Insulated wires with partial discharge resistance and partial discharge inception voltage

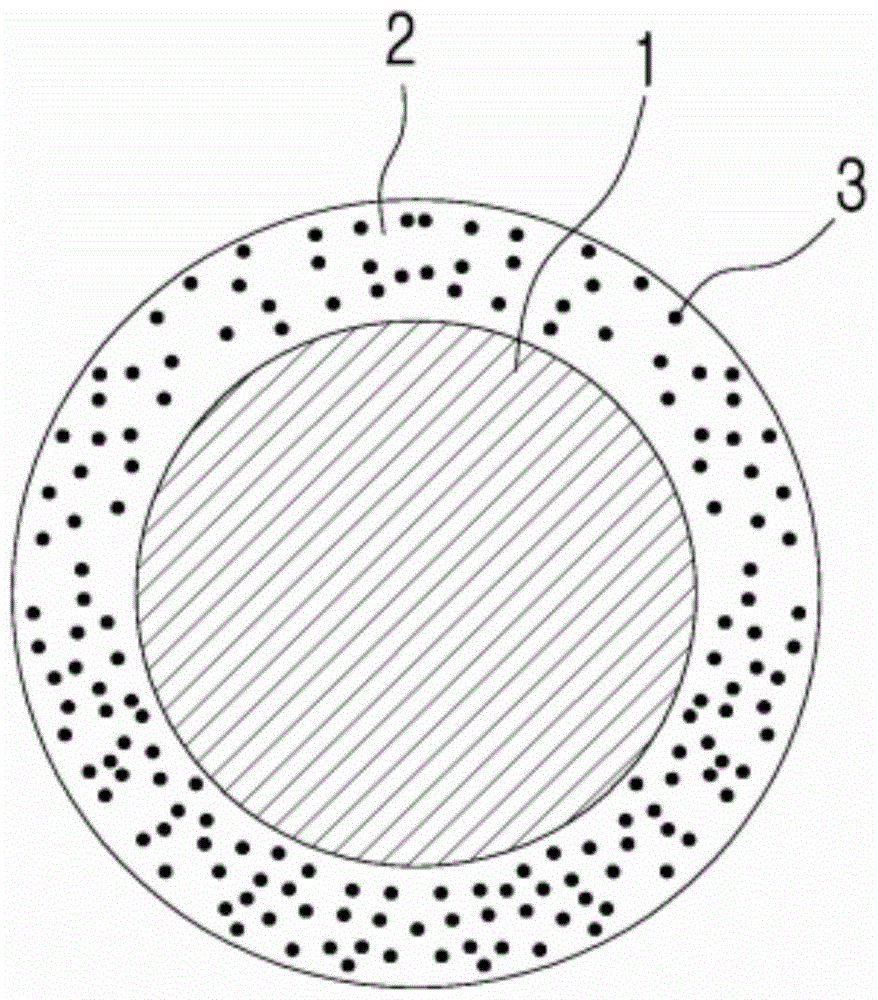

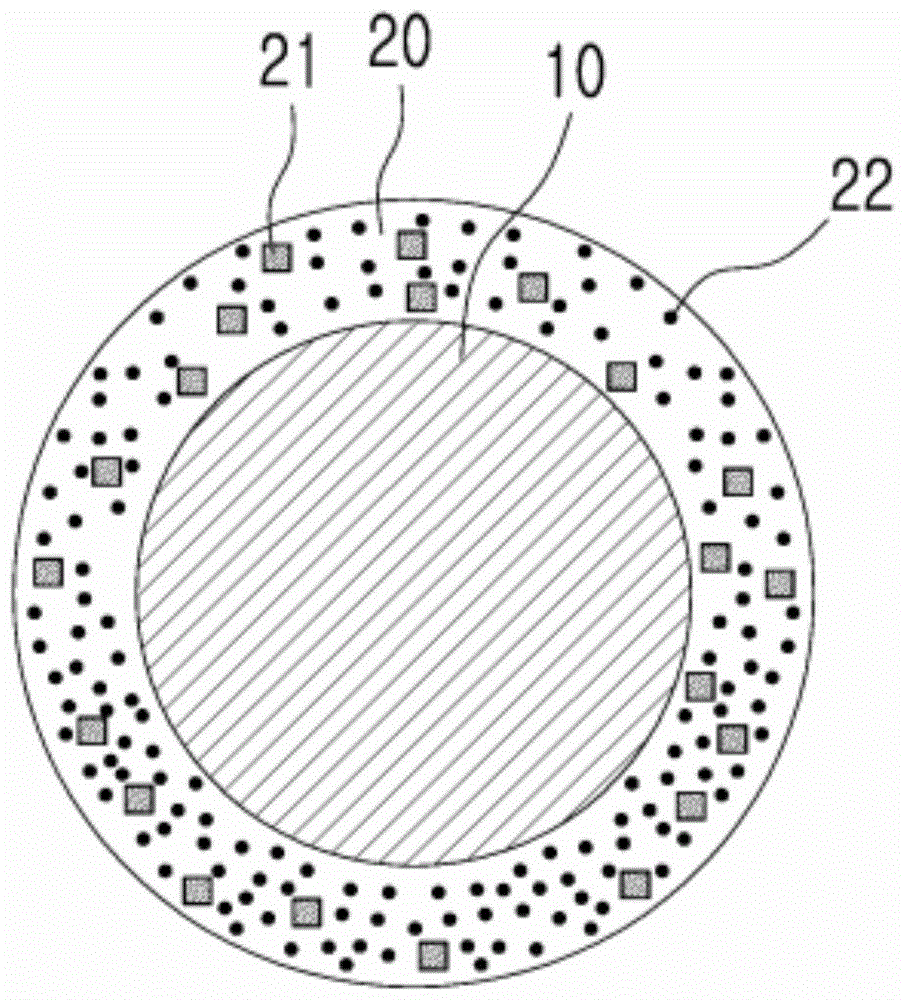

一种绝缘电线、局部放电的技术,应用在绝缘电缆、有机绝缘子、绝缘体等方向,能够解决低介电率化局部放电起始电压提高、空心纳米粒子制造工艺复杂、很难低介电率化等问题,达到制造工艺简单、制造费用低廉、抑制局部放电的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

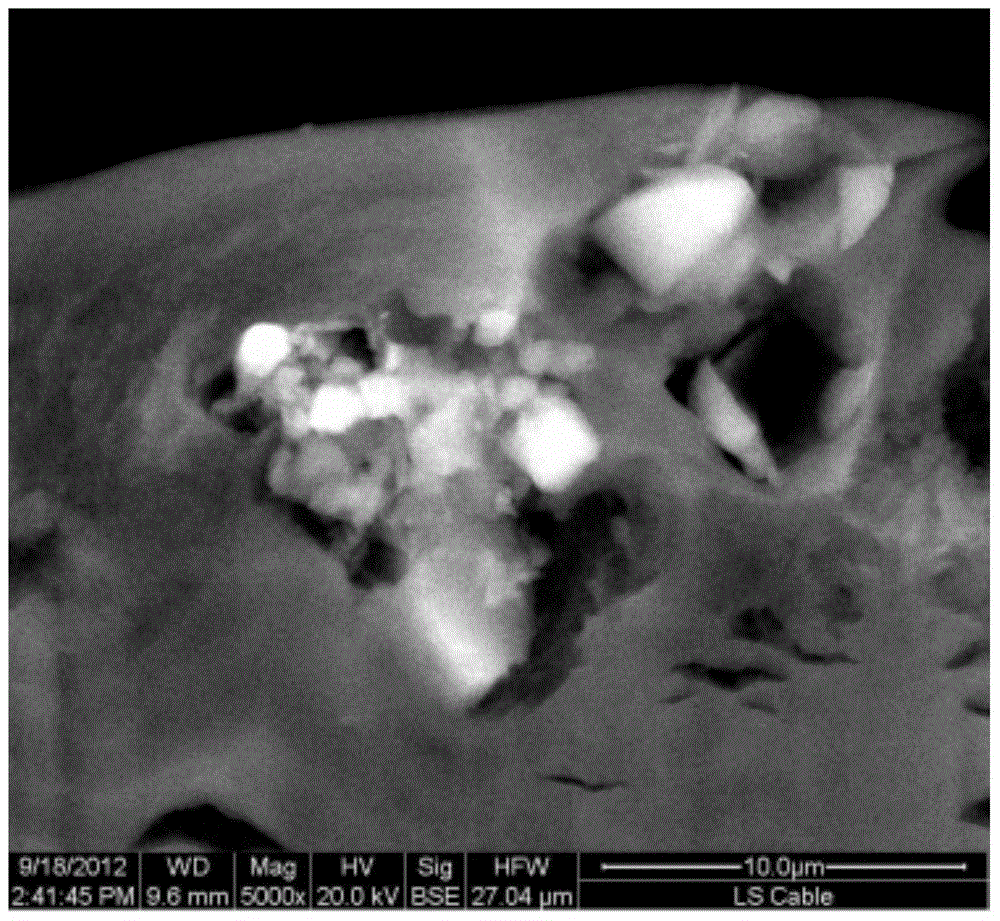

[0068] 1. Manufacturing example

[0069] The constituent components in the following Table 2 were added at the contents indicated in the table, and mixed with a high-speed mixer (manufacturing company: NCtech; product name: JS-MILL) to prepare insulating materials in Examples and Comparative Examples, respectively. . Using a coating device (manufacturing company: SICME Italy; product name: SICME NEV), the insulating material is coated around a circular copper conductor with a diameter of 1.1mm, and is heated at a line speed of 32m in a furnace at 360 to 560°C. / min to form a coating and harden, thereby producing insulated wire test pieces in Examples and Comparative Examples each having an insulating layer thickness of 40 μm.

[0070] 【Table 2】

[0071]

[0072] Base resin: polyamideimide (manufacturing company: Shengwen; product name: MS-30)

[0073] Zeolite particles: dry zeolite particles (manufacturing company: SIGMA; product name: 96096)

[0074] Inorganic Nanopart...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com