Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "High partial discharge inception voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

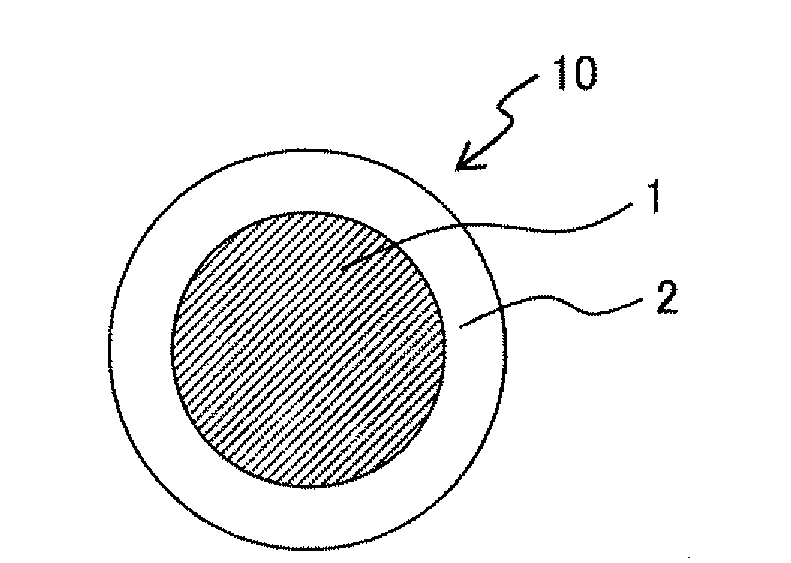

Foamed electrical wire and a method of producing the same

ActiveUS9142334B2Increase resistanceGood partitionPlastic/resin/waxes insulatorsInsulated cablesElectrical conductorGlass transition

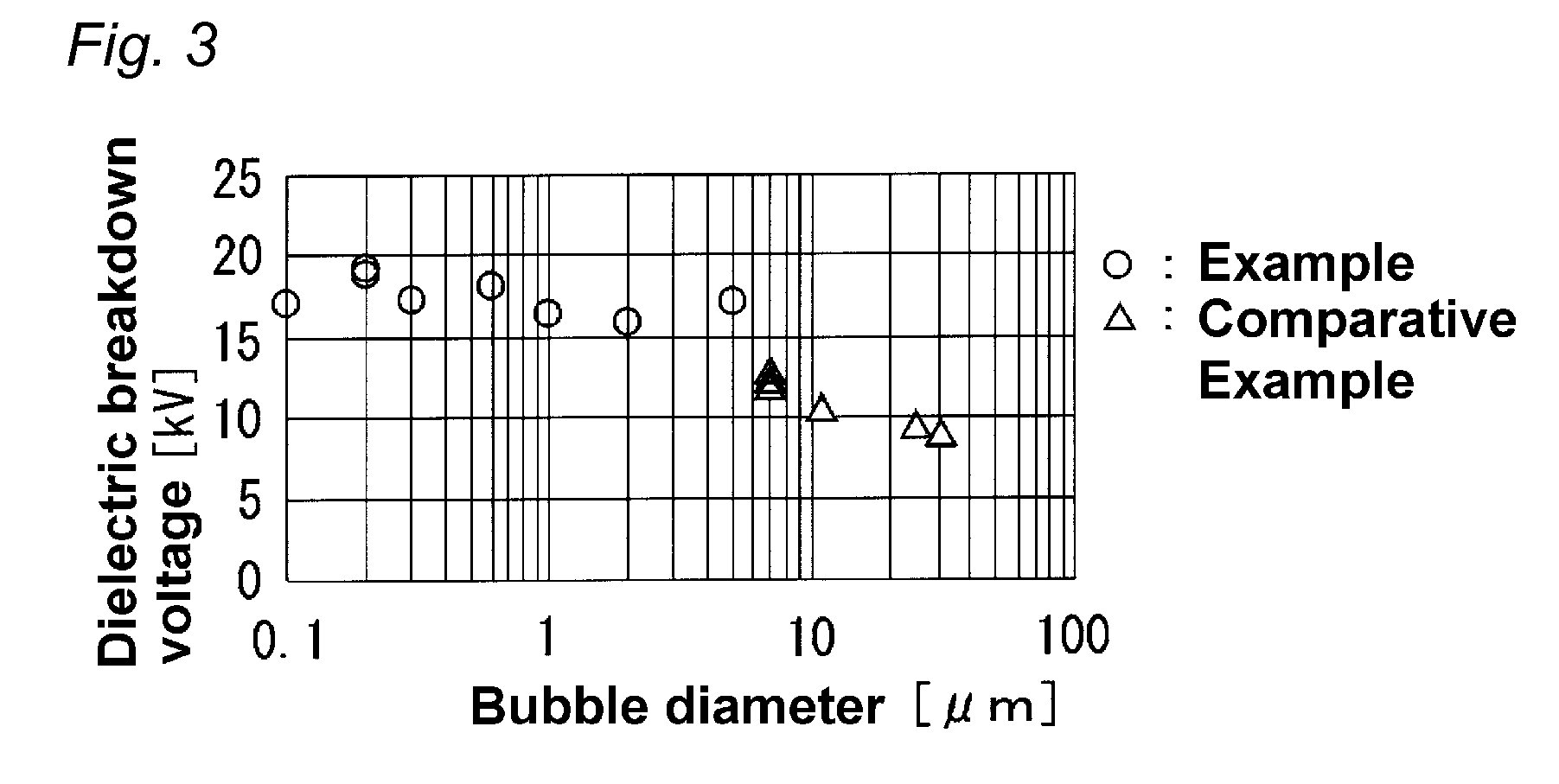

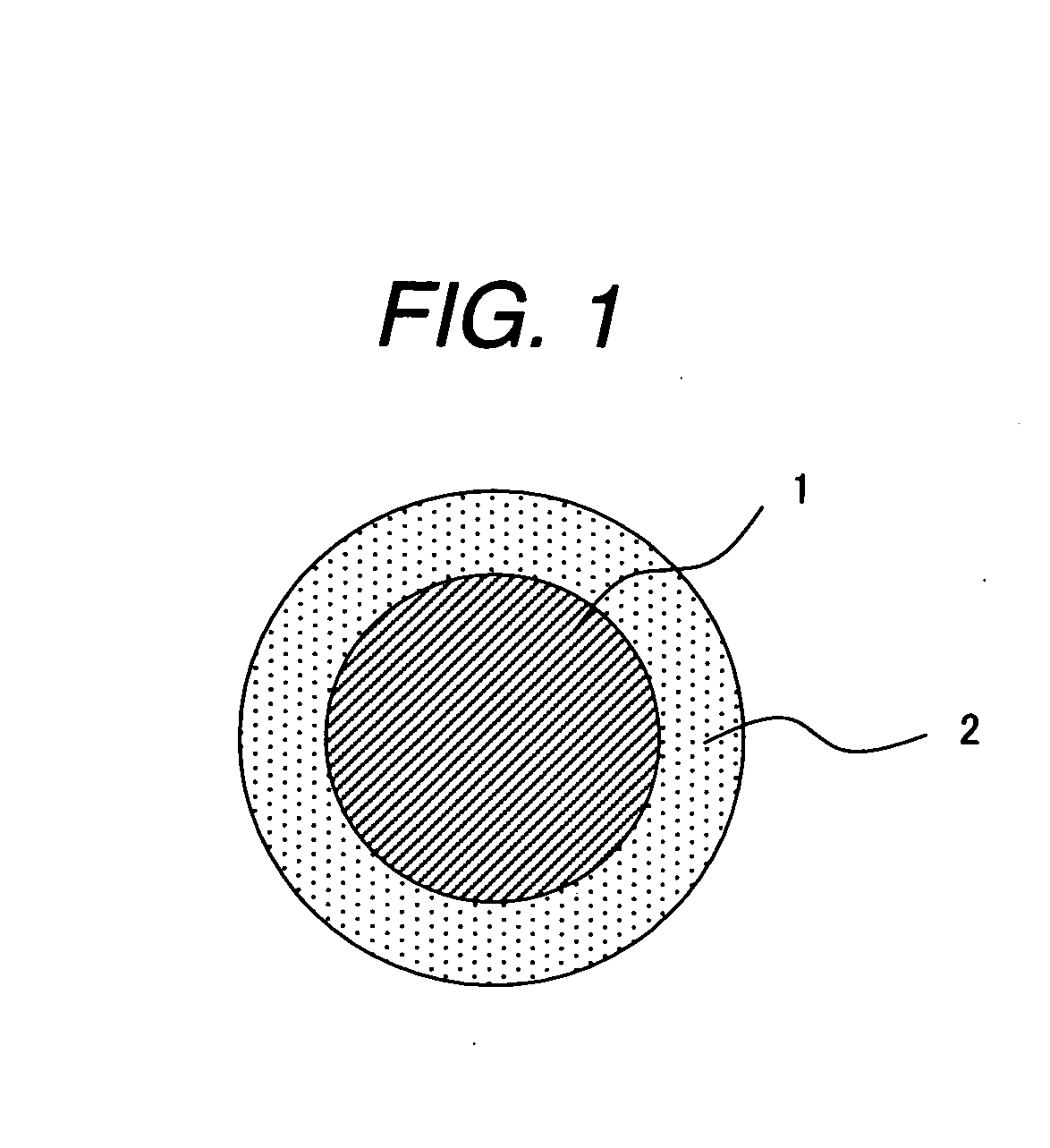

A foamed electrical wire, containing: a conductor; and a foamed insulating layer; in which the foamed insulating layer comprises a thermoplastic resin that is a crystalline thermoplastic resin having a melting point of 150° C. or more or a non-crystalline thermoplastic resin having a glass transition temperature of 150° C. or more, and the average bubble diameter of the foamed insulating layer is 5 μm or less.

Owner:ESSEX FURUKAWA MAGNET WIRE LLC

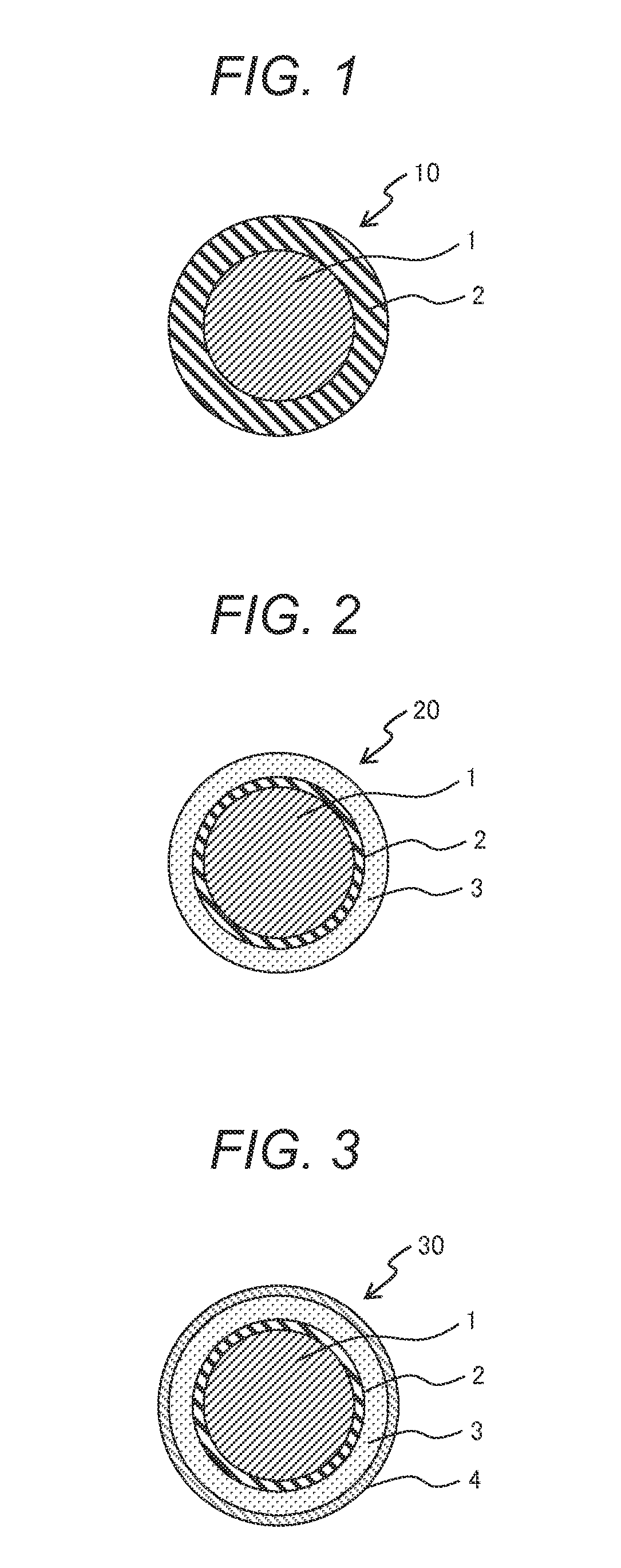

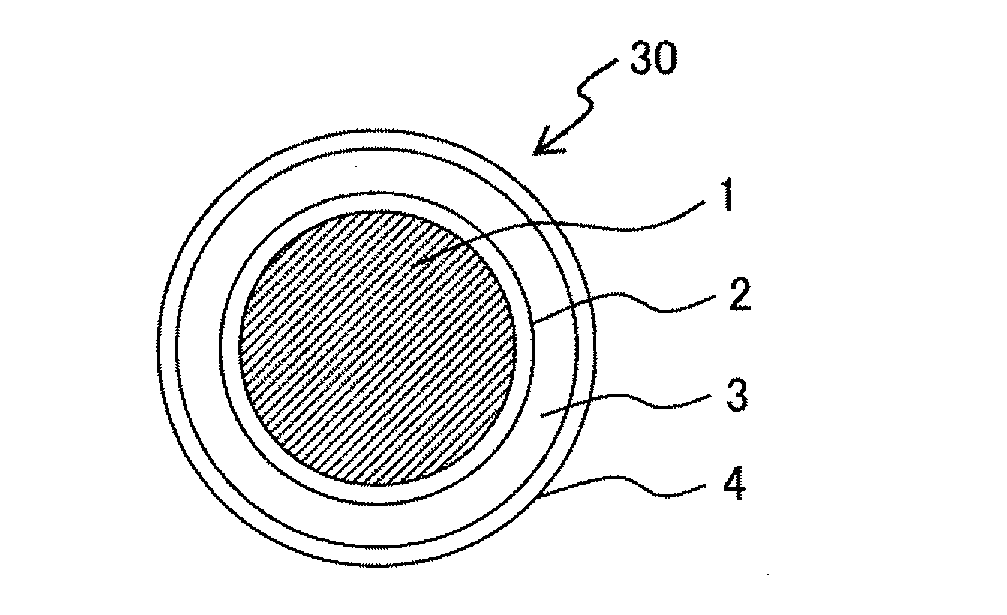

Inverter surge-resistant insulated wire

ActiveUS20150021067A1High partial discharge inception voltageImprove insulation performanceWindings insulation materialPlastic/resin/waxes insulatorsDielectricInsulation layer

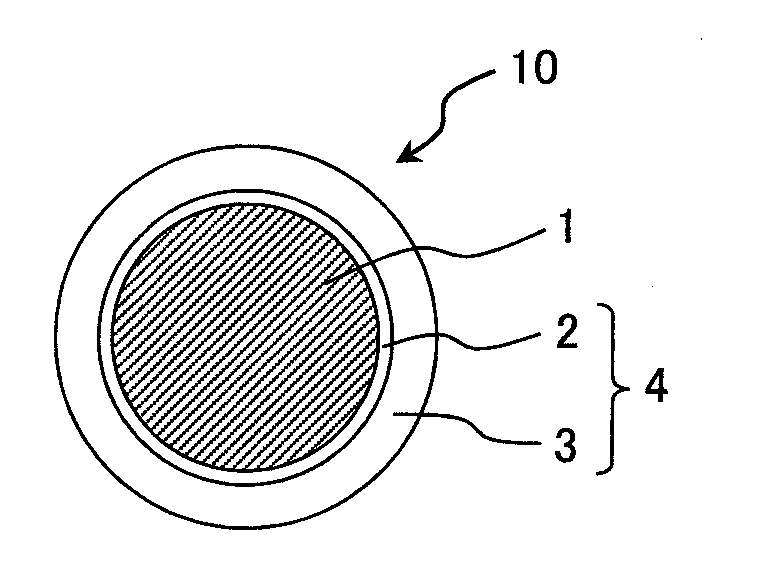

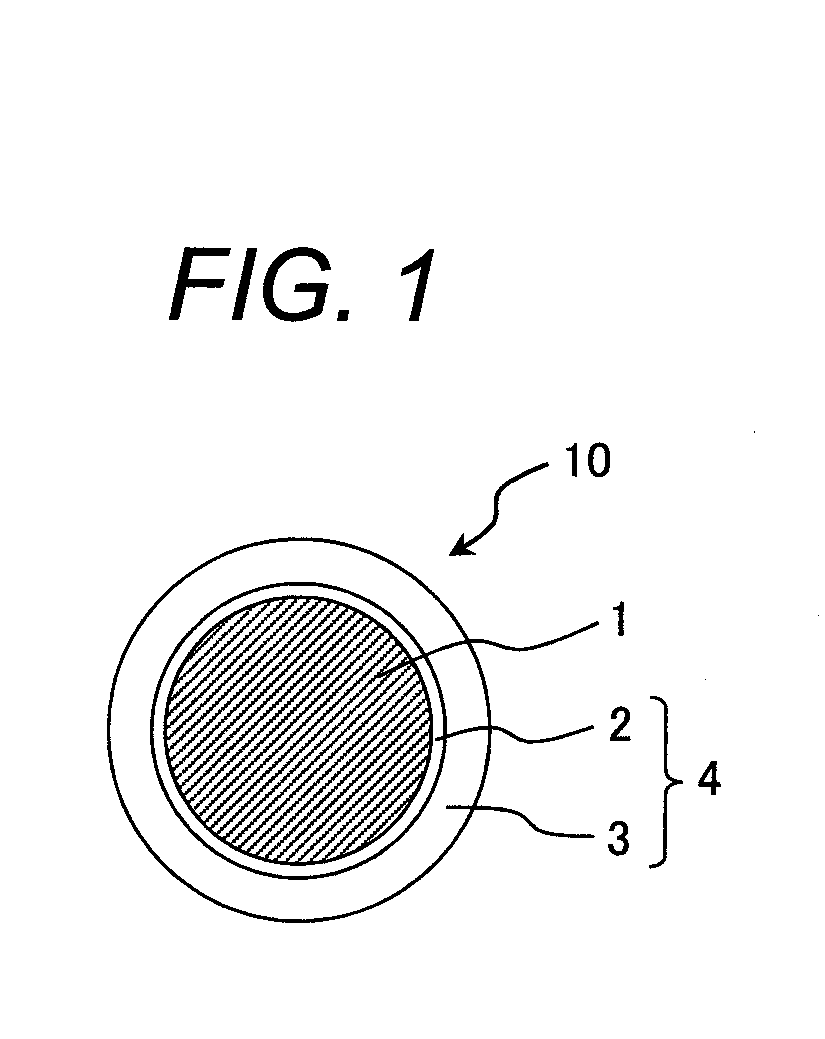

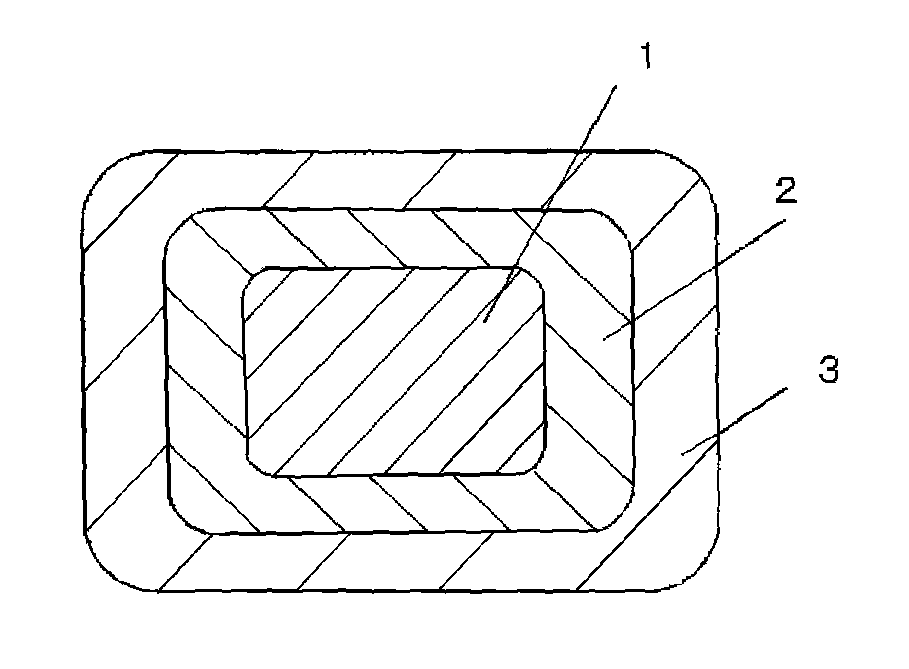

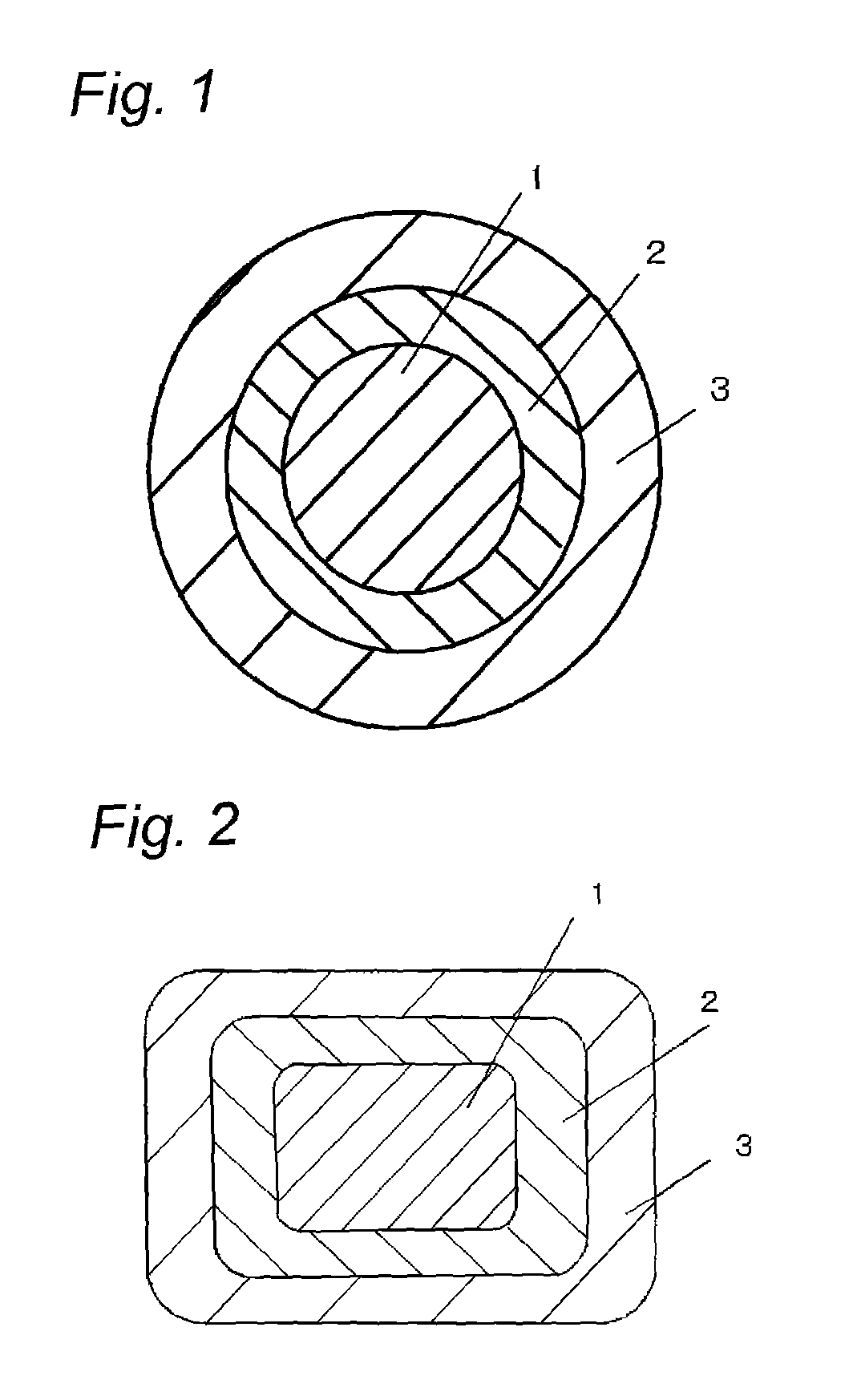

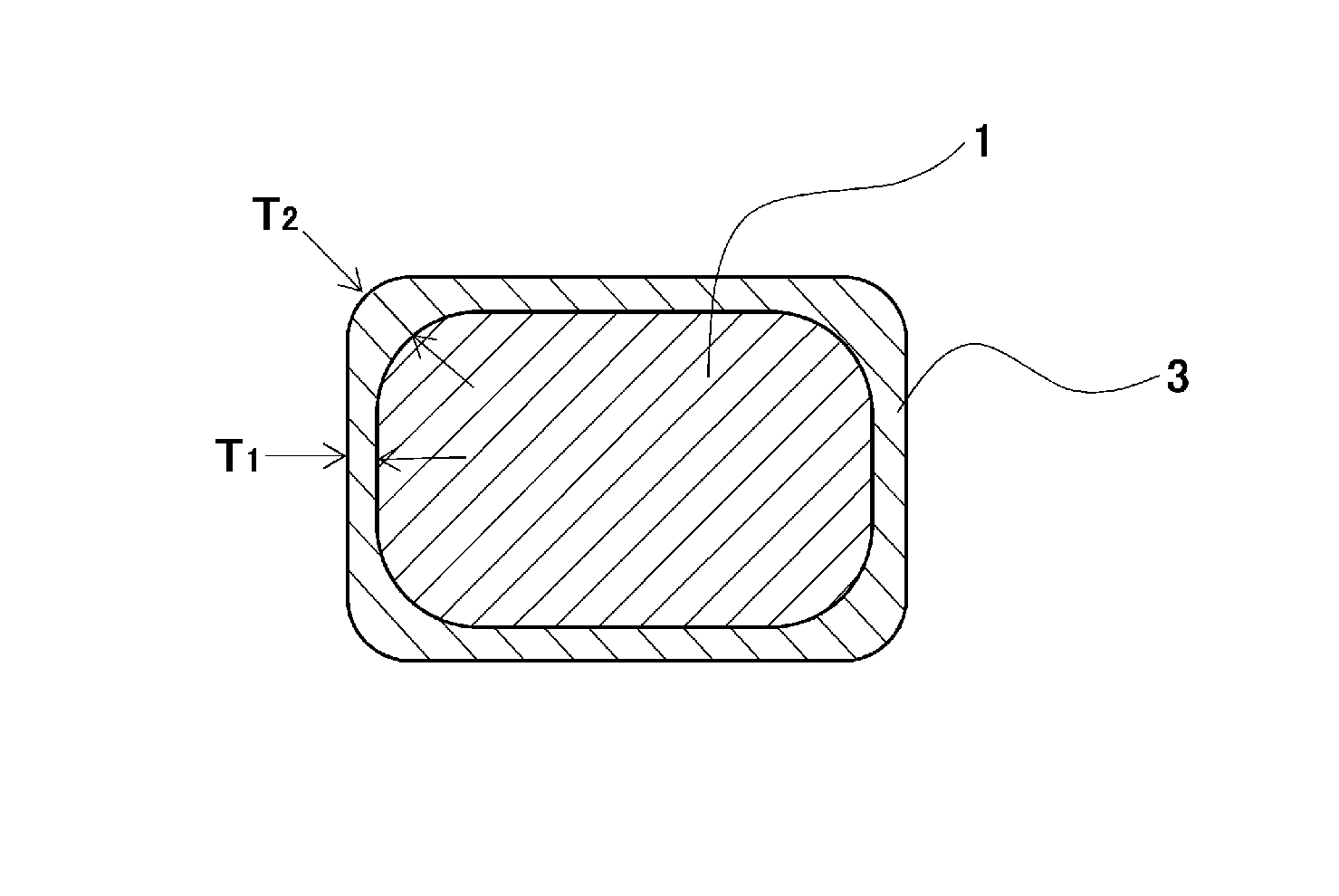

An inverter surge-resistant insulated wire, having at least one baked enamel layer around the outer periphery of a conductor, and an extrusion-coated resin layer at the outside of the baked enamel layer, wherein a total thickness of the baked enamel layer and the extrusion-coated resin layer is 50 μm or more, a thickness of the baked enamel layer is 60 μm or less, and a thickness of the extrusion-coated resin layer is 200 μm or less, wherein the minimum of tensile elastic modulus of the extrusion-coated resin layer at a range of 25 to 250° C. is 100 MPa or more, wherein a dielectric constant of an insulation layer having a combination of the baked enamel layer and the extrusion-coated resin layer is 3.5 or less at 25° C. and 5.0 or less at 250° C., and wherein a relation between dielectric constant (∈1′) of the baked enamel layer at 250° C. and dielectric constant (∈2′) of the extrusion-coated resin layer at 250° C. satisfies (∈2′ / ∈1′)>1.

