Ultra high conductivity polymer fiber and linear super capacitor set and preparation method thereof

A technology of supercapacitors and conductive polymers, applied in the field of linear fibers, can solve the problems of no linear supercapacitors, and achieve the effects of increasing voltage and current, strong weaving ability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]a. Utilize the polypyrrole that concentration is 0.5wt.% to prepare flexible polymer fiber by the method for wet spinning, coagulation bath is the mixed solution (magnesium chloride solution and anhydrous magnesium chloride solution and anhydrous ethanol that mass fraction is 3%) The volume ratio of ethanol is 1:30), and the syringe pump is used to push, the speed of pushing is 0.5ml / min, and the extrusion diameter is 0.2 μm.

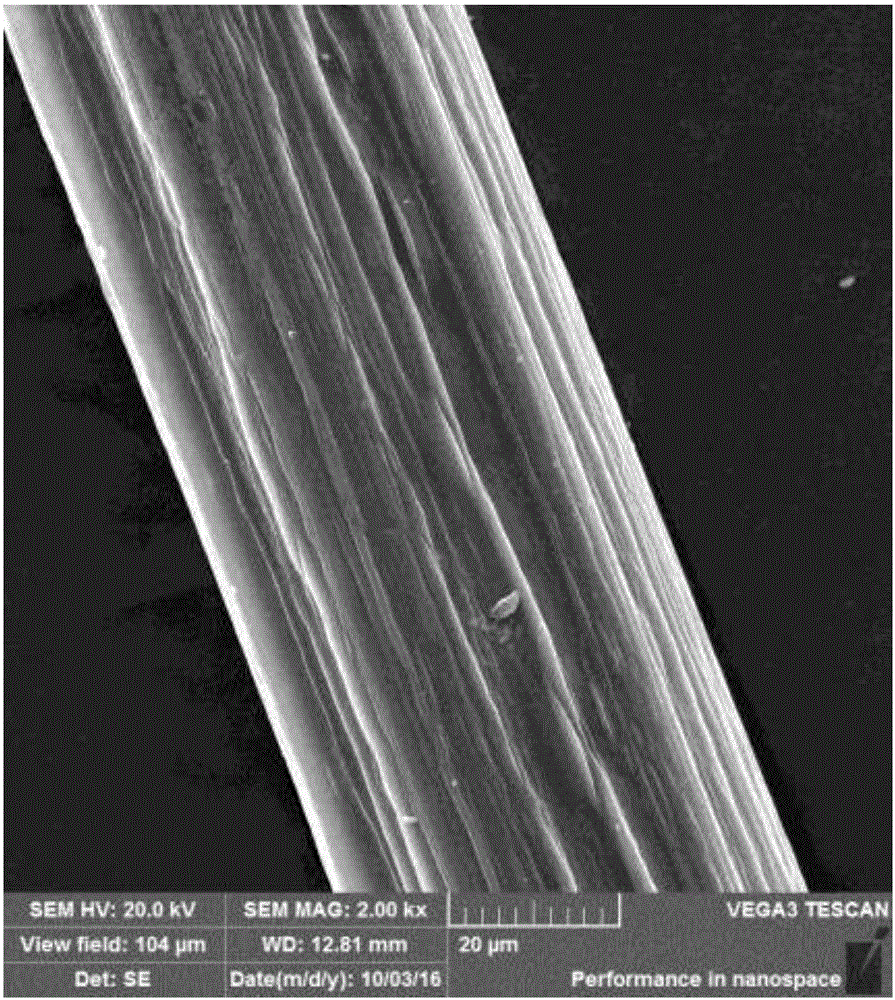

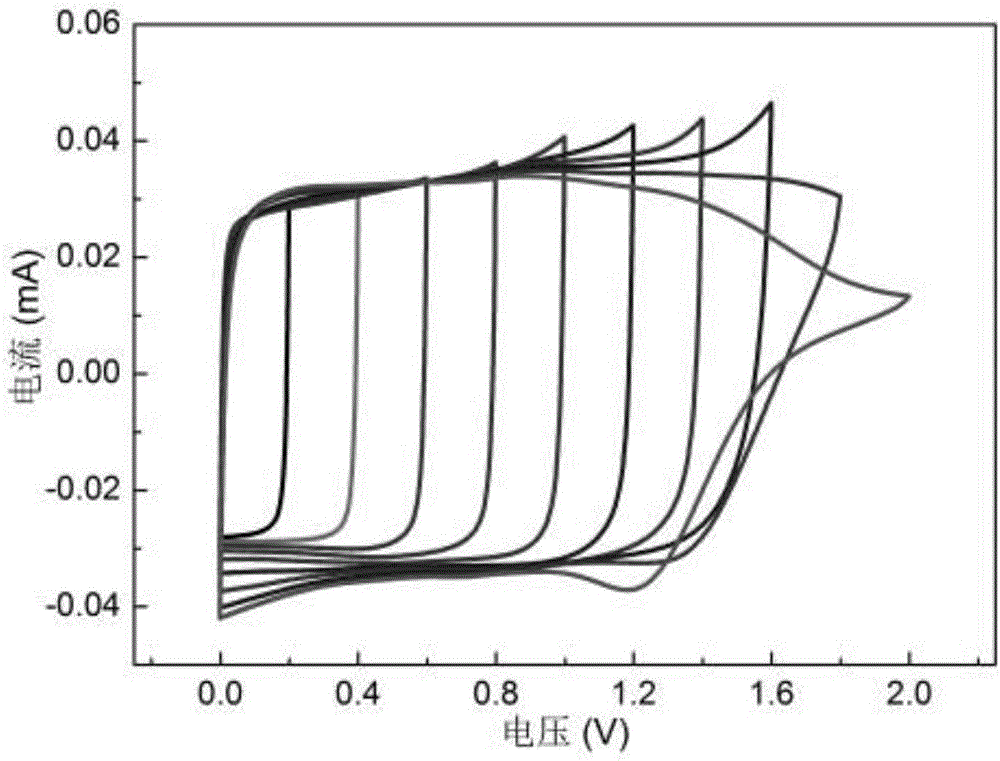

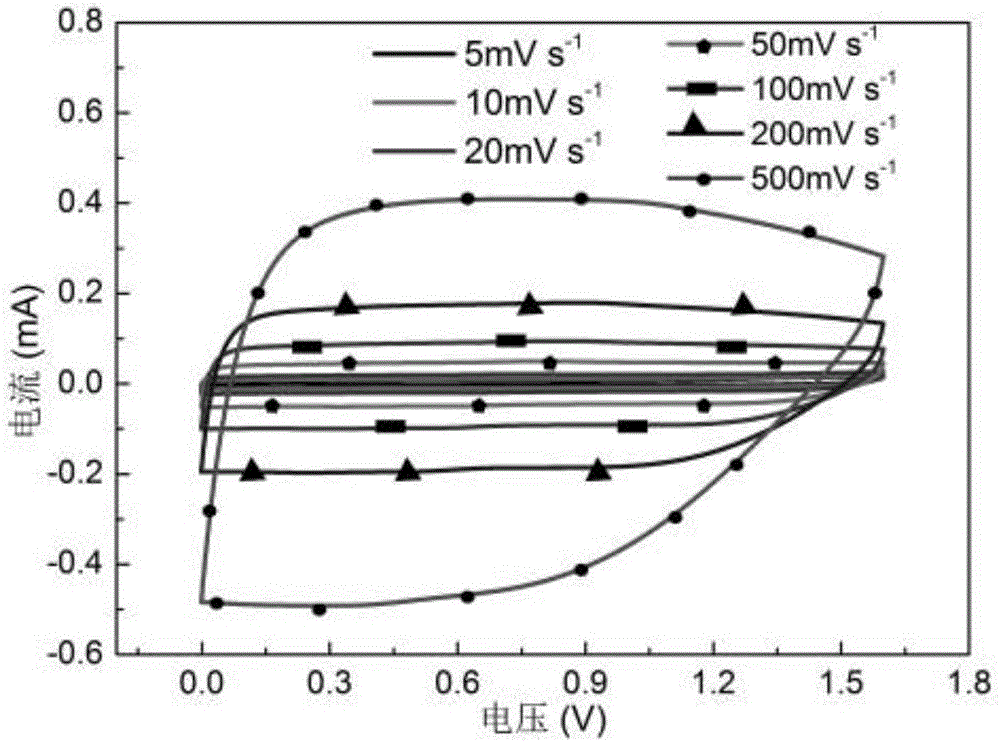

[0041] b. Treat the obtained polymer fiber in concentrated phosphoric acid for 0.1h, wash it with distilled water, and obtain a polymer fiber with a high working voltage window (1.2V) and an ultra-high conductivity (1100S / cm), the SEM image is as follows figure 1 shown.

Embodiment 2

