Insulated wire and method of manufacturing the same

A technology of insulated wires and manufacturing methods, applied in the direction of insulated cables, insulators, insulated conductors, etc., can solve the problems of insulation sheath deterioration and damage of insulated wires, achieve excellent heat resistance and adhesion, and high partial discharge inception voltage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

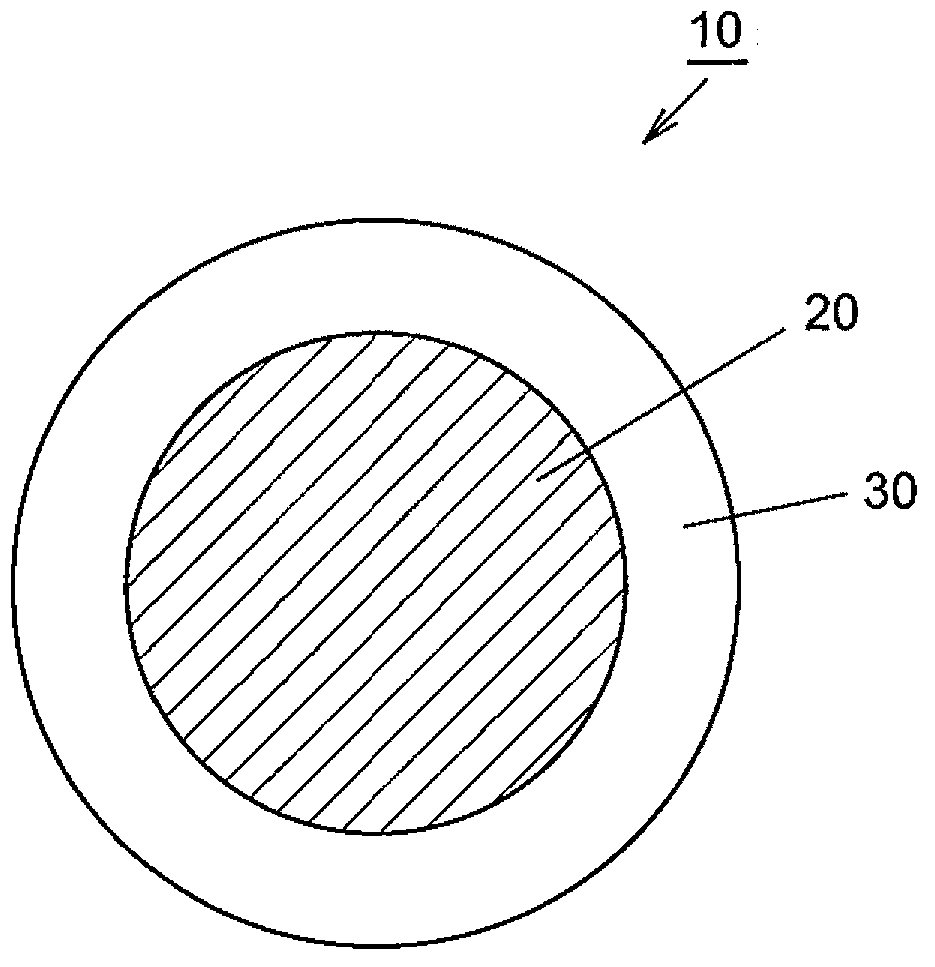

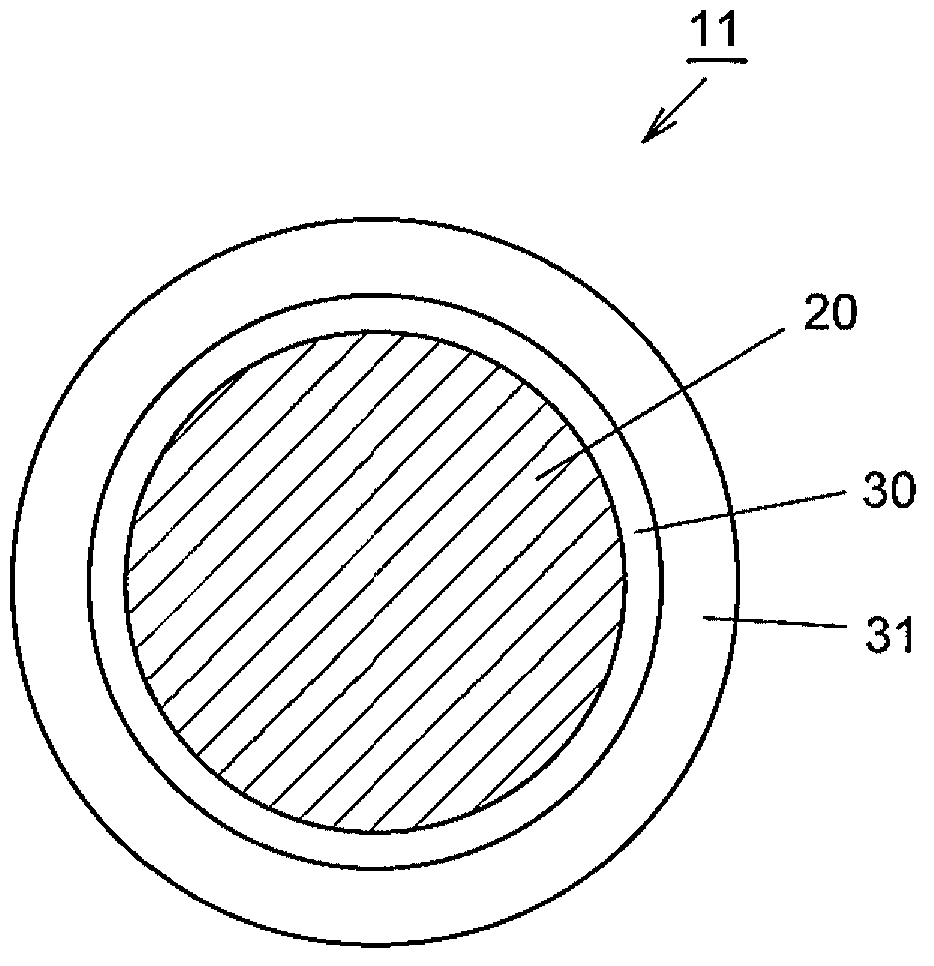

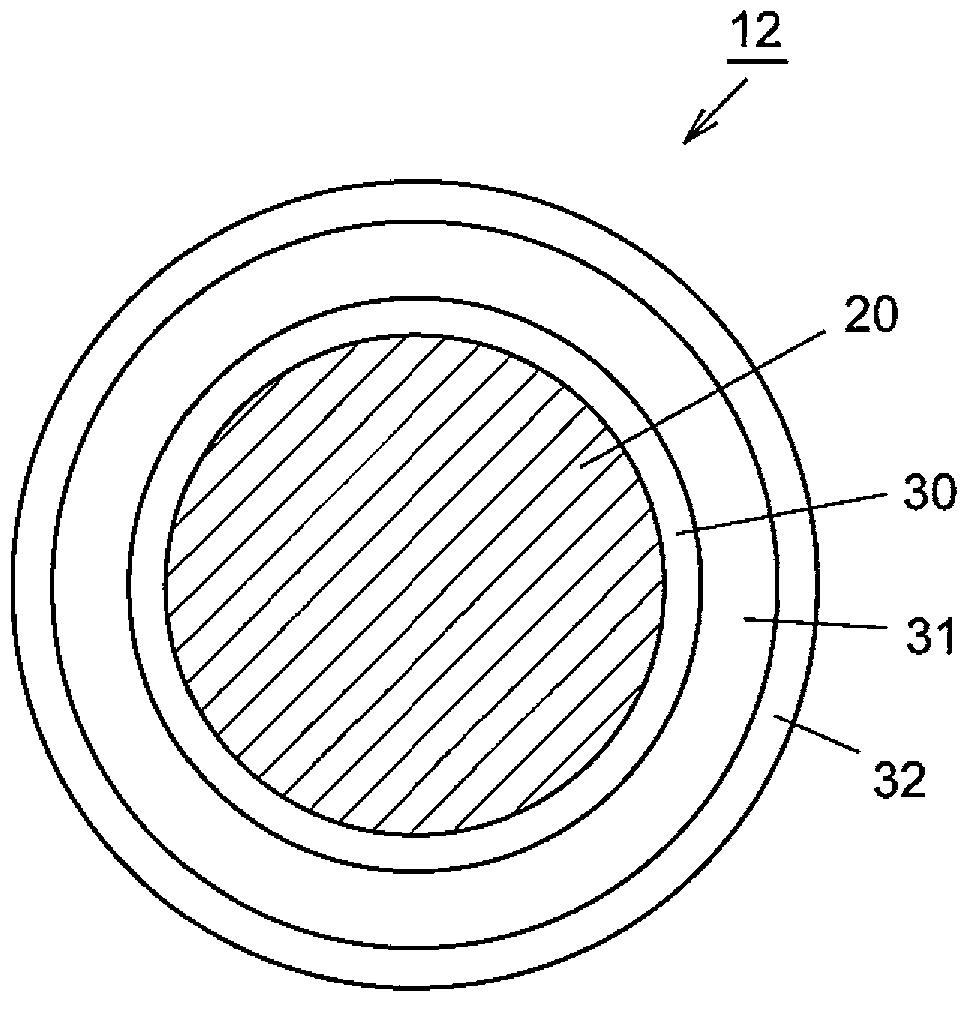

[0039] figure 1 It is a cross-sectional view of an insulated wire according to an embodiment of the present invention. figure 1 In , the symbol 10 representing the whole is an example of a typical insulated wire 10 of this embodiment. The basic configuration of this insulated wire 10 has a conductor 20 and an extruded coating 30 .

[0040] (conductor)

[0041] As the conductor 20, for example, a single wire made of copper or a copper alloy may be used, or a configuration formed by twisting a plurality of copper wires or copper alloy wires may be employed.

[0042] As copper, for example, oxygen-free copper, low-oxygen copper having a small oxygen content, or the like can be used.

[0043] figure 1 In , an example having a circular cross section as the cross-sectional shape of the conductor 20 is illustrated. Of course, the conductor 20 is not limited to the illustrated example, and may have various cross-sectional shapes such as a rectangular cross-section as the cross-se...

Embodiment 1

[0110] Hereinafter, referring to Table 1, the insulated wires of Examples and Comparative Examples, which are more specific embodiments of the present invention, will be described in detail. In addition, this Example cites a typical example of the insulated wire of this invention, and this invention is not limited to these Examples.

[0111] Samples of the insulated wires of Examples 1 to 5 and Comparative Examples 1 to 4 having various extrusion coating layers were prepared. These samples were compared and evaluated for appearance, modulus of elasticity, partial discharge inception voltage, adhesion and heat resistance. The components of the extrusion coating layer, the processing conditions, and the thickness of the extrusion coating layer of each sample are summarized and shown in Table 1 below.

[0112] Table 1

[0113]

[0114] (production of insulated wire)

[0115] A plurality of copper wires with an outer diameter of 1.25 mm were prepared as conductors, and nine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com