Capacitor impregnation liquid containing modified flaxseed oil

A technology of linseed oil and capacitors, applied in capacitors, fixed capacitors, circuits, etc., can solve the problems of unguaranteed performance, consumption, and short insulation recovery time of capacitors, and achieve improved self-healing performance, good heat dissipation, Reduce the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

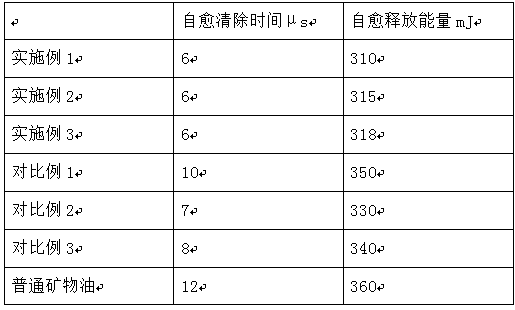

Examples

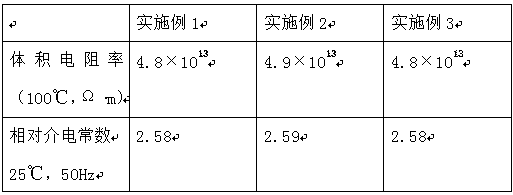

Embodiment 1

[0016] A capacitor impregnating solution containing modified linseed oil, which is made of the following components in parts by weight: castor oil 92, modified sunflower oil 28, urea 1, auxiliary material 3, diffusing agent MF0.4, peanut oil 2, pungent Diacid 5, rice bran oil 2; the auxiliary materials are made of the following components in parts by weight: attapulgite 2, zeolite powder 6, and diatomite 1.

Embodiment 2

[0018] A capacitor impregnating solution containing modified linseed oil, which is made of the following ingredients in parts by weight: castor oil 95, modified sunflower oil 35, urea 4, auxiliary material 6, diffusing agent MF0.7, peanut oil 4, pungent diacid 8, rice bran oil 4; the auxiliary materials are made of the following components in parts by weight: attapulgite 4, zeolite powder 8, diatomite 4.

Embodiment 3

[0020] A capacitor impregnation solution containing modified linseed oil, which is made of the following components in parts by weight: castor oil 94, modified sunflower oil 33, urea 2, auxiliary material 5, diffusing agent MF0.5, peanut oil 3, pungent Diacid 6, rice bran oil 3; the auxiliary materials are made of the following components in parts by weight: attapulgite 3, zeolite powder 7, diatomite 2.

[0021] The preparation method of auxiliary material in the above-mentioned embodiment is:

[0022] Mix attapulgite, zeolite powder and diatomaceous earth together uniformly, calcinate at 280°C for 15min, add to 5% sodium hypochlorite solution and soak for 18min when cooled to 48°C, then filter, wash and dry , Grind into ultrafine powder at 40°C.

[0023] The preparation method of capacitor impregnating agent, comprises the following steps:

[0024] (1) Add the corresponding weight of castor oil and modified sunflower oil into the mixing tank at 60-70°C, and stir at a speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com