[0043] a. utilize the polypyrrole that concentration is 10wt.% to prepare flexible polymer fiber by the method for wet spinning, coagulation bath is the mixed solution (calcium chloride solution) that mass fraction is 3% calcium chloride solution and organic solvent dehydrated alcohol The volume ratio to absolute ethanol is 5:1), and the syringe pump is used to push, the speed of pushing is 5ml / min, and the extrusion diameter is 10 μm.

[0044] b. Treat the obtained polymer fibers in fuming nitric acid with a concentration>90% for 2 hours, and wash them with distilled water to obtain polymer fibers with high working voltage window (1.5V) and ultrahigh conductivity (1300S / cm).

Embodiment 3

[0046] A. utilize concentration to be 20wt.% polyacetylene to prepare flexible polymer fiber by the method for wet spinning, coagulation bath is the mixed solution (calcium chloride solution) that mass fraction is 5% calcium chloride solution and organic solvent n-butanol The volume ratio to n-butanol is 10:1), and the syringe pump is used to push, the speed of pushing is 25ml / min, and the extrusion diameter is 100 μm.

[0047] b. Treat the obtained polymer fibers in oleum with a concentration>98.5% for 5 hours, and wash them with distilled water to obtain polymer fibers with high operating voltage window (1.6V) and ultrahigh conductivity (1500S / cm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com