Owner:ESSEX FURUKAWA MAGNET WIRE LLC

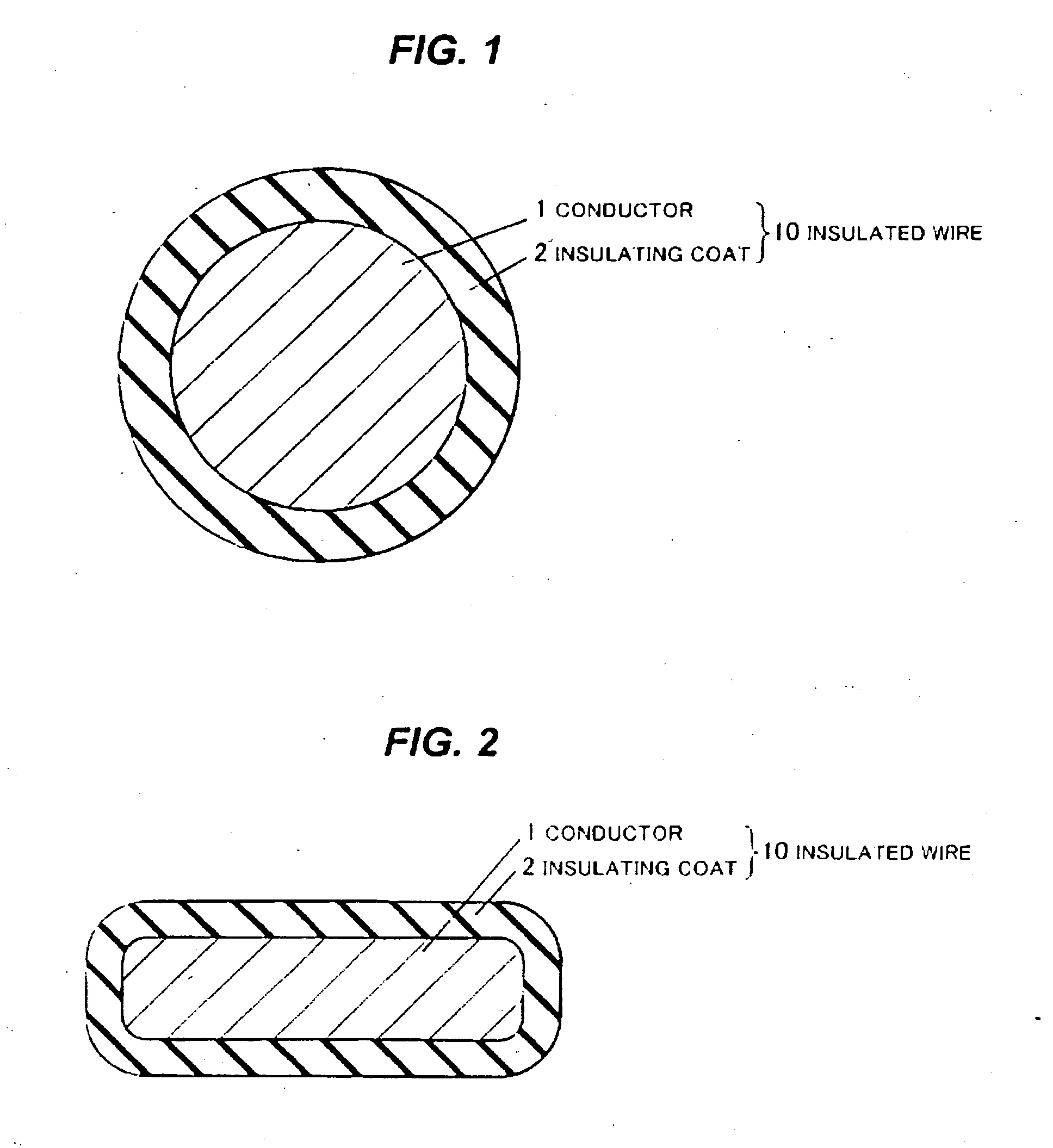

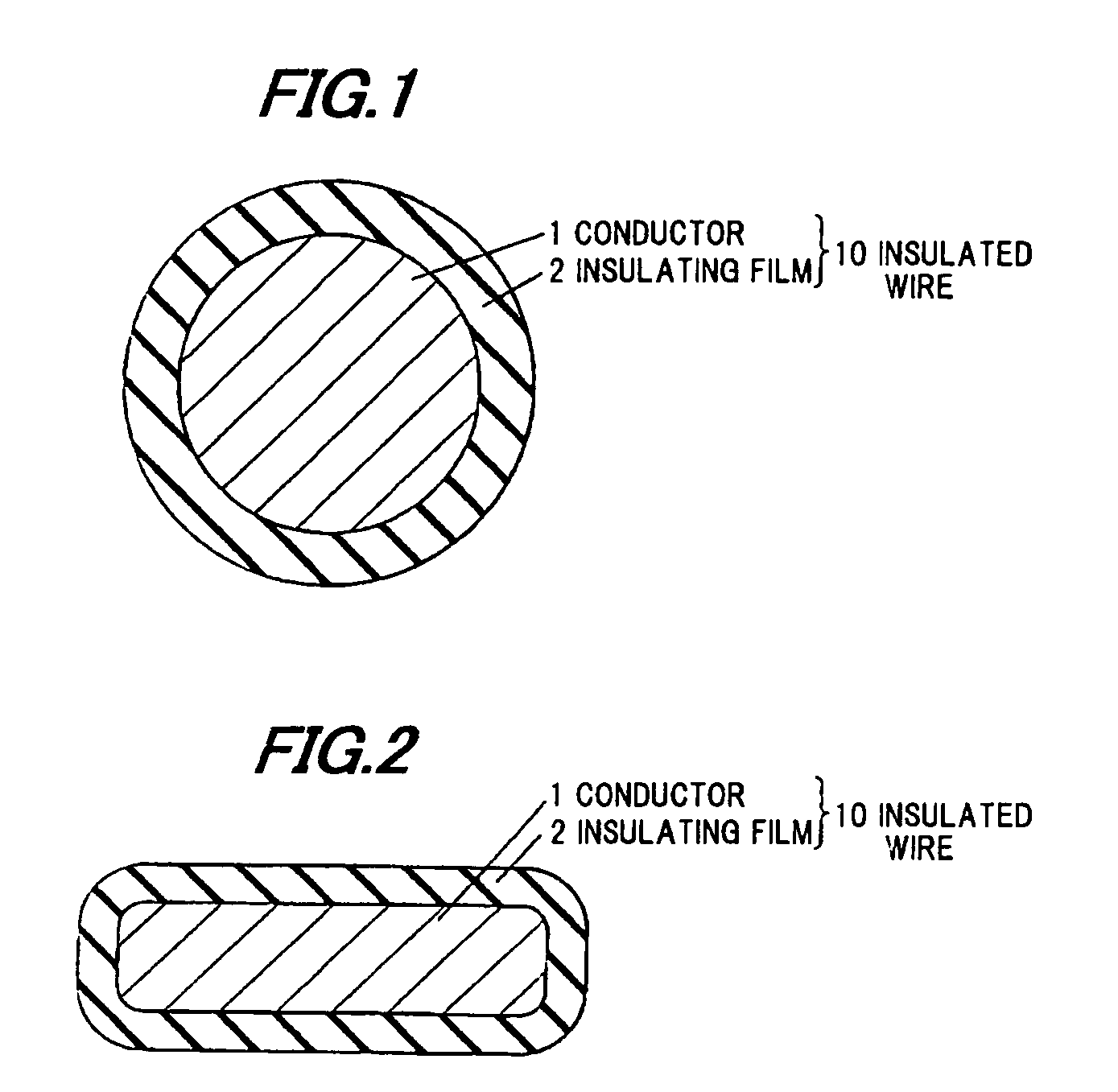

Insulated wire

InactiveUS20110192632A1AdhesionImprove adhesionInsulated cablesInsulatorsTetrafluoroethylenePolymer alloy

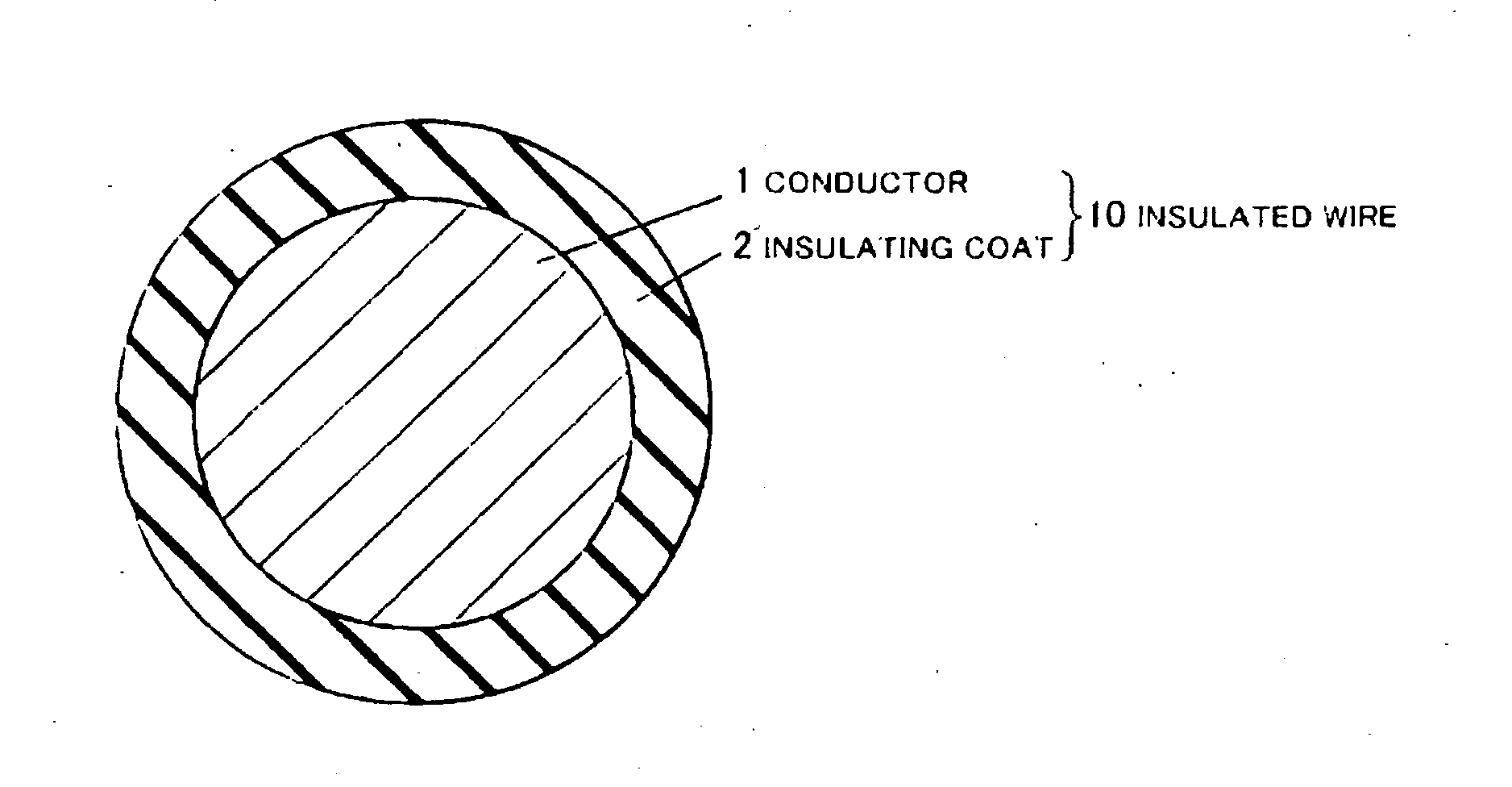

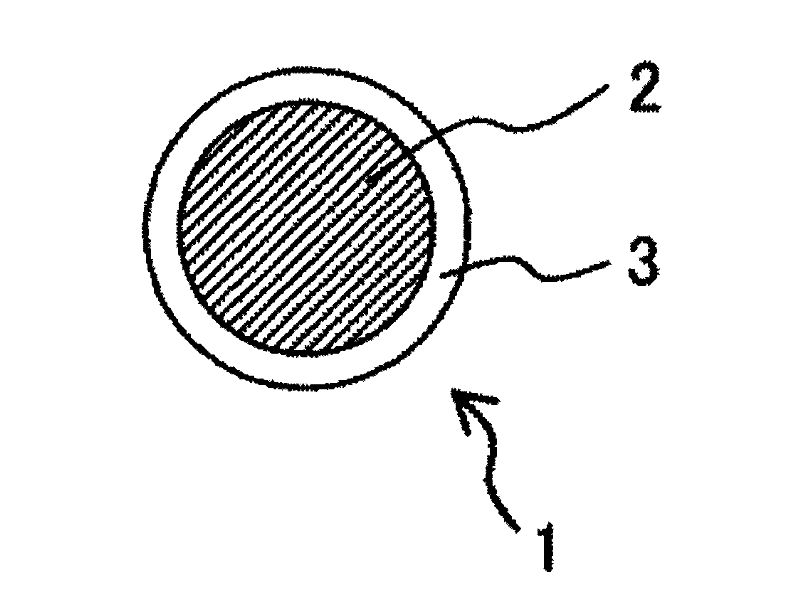

There is provided an insulated wire having an insulation film composed of a plurality of layers provided on a conductor, in which: the insulation film includes a first film layer and a second film layer; the first film layer is made of a first resin composition formed by graft-polymerizing a graft compound with an ethylene-tetrafluoroethylene copolymer and is provided on a circumference of the conductor; and the second film layer is made of a second resin composition being a polymer alloy made of a polyphenylene sulfide resin and a polyamide resin, or being a polymer alloy made of a polyether ether ketone resin and a polyamide resin and is provided on a circumference of the first film layer.

Owner:HITACHI CABLE +1

Insulating varnish and insulated wire formed by using the same

InactiveUS20110290528A1Improve compatibilityHigh partial discharge inception voltagePlastic/resin/waxes insulatorsInsulated cablesPolyamide-imideVarnish

An insulating varnish includes a polyamide-imide resin varnish including a solvent and a polyamide-imide resin, and an organosol. The polyamide-imide resin varnish is obtained by a synthesis reaction between a resin component (X) and an isocyanate component (Y). The resin component (X) is obtained by a synthesis reaction between a diamine component and an acid component in presence of an azeotropic medium. The diamine component includes aromatic diamines including a divalent aromatic group having three or more aromatic rings. The isocyanate component (Y) includes a diisocyanate (Y1) a molecule of which includes a bend structure.

Owner:HITACHI CABLE

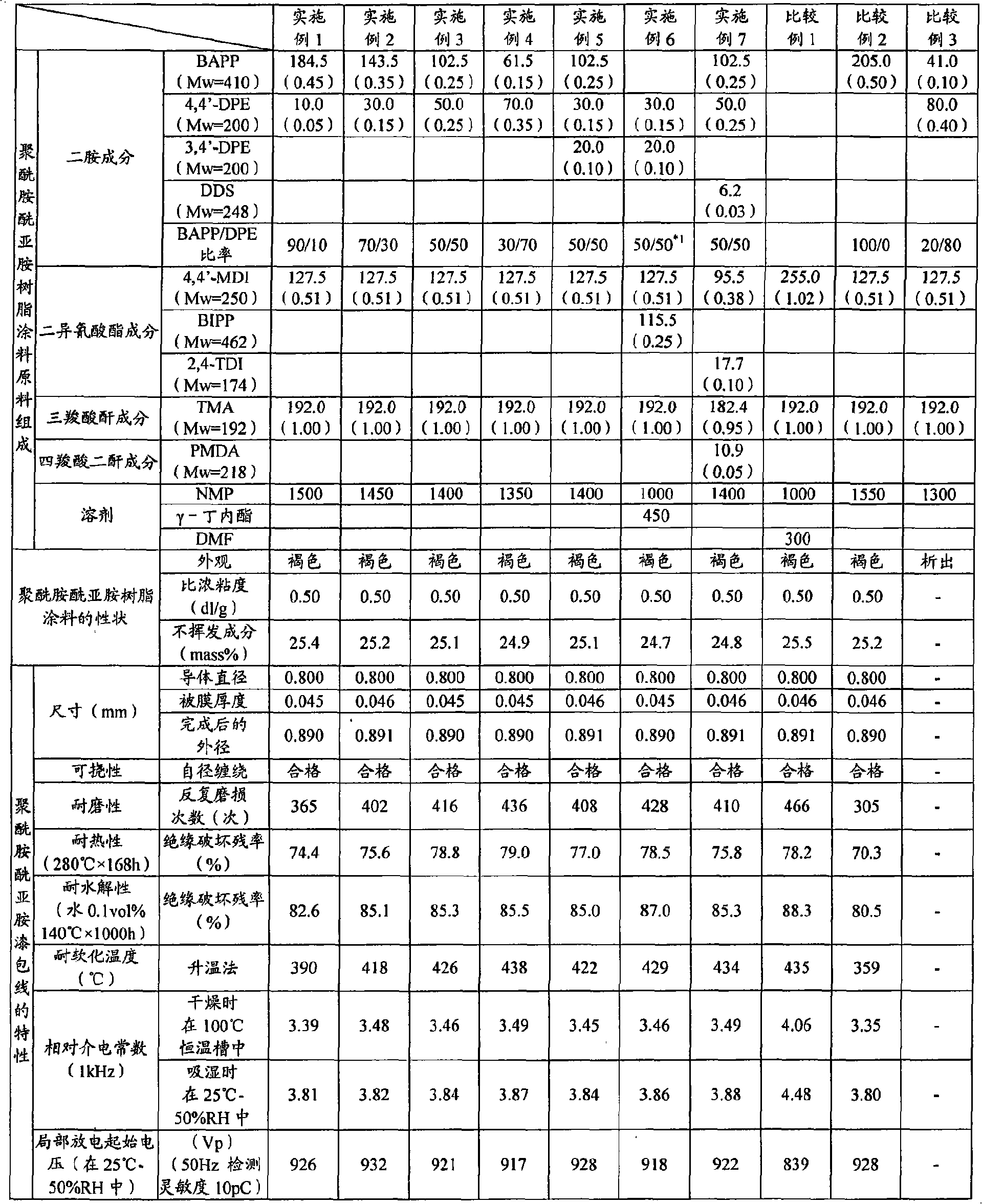

Polyamide-imide resin insulating varnish and insulated wire using the same

ActiveCN101597462AHigh partial discharge inception voltageNo reduction in softening temperaturePlastic/resin/waxes insulatorsCoatingsHeat resistancePolyamide-imide

This invention relates to a polyamide-imide resin insulating varnish and an insulated wire using the polyamide-imide resin insulating varnish. A polyamide-imide resin insulating varnish includes an aromatic diamine component, an aromatic diisocyanate component, an acid component including an aromatic tricarboxylic acid anhydride, and a solvent. The aromatic diamine component includes an aromatic diamine with three or more benzene rings and an aromatic diamine with two or less benzene rings. The polyamide-imide resin insulating varnish allows reduction in permittivity while retaining its heat resistance, mechanical performance, oil resistance etc. for producing a covering with a high partial discharge inception voltage.

