawing diesApparatus for feeding conductors/cablesEngineeringCopper

A wire-drawing method comprises providing a rod comprising a wrapped sheet, wherein the sheet comprises a plurality of copper layers and a plurality of graphene layers; extracting an inner layer of the wrapped sheet from the rod to form a spiral; and forming a wire by feeding the spiral through an opening of a die unit.

Owner:ULTRA CONDUCTIVE COPPER CO INC

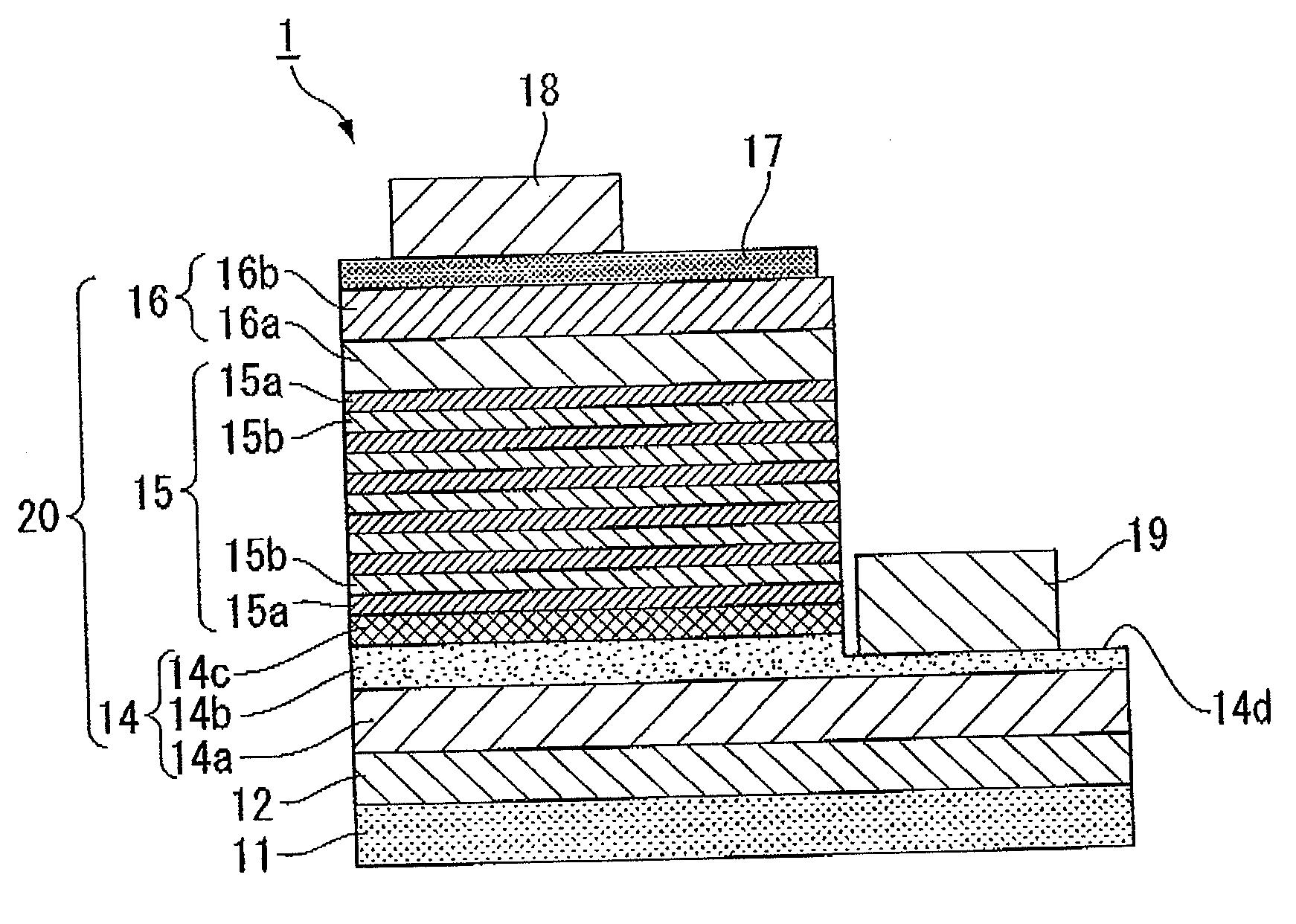

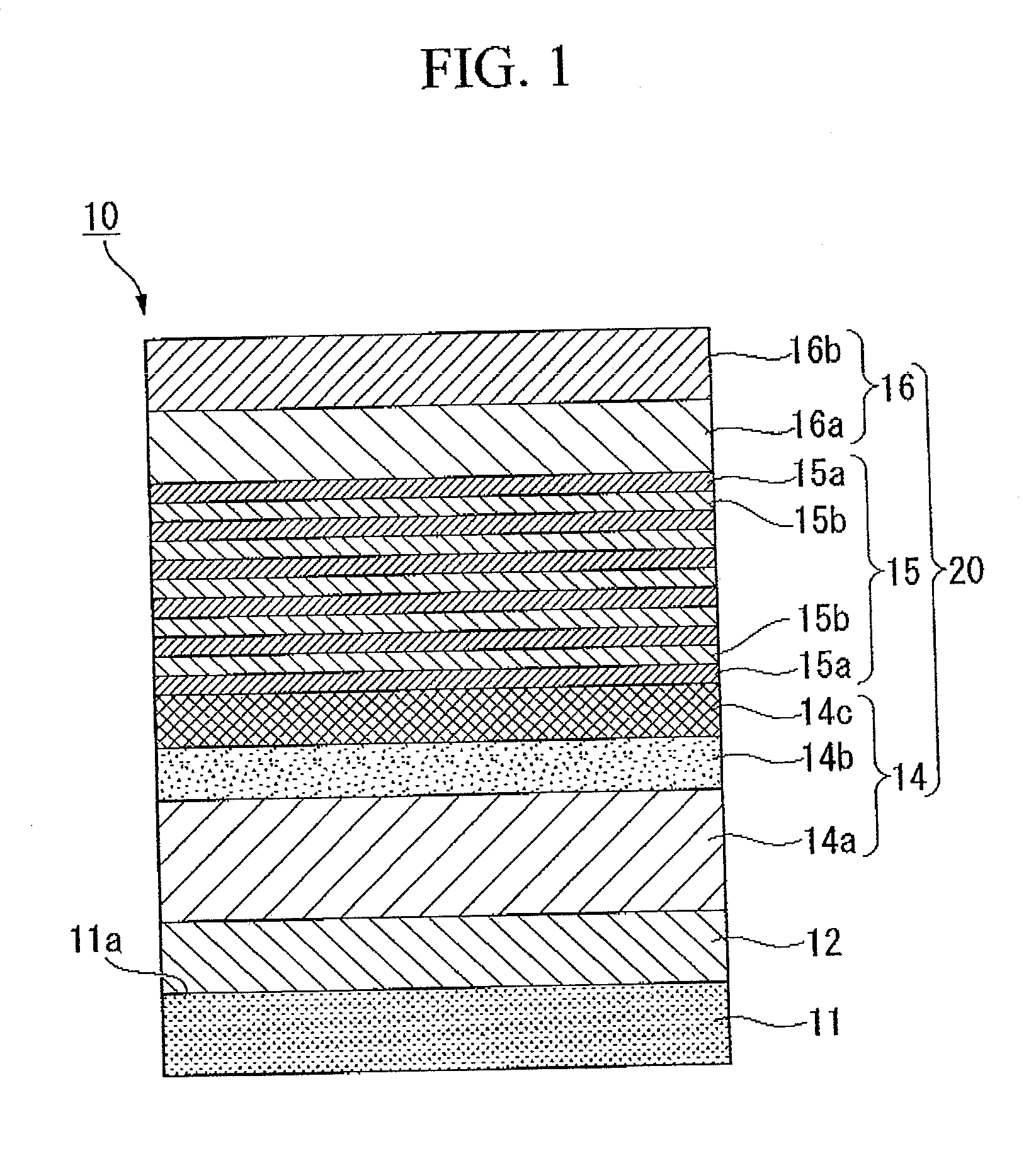

Light emitting device and optical coupling module

ActiveUS20100158440A1Efficiently formEfficiently formedSolid-state devicesCoupling light guidesComputer moduleOptical coupling

Provided are a light emitting device and an optical coupling module. The device includes a substrate, a light emitting part provided to the substrate, and a reflecting part provided to a lower surface of the substrate. The light emitting part includes an active pattern disposed on the substrate, an upper mirror provided to an upper portion of the active pattern, and a lower mirror provided to a lower portion of the active pattern. The light emitting part may emit light normal to the substrate, and the reflecting part may reflect the emitted light to a side surface of the substrate.

