Insulated electric wire, electric device, and process for production of insulated electric wire

A technology of insulated wires and insulation skins, which is applied in the direction of insulated cables, cable/conductor manufacturing, winding insulation shape/style/structure, etc. It can solve the problems of poor wear resistance of insulated wires and easy damage to the insulation film, and achieve high Excellent insulation breakdown voltage, excellent life characteristics, and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

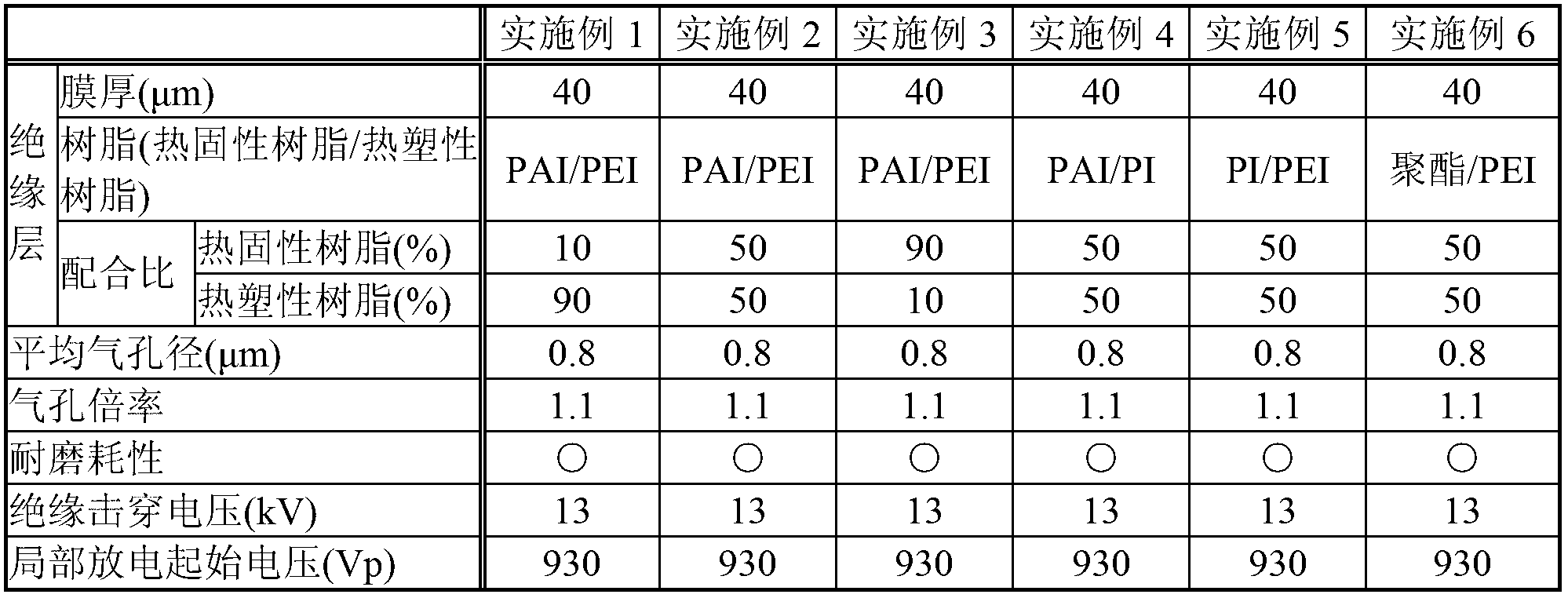

Embodiment 1

[0062]

[0063] 1600 g of NMP (2-methylpyrrolidone) was added to a 2 L separable flask, and 400 g of pellets of polyetherimide resin (PEI) which is a thermoplastic resin were added in small portions. This was heated to 110° C. and stirred for 5 hours to obtain a transparent yellow 20% by mass thermoplastic resin varnish. 139 g of a thermosetting resin varnish was added to this thermoplastic resin varnish to prepare a resin varnish containing a thermoplastic resin and a thermosetting resin. Among them, HI406 (a polyamide-imide (PAI) solution having a resin component of 32% by mass) (trade name, manufactured by Hitachi Chemical Co., Ltd.) was used as the thermosetting resin varnish.