Owner:HITACHI MAGNET WIRE CORP +1

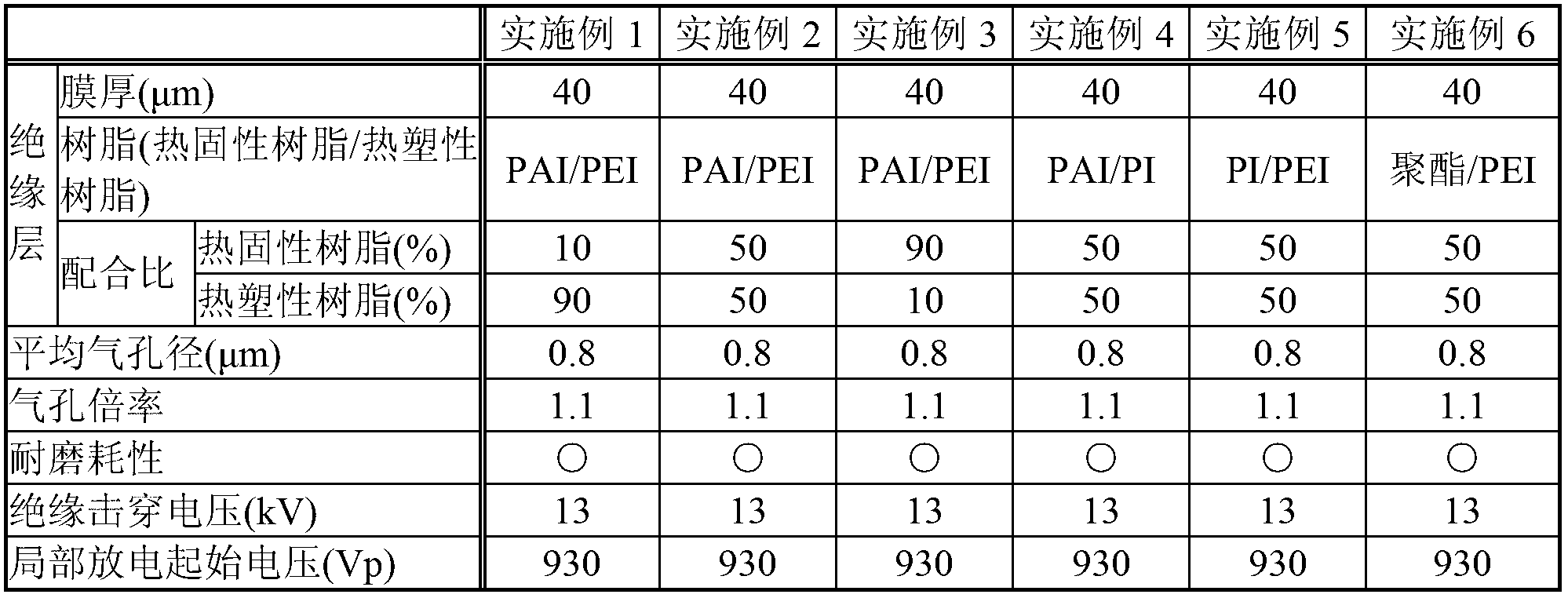

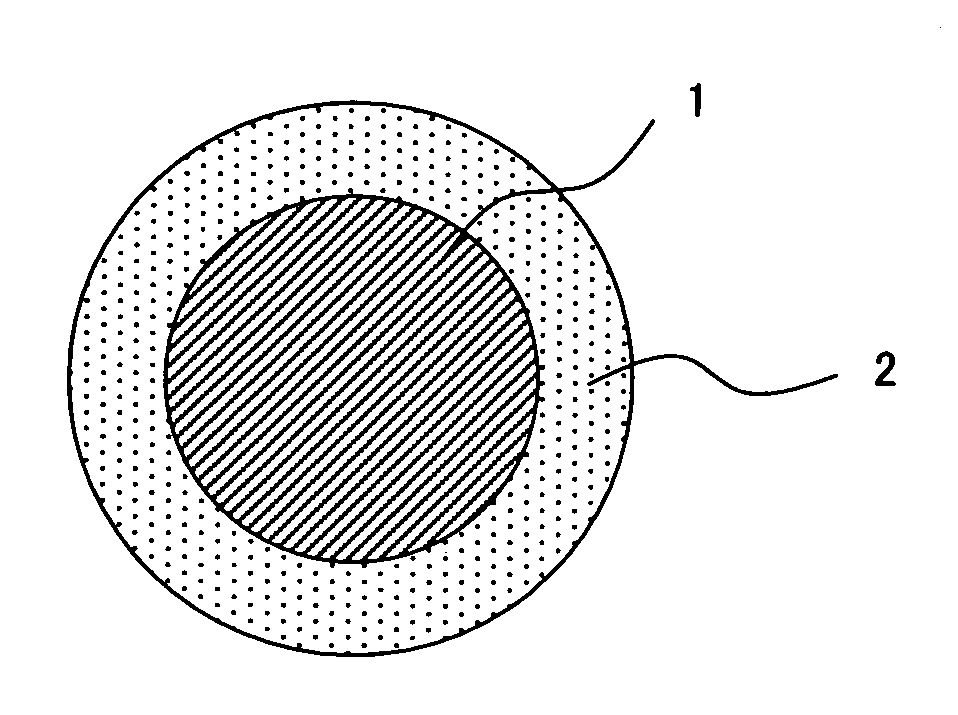

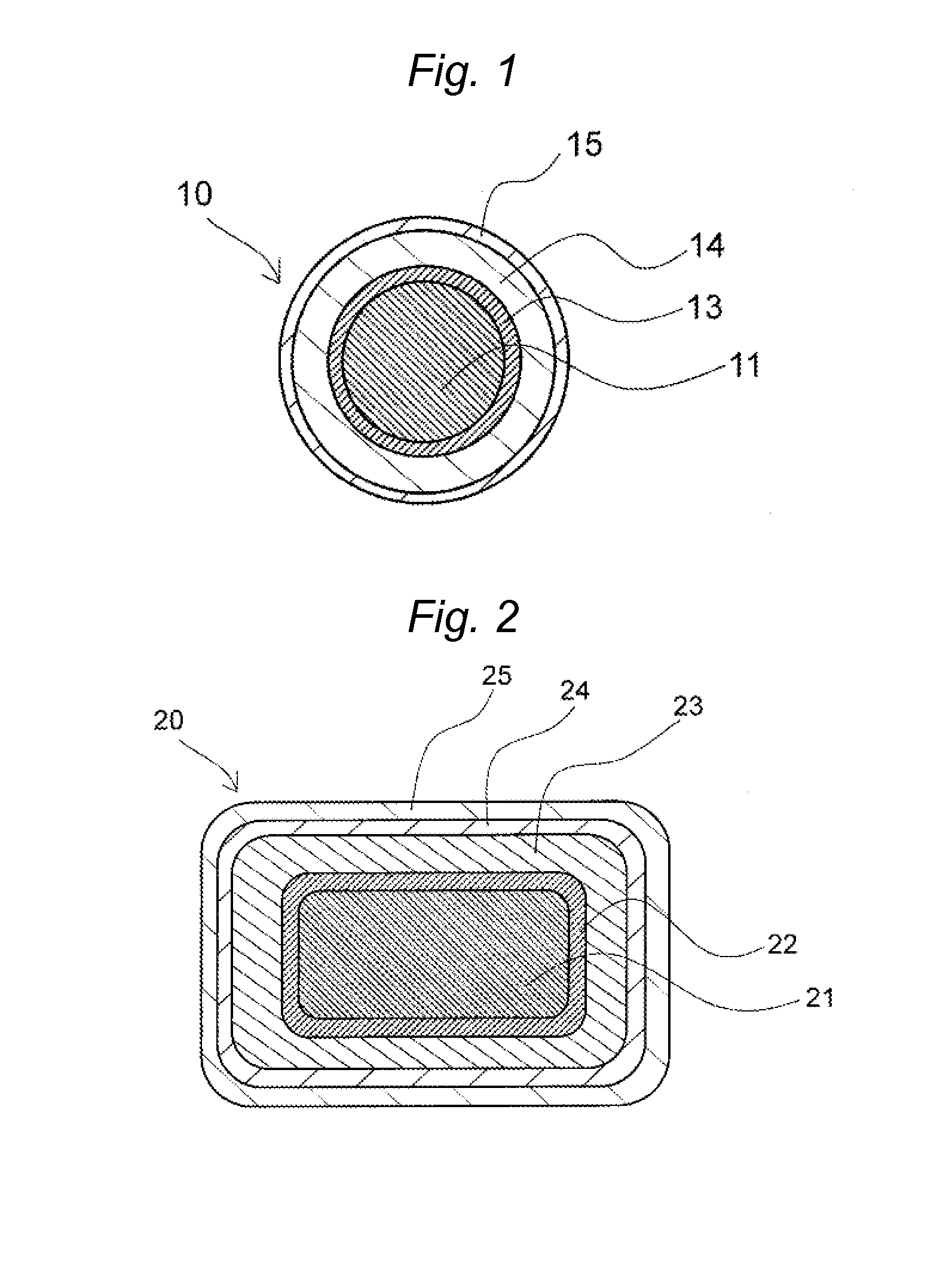

Insulated electric wire, electric device, and process for production of insulated electric wire

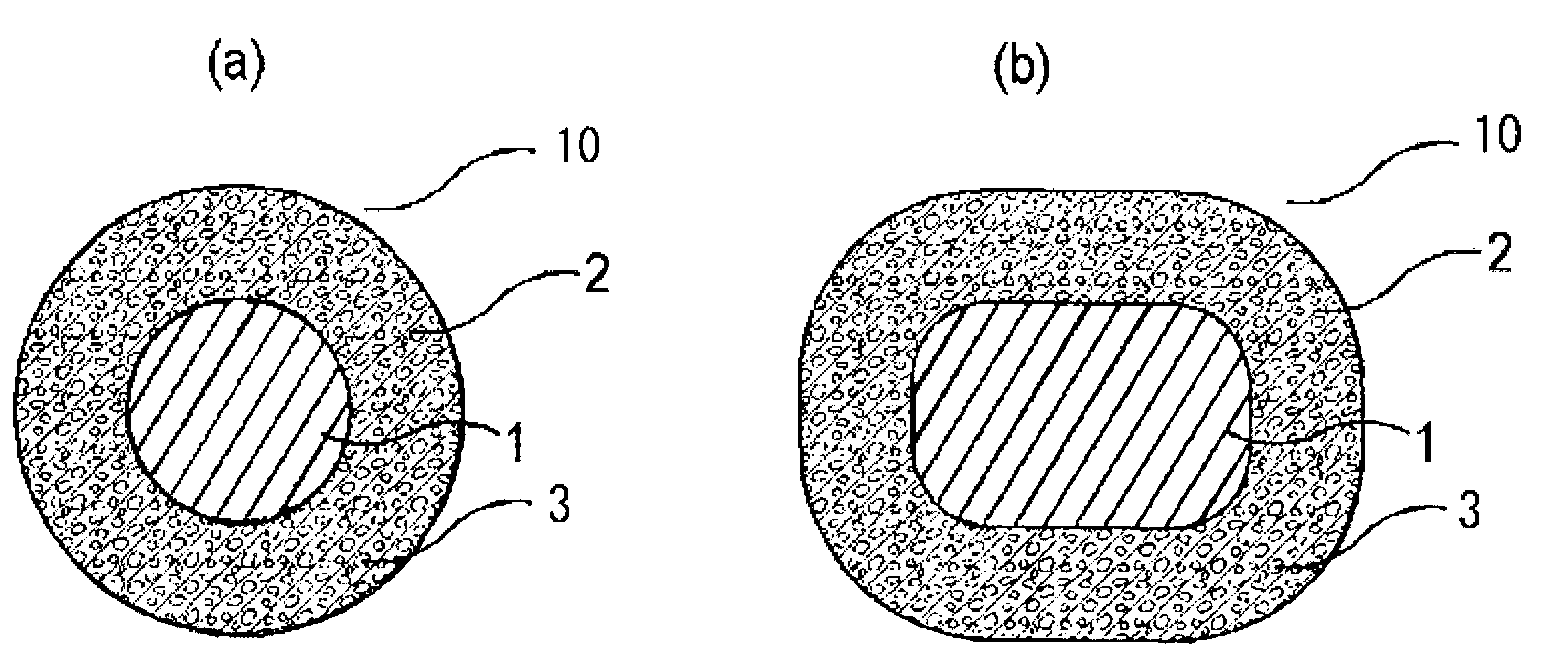

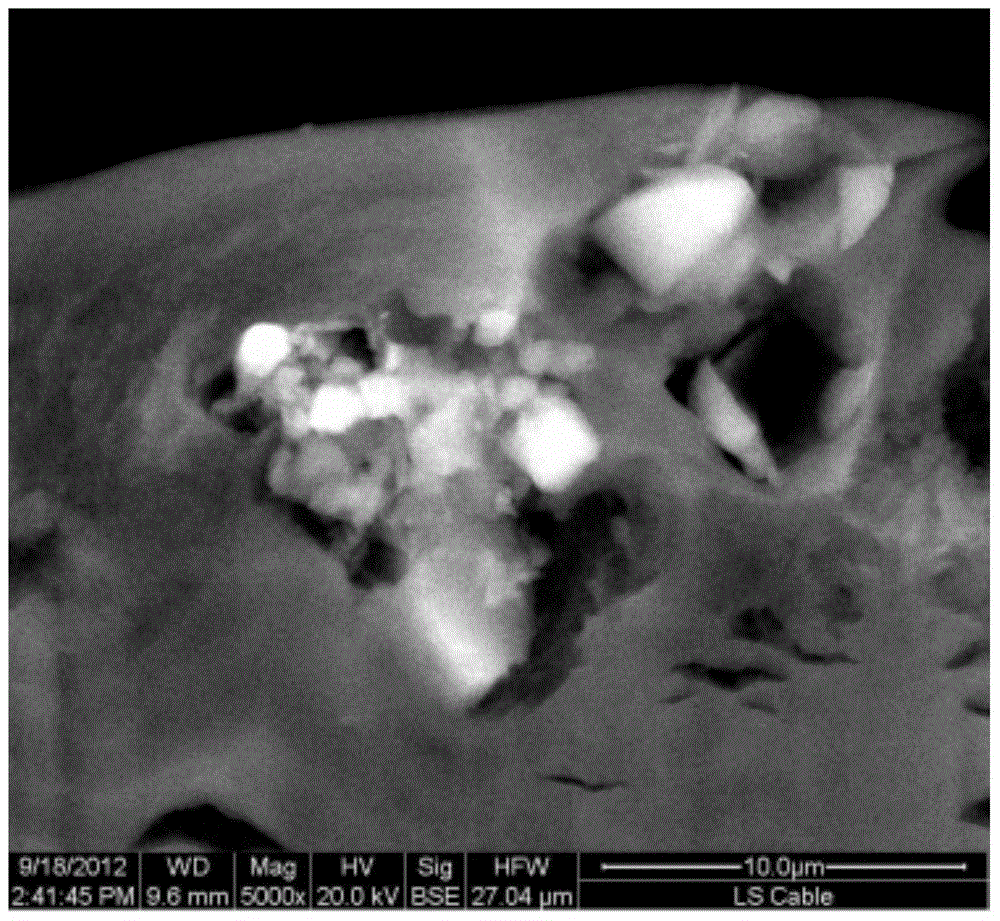

ActiveCN102844822AHigh partial discharge inception voltageImprove insulation performanceWindings insulation materialWindings insulation shape/form/constructionConductive materialsEngineering

An insulated electric wire which comprises a conductive material and an insulating coating film that covers the outer periphery of the conductive material, wherein the insulating coating film comprises a cured product of a thermosetting resin composition comprising a thermoplastic resin and has very small air holes.

Owner:ESSEX FURUKAWA MAGNET WIRE LLC

Polyamide-imide resin insulating paint and insulation wire using same

ActiveUS20090176961A1High partial discharge inception voltageMaintenance characteristicPlastic/resin/waxes insulatorsSynthetic resin layered productsIsocyanateHalogen

A polyamide-imide resin insulating paint according to the present invention includes polyamide-imide resin containing no halogen element in its molecular chain which is dissolved in a polar solvent, in which the polyamide-imide resin contains an aromatic diisocyanate component (A) having three or more benzene rings or an aromatic diamine component (E) having three or more benzene rings in a monomer, and a ratio M / N between a molecular weight (M) of the polyamide-imide resin per repeat unit and an average number (N) of amide groups and imide groups is equal to or more than 200.

Owner:HITACHI METALS LTD

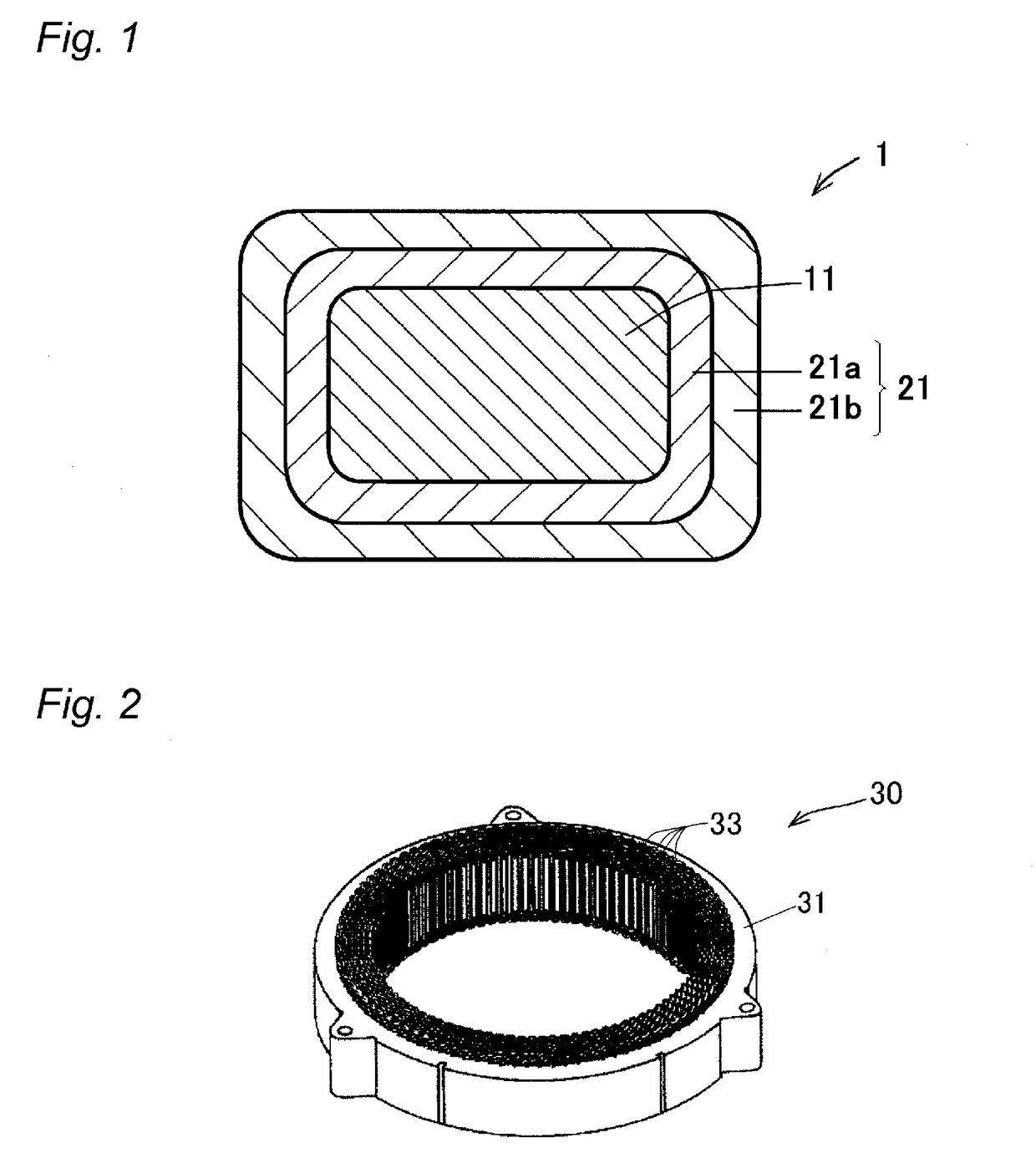

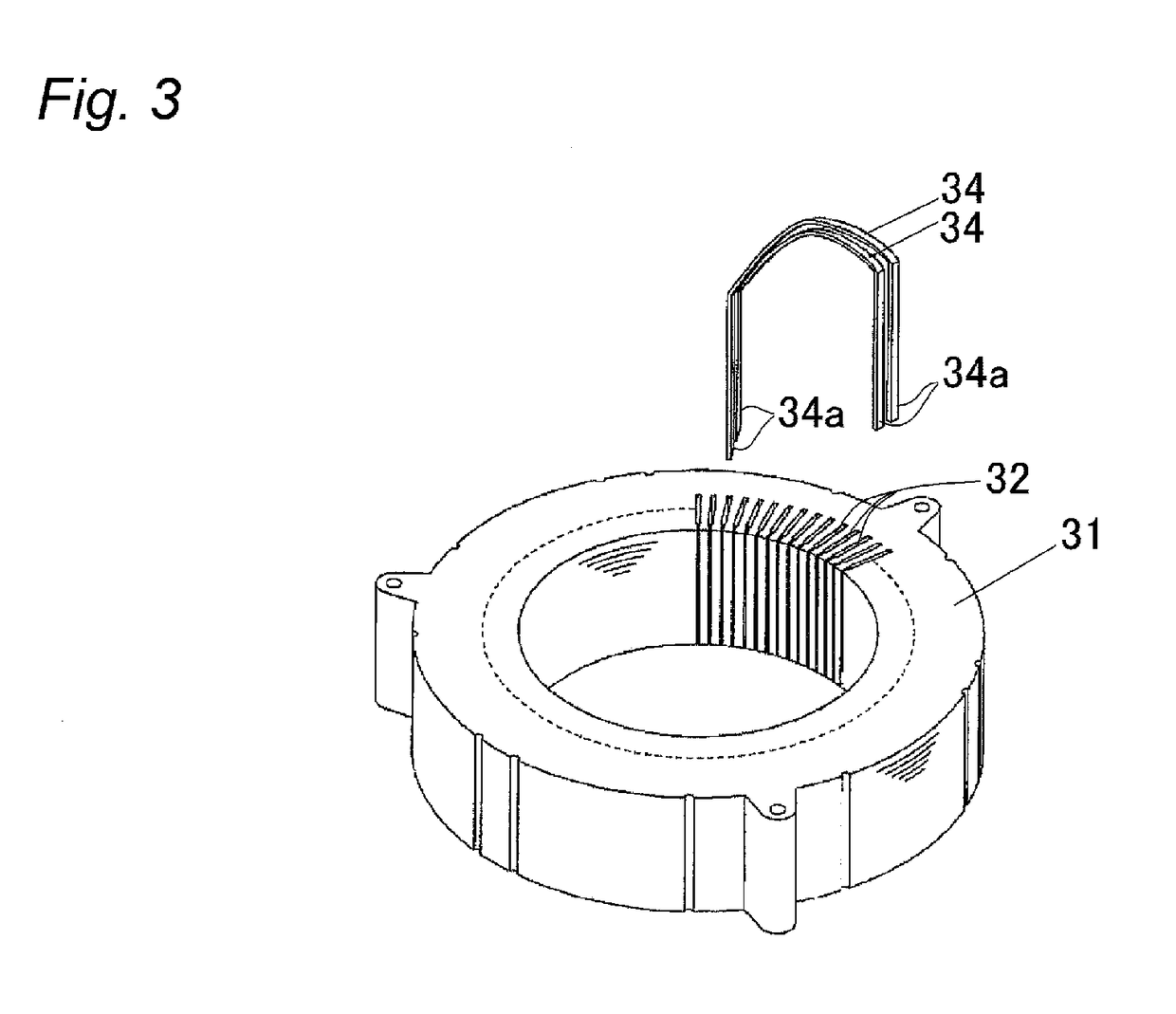

Insulated wire and coil using same

ActiveUS20140102752A1Small sizeReduce weightPlastic/resin/waxes insulatorsInsulated cablesElectrical conductorEngineering

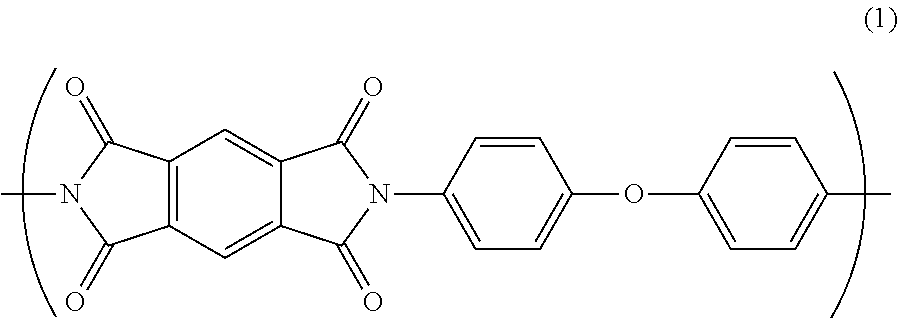

An insulated wire includes a conductor and an insulating layer formed on an outer periphery of the conductor, and the insulating layer is composed essentially of a polyimide resin having a repeating unit A represented by Formula (1) as a part of a molecular structure, in which a water absorption coefficient is not greater than 2.8% after 24 hours under condition at temperature of 40° C. and humidity of 95%

Owner:HITACHI METALS LTD

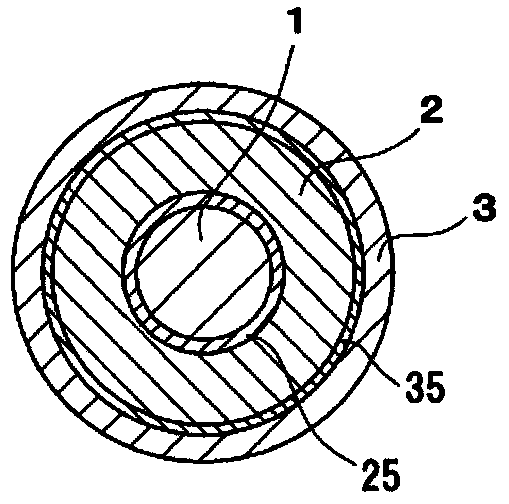

Enamel resin-insulating laminate, insulated wire using the same and electric/electronic equipment

