Broadband and high-magnetic-permeability ferrite teflon tape and production method thereof

A ferrite raw material, high magnetic permeability technology, applied in the field of magnetic materials, can solve the problem of high Curie temperature, and achieve the effects of high Curie temperature, fine grain, and high inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

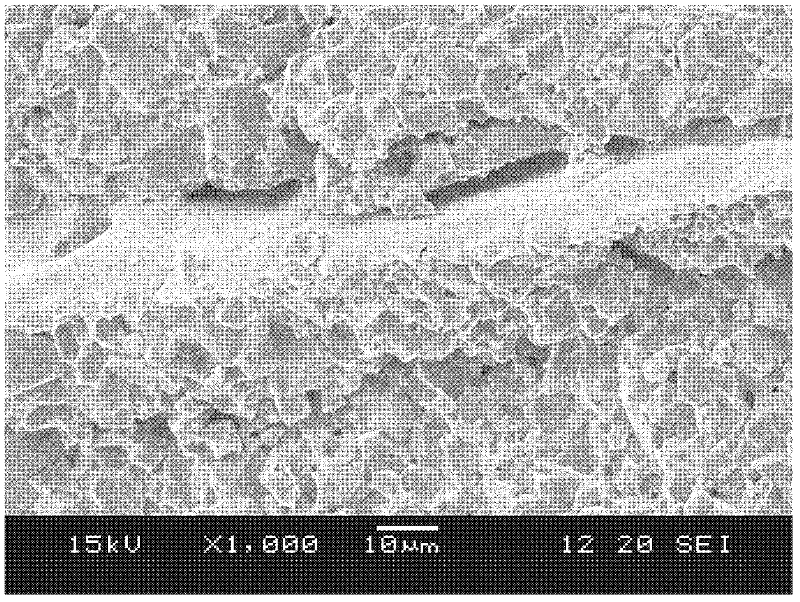

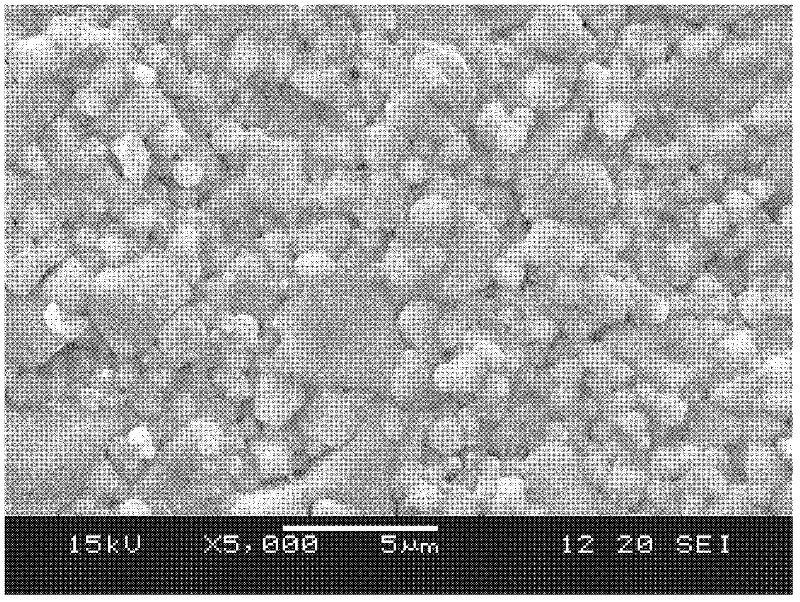

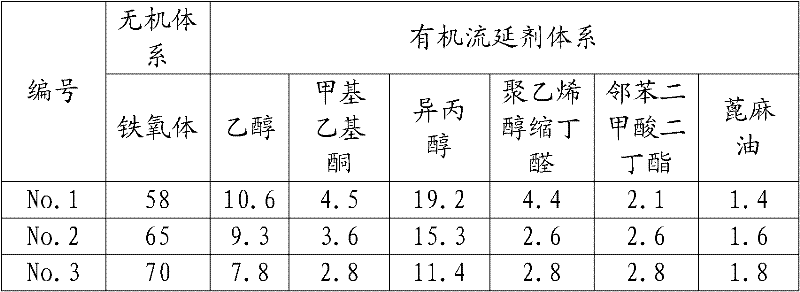

[0030] Table 1 shows the content of each component of the specific example 1 of the present invention. Weigh the calcined ferrite powder according to the formula in Table 1, add solvent and dispersant and ball mill for 3-6 hours, add binder and plasticizer and ball mill for 3-6 hours, vacuum defoaming, tape casting, and drying to obtain The low-temperature co-fired ferrite raw tape of the present invention.

[0031] In the present invention, the prepared raw material tape is engraved to make a standard test ring, the temperature is raised at 2°C / min to 450°C for 3 hours to remove glue, and then the temperature is raised from 450°C to 900°C for 3 hours at 2.5°C / min for sintering. During the cooling process, the temperature was controlled to drop to 250°C for 10 hours, and then cooled naturally with the furnace, and the performance of the sintered body was tested (see Table 2).

[0032] Table 1 The content (wt%) of each component of the low temperature co-fired ferrite raw belt...

Embodiment 2

[0037] Table 4 shows the content of each component of the specific example 2 of the present invention. Weigh the calcined ferrite powder according to the formula in Table 4, add solvent and dispersant and ball mill for 3-6 hours, add binder and plasticizer and ball mill for 3-6 hours, vacuum defoaming, tape casting, and drying to obtain The low-temperature co-fired ferrite raw tape of the present invention.

[0038] In the present invention, ring-cutting is performed on the prepared raw material belt, the temperature is raised to 450°C at 2°C / min and kept for 3 hours to remove glue, and then the temperature is raised from 450°C to 900°C for 3 hours at 2.5°C / min for sintering. During the cooling process, the temperature was controlled to drop to 250°C for 10 hours, and then cooled naturally with the furnace, and the performance of the sintered body was tested (see Table 5).

[0039] Table 4 The content (wt%) of each component of the low temperature co-fired ferrite raw materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| magnetic permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com