[0064]

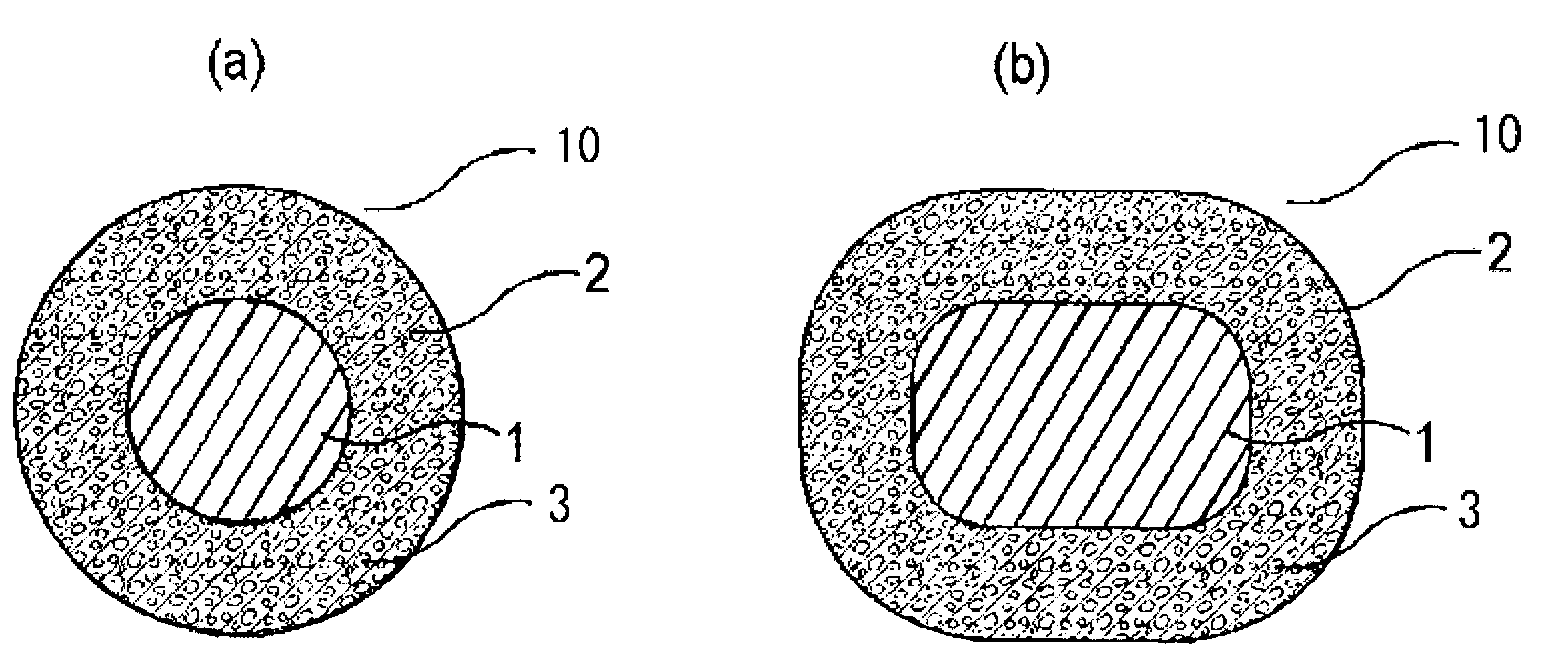

[0065] The above-mentioned resin varnish (PAI:PEI=10:90) containing thermoplastic resin and thermosetting resin was coated on the outer periphery of a copper wire with a diameter of 1 mm, and fired at 520°C to obtain an electric wire with a film thickness of 40 μm on the outer peripher...

Embodiment 2

[0067] In Example 1, except having made the quantity of the thermosetting resin varnish to add into 1250g, it carried out similarly to Example 1, and prepared the resin varnish. Using the obtained resin varnish (the compounding ratio of PAI and PEI is PAI:PEI=50:50), obtain in the same manner as in Example 1 figure 2 (a) The insulated wire of Example 2 shown.

Embodiment 3

[0069] In Example 1, except having made the quantity of the thermosetting resin varnish to add into 11250g, it carried out similarly to Example 1, and prepared the resin varnish. Using the obtained resin varnish (the compounding ratio of PAI and PEI is PAI:PEI=90:10), obtain in the same manner as in Example 1 figure 2 (a) The insulated wire of Example 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com