Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Promote decomposition reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

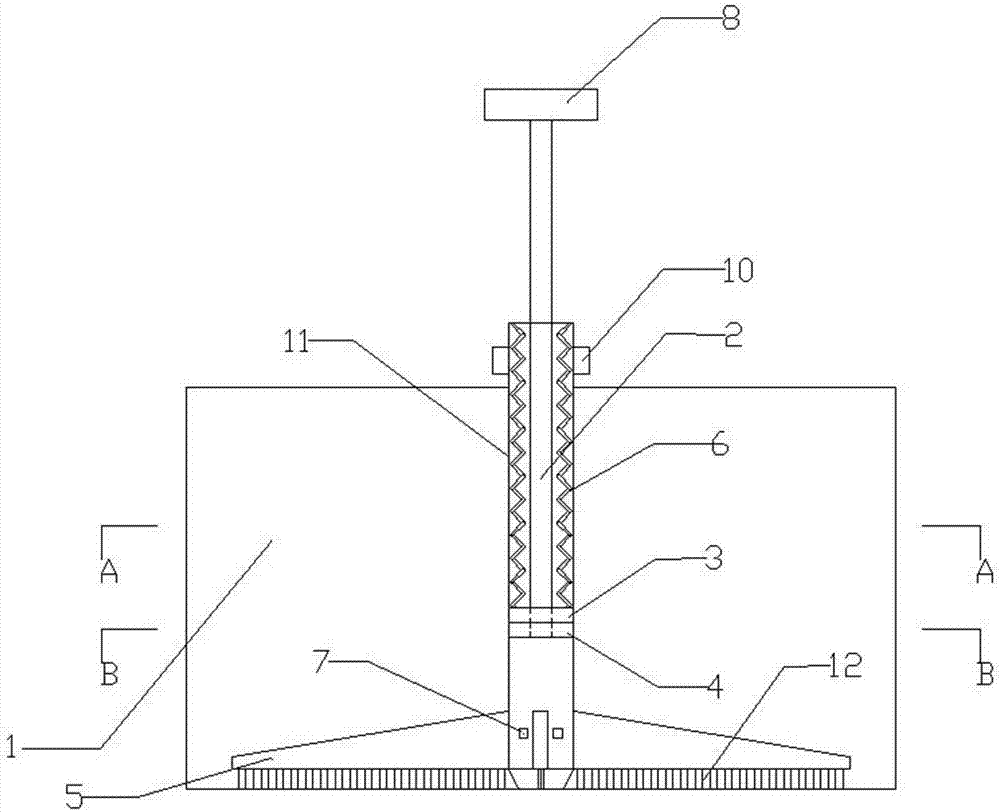

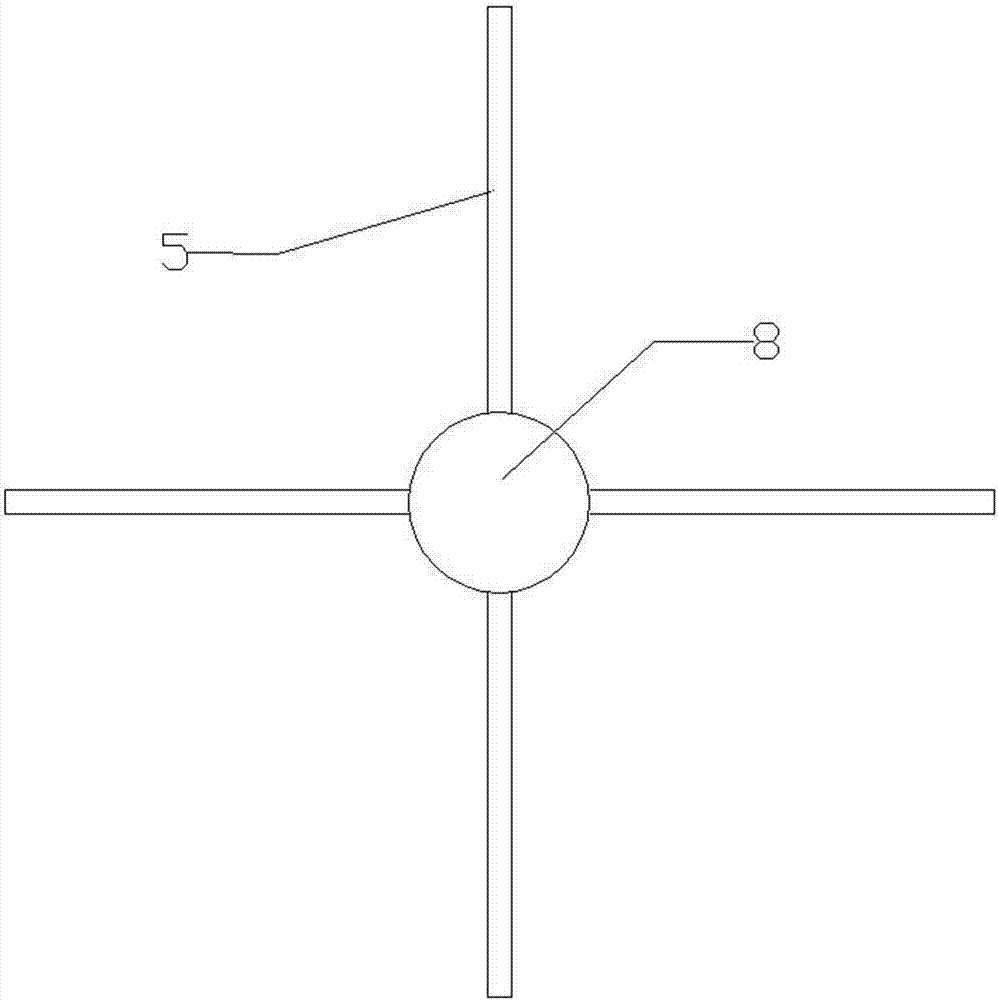

Resin bendable grinding wheel and preparation method and device

InactiveCN101804602AAvoid carbonizationIncrease contentFlexible-parts wheelsGrinding devicesFiberglass meshCarbide silicon

The invention discloses a resin bendable grinding wheel and a preparation method and a device thereof. The resin bendable grinding wheel consists of brown aluminium oxide, calcined alumina, white alundum, black silicon carbide, phenolic resin powder, phenolic resin liquid, cryolite, barium sulphate, pyretic, iron oxide red, Hunori gel, alkali-free high tensile glass fiber mesh and non-woven black cloth. Compared with the prior art, through the optimization configuration on the aspect of the material selection and working procedures, the strength, the flexibility and the aging resistance of the grinding wheel are greatly improved, and at the same time, the resource and the energy are saved; and the strength of the grinding wheel is more than 80m / s, the grinding ratio is more than or equal to 1:15, the maximum bendable angle can reach 40 degrees, the tensile strength is greatly improved, the service life is prolonged by two times, the energy consumption is reduced by 5 to 10 percent, and the yield of the finished product can reach more than 99 percent.

