Insulated wire

An insulated wire and insulating coating technology, applied in the direction of insulated cables, insulators, insulated conductors, etc., can solve the problems of damage and deterioration of the insulating coating, and achieve the effects of excellent heat resistance and high partial discharge inception voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0049] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited to these examples.

[0050] (Preparation of Examples 1-9 and Comparative Examples 1-3)

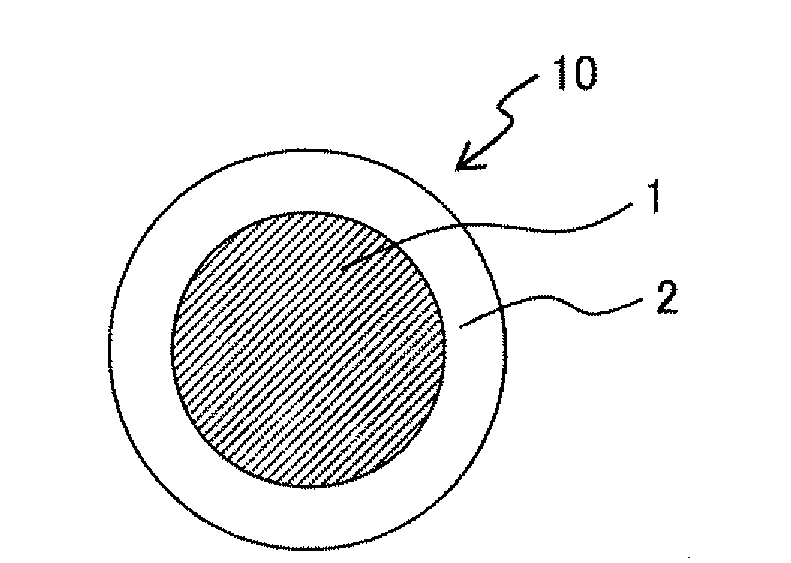

[0051] Use a copper wire with an outer diameter of 1.25 mm as a conductor, and use an extruder to extrude and coat the resin composition shown in Table 1 on the outer layer of the copper wire to produce figure 1 Insulated wires of the shape shown. The resin temperature during extrusion coating was set to about 360° C., and the thickness of the insulating coating layer (first extrusion coating layer) was set to about 100 μm. Table 1 shows the compositions of the resin compositions constituting the extrusion coating layers of Examples 1-9 and Comparative Examples 1-3. In addition, in Table 1, the apparent viscosity of the resin (A) is measured at a temperature of 380°C and a shear rate of 10 sec using a capillary rheometer (manufactured by Toyo Seiki Co., L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com