Insulated wire

一种绝缘电线、绝缘膜的技术,应用在绝缘体、绝缘体、有机绝缘子等方向,能够解决绝缘膜恶化、损伤等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

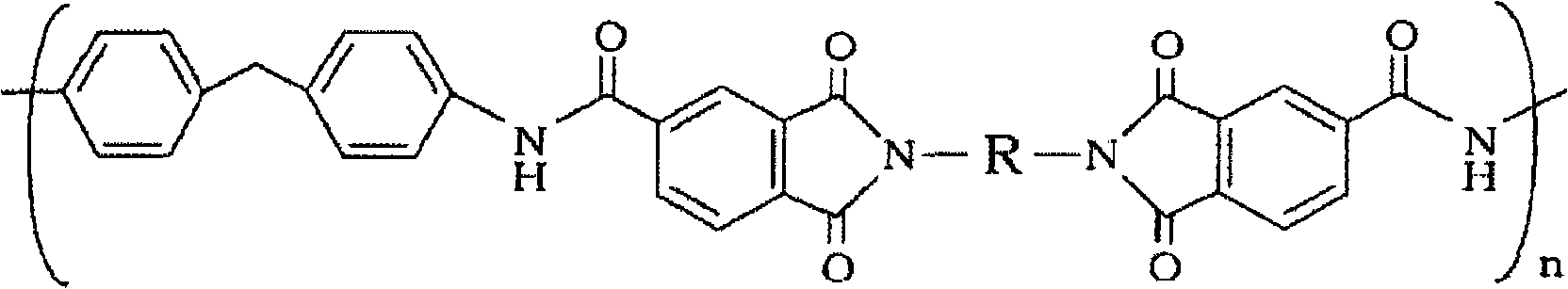

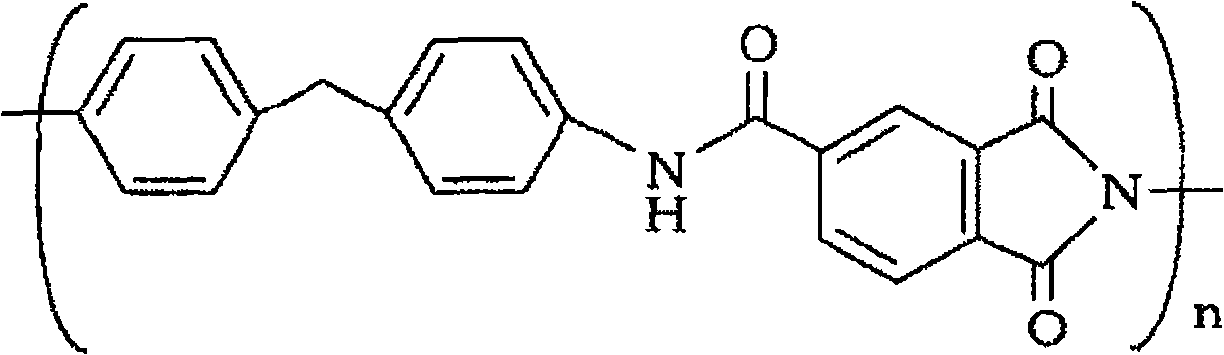

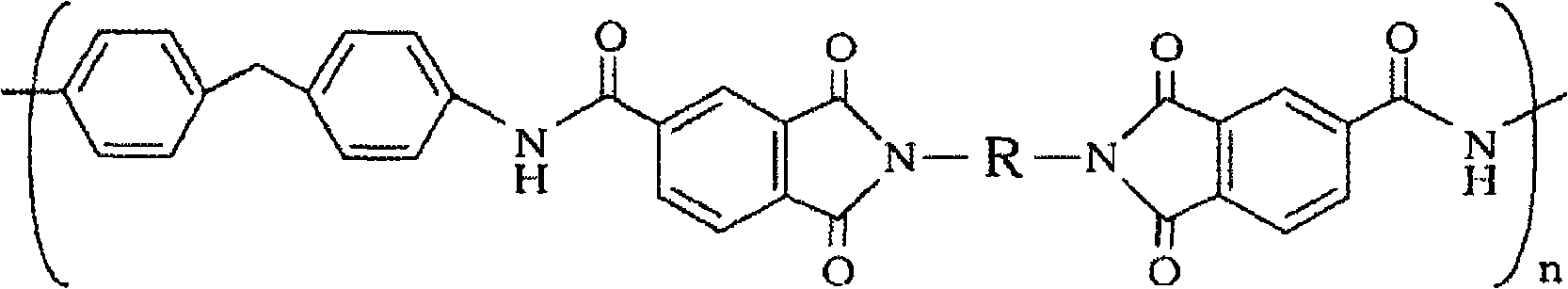

Method used

Image

Examples

Embodiment 1

[0078] Apply and bake polyamide-imide resin insulating paint A around a conductor with a conductor diameter φ of 0.8 mm to form a first insulating film with a thickness of 5 μm, then apply and bake polyamide-imide resin insulating paint B , and further formed a 35 μm second insulating film, thereby producing an insulated wire including a total of 40 μm insulating film layers.

Embodiment 2

[0080] Apply and bake polyamide-imide resin insulating paint A around a conductor with a conductor diameter φ of 0.8mm to form a first insulating film with a thickness of 10 μm, then apply and bake polyamide-imide resin insulating paint B , and further formed a 30 μm second insulating film, thereby producing an insulated wire including a total of 40 μm insulating film layers.

Embodiment 3

[0082] Apply and bake polyamide-imide resin insulating paint A around a conductor with a conductor diameter φ of 0.8 mm to form a first insulating film with a thickness of 5 μm, then apply and bake polyamide-imide resin insulating paint C , and further formed a 35 μm second insulating film, thereby producing an insulated wire including a total of 40 μm insulating film layers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com