Owner:GUIZHOU FUSUN INDAL

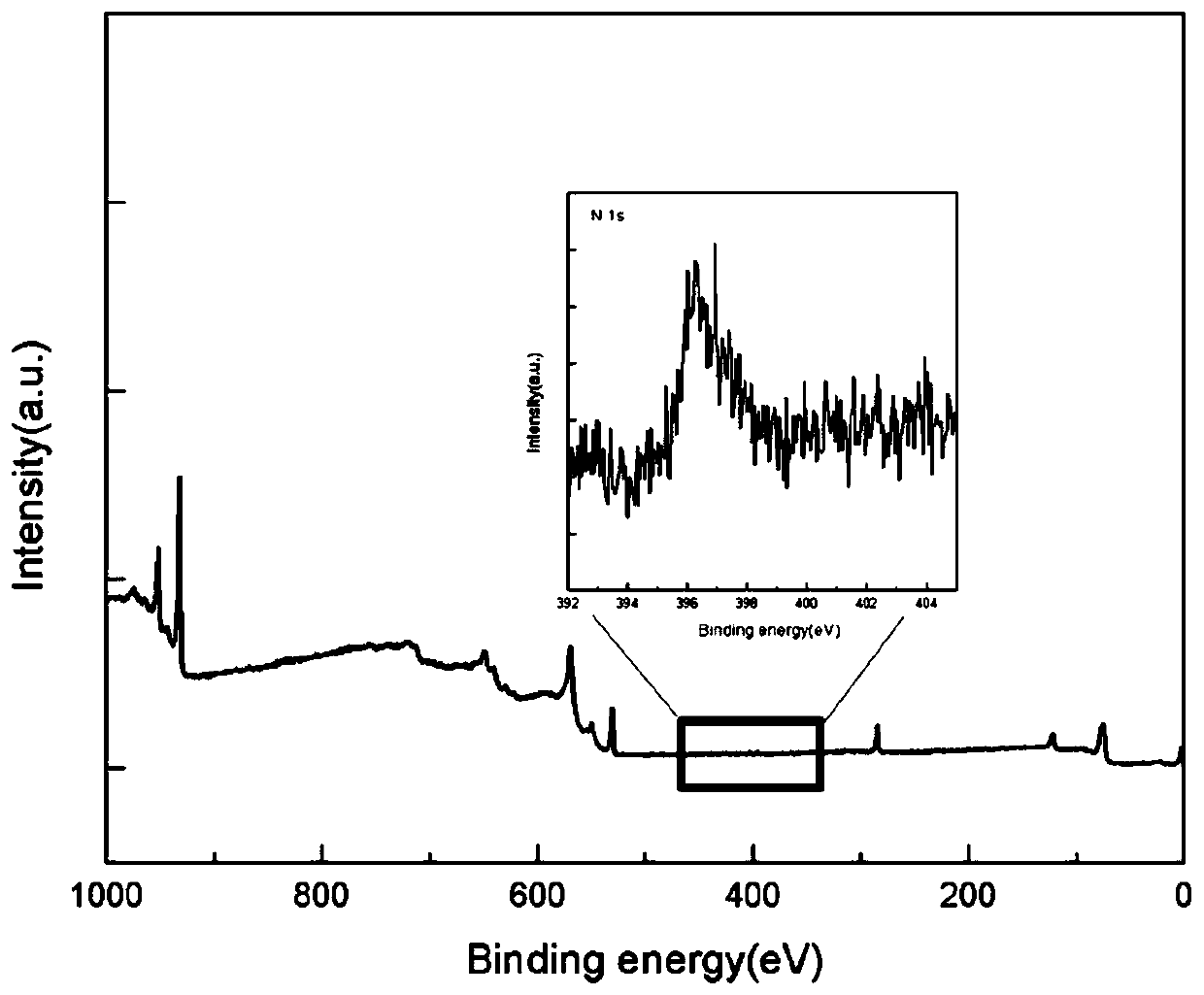

Preparation and application of transition metal phosphide/core-shell nitrogen-doped carbon nanofiber composite material

ActiveCN110052282AImprove conductivityImprove stabilityPhysical/chemical process catalystsElectrodesFiberElectrolysis

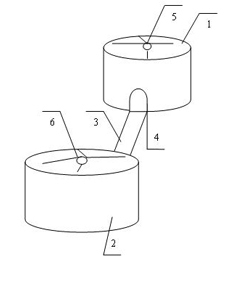

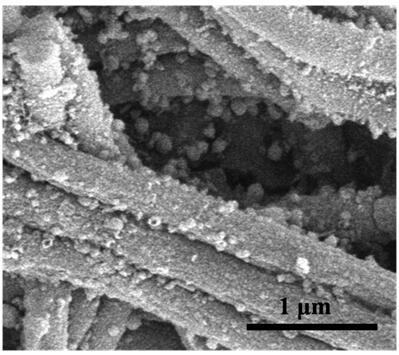

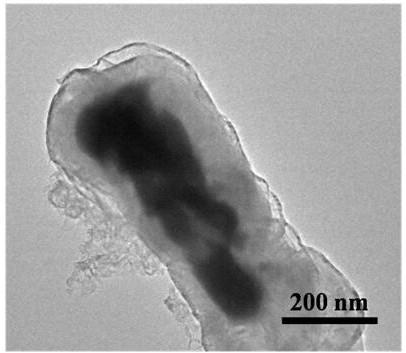

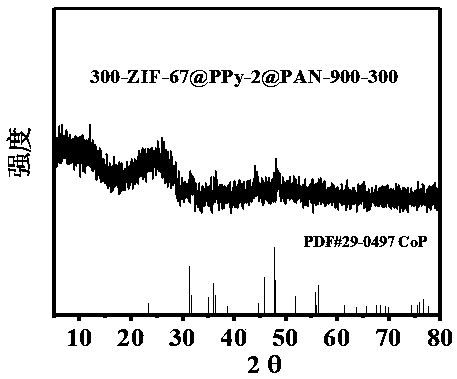

The invention provides a preparation method of a transition metal phosphide / core-shell nitrogen-doped carbon nanofiber composite material. The preparation method includes preparing a carbon nanofiberaccording to an electrospinning technique by taking a carbon-containing high-molecular polymer as a carbon source, coating the carbon nanofiber with an electroconductive polymer through surface polymerization, loading an MOF material onto the surface of the carbon nanofiber coated with the electroconductive polymer according to an in-situ growth method to obtain a precursor, and subjecting the precursor to high-temperature carbonizing and phosphating to obtain the transition metal phosphide / core-shell nitrogen-doped carbon nanofiber composite material. Activity test results show that the transition metal phosphide / core-shell nitrogen-doped carbon nanofiber composite material prepared by the preparation method has high electrocatalytic activity for total decomposition reaction of HER, OER and water and has high stability in acid-base media, thereby being a dual-functional catalyst that can replace precious metal and having a good development prospect in water electrolysis reaction.