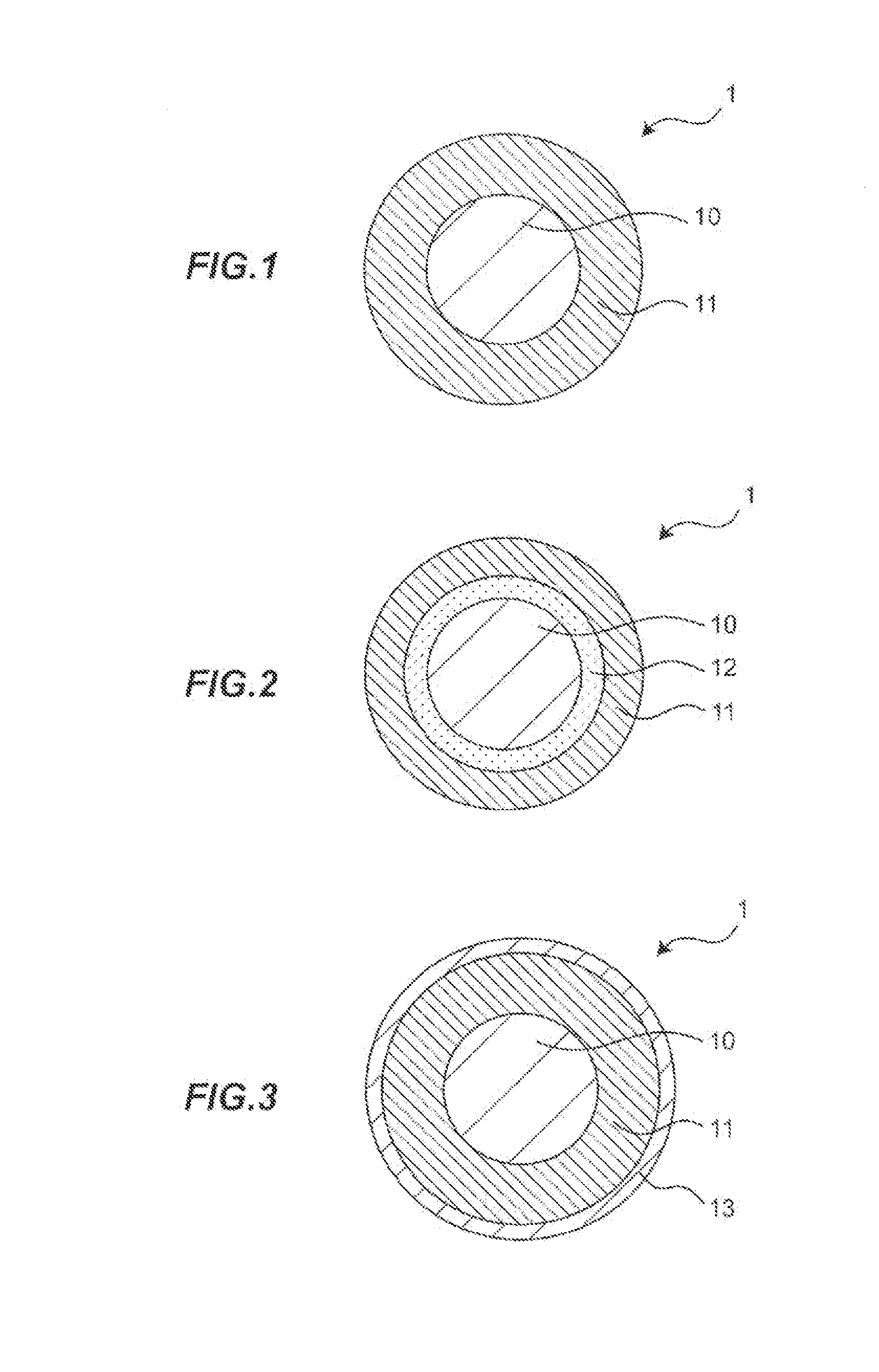

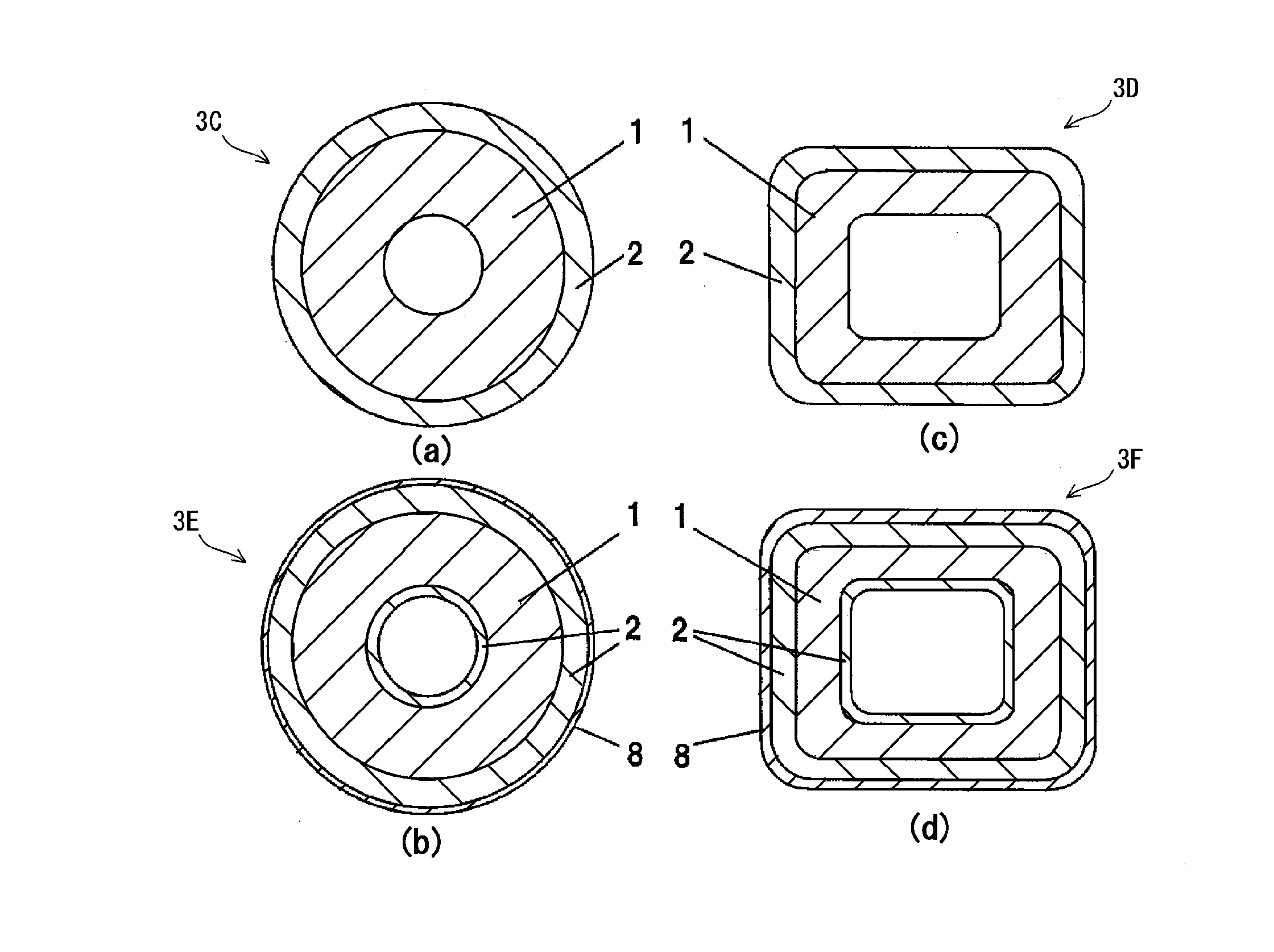

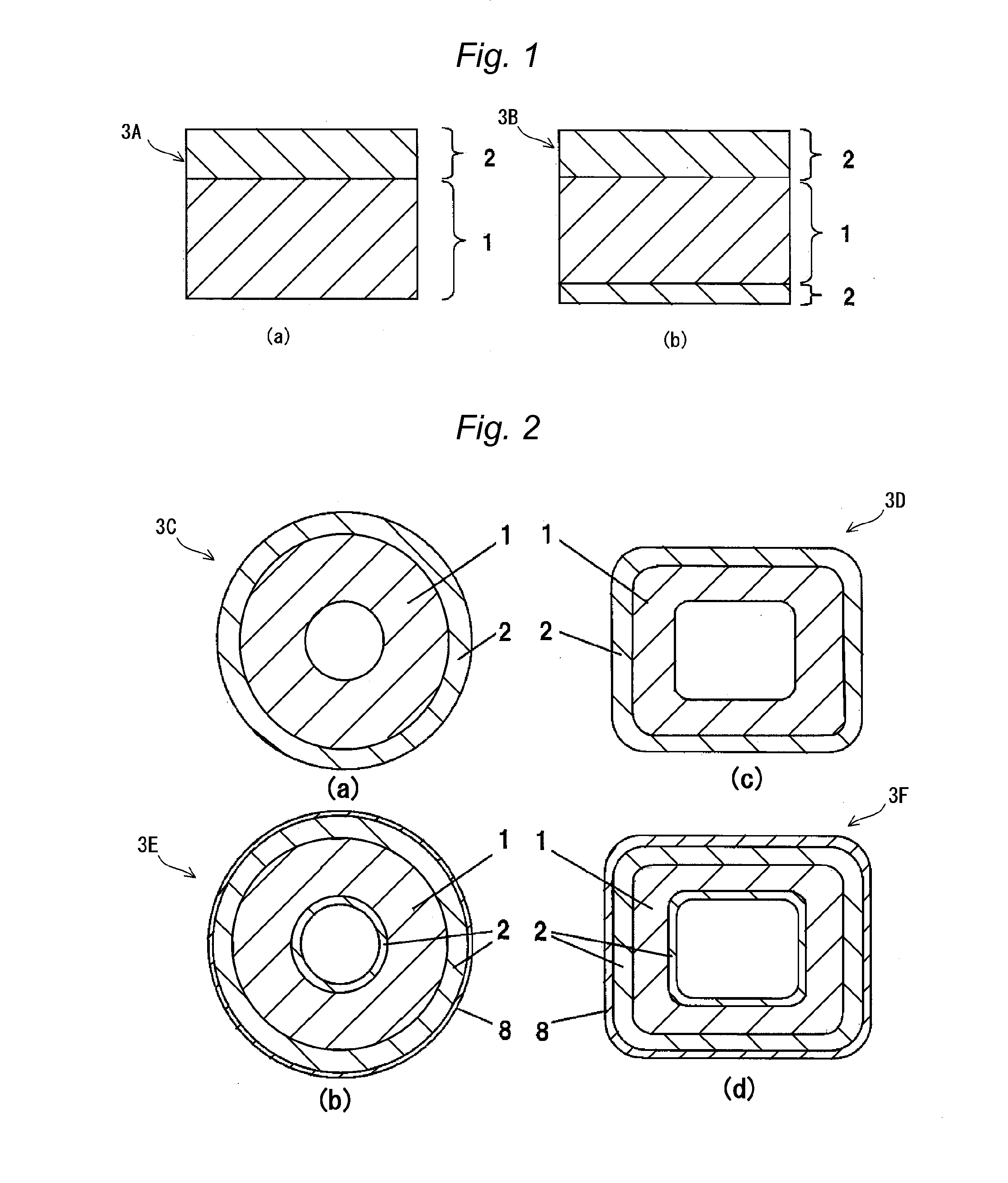

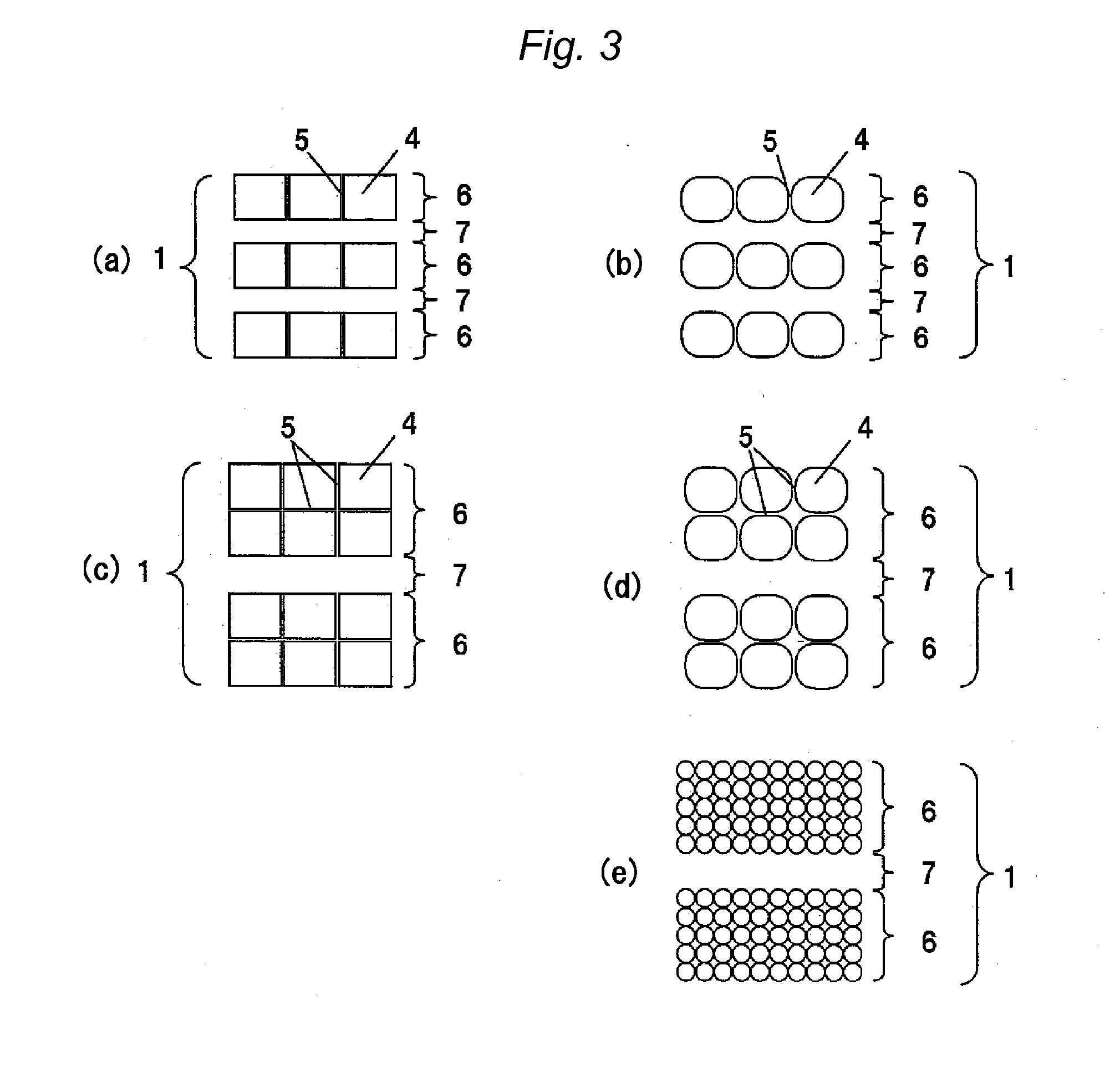

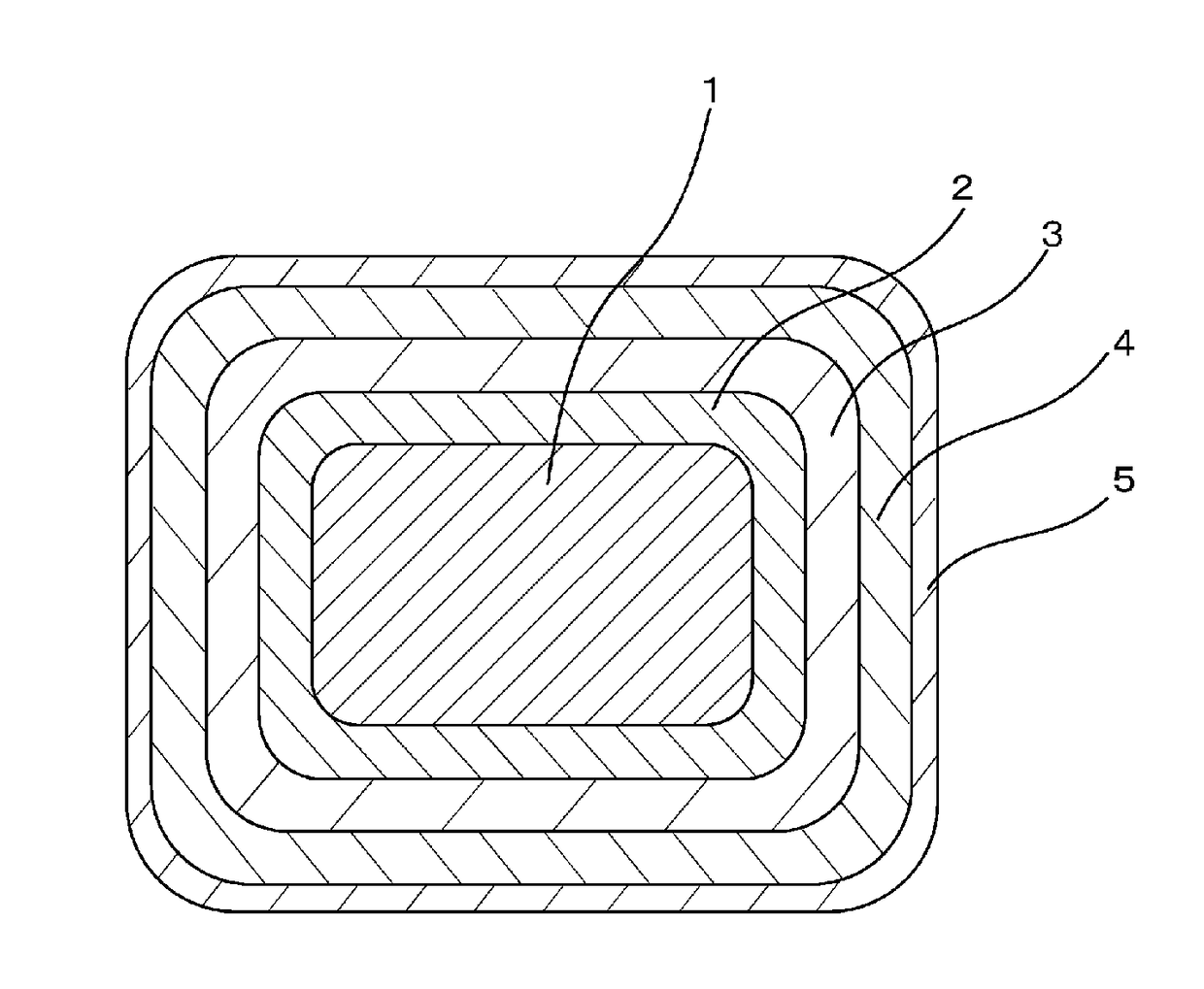

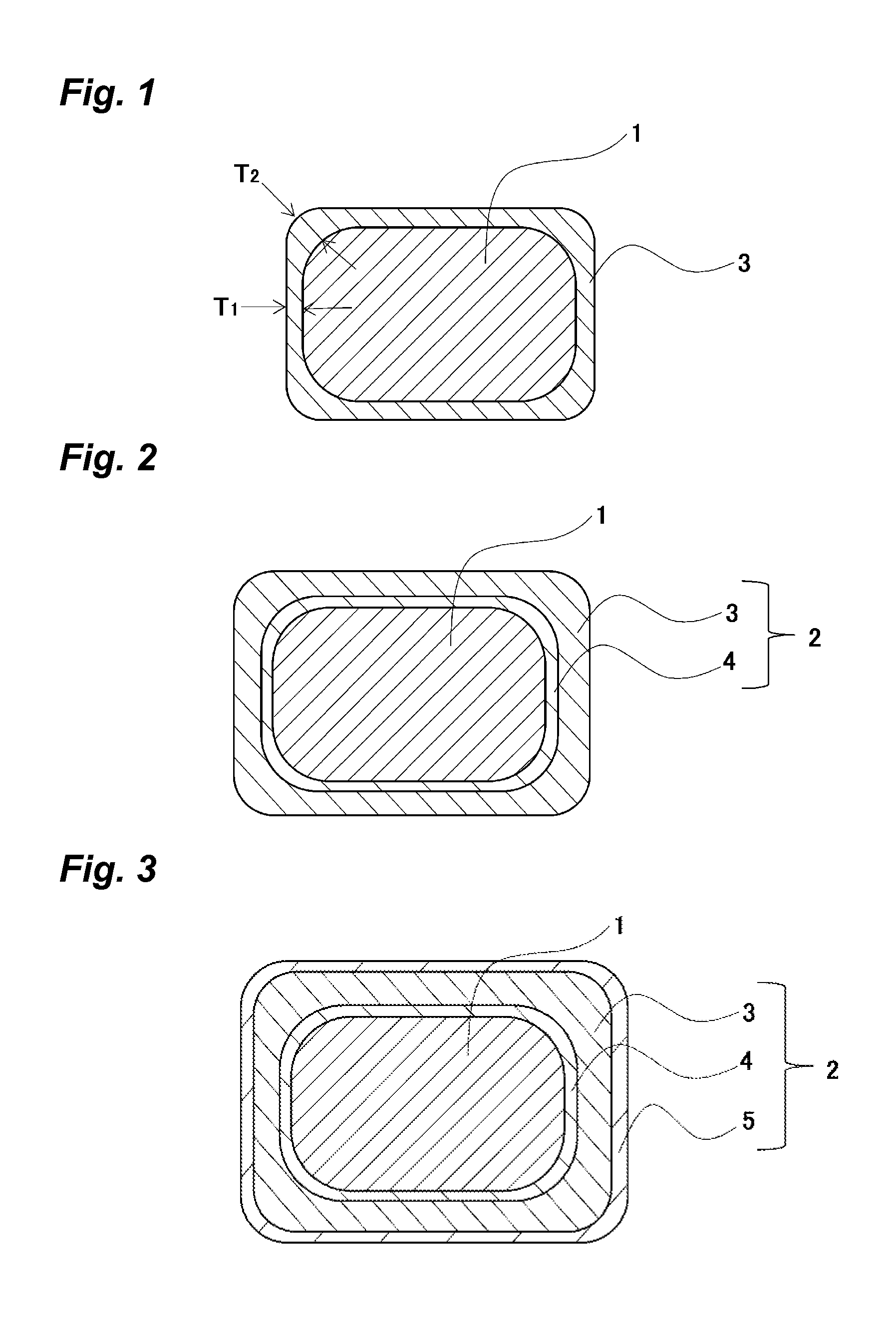

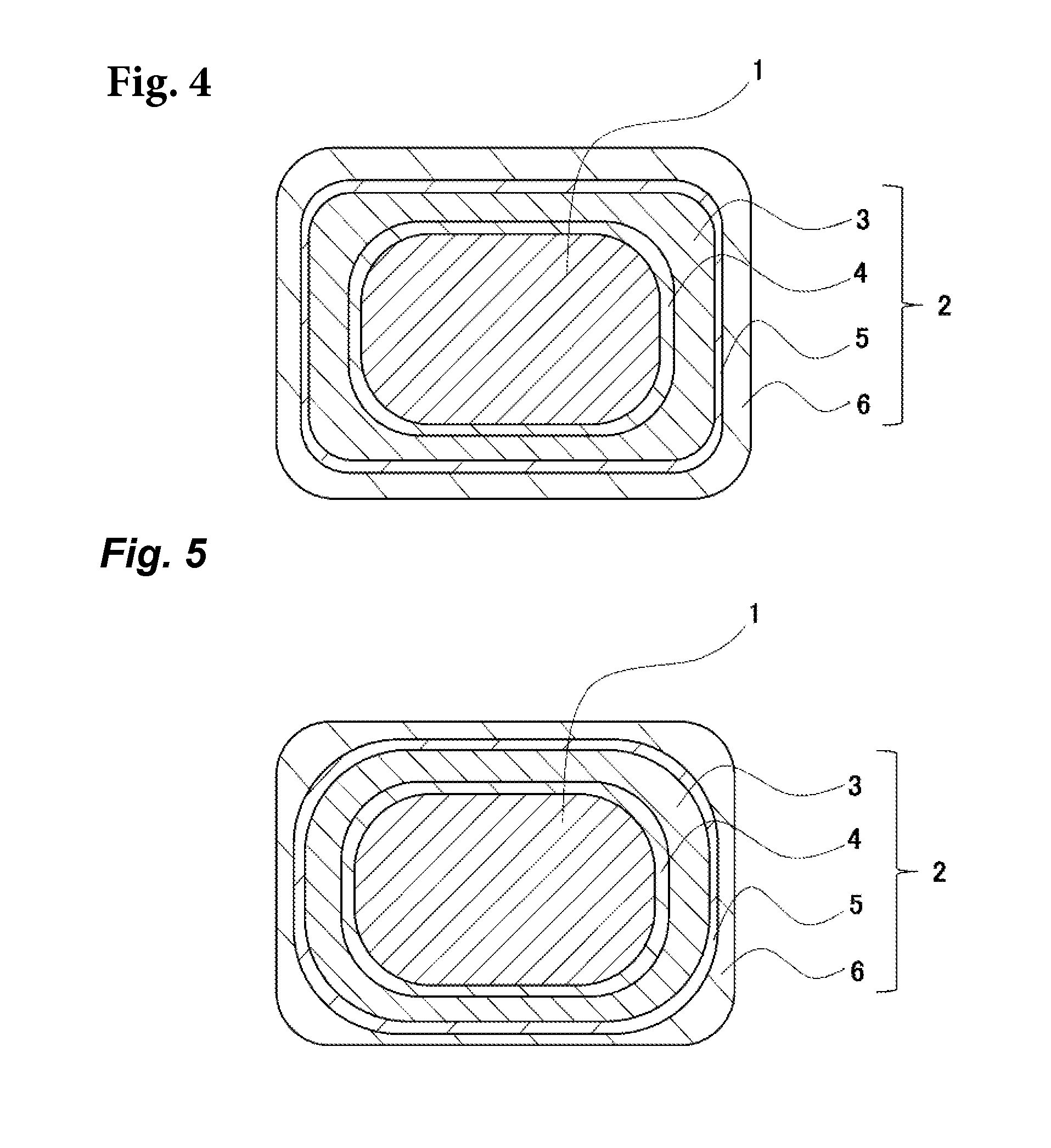

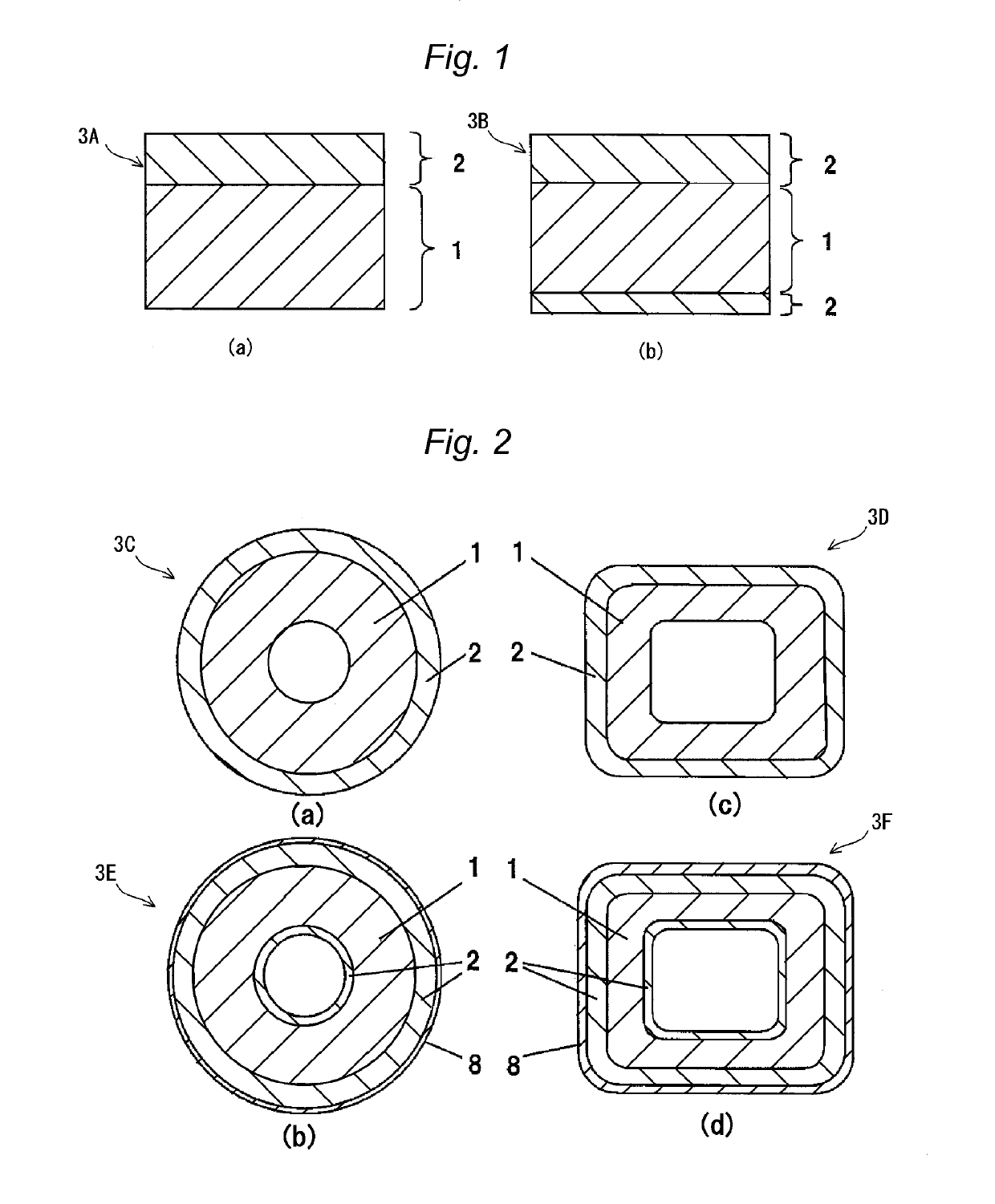

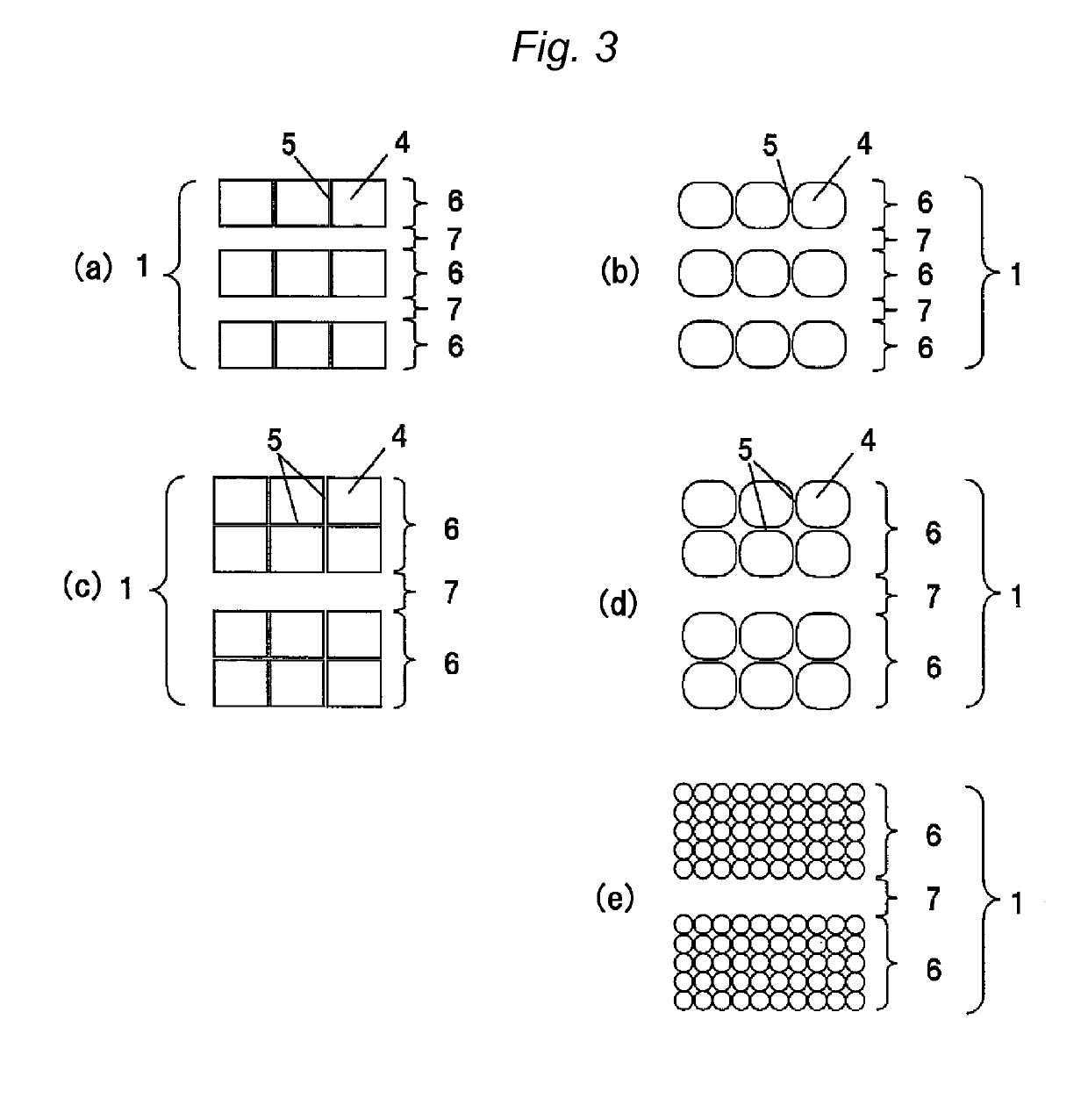

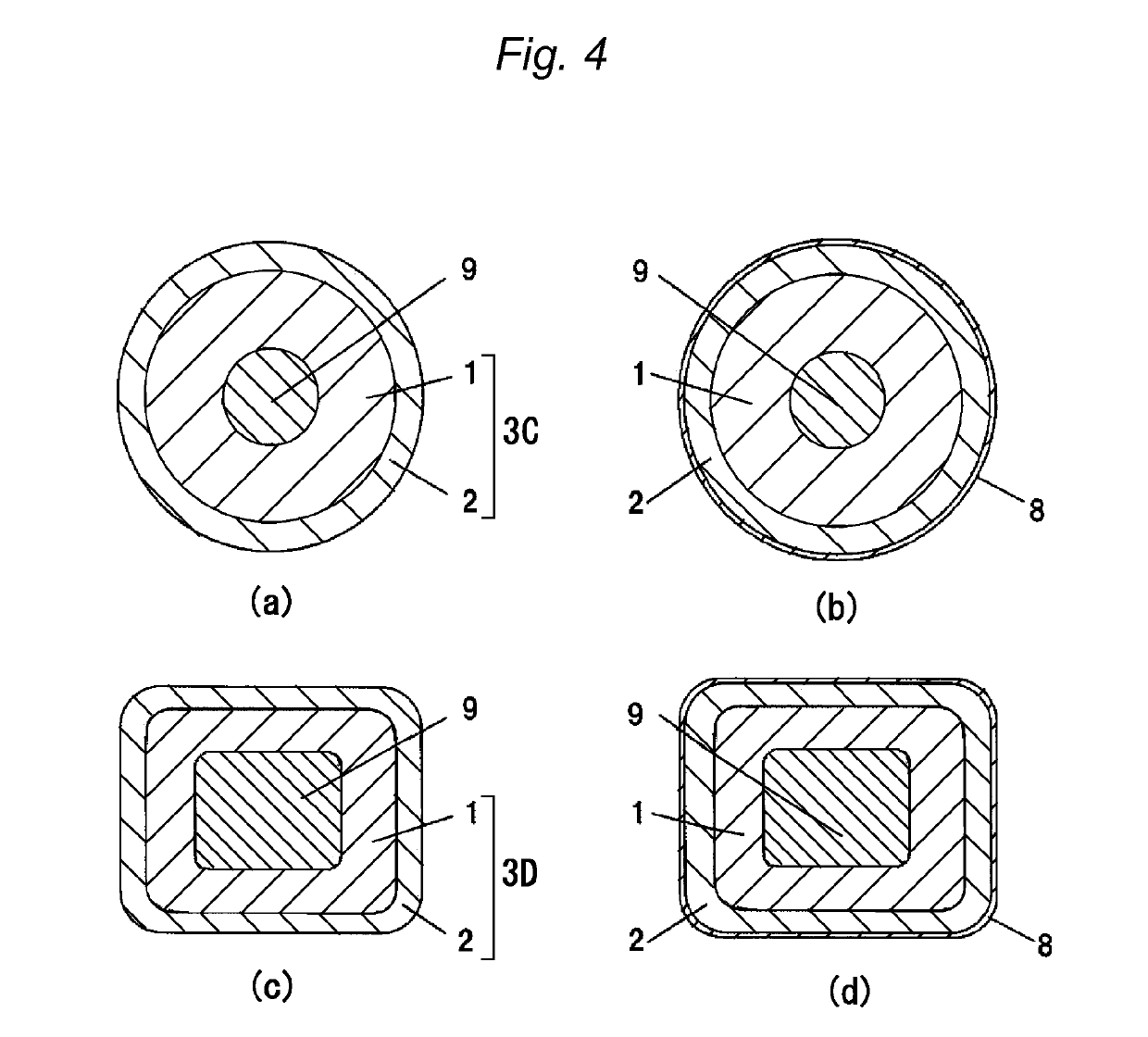

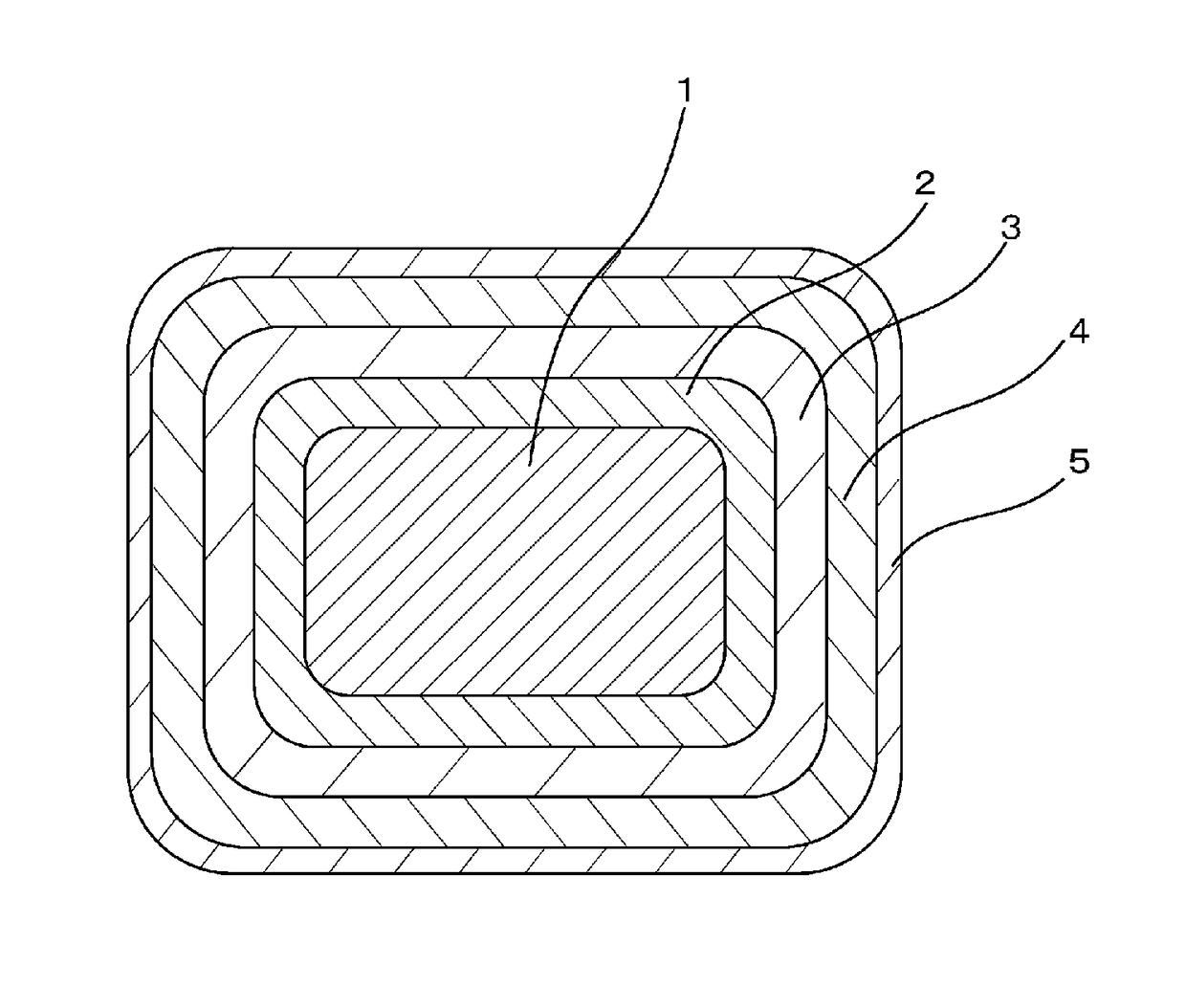

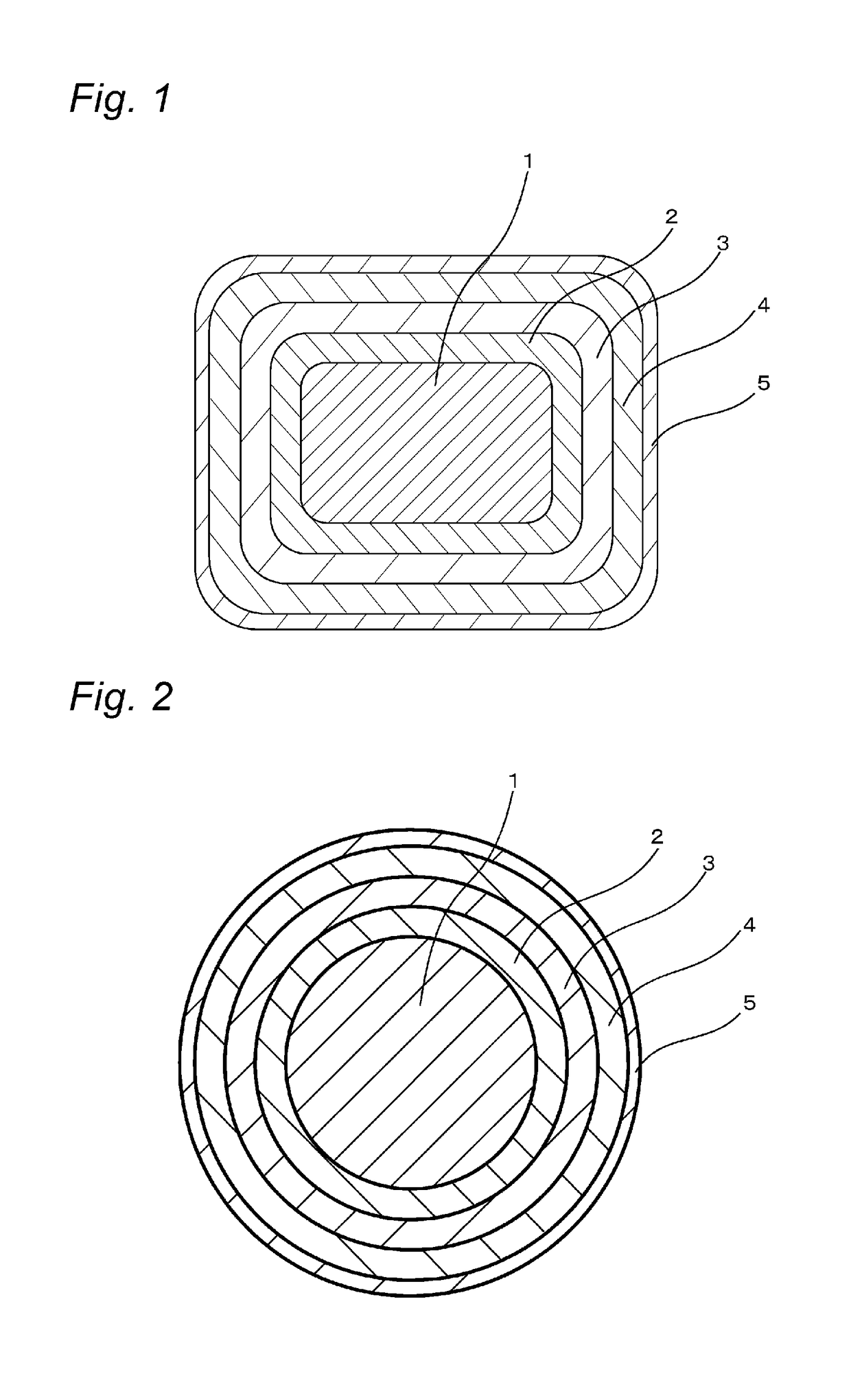

ActiveUS20150325333A1Improve partial dischargeSmall dielectric constantWindings insulation materialLayered productsElectrical conductorCell layer

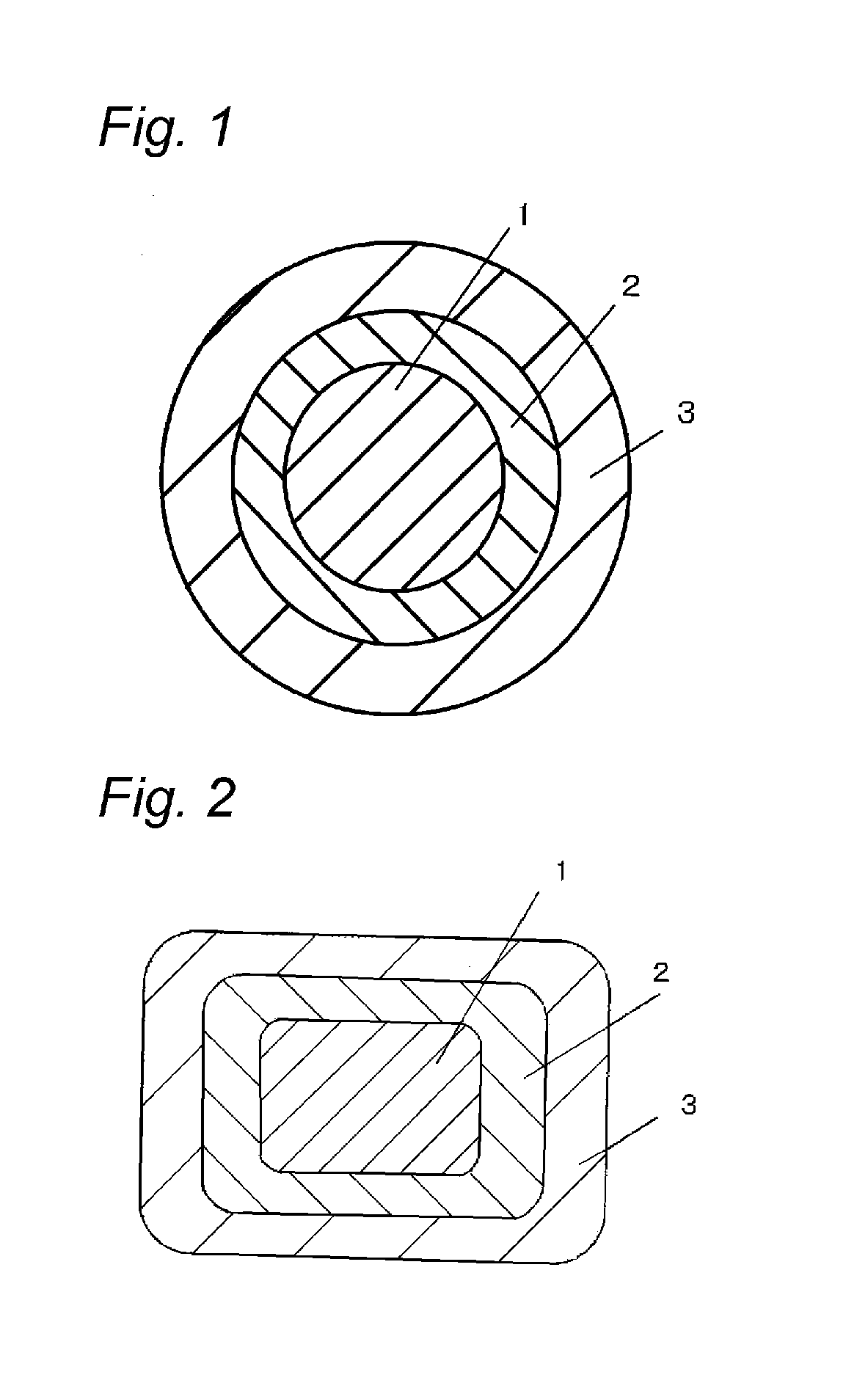

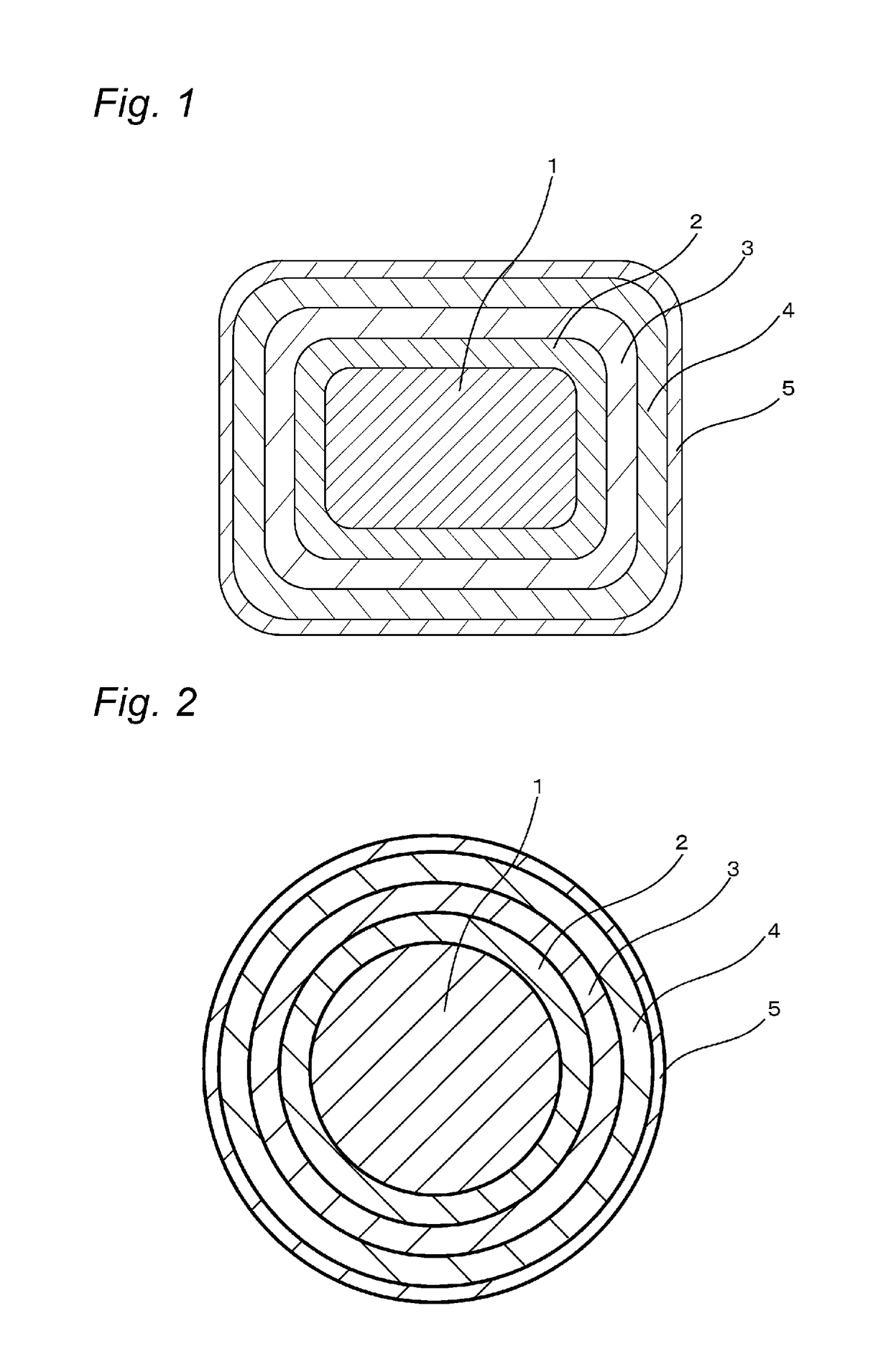

An enamel resin-insulating laminate that has a foamed region including cells and a non-foamed region including no cells on at least one surface of the foamed region, and is shaped into a flat plate form or cylindrical form, wherein the foamed region is configured such that a non-cell layer including no cells has cell layers formed of closed cells on both