Symmetric warp let-off method and device of single needle bed warp knitting machine

A technology of warp knitting machine and single needle bed, which is applied in the direction of warp knitting, knitting, textiles and papermaking, etc. It can solve problems such as difficulty in finding broken yarns, reducing yarn threading speed, and different warp let-off tensions, etc., and achieves Reduce the chance of kinking and entanglement, improve weavability, and ensure the effect of fabric quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

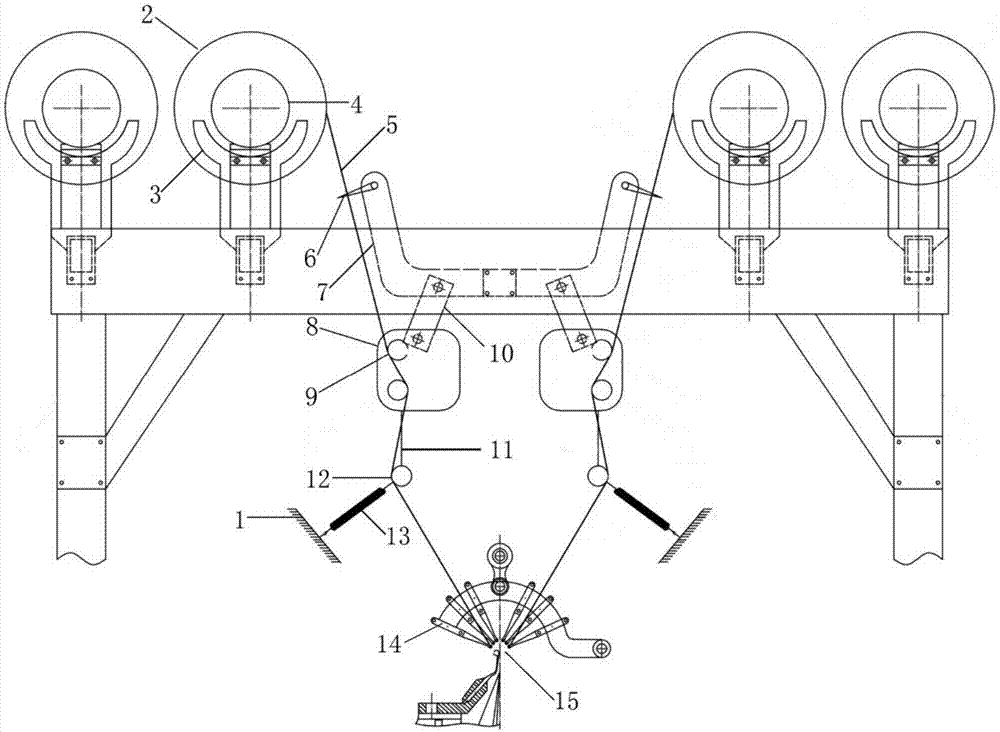

[0027] A symmetrical warp let-off device of a single needle bed warp knitting machine, such as figure 1 As shown, the symmetrical warp let-off device is mainly composed of two sets of warp let-off systems located horizontally and symmetrically on both sides of the warp knitting machine body 1, and each warp let-off system is mainly composed of a yarn spreading mechanism, a yarn tension regulating mechanism and a loop forming mechanism , the yarn is unfolded by the yarn unfolding mechanism, and then the tension is adjusted by the yarn tension regulating mechanism, and then sent into the loop forming mechanism. The fuselage 1 is a metal frame structure and includes a central beam. Two sets of let-off systems are symmetrically distributed in On both sides of the symmetrical axis of the central beam, the yarn unfolding mechanism is mainly composed of pan head 2, warp beam bracket 3 and warp beam 4, pan head 2 is set on warp beam 4, and warp beam 4 is connected with warp beam bracke...

Embodiment 2

[0029]A symmetrical warp let-off device for a single-needle bed warp knitting machine. The symmetrical warp let-off device is mainly composed of 4 sets of warp let-off systems located horizontally and symmetrically on both sides of the warp knitting machine body. Each set of warp let-off system is mainly composed of a yarn unfolding mechanism, The yarn tension regulating mechanism and the knitting mechanism are composed. After the yarn is unfolded by the yarn unfolding mechanism, the tension is adjusted by the yarn tension regulating mechanism and then sent to the knitting mechanism. The fuselage is a metal frame structure and includes a central beam. , 4 sets of warp let-off systems are symmetrically distributed on both sides of the symmetrical axis of the central beam. The yarn unfolding mechanism is mainly composed of pan head, warp beam bracket and warp beam. The pan head is set on the warp beam, and the warp beam and warp beam bracket rotate. The warp beam bracket is fixed...

Embodiment 3

[0031] A symmetrical warp let-off device for a single-needle bed warp knitting machine. The symmetrical warp let-off device is mainly composed of 6 sets of warp let-off systems located horizontally and symmetrically on both sides of the warp knitting machine body. Each set of warp let-off system is mainly composed of a yarn unfolding mechanism, The yarn tension regulating mechanism and the knitting mechanism are composed. After the yarn is unfolded by the yarn unfolding mechanism, the tension is adjusted by the yarn tension regulating mechanism and then sent to the knitting mechanism. The fuselage is a metal frame structure and includes a central beam. , 6 sets of let-off systems are symmetrically distributed on both sides of the symmetrical axis of the central beam. The yarn unfolding mechanism is mainly composed of pan head, warp beam bracket and warp beam. The pan head is set on the warp beam, and the warp beam and warp beam bracket rotate. The warp beam bracket is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com