Owner:ELECTRONICS & TELECOMM RES INST

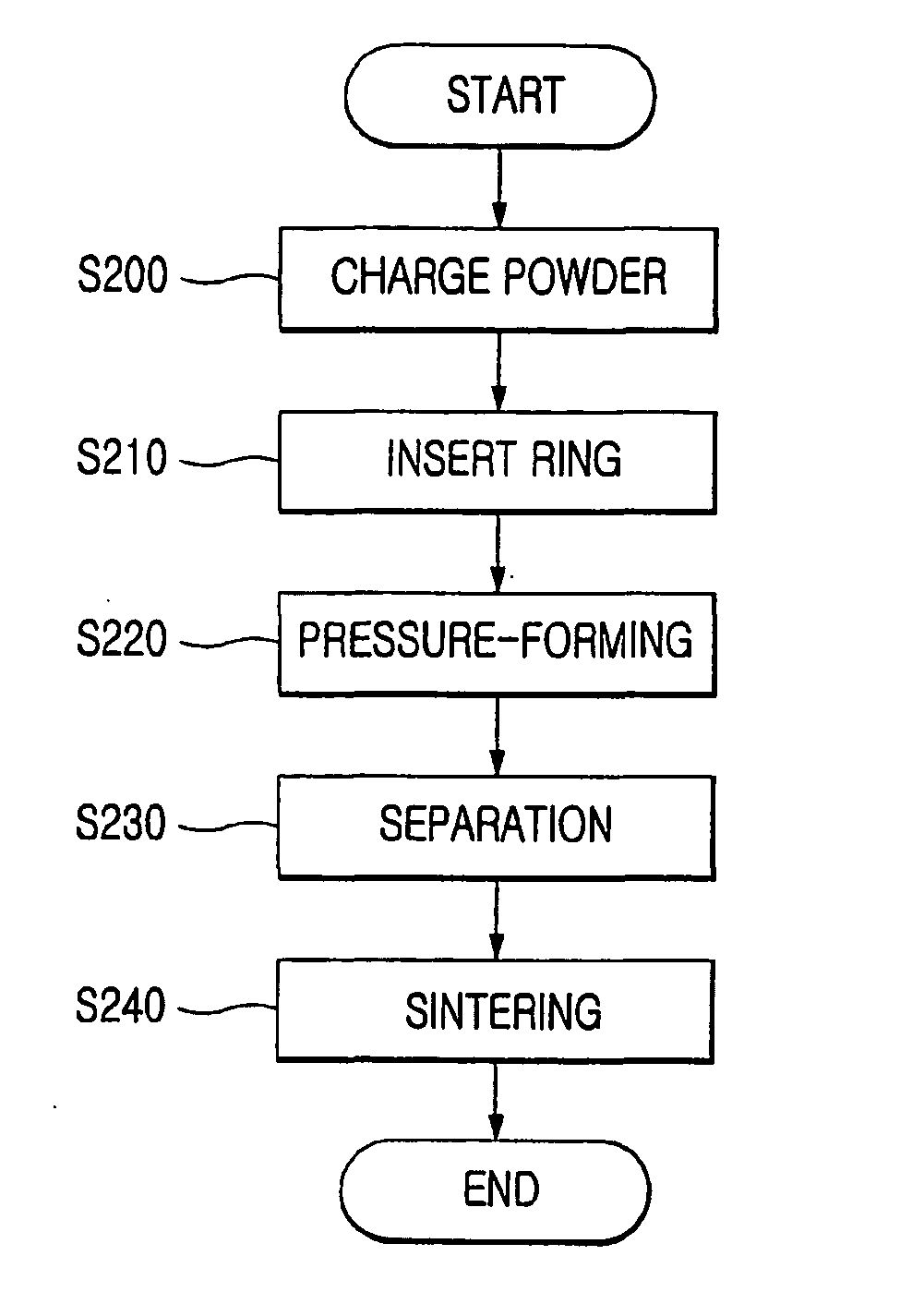

Method for manufacturing flange for compressor

InactiveUS20040071582A1Efficiently formExcellent strength and sealingMetal-working apparatusMachines/enginesMetallurgyFlange