surface sides of the non-cell layer, a thickness of the non-cell layer is larger than a thickness of a partition wall among the closed cells, and 5 to 60% of a thickness of the foamed region, and at least the cell layer in the foamed region is formed of a thermosetting resin; an inverter surge-resistant insulated wire having a conductor and the enamel resin-insulating laminate; and electric / electronic equipment.

Owner:ESSEX FURUKAWA MAGNET WIRE LLC

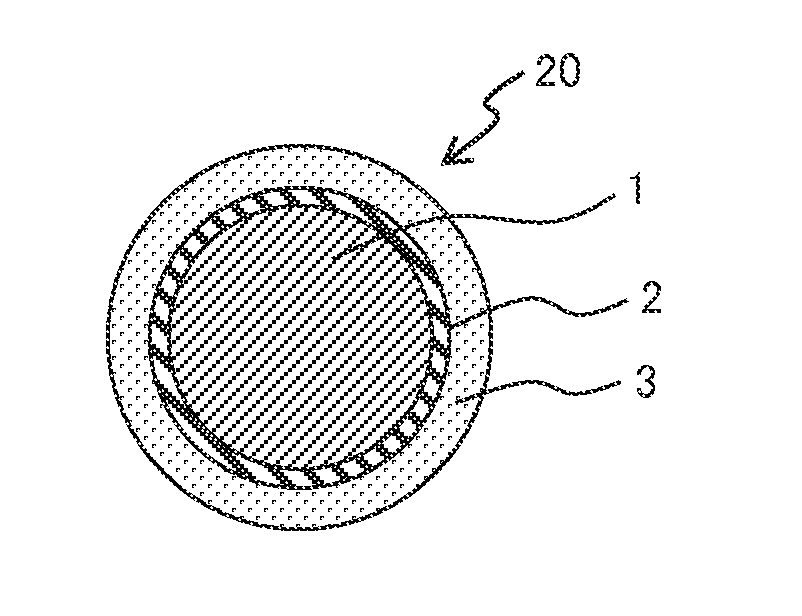

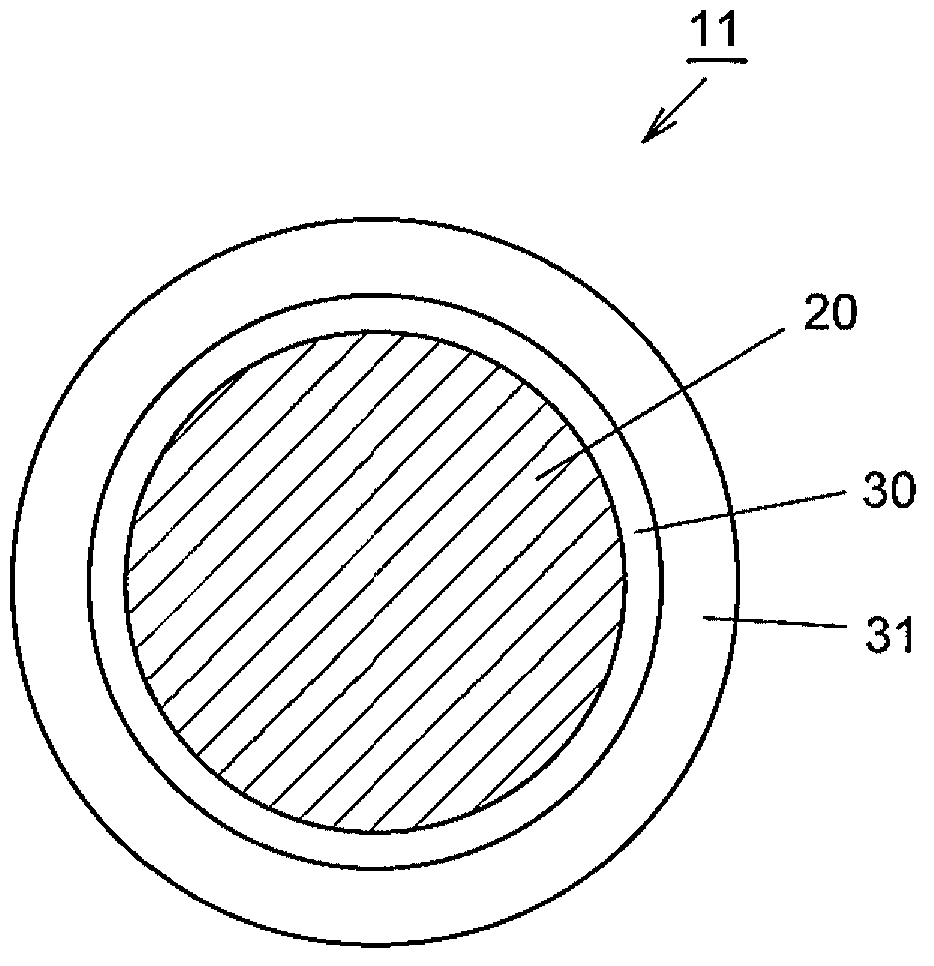

Insulated wire and method of producing the same

ActiveUS20170084361A1Improve adhesionReduced strengthWindings insulation materialPlastic/resin/waxes insulatorsInsulation layerElectrical conductor

An insulated wire which comprises an aluminum conductor, having: an adhesion layer formed by directly baking, on the aluminum conductor, varnish containing a carboxy group; an insulation layer as an outer layer of the adhesion layer; and a reinforcement insulation layer as an outer layer of the insulation layer; and a method of producing the same.

