Insulating paint and insulated wire using same

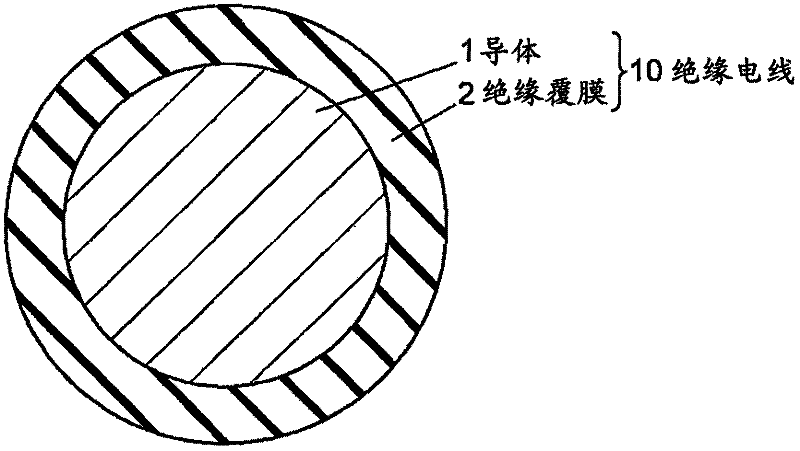

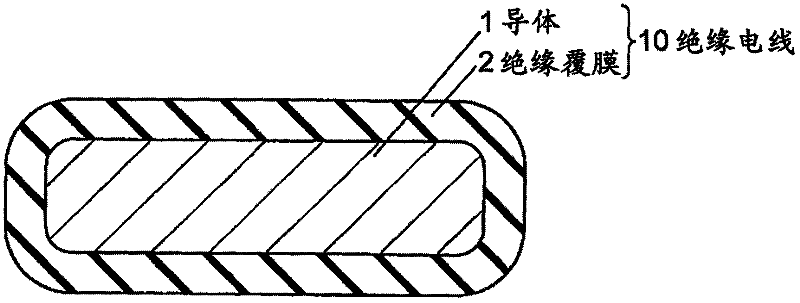

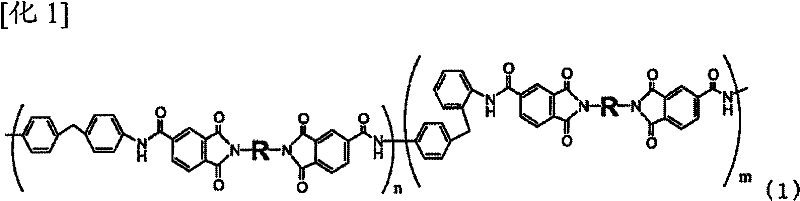

A technology of insulating coatings and coatings, which is applied to insulated cables, insulators, insulated conductors, etc., and can solve problems such as deterioration and damage of insulating coatings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] With respect to 100 mass parts of resin components of polyamide-imide resin paint A, make the silicon dioxide component of silica microparticle sol be 10 mass parts, make silica microparticle sol (dispersion medium: γ-butylene sol) in such a ratio Lactone, the average particle diameter of silica particles is 12nm, γ-butyrolactone: silica = 90:30 (mass ratio)) are dispersed in polyamide-imide resin coating A which is being stirred, thereby obtaining insulation coating. Next, this insulating paint was repeatedly applied and baked on a copper conductor having a conductor diameter of 0.80 mm so that the film thickness became 0.045 mm, thereby obtaining the insulated wire of Example 1.

Embodiment 2

[0089] With respect to 100 mass parts of resin components of polyamide-imide resin paint A, make the silica component of silica microparticle sol be 90 mass parts, make silica microparticle sol (dispersion medium: γ-butylene sol) in such a ratio Lactone, the average particle diameter of silica particles is 12nm, γ-butyrolactone: silica = 90:30 (mass ratio)) are dispersed in polyamide-imide resin coating A which is being stirred, thereby obtaining insulation coating. Next, this insulating paint was repeatedly applied and baked on a copper conductor having a conductor diameter of 0.80 mm so that the film thickness became 0.045 mm, thereby obtaining the insulated wire of Example 2.

Embodiment 3

[0091] With respect to 100 parts by mass of the resin component of the polyamide-imide resin coating B, the silica component of the silica microparticle sol was 10 mass parts, and the silica microparticle sol (dispersion medium: γ-butane Lactone, the average particle diameter of silica particles is 12nm, γ-butyrolactone: silica = 90:30 (mass ratio)) are dispersed in the polyamideimide resin coating B which is being stirred, thereby obtaining insulating coating. Next, this insulating paint was repeatedly applied and baked on a copper conductor having a conductor diameter of 0.80 mm so as to have a film thickness of 0.045 mm, whereby an insulated wire of Example 3 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com