Insulated electric wire and motor

A technology of insulated wires and insulating layers, applied in the direction of insulated cables, insulators, insulated conductors, etc., can solve the problems of damaged insulating layers, insufficient wear resistance of the insulating layer surface, etc., and achieve the effect of high damage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

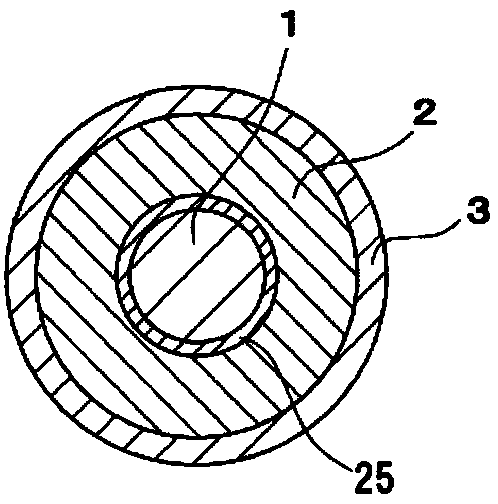

[0115] Made in the following way figure 2 insulated wire shown. First, the foamed polyamide-imide varnish for forming the foamed insulating layer 2 was prepared as follows. Put HI-406 (trade name, manufactured by Hitachi Chemical Co., Ltd.) in a 2L separable flask, and add triethylene glycol dimethyl ether and diethylene glycol dibutyl ether as bubble forming agents to the solution, and then use dimethyl Diluted with sulfoxide, thus obtained.

[0116] In addition, HI-406 was used as the polyamide-imide varnish for forming the inner non-foamed insulating layer for forming the inner non-foamed insulating layer 25 . This varnish was prepared as a 30% by mass solution using NMP as a solvent.

[0117] Each varnish was applied by dip coating, and the coating amount was adjusted by a die. Specifically, the prepared polyamideimide varnish for forming an inner non-foamed insulating layer was coated on a copper conductor 1 with a circular cross-section of 1.0 mmφ, and fired at a fu...

Embodiment 2

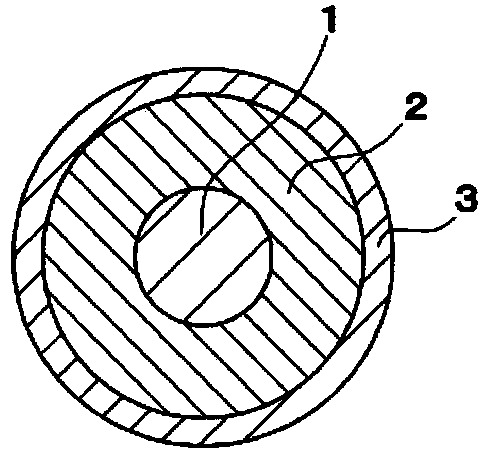

[0120] Made in the following way figure 1 insulated wire shown. The outer peripheral surface of a copper conductor 1 with a circular cross-section of 1.0 mmφ is directly coated with the foamed polyamideimide varnish prepared in Example 1, and fired at a furnace temperature of 510° C. to obtain a thickness formed. A molded body (undercoated line) of the foamed insulating layer 2 of 20 μm. Next, HI-406 (trade name, manufactured by Hitachi Chemical Co., Ltd.) was fired at a furnace temperature of 510°C so as to have a thickness of 80 μm. The undercoating line was coated with HI-406, and then heated to 600° C. in a tubular furnace ( Koyo Thermo Systems Co., Ltd.; KTF030N1 (trade name)) was reheated for 20 seconds to form the outer non-foamed insulating layer 3 . The insulated electric wire of Example 2 was manufactured in the above-mentioned manner.

Embodiment 3

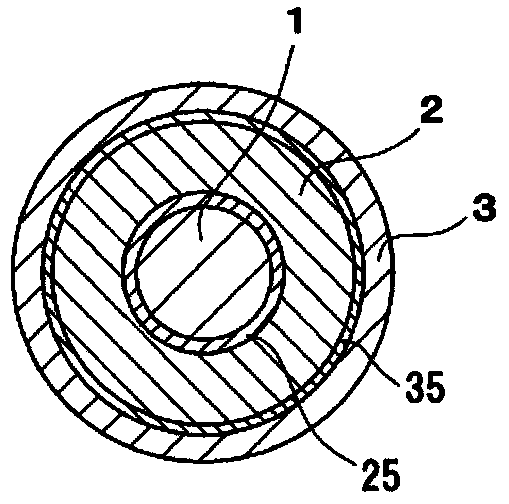

[0122] Made in the following way Figure 5 insulated wire shown. First, the foamed polyimide varnish for forming the foamed insulating layer 2 was prepared as follows. A solution was prepared by adding Uimide (NMP solution of 25% by mass of resin component) (manufactured by Unitika, trade name) to a 2L separable flask, and adding NMP, DMAC, and tetraethylene glycol dimethyl ether as a solvent.

[0123] The polyimide varnish for forming the inner non-foamed insulating layer used to form the inner non-foamed insulating layer 25 was prepared using Uimide and adding DMAC as a solvent to the resin.

[0124] In 1.8 * 3.4mm (thickness * width) and the chamfering radius r of four corners is the outer peripheral surface of copper conductor 1 of 0.3mm flat coating inside non-foaming insulating layer formation polyimide varnish, it is in furnace temperature Firing was performed at 520° C. to form inner non-foamed insulating layer 25 with a thickness of 4 μm. Next, the prepared foamed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com