Owner:ESSEX FURUKAWA MAGNET WIRE LLC

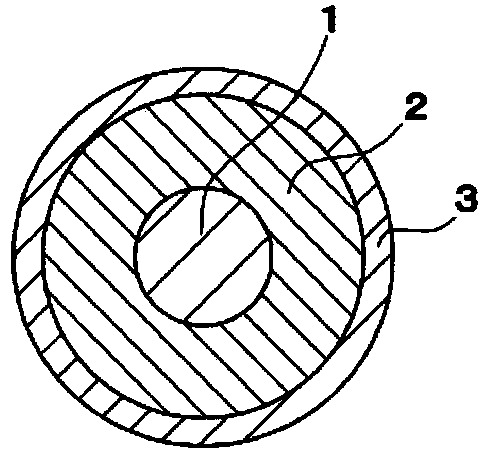

Inverter surge-resistant insulated wire

ActiveUS9224523B2High partial discharge inception voltageImprove insulation performanceWindings insulation materialPlastic/resin/waxes insulatorsDielectricElectrical conductor

An inverter surge-resistant insulated wire, having at least one baked enamel layer around the outer periphery of a conductor, and an extrusion-coated resin layer at the outside of the baked enamel layer, wherein a total thickness of the baked enamel layer and the extrusion-coated resin layer is 50 μm or more, a thickness of the baked enamel layer is 60 μm or less, and a thickness of the extrusion-coated resin layer is 200 μm or less, wherein the minimum of tensile elastic modulus of the extrusion-coated resin layer at a range of 25 to 250° C. is 100 MPa or more, wherein a dielectric constant of an insulation layer having a combination of the baked enamel layer and the extrusion-coated resin layer is 3.5 or less at 25° C. and 5.0 or less at 250° C., and wherein a relation between dielectric constant (∈1′) of the baked enamel layer at 250° C. and dielectric constant (∈2′) of the extrusion-coated resin layer at 250° C. satisfies (∈2′ / ∈1′)>1.

Owner:ESSEX FURUKAWA MAGNET WIRE LLC

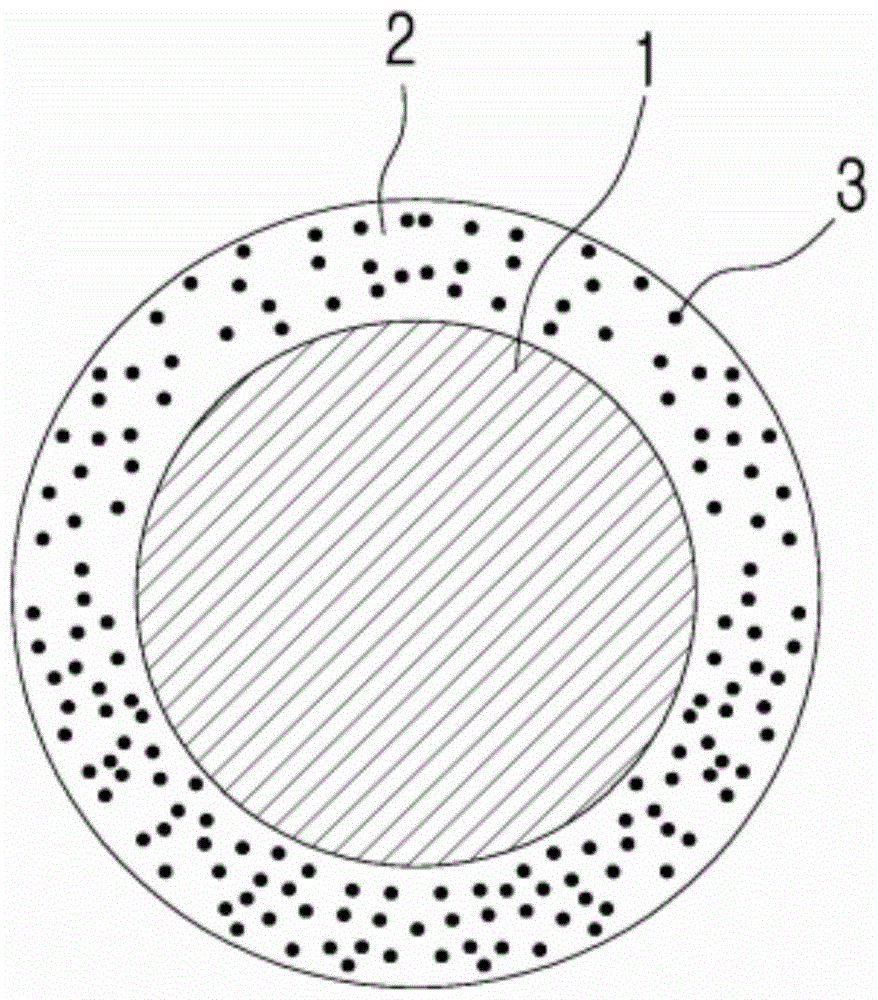

Insulated wire

InactiveUS20130130031A1Improve heat resistanceHigh partial discharge inception voltagePlastic/resin/waxes insulatorsInsulated cablesEngineeringElectrical conductor

There is provided an insulated wire including a wire conductor and at least one extruded insulation layer formed on the wire conductor. The at least one extruded insulation layer is made of a phase separated resin composition including: a resin (A) including polyether ether ketone as a continuous phase; and a resin (B) with a relative dielectric constant of 2.6 or less as a dispersed phase.

Owner:HITACHI METALS LTD

Insulated wire

InactiveCN103123816AImprove heat resistanceHigh partial discharge inception voltageInsulated cablesInsulatorsElectrical conductorInsulation layer

There is provided an insulated wire including a wire conductor and at least one extruded insulation layer formed on the wire conductor. The at least one extruded insulation layer is made of a phase separated resin composition including: a resin (A) including polyether ether ketone as a continuous phase; and a resin (B) with a relative dielectric constant of 2.6 or less as a dispersed phase.

Owner:HITACHI METALS LTD

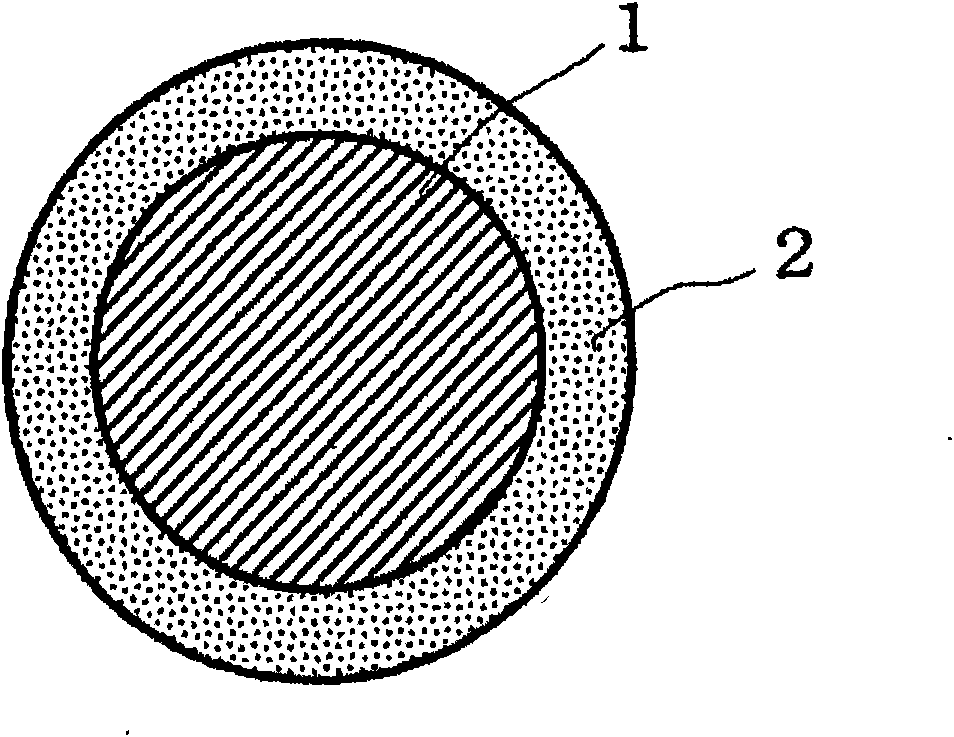

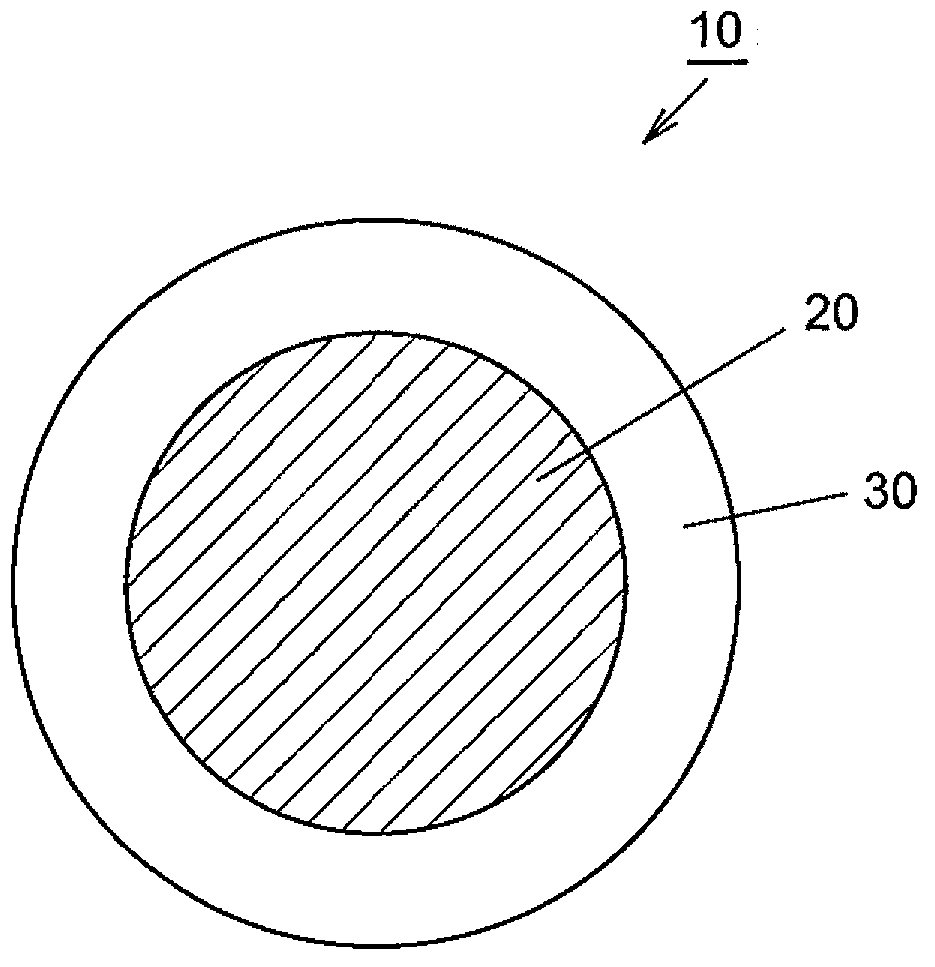

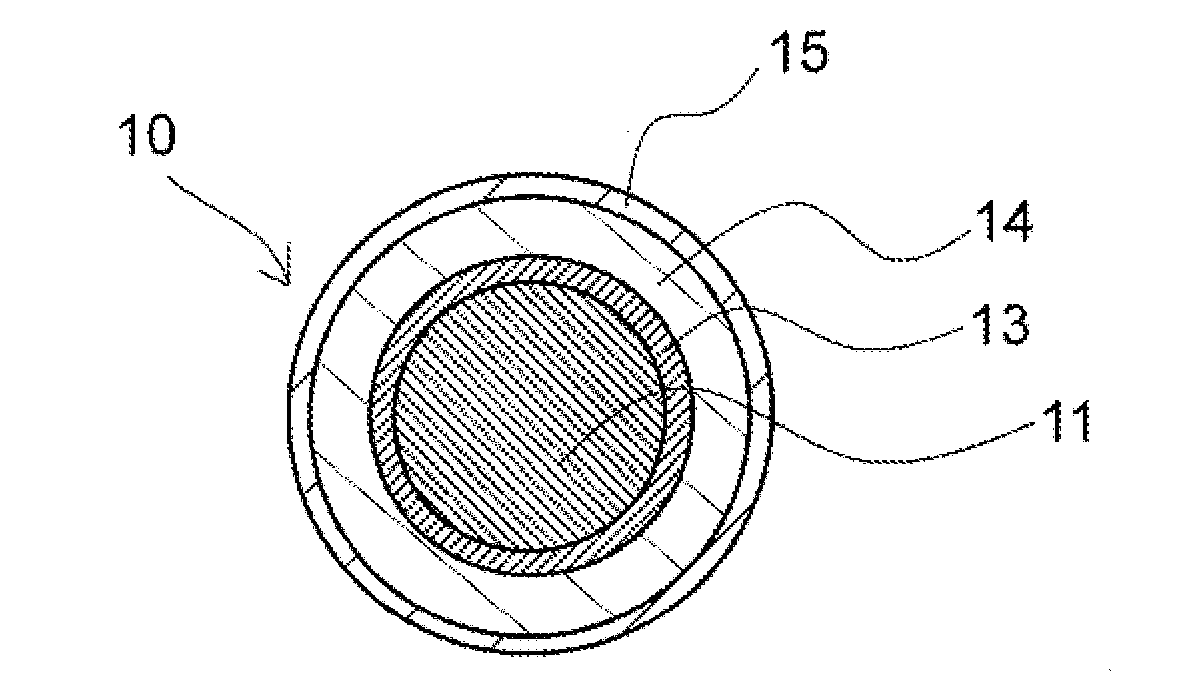

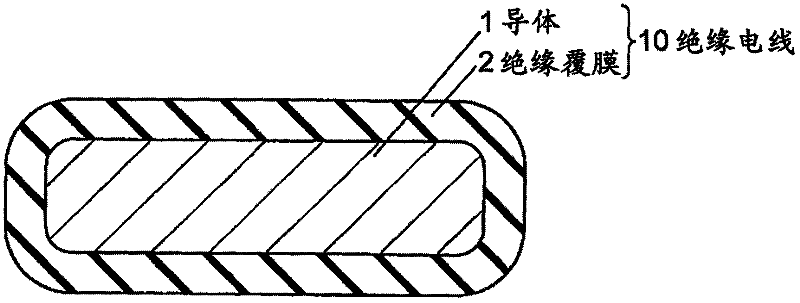

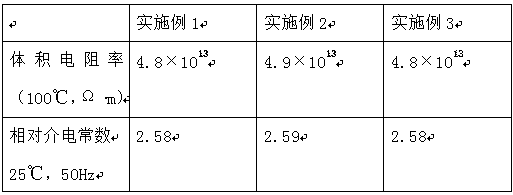

Insulated wire and method of manufacturing the same

InactiveCN102915795AHigh partial discharge inception voltageImprove heat resistancePlastic/resin/waxes insulatorsInsulated cablesElectrical conductorHeat resistance

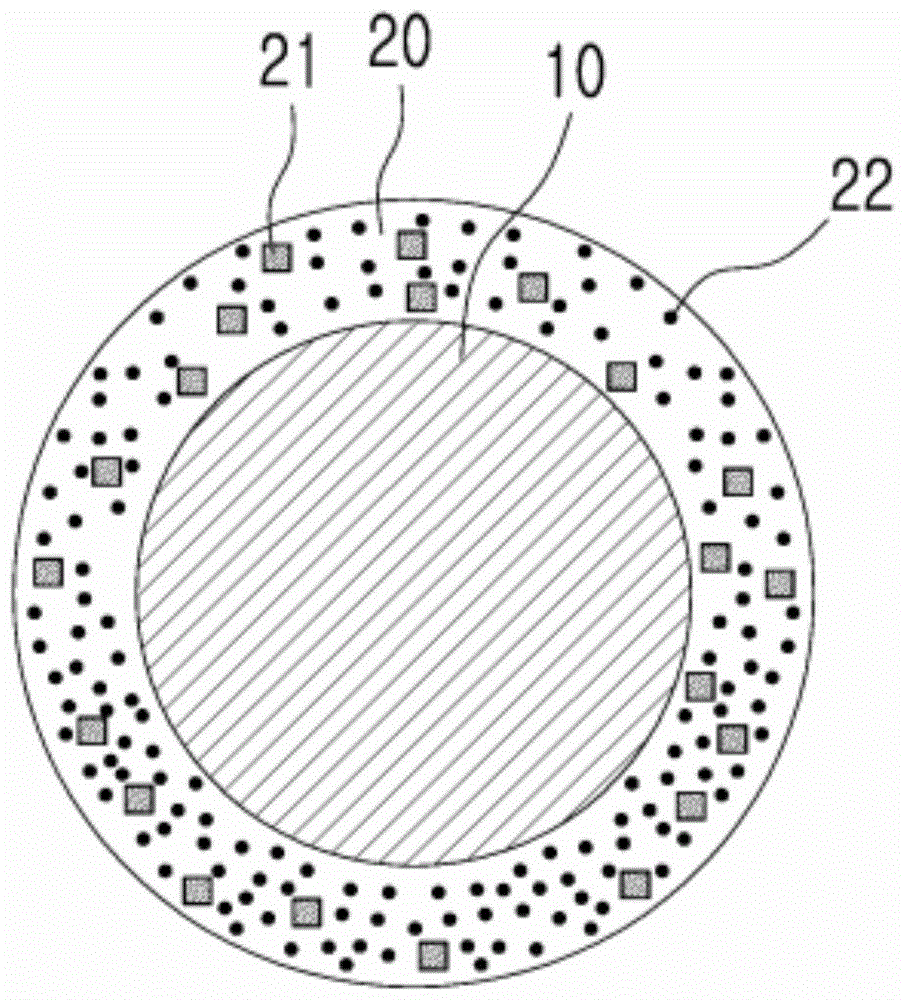

The invention provides a insulated wire and method of manufacturing the same, wherein the insulated wire is characterized by a high partial discharge inception voltage, and excellent heat resistance and adaption tightness. The insulated wire (10) includes a conductor, and an insulation covering layer around the conductor. The insulation covering layer includes a resin composition containing a resin (A) including at least one of a polyphenylene sulfide resin and a polyetheretherketone resin and a resin (B) containing a polyethylene. The resin composition has a storage elastic modulus at 150 DEG C. of not less than 1105 Pa and not more than 1109 Pa, and a store elastic modulus at 300 DEG C. of not less than 1104 Pa and not more than 1108 Pa.

Owner:HITACHI METALS LTD

Insulated wire, and electric/electronic equipments, motor and transformer using the same

ActiveUS9424961B2Increase spacingReduce insulation thicknessWindings insulation materialWindings insulation shape/form/constructionElectrical conductorTransformer

Owner:ESSEX FURUKAWA MAGNET WIRE LLC

Insulated wire

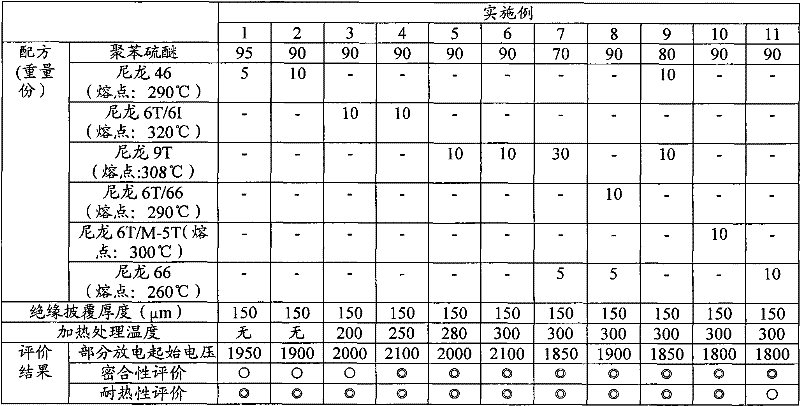

InactiveCN102208230AAdhesion does not decreaseHigh partial discharge inception voltagePlastic/resin/waxes insulatorsFlexible cablesElectrical conductorPolyamide

An objective of the present invention is to provide an insulated wire having a higher partial discharge inception voltage than conventional insulated wires without sacrificing the adhesion between the wire conductor and the insulating coating. There is provided an insulated wire including a wire conductor and an insulation coating formed on the wire conductor by extrusion coating a resin composition. The resin composition is a mixture of a polyphenylene sulfide-based resin (A) and a polyamide-based resin (B), in which a ratio of parts by mass of the resin (B) to that of the resin (A), i.e. (B) / (A), is not less than 5 / 95 and not more than 30 / 70.

Owner:PROTERIAL LTD

Polyamide-imide resin insulating coating material and insulated wire using the same

InactiveUS20120211258A1High partial discharge inception voltageDesired characteristicPlastic/resin/waxes insulatorsCoatingsPolyamide-imideTricarboxylic acid

A polyamide-imide resin insulating coating material includes a polyamide-imide resin produced by reacting an aromatic diisocyanate component with a composition obtained by a synthesis reaction of a diamine component with an acid component that includes an aromatic tricarboxylic acid anhydride component (A) and an aromatic tetracarboxylic dianhydride component (B). The aromatic tetracarboxylic dianhydride component (B) includes an aromatic tetracarboxylic dianhydride component (B-1) having not less than four aromatic rings.

Owner:HITACHI METALS LTD

Nonflammable and disaster prevention type capacitor

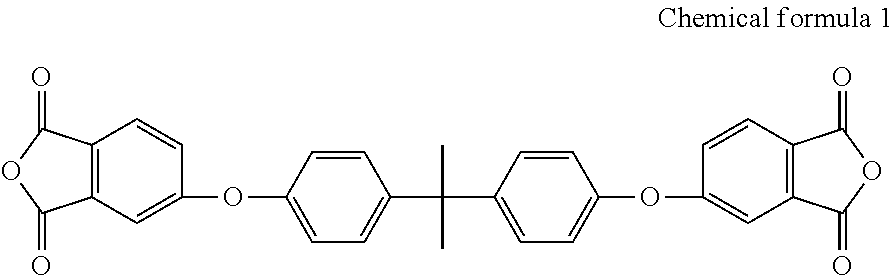

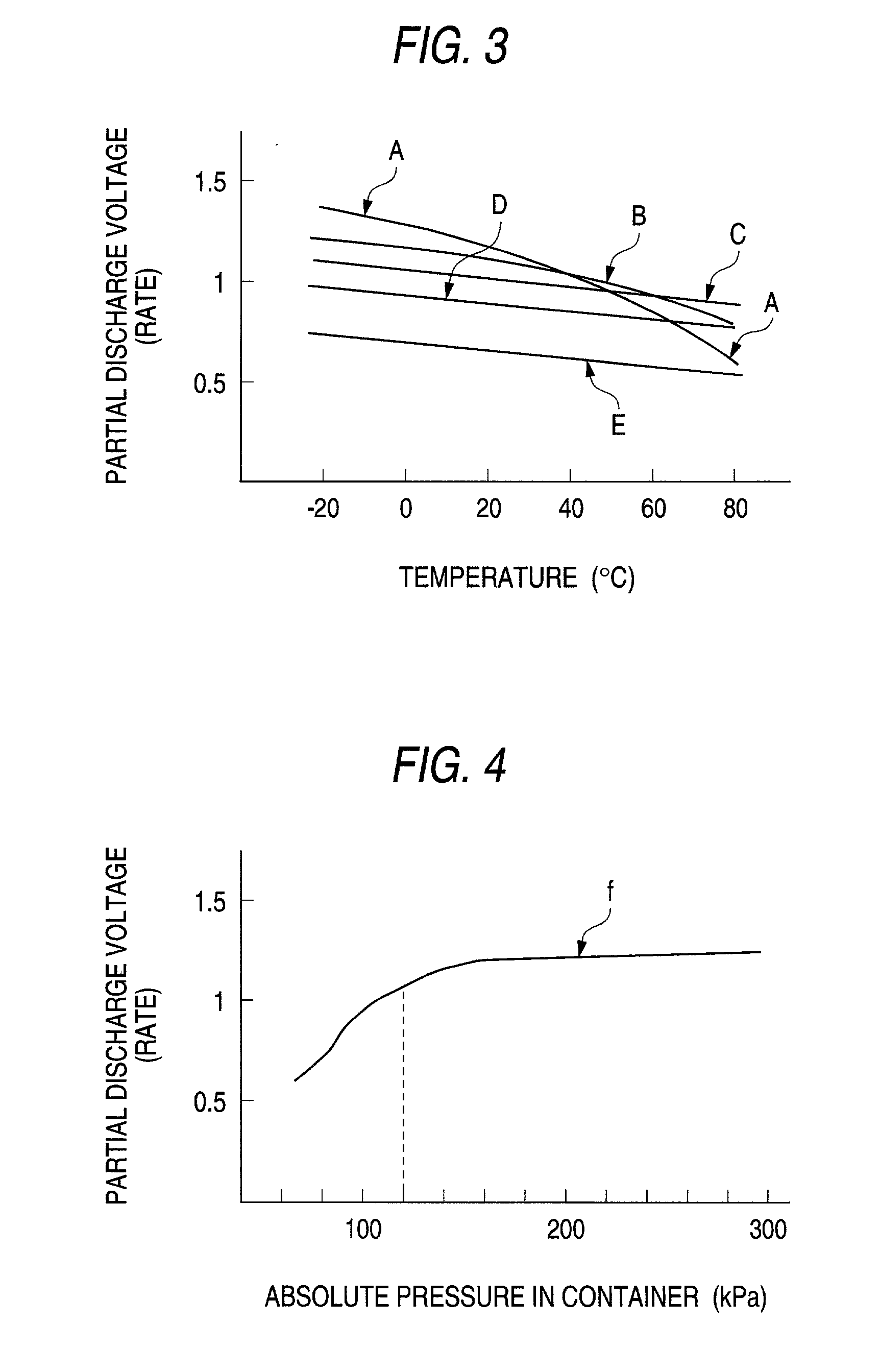

InactiveUS20010033473A1Downsizing of the capacitorEasy to useMultiple fixed capacitorsLiquid organic insulatorsBoiling pointEngineering

In a nonflammable and disaster prevention type capacitor, the sealing property of the capacitor container is increased, a plurality of capacitor elements are collected, is accommodated in the container, and its inside is vacuum deaerated, the perfluorocarbon liquid deaerated by a deaeration apparatus is filled, and a capacitor which maintains an amount of residual air in the perfluorocarbon liquid to be not larger than 5%, is formed. A fluoride liquid to be filled in the container, consisting of a connection of carbon, fluorine and oxygen, and which includes per fluoropolyether by not smaller than 90% and whose boiling point is not lower than 120° C. and not higher than 270° C., and whose dynamic viscosity at 25° C. is from 0.9 mm2 / s to not larger than 14 mm2 / s, is impregnated into the capacitor element. An absolute pressure in the container is not smaller than 120 kPa and not larger than 300 kPa.

