Glass steel tube produced in continuous winding process

A glass steel pipe, weight ratio technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of poor flexibility, unsatisfactory tensile strength and rigidity, and low interlayer strength of glass steel pipes. The effect of strong overall strength and stiffness, high interlayer bonding strength and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

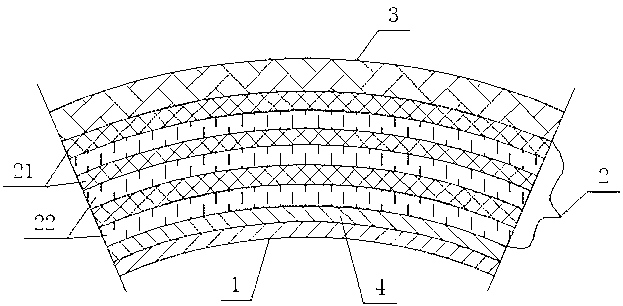

[0032] Embodiment 1: A continuous winding glass steel pipe, comprising an inner lining layer 1, a structural layer 2 and an outer protective layer 3, the structural layer 2 is composed of multiple layers of long fiber layers 21 and short fiber layers 22 interlaced up and down;

[0033] Described long fiber layer 21 is made of the following components by weight ratio:

[0034] Long-cut glass fiber, accounting for 60%; resin, accounting for 40%;

[0035] Described short fiber layer 22 is made of following components by weight ratio:

[0036] Chopped glass fiber, accounting for 14%; quartz sand, accounting for 43%; resin, accounting for 43%.

[0037] Described lining layer 1 is made of the following components by weight ratio:

[0038] Fiberglass surface mat, accounting for 10%; resin, accounting for 90%.

[0039] Described outer protective layer 3 is made of the following components by weight ratio:

[0040] Polyester surface felt, 10%; resin, 90%.

[0041] A secondary inne...

Embodiment 2

[0043] Embodiment 2: A continuously wound glass steel pipe, comprising an inner lining layer 1, a structural layer 2 and an outer protective layer 3, the structural layer 2 is composed of multiple layers of long fiber layers 21 and short fiber layers 22 interlaced up and down;

[0044] Described long fiber layer 21 is made of the following components by weight ratio:

[0045] Long-cut glass fiber, accounting for 55%; resin, accounting for 45%;

[0046] Described short fiber layer 22 is made of following components by weight ratio:

[0047] Chopped glass fiber, 10%; quartz sand, 45%; resin, 45%.

[0048] Described lining layer 1 is made of the following components by weight ratio:

[0049] Fiberglass surface mat, accounting for 5%; resin, accounting for 95%.

[0050] Described outer protective layer 3 is made of the following components by weight ratio:

[0051] Polyester surface felt, 5%; resin, 95%.

[0052] A secondary inner layer 4 is also provided between the structur...

Embodiment 3

[0054] Embodiment 3: A continuous winding glass steel pipe, including an inner lining layer 1, a structural layer 2 and an outer protective layer 3, the structural layer 2 is composed of multiple layers of long fiber layers 21 and short fiber layers 22 interlaced up and down;

[0055] Described long fiber layer 21 is made of the following components by weight ratio:

[0056] Long-cut glass fiber, accounting for 65%; resin, accounting for 35%;

[0057] Described short fiber layer 22 is made of following components by weight ratio:

[0058] Chopped glass fiber, accounting for 20%; quartz sand, accounting for 40%; resin, accounting for 40%.

[0059] Described lining layer 1 is made of the following components by weight ratio:

[0060] Fiberglass surface felt, accounting for 15%; resin, accounting for 85%.

[0061] Described outer protective layer 3 is made of the following components by weight ratio:

[0062] Polyester surface felt, accounting for 15%; resin, accounting for 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com