Owner:KOREA SINTERED METAL

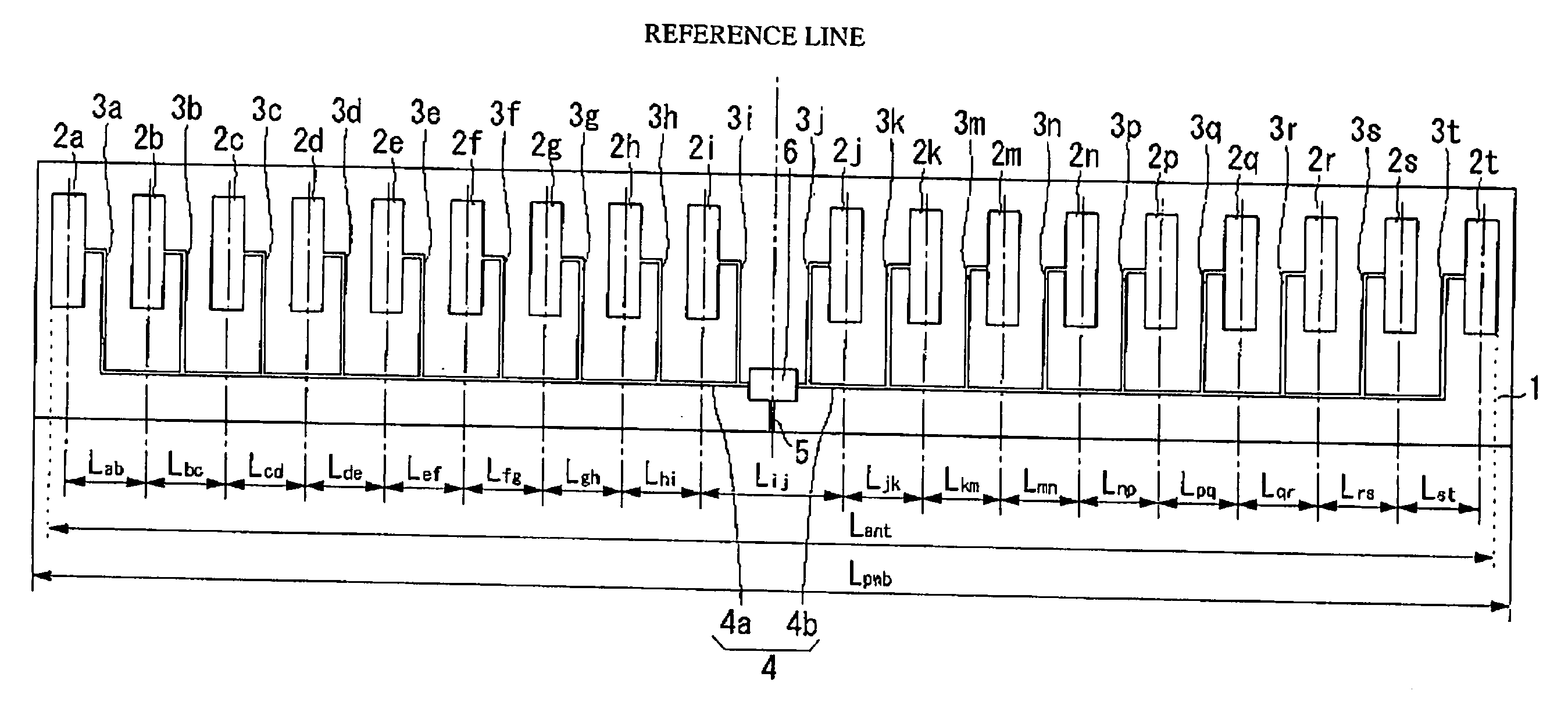

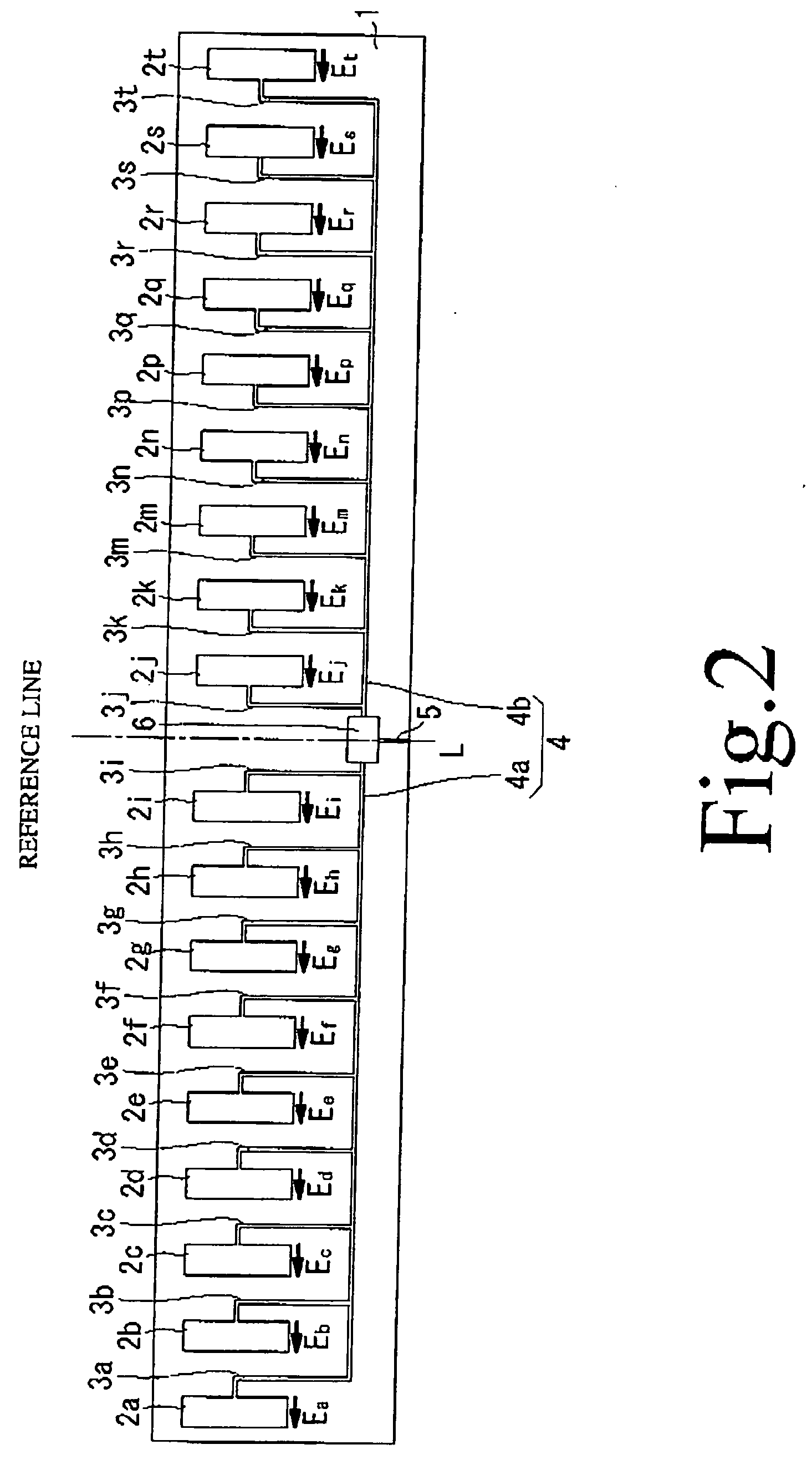

Array antenna

ActiveUS20050259028A1Efficiently formDesired directivityParticular array feeding systemsSimultaneous aerial operationsFeed lineEngineering