Owner:NISSIN ELECTRIC CO LTD

Insulated wire

ActiveCN102081997AHigh partial discharge inception voltagePlastic/resin/waxes insulatorsFlexible cablesElectrical conductorPolyamide-imide

Provided is an insulated wire, which is one having a high partial discharge inception voltage even if an insulated coating layer disposed on a conductor is only made of an insulated film. The insulated film is formed in the insulated coating layer around the conductor. The insulating film is formed by applying and baking the polyamide-imide resin insulating material having a low dieleltric constant and made of divalent aromatic diamines having three or more aromatic rings.

Owner:PROTERIAL LTD

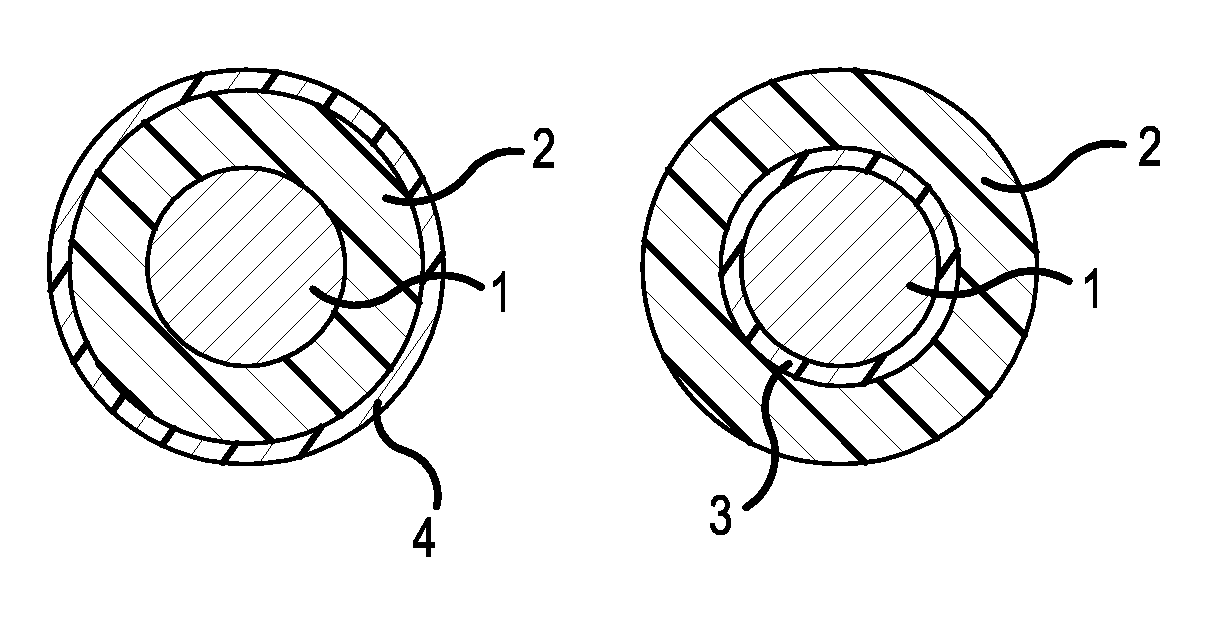

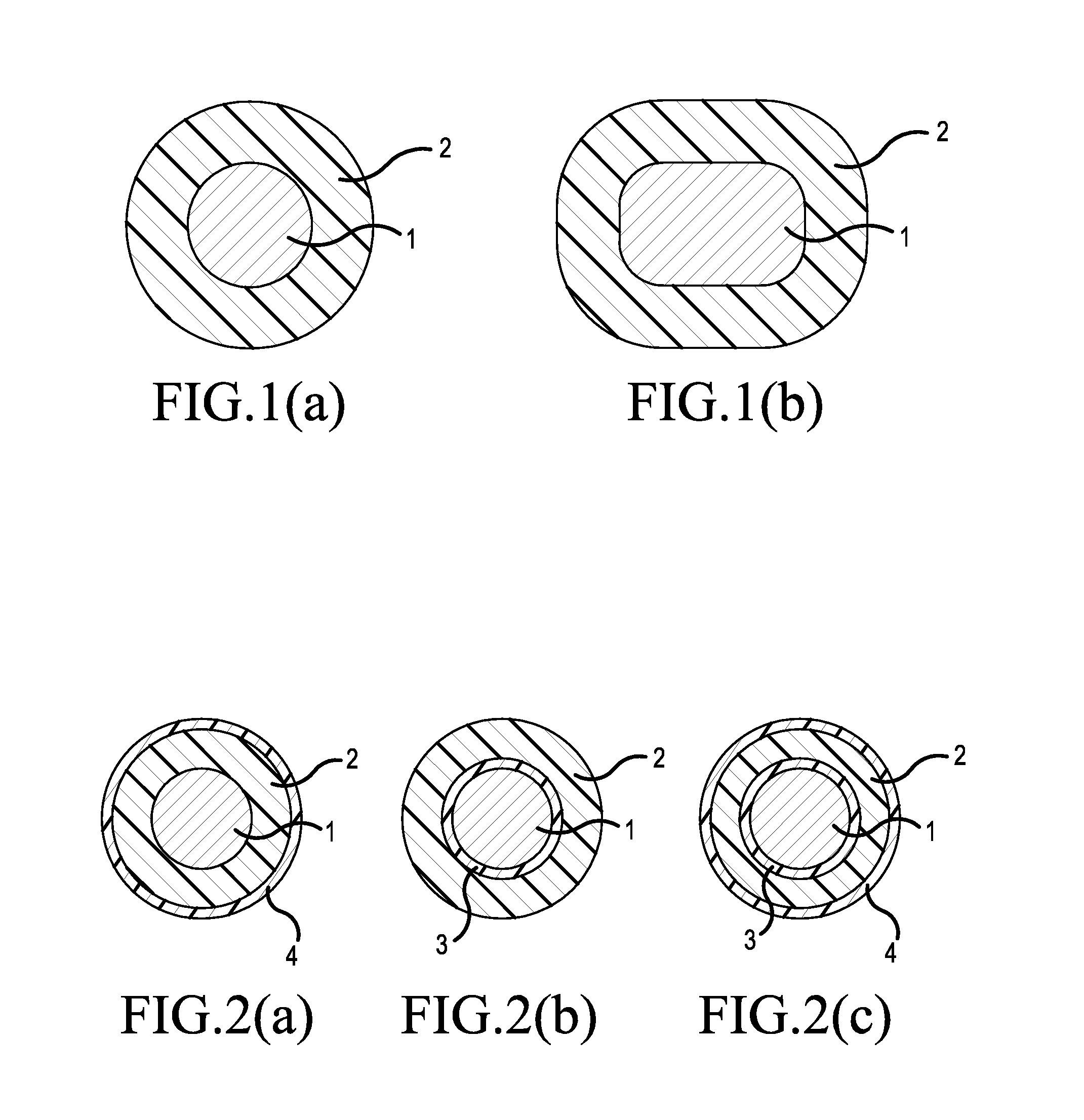

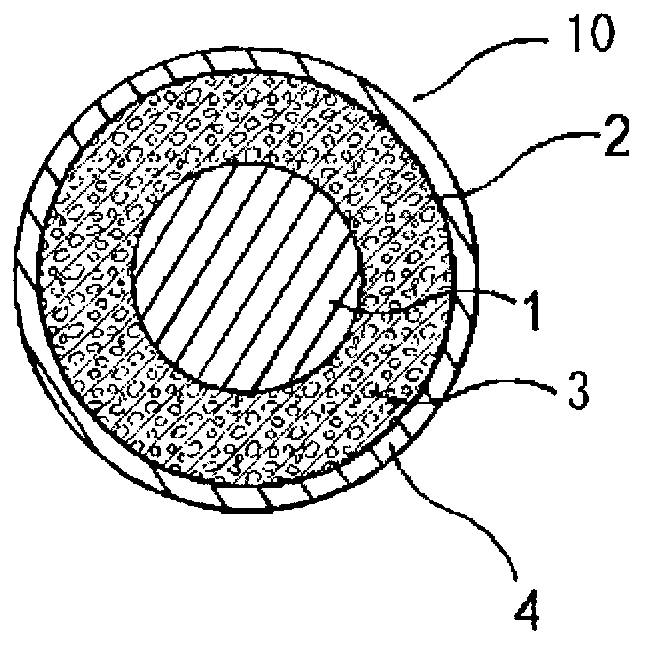

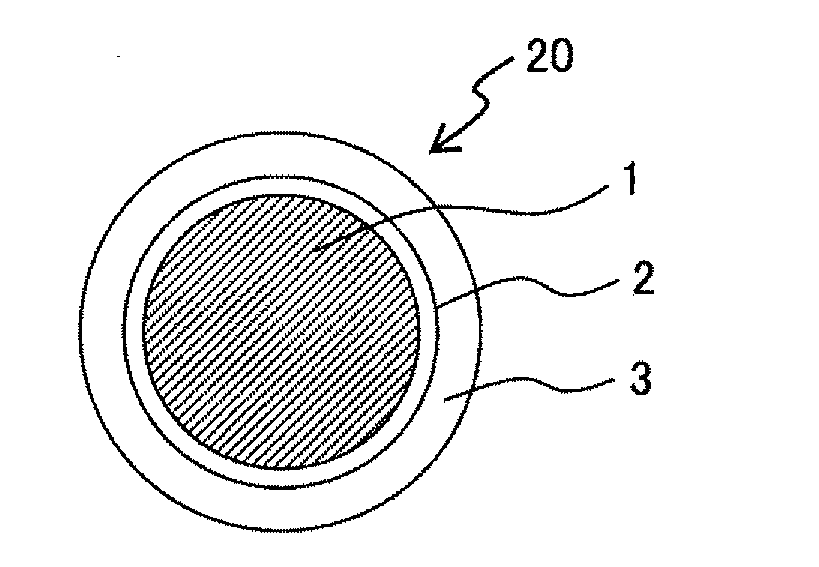

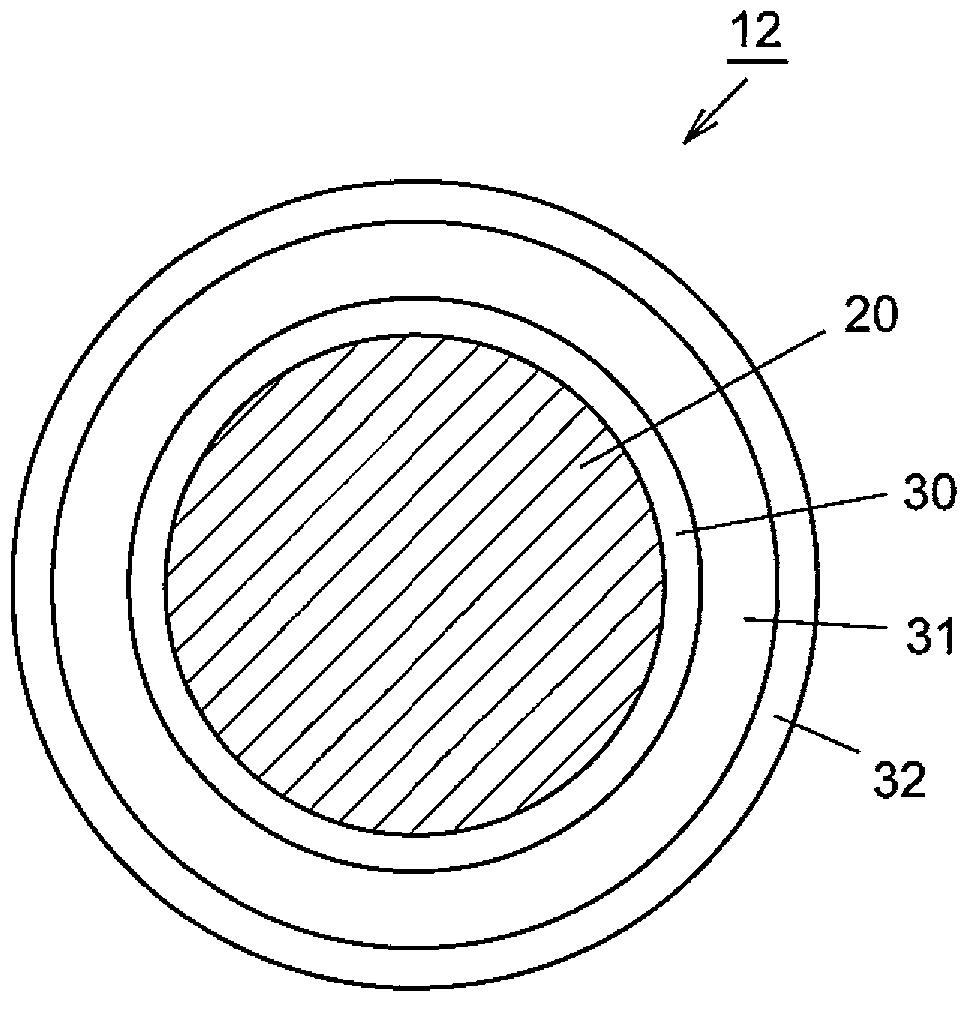

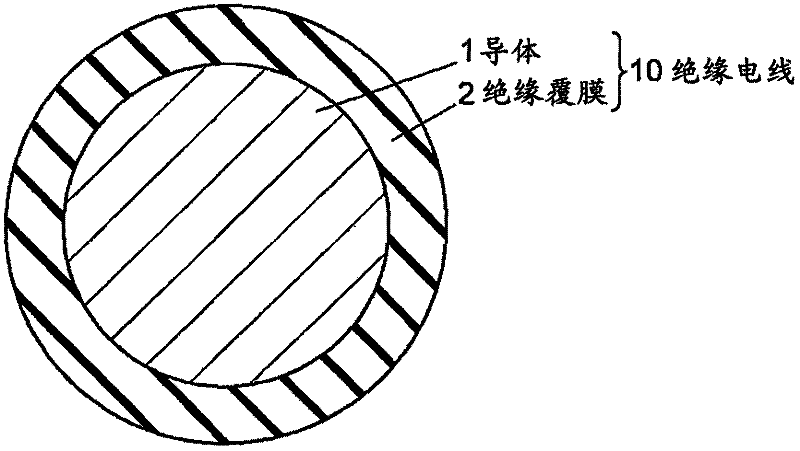

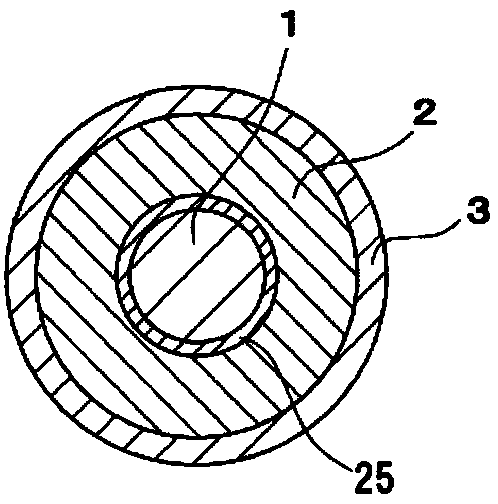

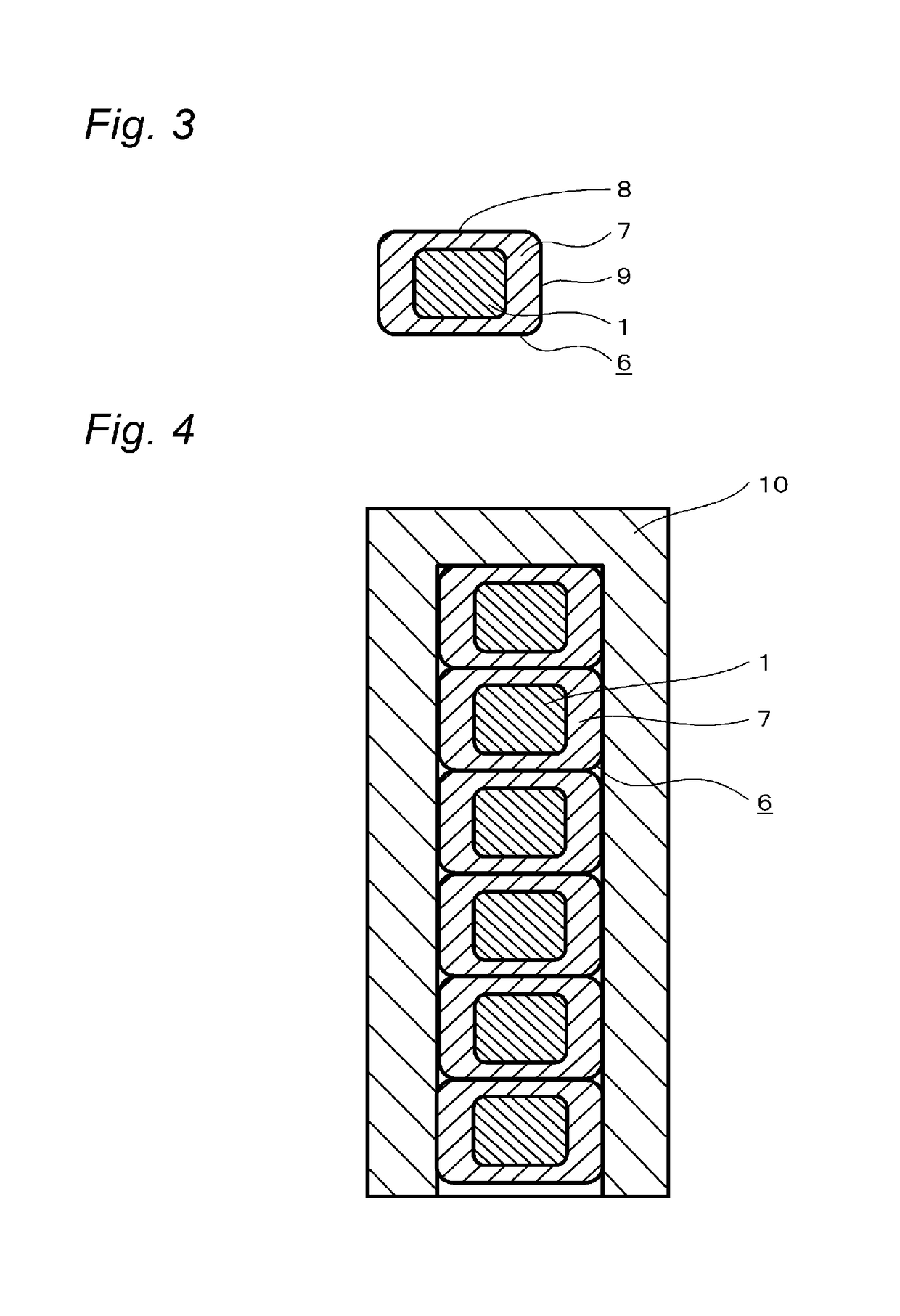

Insulated wire having a layer containing bubbles, electrical equipment, and method of producing insulated wire having a layer containing bubbles

ActiveUS20140354394A1High partial discharge inception voltageHigh heat resistanceWindings insulation shape/form/constructionTransformers/inductances coils/windings/connectionsVarnishEngineering

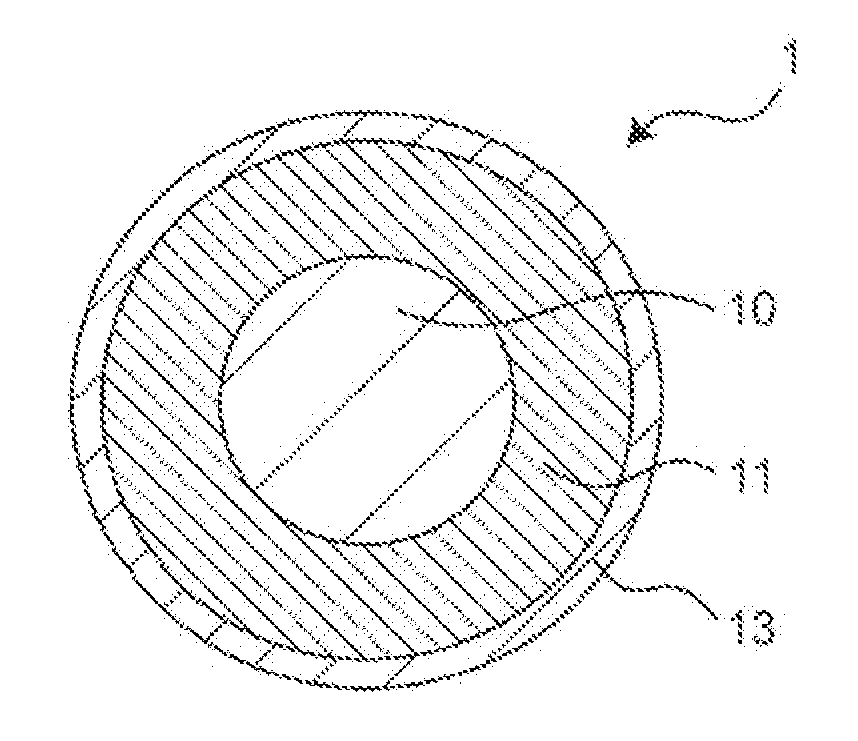

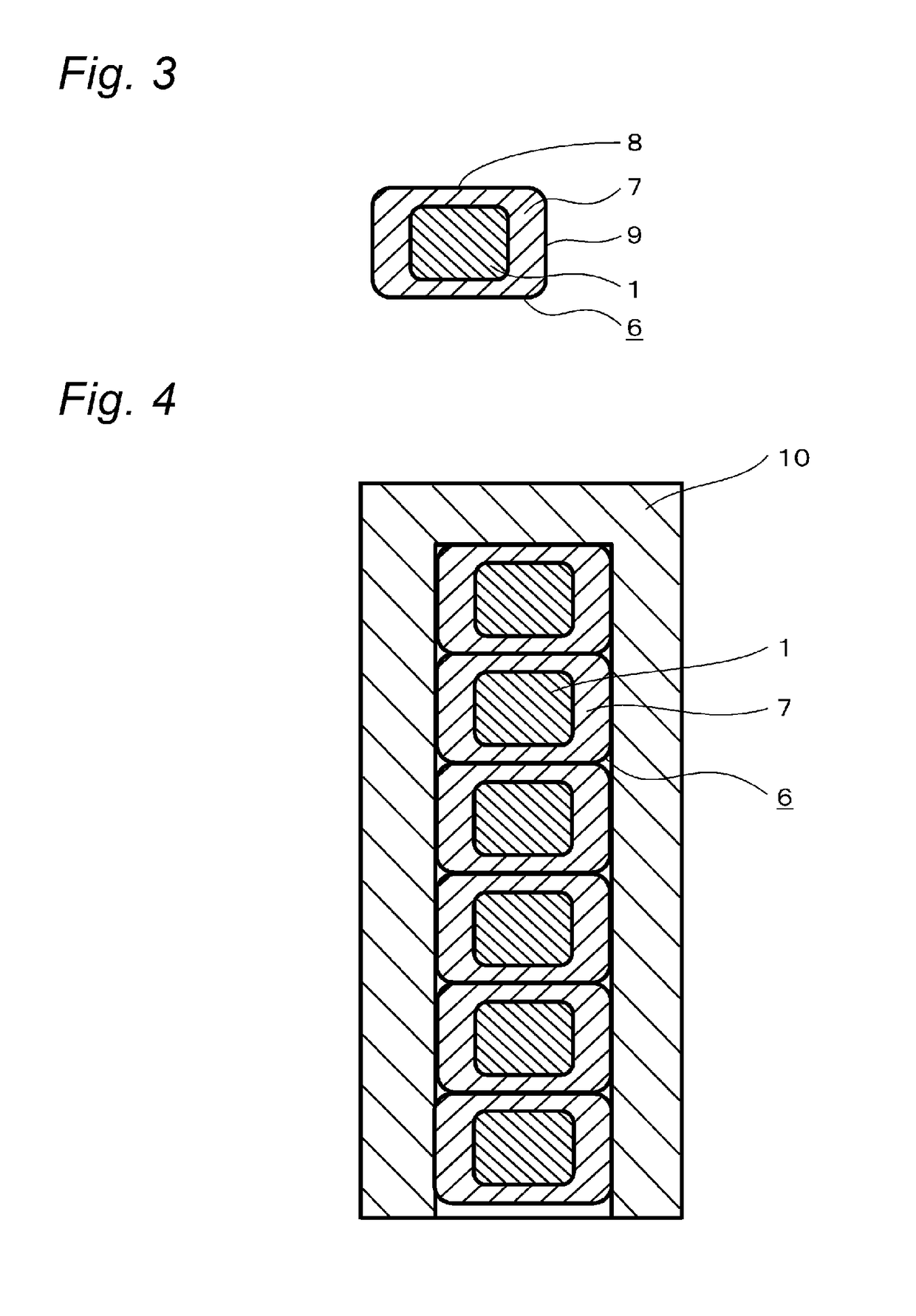

An insulated wire, containing: an insulating film made from a thermosetting resin disposed on a conductor directly or via an insulating layer interposed therebetween, in which the insulating film made from a thermosetting resin is a layer containing bubbles prepared by baking a varnish of thermosetting resin, and a layer containing no bubbles is formed as an upper or lower layer of the layer containing bubbles.

Owner:ESSEX FURUKAWA MAGNET WIRE LLC

Insulating paint and insulated wire using same

ActiveCN102260454AHigh partial discharge inception voltagePlastic/resin/waxes insulatorsInsulated cablesPolyamide-imideVarnish

Owner:HITACHI METALS LTD

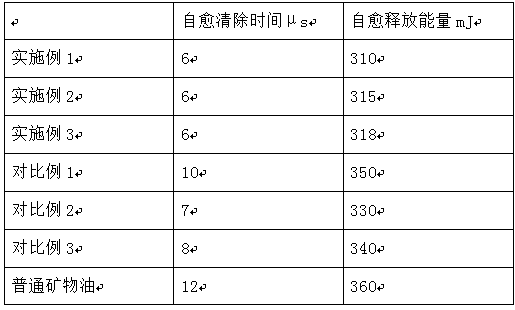

Capacitor impregnation liquid containing modified flaxseed oil

The invention discloses capacitor impregnation liquid containing modified flaxseed oil. The capacitor impregnation liquid is prepared from castor oil, modified sunflower seed oil, urea, ingredients, dispersant MF, peanut oil, octanedioic acid and rice bran oil; the ingredients are prepared from attapulgite, zeolite powder and diatomite. The prepared capacitor impregnant is environmentally friendlyand free of pollution, good in using effect, high in high-temperature resistance, high in heat dissipation performance, safe, reliable and durable, through the synergetic effect of the modified sunflower seed oil, urea, octanedioic acid and the rice bran oil, the local discharge initial voltage of a medium system can be increased, and the self-healing performance of a capacitor medium is greatlyimproved. By adding the prepared ingredients, the occurrence of corrosion of a counter electrode and lowering of capacitance can be reduced, the dielectric strength and volume resistivity of the impregnant can also be increased to a certain degree, and thus the using performance of a capacitor can be further improved.

