Preparation method of multiaperture ferrite

A technology of porous iron and oxygen, which is applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of increasing process complexity and cumbersome preparation process of porous materials, and achieve good application value, good crystallization, and crystal phase The effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

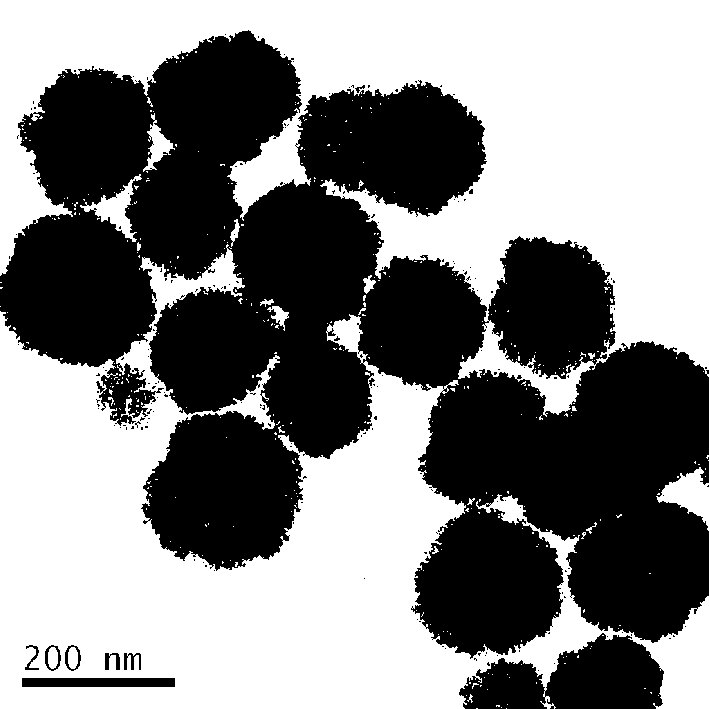

[0021] At room temperature, 1.514g FeCl 3 ·6H 2 O and 0.666g NiCl 2 ·6H 2 O was dissolved in 70mL of ethylene glycol solution, stirred and dissolved at room temperature to obtain a uniformly dispersed solution; weighed 1.298g of dodecylamine and added to the above solution, stirred evenly by magnetic force to form a clear and transparent solution; transferred the solution to the reaction kettle (Reaction kettle capacity is 100mL), sealed. The reaction kettle was put into an oven and kept at 200oC for 12 hours. After the reactor was naturally cooled to room temperature, the product was taken out, and the product was separated magnetically. The separated product was washed three times with deionized water and absolute ethanol respectively, and dried at 50oC to obtain nickel ferrite. from figure 1 It can be seen from the transmission electron microscope photos that the nickel ferrite is a porous spherical shape with a particle size of 100-300nm.

Embodiment 2

[0023] At room temperature, 1.514g FeCl 3 ·6H 2 O and 0.666g NiCl 2 ·6H 2 O was dissolved in 70mL of ethylene glycol solution, stirred and dissolved at room temperature to obtain a uniformly dispersed solution; weighed 1.298g of dodecylamine and added to the above solution, stirred evenly by magnetic force to form a clear and transparent solution; transferred the solution to the reaction kettle (Reaction kettle capacity is 100mL), sealed. The reaction kettle was put into an oven and kept at 200oC for 18 hours. After the reactor was naturally cooled to room temperature, the product was taken out, and the product was separated magnetically. The separated product was washed three times with deionized water and absolute ethanol respectively, and dried at 50oC to obtain nickel ferrite. from figure 2 It can be seen from the transmission electron microscope photos that the nickel ferrite is a porous spherical shape with a particle size of 100-300nm.

Embodiment 3

[0025] At room temperature, 1.514g FeCl 3 ·6H 2 O and 0.382g ZnCl 2 Dissolve in 70mL ethylene glycol solution, stir and dissolve at room temperature to obtain a uniformly dispersed solution; weigh 1.298g of dodecylamine and add it to the above solution, stir and mix evenly to form a clear and transparent solution; transfer the solution into the reaction kettle ( The capacity of the reaction kettle is 100mL), sealed. The reaction kettle was put into an oven and kept at 200oC for 18 hours. After the reaction kettle was naturally cooled to room temperature, the product was taken out, and the product was separated by centrifugation. The separated product was washed three times with deionized water and absolute ethanol respectively, and dried at 50oC to obtain zinc ferrite. from image 3 It can be seen from the transmission electron microscope photos that the zinc ferrite is a porous spherical shape with a particle size of 200-400nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com