Antenna elements are arranged in line on a surface of a substrate at specific intervals along a longitudinal direction of the substrate. A phase-inverting distributor is formed on the surface of the substrate in an area located between two antenna elements which are closest to and located on both sides of a vertical centerline, or a reference line, of the substrate. A primary feeder line formed along the longitudinal direction of the substrate extends from the phase-inverting distributor on both left and right sides thereof. The individual antenna elements are connected to the primary feeder line by secondary feeder lines having predetermined impedances. The secondary feeder lines are connected to the respective antenna elements on sides thereof which are perpendicular to the longitudinal direction of the substrate and face the reference line on which the phase-inverting distributor is located.

Owner:FURUNO ELECTRIC CO LTD

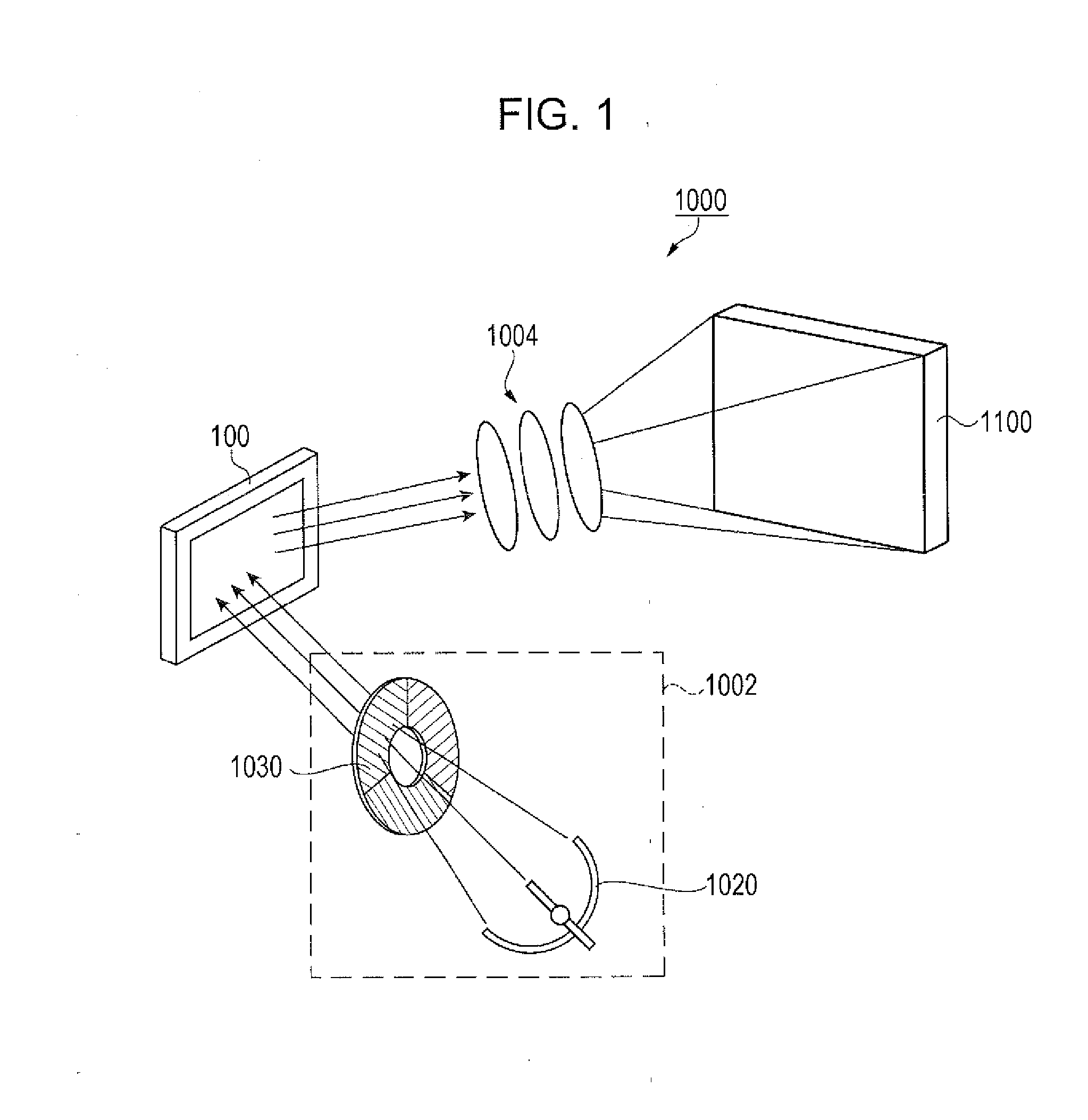

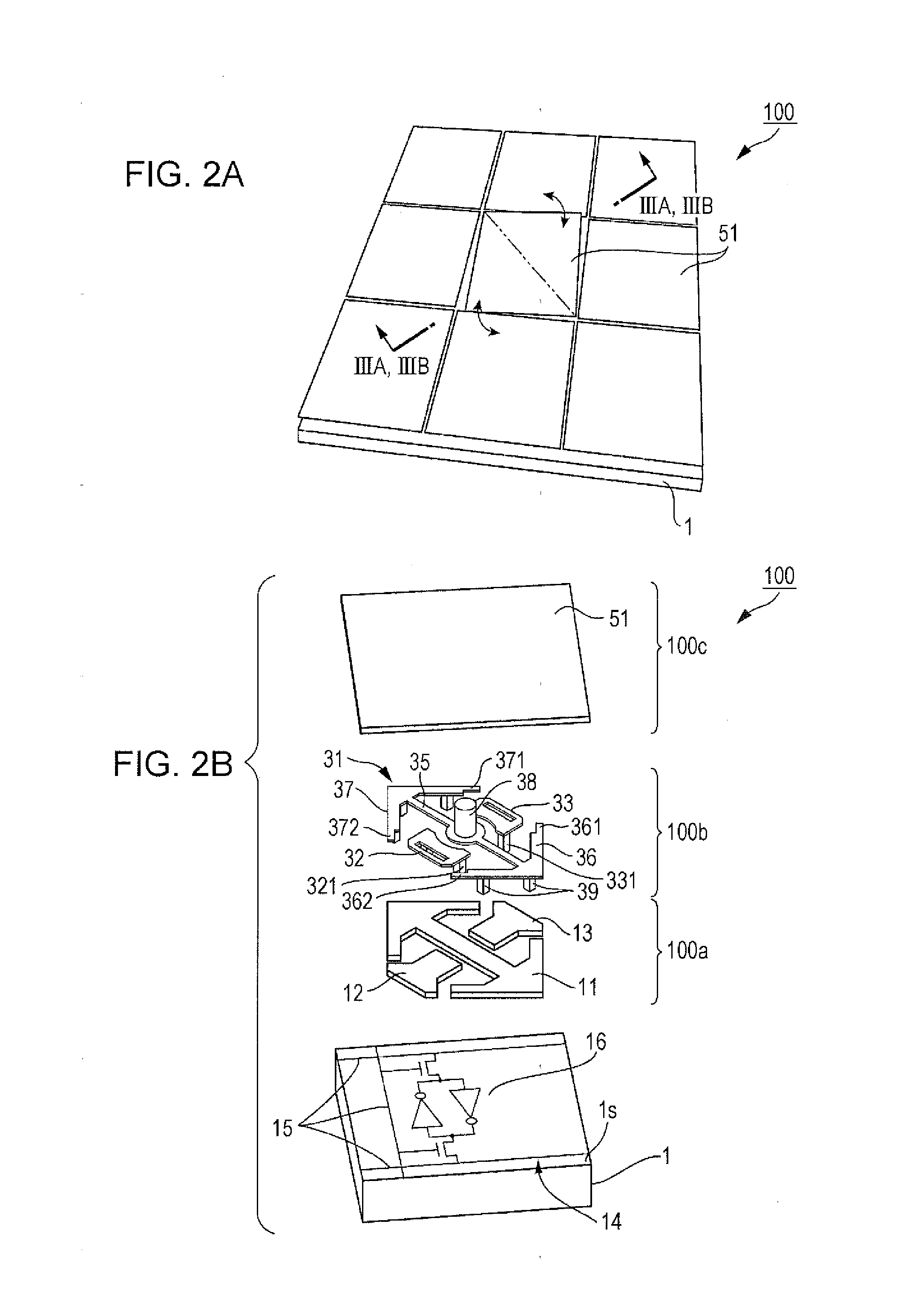

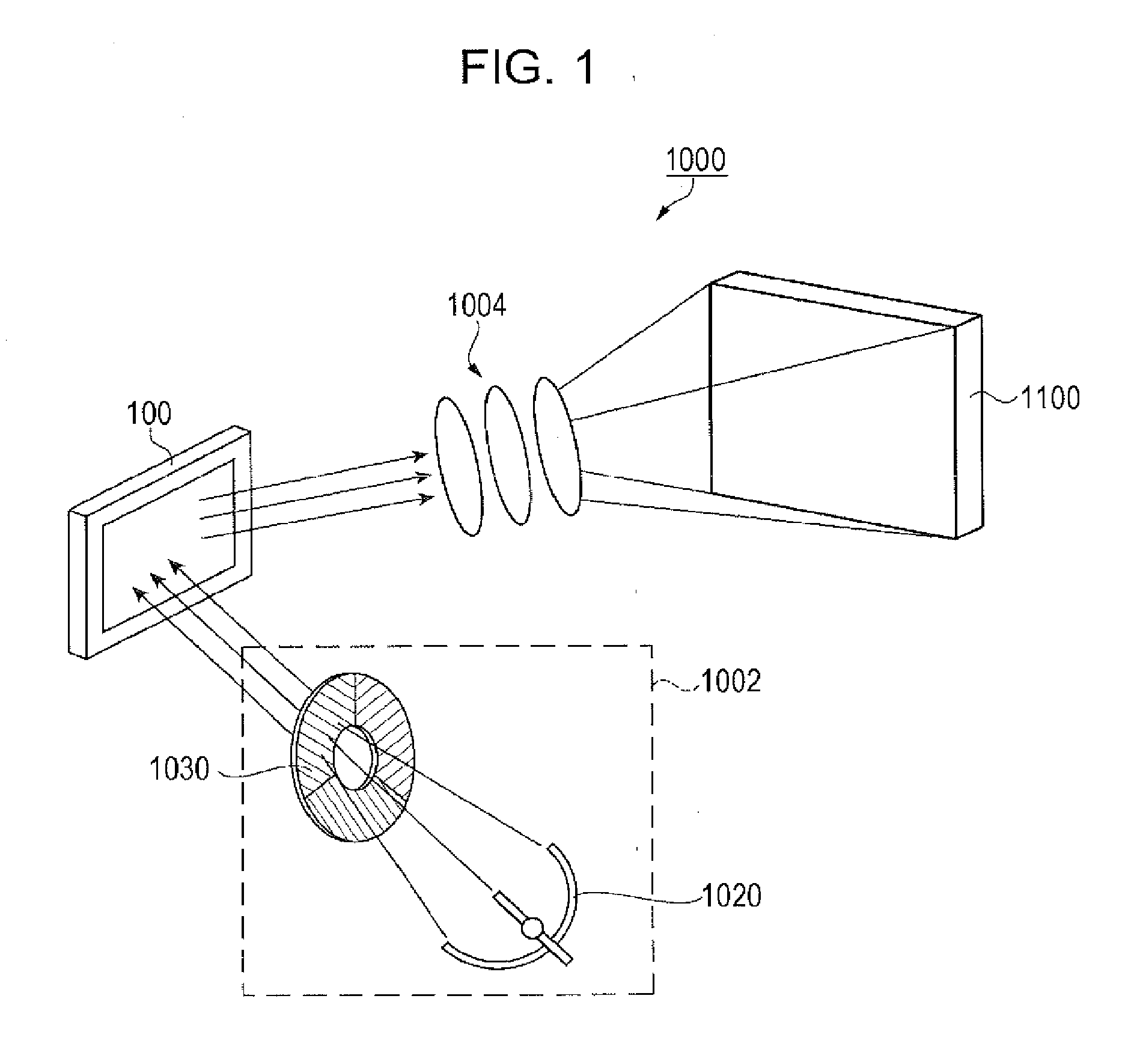

Electro-optical device, method of manufacturing electro-optical device, and electronic apparatus

ActiveUS20160291319A1Efficiently formImprove utilization efficiencySemiconductor devicesOptical elementsElectric equipmentElectron