Owner:陈馨雅

Polyester imide resin insulating coating material, insulated wire using same, and coil

ActiveUS8986834B2High partial discharge inception voltagePlastic/resin/waxes insulatorsSynthetic resin layered productsPolyesterImide

A insulated wire includes a conductor, and an insulating coating on a periphery of the conductor. The insulating coating includes an insulating film formed by applying and baking a polyester imide resin insulating coating material, and the insulating film has a relative permittivity of less than 3.5 both in a dried state and in a moisture-absorbed state. The insulating film is formed by applying and baking a polyester imide resin insulating coating material including an imide dicarboxylic acid and an alcohol component, the imide dicarboxylic acid being obtained by synthesizing a diamine component including aromatic diamine having not less than three aromatic rings and an acid component including aromatic tricarboxylic acid anhydride.

Owner:HITACHI METALS LTD

Insulated electric wire and motor

ActiveCN104321832AHigh partial discharge inception voltageImprove resistance to damageWindings insulation materialWindings insulation shape/form/constructionInsulation layerElectrical conductor

Provided is an insulated electric wire comprising a conductor, an insulation layer including a foam heat-curable resin and which covers the outer circumferential surface of the conductor, and an outside non-foam insulation layer that covers the outer circumferential surface of the insulation layer. The thickness deformation rate of the insulation layer when a pressure of 1 MPa is applied at 25°C is 15%-50%. The pencil hardness of the outside non-foam insulation layer is at least 4H and the ratio between the insulation layer thickness and the outside non-foam insulation layer thickness is 20:80-80:20. Also provided is a motor having this insulated electric wire wound around a stator slot, in a state in which pressure is applied in the direction in which the outer diameter of the insulated electric wire decreases, and the thickness of the insulation layer is reduced.

Owner:ESSEX FURUKAWA MAGNET WIRE LLC

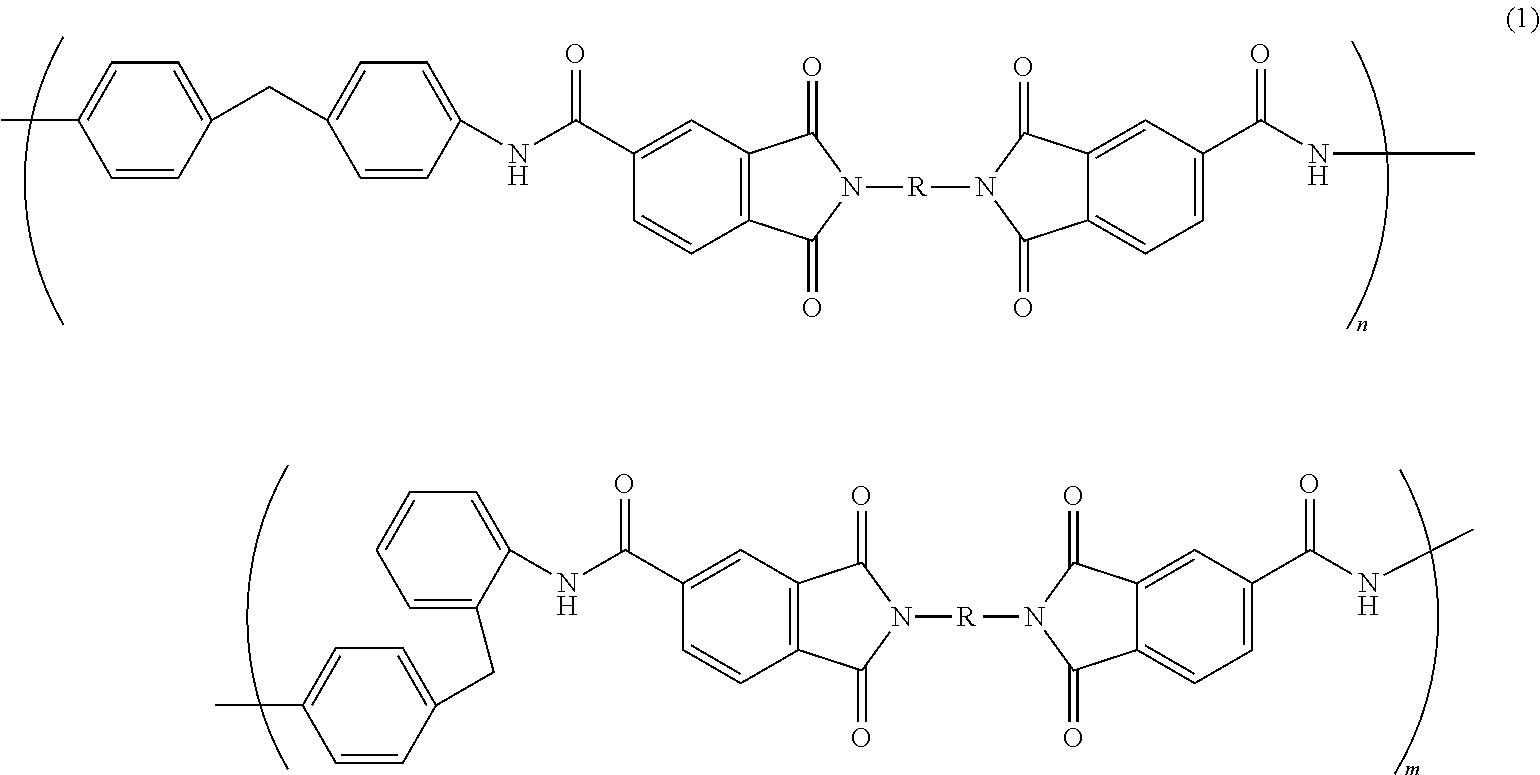

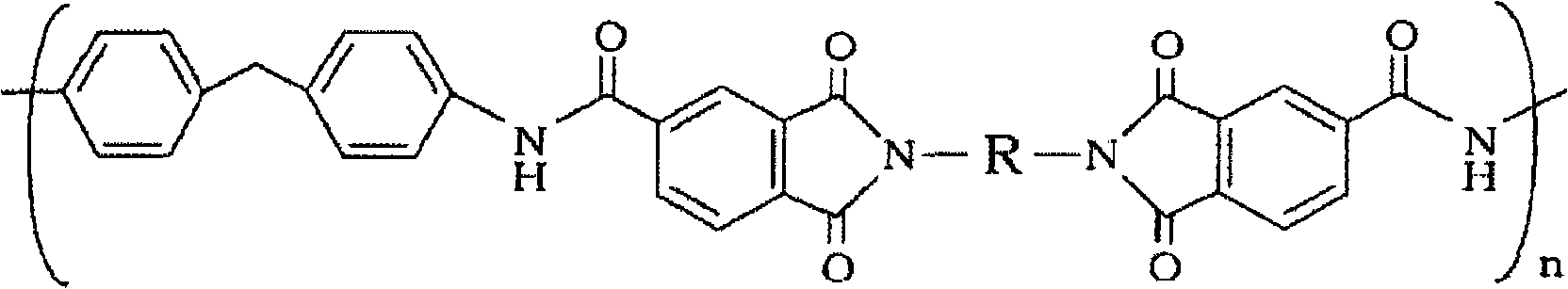

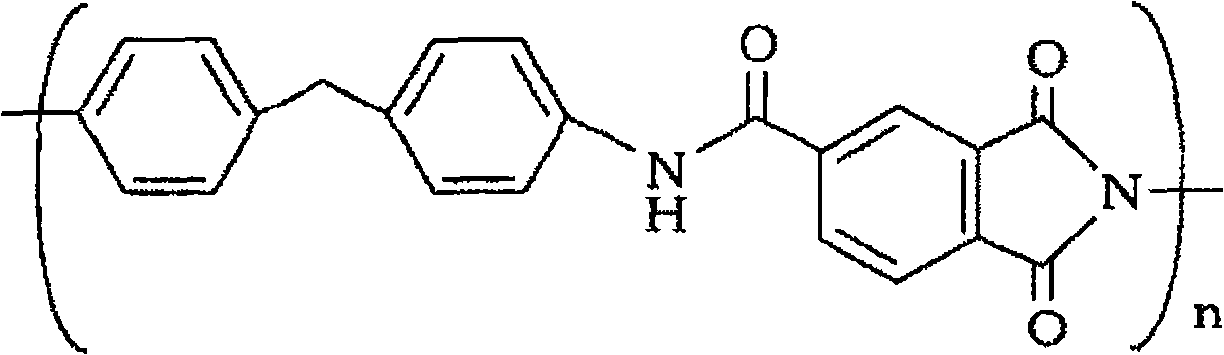

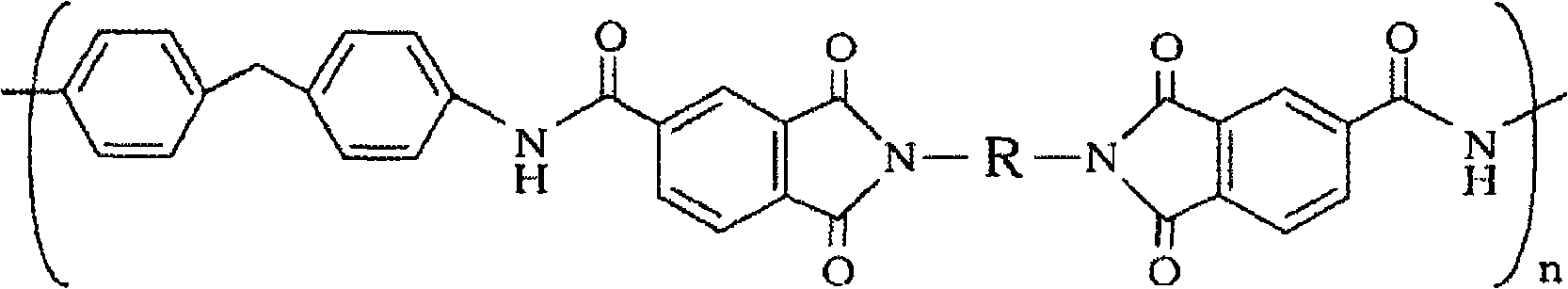

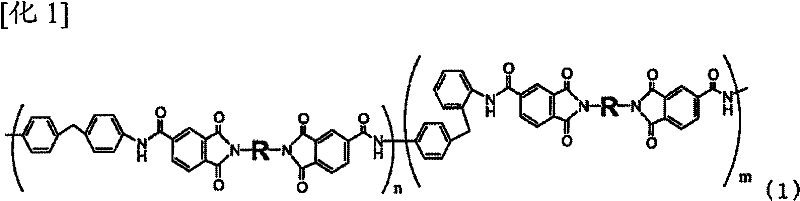

Insulated wire

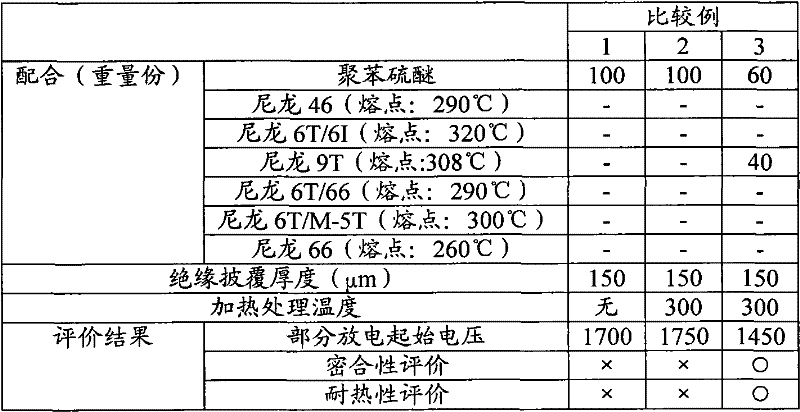

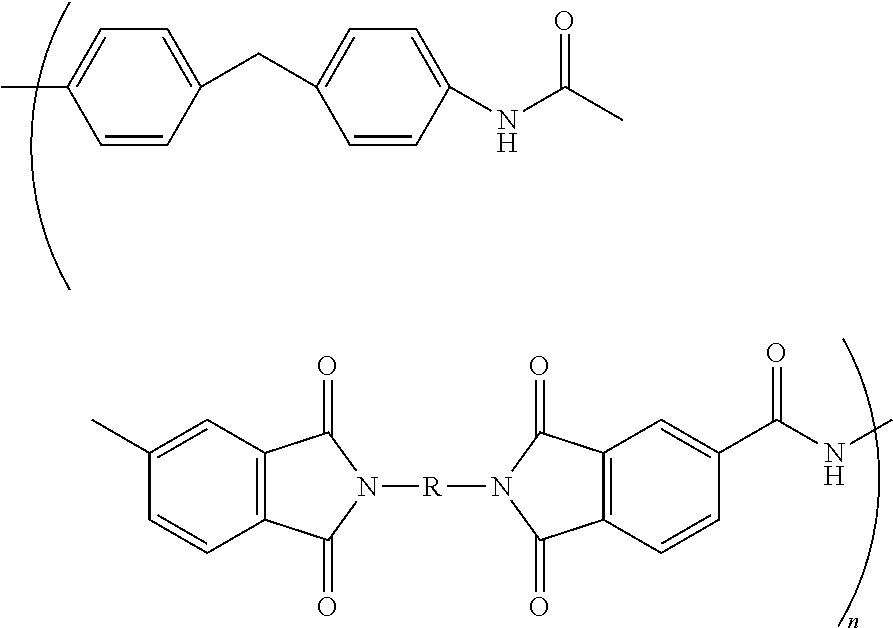

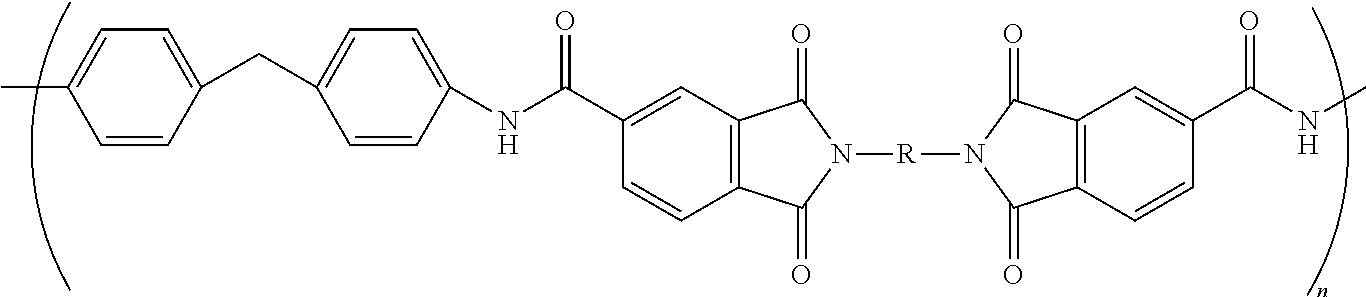

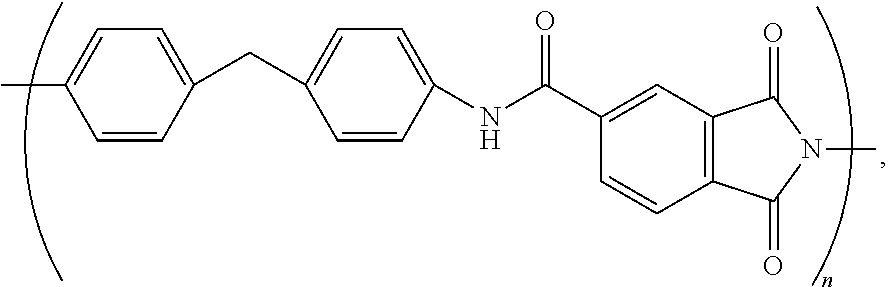

ActiveUS8741441B2Improve adhesionExcellent in adhesion to conductor and in flexibilitySynthetic resin layered productsCoatingsImideElectrical conductor

An insulated wire includes a conductor, and an insulating covering layer formed on a periphery of the conductor and including two or more insulating coatings. The insulating coatings include a polyamide-imide resin insulating material represented by chemical formula 1:where R indicates a divalent aromatic diamine including three or more aromatic rings. The insulating coatings are formed by applying and baking the polyamide-imide resin insulating material, and the polyamide-imide resin insulating material is obtained by reacting an imide group containing dicarboxylic acid with a diisocyanate, the imide group containing dicarboxylic acid being obtained by dehydration reaction of a diamine comprising a divalent aromatic diamine including three or more aromatic rings with an acid using an azeotropic solvent.

Owner:HITACHI METALS LTD

Silicon nitride substrate, silicon nitride circuit board utilizing the same, and use thereof

InactiveUS8029903B2Excellent electrical propertiesHigh partial discharge inception voltageSemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsPower control

Provided are a silicon nitride substrate and a silicon nitride circuit board with excellent electrical characteristics, and power control parts utilizing them.A silicon nitride substrate comprises a silicon nitride sintered body obtainable by sintering a silicon nitride powder in the presence of a sintering aid comprising MgO, Y2O3 and SiO2 in a proportion of (1) MgO / (MgO+SiO2)=34-59 mol %, and (2) Y2O3 / (Y2O3+SiO2)=50-66 mol %, and a silicon nitride circuit board utilizes it.

Owner:DENKA CO LTD

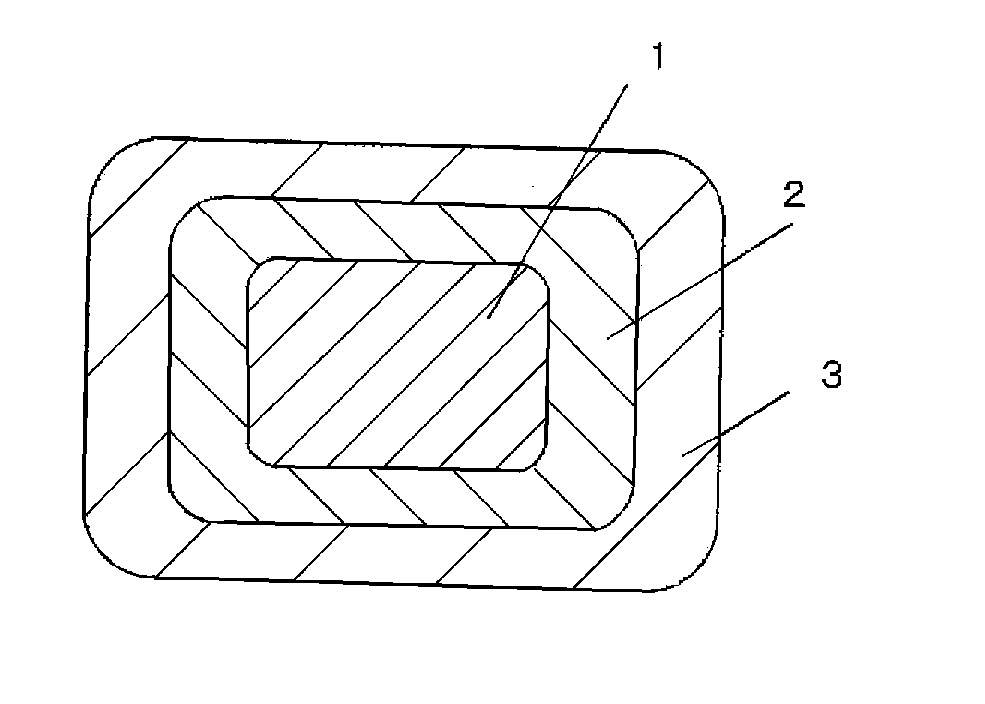

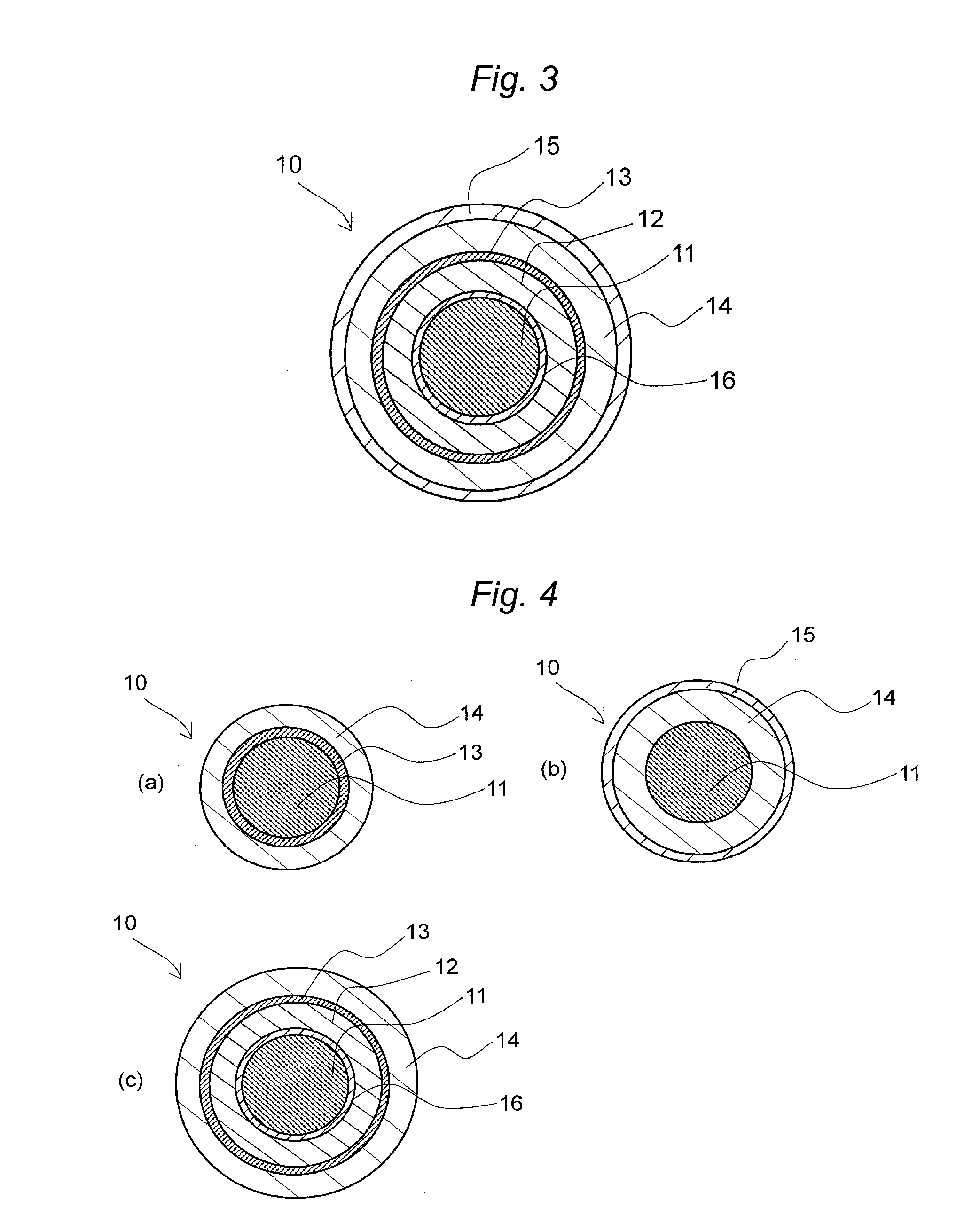

Insulated wire, coil and electrical or electronic equipment

ActiveUS20190027271A1High dielectric strengthImprove mechanical propertiesWindings insulation materialPlastic/resin/waxes insulatorsElectricityElectrical conductor

An insulated wire, containing:a conductor having a rectangular cross-section; andan insulating coated film having at least two insulating layers laminated together on the conductor,wherein the laminated insulating coated film is composed of:an enamel insulating layer formed from a thermosetting resin on the outer periphery of the conductor, andan extruded insulating layer formed from a thermoplastic resin on the outer side of the enamel insulating layer,wherein the thickness of the enamel insulating layer is 50 μm or more, and wherein the total thickness (T) and the relative permittivity (ε) at 100° C. of the laminated insulating coated film; and the maximum thickness (Tmax), and the maximum value (εmax) and the minimum value (εmin) of the relative permittivity at 100° C. of one layer among the laminated insulating layers; satisfy all of the following relations:T≥100 μm (1.1)Tmax≤100 μm (1.2)1.5≤ε≤3.5 (2.1)1.0≤εmax / εmin≤1.2 (2.2)a coil; andan electrical or electronic equipment.

Owner:ESSEX FURUKAWA MAGNET WIRE LLC

Enamel resin-insulating laminate, inverter surge-resistant insulated wire using the same and electric/electronic equipment

ActiveUS10418151B2Improve partial dischargeSmall dielectric constantWindings insulation materialPlastic/resin/waxes insulatorsElectrical conductorCell layer

An inverter surge-resistant insulated wire comprising a conductor and an enamel resin-insulating laminate that has a foamed region including cells and a non-foamed region including no cells on at least one surface of the foamed region on the conductor, wherein the foamed region is configured such that a non-cell layer including no cells has cell layers formed of closed cells on both surface sides of the non-cell layer, a thickness of the non-cell layer is larger than a thickness of a partition wall among the closed cells, and 5 to 60% of a thickness of the foamed region, and at least 10 the cell layer in the foamed region is formed of a thermosetting resin; an inverter surge-resistant insulated wire having a conductor and the enamel resin-insulating laminate; and electric / electronic equipment.

Owner:ESSEX FURUKAWA MAGNET WIRE LLC

Insulated wire and method of producing the same

ActiveUS10020092B2Improve adhesionReduced strengthWindings insulation materialPlastic/resin/waxes insulatorsInsulation layerElectrical conductor

Owner:ESSEX FURUKAWA MAGNET WIRE LLC

Insulated wires with partial discharge resistance and partial discharge inception voltage

ActiveCN103971797BImprove the dielectric rateLow dielectric constantInsulated cablesCoatingsInsulation layerElectrical conductor

The present invention relates to an insulated electric wire having partial discharge resistance and a partial discharge inception voltage. Specifically, the present invention relates to an insulated electric wire having partial discharge resistance, which not only has excellent partial discharge resistance, The voltage is high, and the adhesion between the conductor and the insulating layer, the flexibility of the insulating layer, etc. are also excellent, and the manufacturing process is simple and the manufacturing cost is low.

Owner:LSEVC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com