Preparation method of sizing enhancer

A technology of reinforcing agent and initiator, which is applied in the field of preparation of sizing reinforcing agent, can solve the problems of high cost of dry strength agent, low retention rate of sizing agent, influence on sizing and strengthening effect, etc., and achieve good strengthening effect, The effect of fast sizing and curing speed and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of sizing enhancer is to mix starch and water according to the mass ratio of 1:2~5, stir and heat up, add starch viscosity reducer, degrade at 75~95°C with heat preservation, and after the viscosity reaches 5~50mPa, blow nitrogen, Cool down to 60-80°C, add an initiator, and react for 10-30 minutes to activate the degraded starch molecular chains to generate free radicals; add hydrophobic monomer mixture, hydrophilic monomer Bulk solution and initiator aqueous solution, control the dropping time for 20-90 minutes, during which the reaction temperature is controlled at 65°C-95°C; after dropping, control the temperature at 80°C-95°C for 10-60 minutes, add the initiator, continue React at 80°C-95°C for 30-90 minutes. After there is no reflux in the reactor and the viscosity reaches 50-500mPa.s at 25°C, add a terminator, cool down to 30°C, add an external linking agent, and adjust the pH value to 4. ~6, that is, the sizing enhancer is obtained.

[002...

Embodiment 1

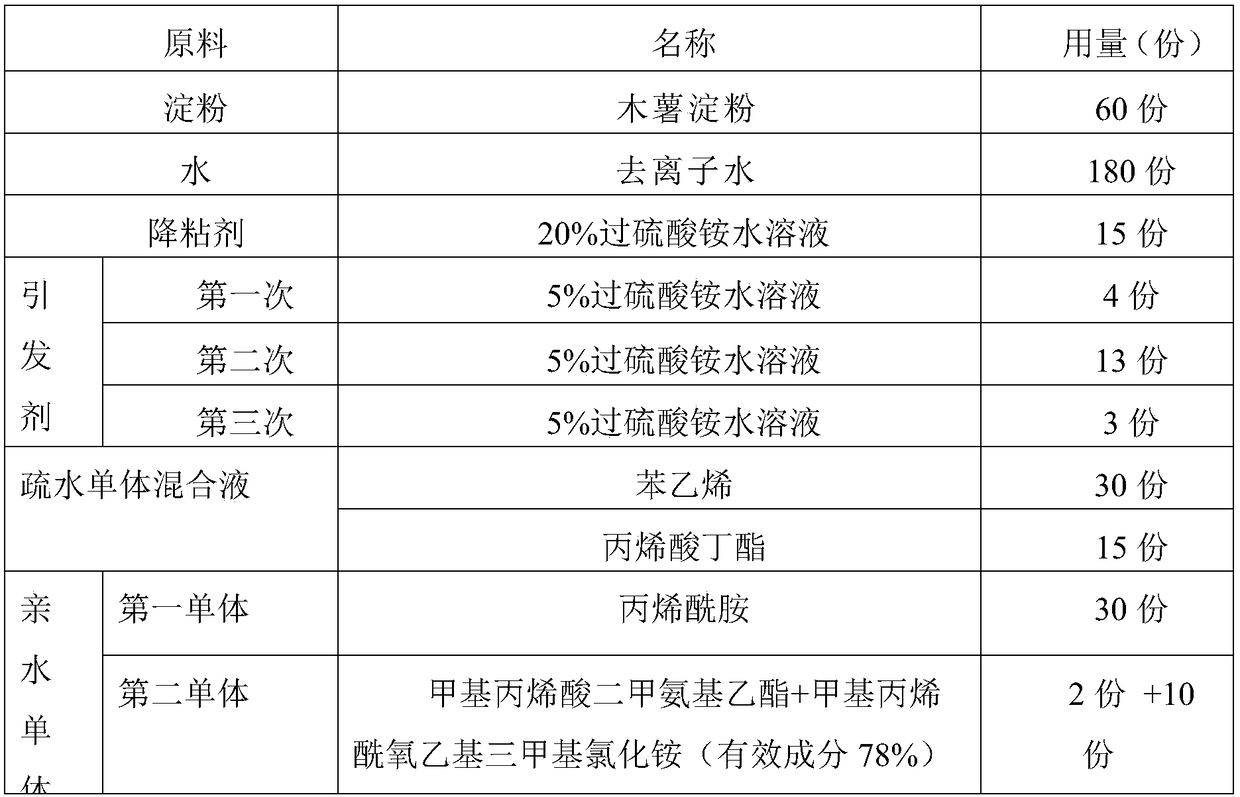

[0045] The main raw materials used and the amount of feed are shown in the table below:

[0046]

[0047]

[0048] Add 180 parts of deionized water to the reaction kettle with agitator, thermometer, reflux condenser and nitrogen inlet pipe, slowly add 60 parts of tapioca starch under stirring, add 15 parts of ammonium persulfate with 20% viscosity reducer, and heat up to 90°C, keep warm at 88-93°C for 60 minutes, and check the viscosity at 85°C to be 15mPa.s; pass nitrogen gas, when the temperature drops to 75°C, add 4 parts of the first initiator 5% ammonium persulfate aqueous solution, and react for 15 Minutes, then drop the hydrophobic monomer mixed solution, hydrophilic monomer mixed solution, internal crosslinking monomer solution and initiator aqueous solution simultaneously, wherein, the hydrophobic monomer mixed solution consists of 30 parts of styrene, 15 parts of butyl acrylate Composition, the hydrophilic monomer mixed solution consists of 30 parts of acrylami...

Embodiment 2

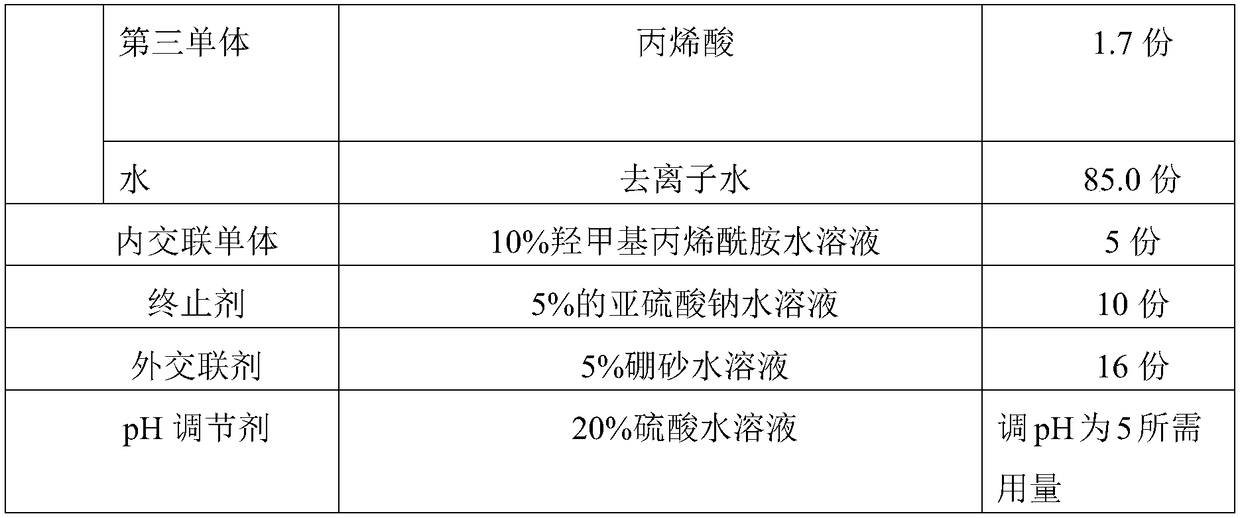

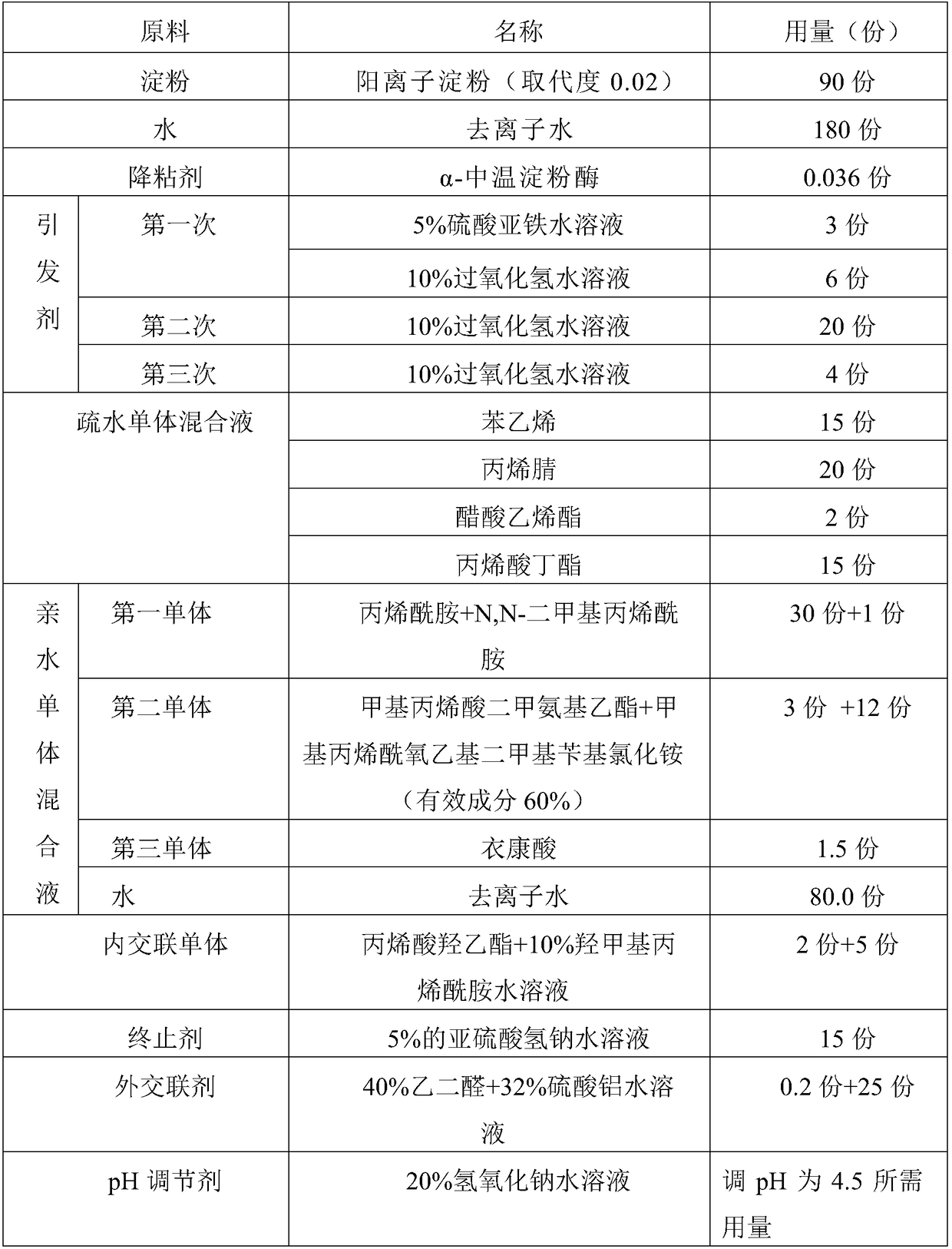

[0050] The main raw materials used and the amount of feed are shown in the table below:

[0051]

[0052] Add 180 parts of deionized water to a reaction kettle with a mixer, a thermometer, a reflux condenser and a nitrogen inlet pipe, slowly add 90 parts of cationic starch (substitution degree 0.02) under stirring, and add 0.036 parts of α-medium temperature amylase, Raise the temperature to 80°C, keep it warm for 20 minutes between 78°C and 82°C, and check the viscosity at 77°C to be 10mPa.s; pass nitrogen gas, when the temperature drops to 75°C, add the first initiator 5% ferrous sulfate aqueous solution 3 parts, 6 parts of 10% hydrogen peroxide aqueous solution, reacted for 20 minutes, and then added dropwise the hydrophobic monomer mixed solution, the hydrophilic monomer mixed solution, the internal crosslinking monomer solution and the aqueous initiator solution, wherein the hydrophobic monomer The body mixed solution is composed of 15 parts of styrene, 20 parts of acr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com