In an electro-optical device, a torsion hinge and a mirror support post are formed as one piece together with a conductive member, and in the mirror support post, a first end portion on a substrate side is an open end which is opened toward the substrate. In the mirror support post, a second end portion on a mirror side is a flat plate which closes an opening of the mirror support post, and the mirror is in contact with a surface of the fiat plate at a side opposite to the substrate. The first sacrificial layer which is used for manufacturing the electro-optical device is formed by exposure, development, and etching in a state in which a hard mask is formed, with respect to the photosensitive resin layer.

Owner:SEIKO EPSON CORP

Method for forming copper distributing wires

ActiveUS20100291290A1Excellent step-covering abilityEfficiently formOrganic chemistrySemiconductor/solid-state device detailsThin membraneSemiconductor

A primary coat, which consists of a V- or Ti-containing film, is formed on the surface of a subject on which holes or the like have been formed, according to the CVD technique, while using, for instance, a tetravalent amide-type vanadium-containing organometal compound as a raw gas and using, for instance, tertiary butyl hydrazine as a reducing gas, and a copper-containing film is then formed on the primary coat, according to the CVD technique, to thus fill the holes or the like with the copper-containing film and to thus form copper distributing wire, which is excellent in the hole-filling properties and excellent in the adhesion to a primary coat, this process can be applied to the field of copper distributing wires used in the semiconductor industries.

Owner:ULVAC INC

Electro-optical device, method of manufacturing electro-optical device, and electronic apparatus

ActiveUS20160291322A1Efficiently formImprove utilization efficiencySemiconductor devicesOptical elementsMechanical engineeringElectron

In an electro-optical device, a torsion hinge and a mirror support post are formed as one piece together with a conductive member, and in the mirror support post, a first end portion on a substrate side is an open end which is opened toward the substrate. In the mirror support post, a second end portion on a mirror side is a flat plate which closes an opening of the mirror support post, and the mirror is in contact with a surface of the flat plate at a side opposite to the substrate. The first sacrificial layer which is used for manufacturing the electro-optical device is formed by exposure, development, and etching in a state in which a hard mask is formed, with respect to the photosensitive resin layer.

Owner:SEIKO EPSON CORP

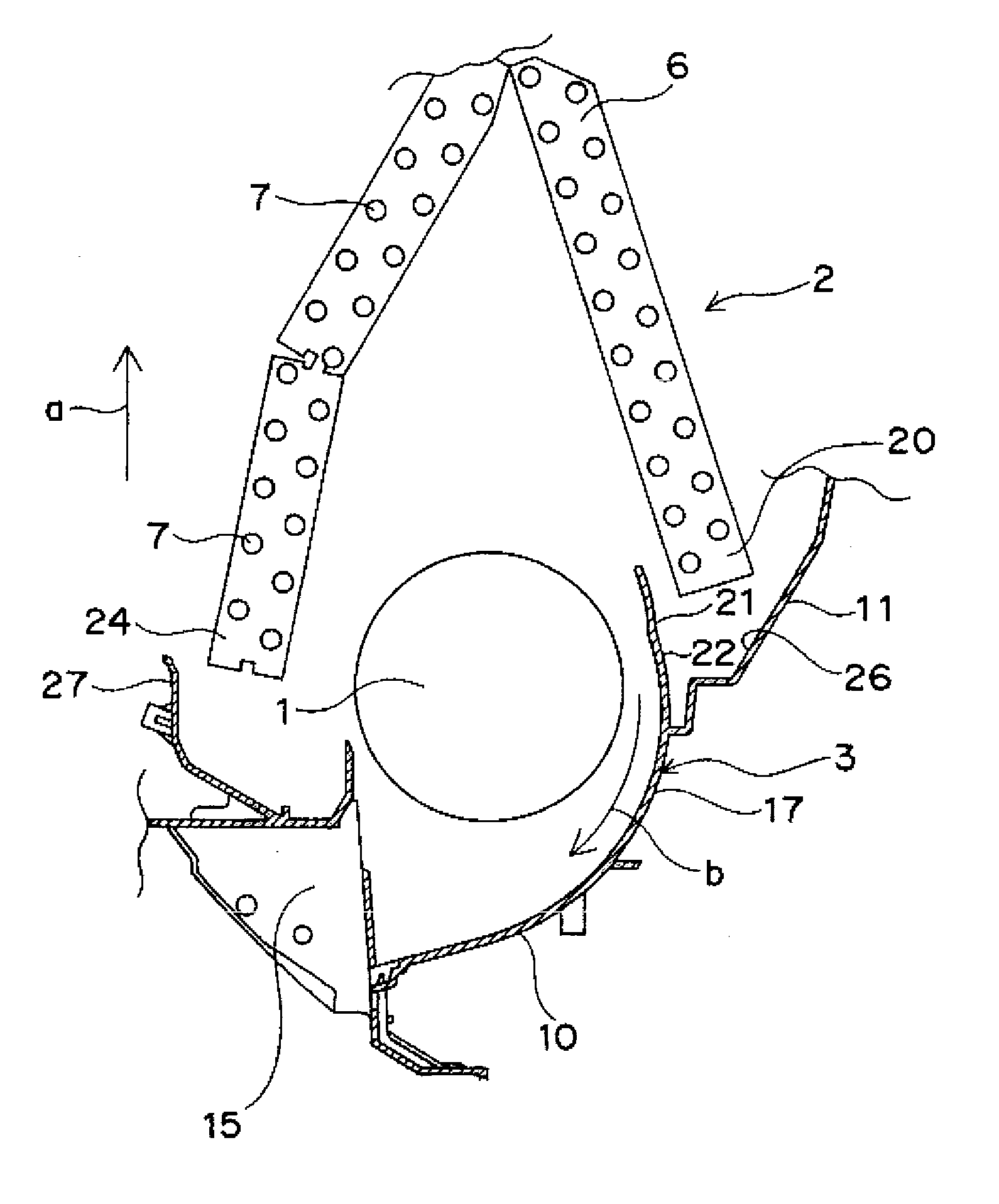

Indoor unit of air conditioner

InactiveUS20100132392A1Efficiently formSmoothly collectCondensate preventionLighting and heating apparatusTongue partEngineering

Grooves are formed on a back surface 22 of a tongue part 21 of a rear plate 3 which surface does not guide a flow of air.

Owner:DAIKIN IND LTD

Method for forming copper distributing wires

ActiveUS8034403B2Excellent step-covering abilityEfficiently formOrganic chemistrySemiconductor/solid-state device detailsSemiconductorSemiconductor industry

A method of forming a primary coat, which consists of a V- or Ti-containing film, formed on the surface of a subject on which holes or the like have been formed, according to the CVD technique, while using, for instance, a tetravalent amide-type vanadium-containing organometal compound as a raw gas and using, for instance, tertiary butyl hydrazine as a reducing gas, and a copper-containing film is then formed on the primary coat, according to the CVD technique, to thus fill the holes or the like with the copper-containing film and to thus form copper distributing wire, which is excellent in the hole-filling properties and excellent in the adhesion to a primary coat, this process can be applied to the field of copper distributing wires used in the semiconductor industries.

Owner:ULVAC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com