Owner:NORTHWEST NORMAL UNIVERSITY

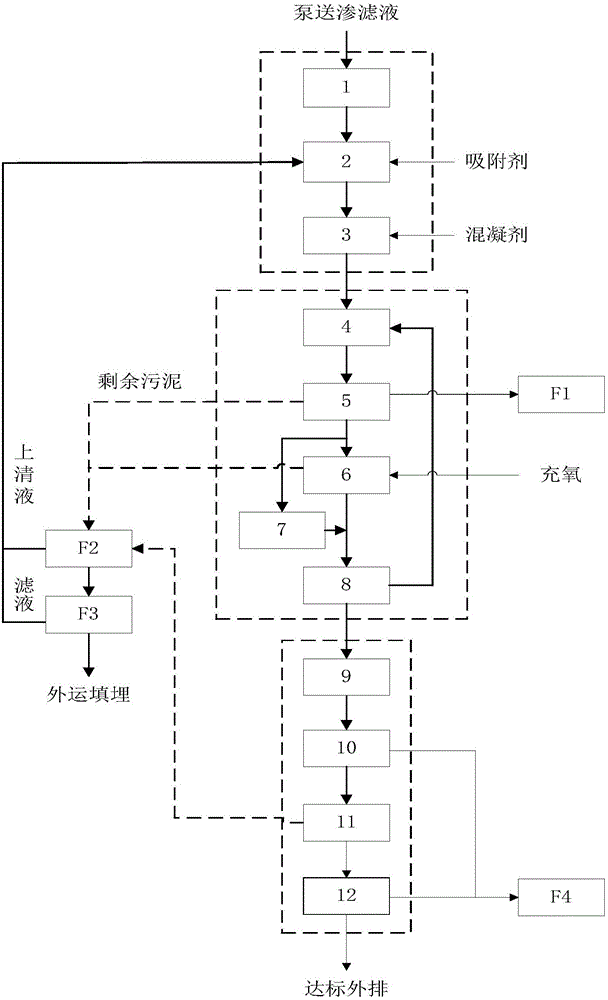

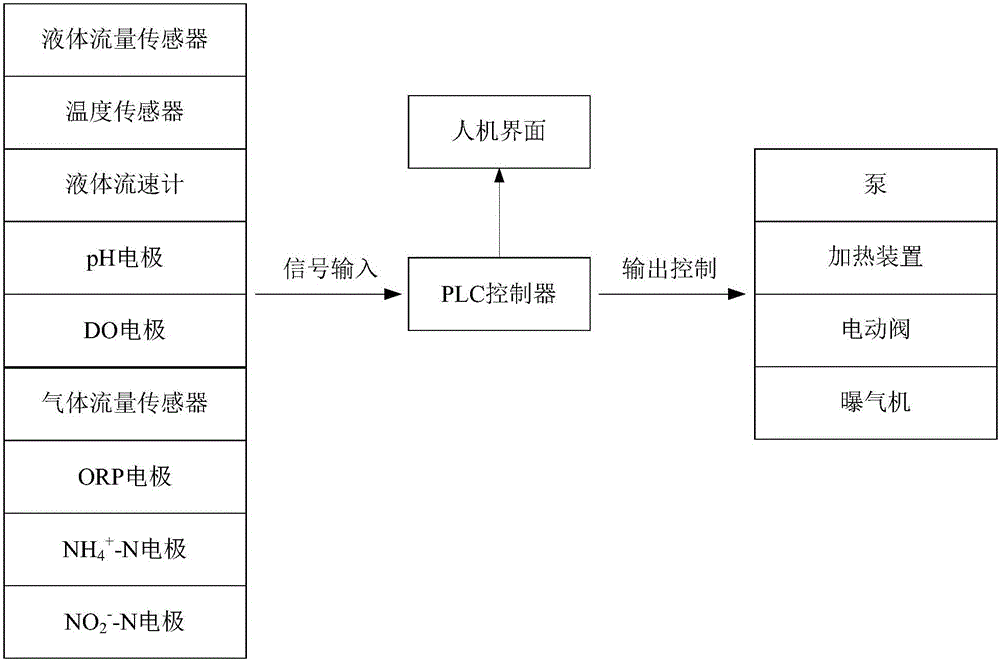

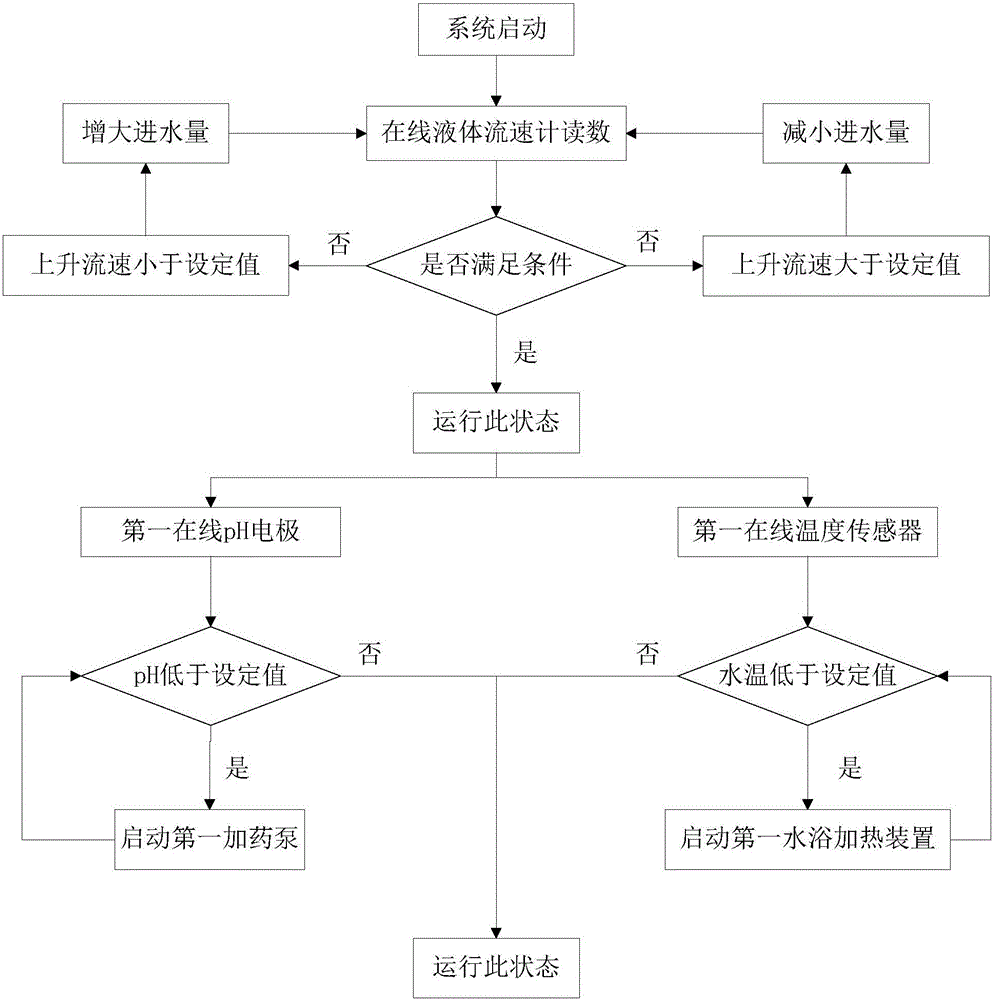

Anaerobic-autotrophic nitrogen removal-ozone oxidation coupling landfill leachate whole flow process zero emission processing process

ActiveCN105776775AReduce outputImprove nitrogen removal efficiencyWaste based fuelTreatment with anaerobic digestion processesNitrationTotal nitrogen

The invention provides a landfill leachate processing process. Landfill leachate sequentially passes through a pretreatment system, a main body biological treatment system and a deep treatment system; the pretreatment system consists of a regulating pool, an adsorption pool and a coagulating pool; wastewater is pretreated sequentially through the devices; outlet water enters the main body biological treatment system; the main body biological treatment system comprises an anaerobic EGSB (expanded granular sludge bed) reactor, an A / O short-range nitratlon reaction pool and an anaerobic ammonia oxidation UASB (upflow anaerobic sludge blanket) reactor; the treatment devices perform real-time regulation control through a PLC (programmable logic controller) control system for denitrification decarbonization reaction; the outlet water enters the deep treatment system for further treatment; the deep treatment system comprises a secondary coagulating pool, a primary homogeneous catalysis ozone oxidation reaction pool, a MBR (meane biological reactor) secondary biological reaction pool and a secondary homogeneous catalysis ozone oxidation reaction pool; finally, organic matters, total nitrogen and ammonia nitrogen of the outlet water reach the discharge standard. The landfill leachate processing process has the advantages that efficient denitrification and carbon removal are realized; the energy is saved; the consumption is reduced; the operation is stable; meanwhile, the goal of zero concentrated liquid generation is realized.

Owner:SHANGHAI BI ZONE ENVIRONMENTAL EQUIP & ENG

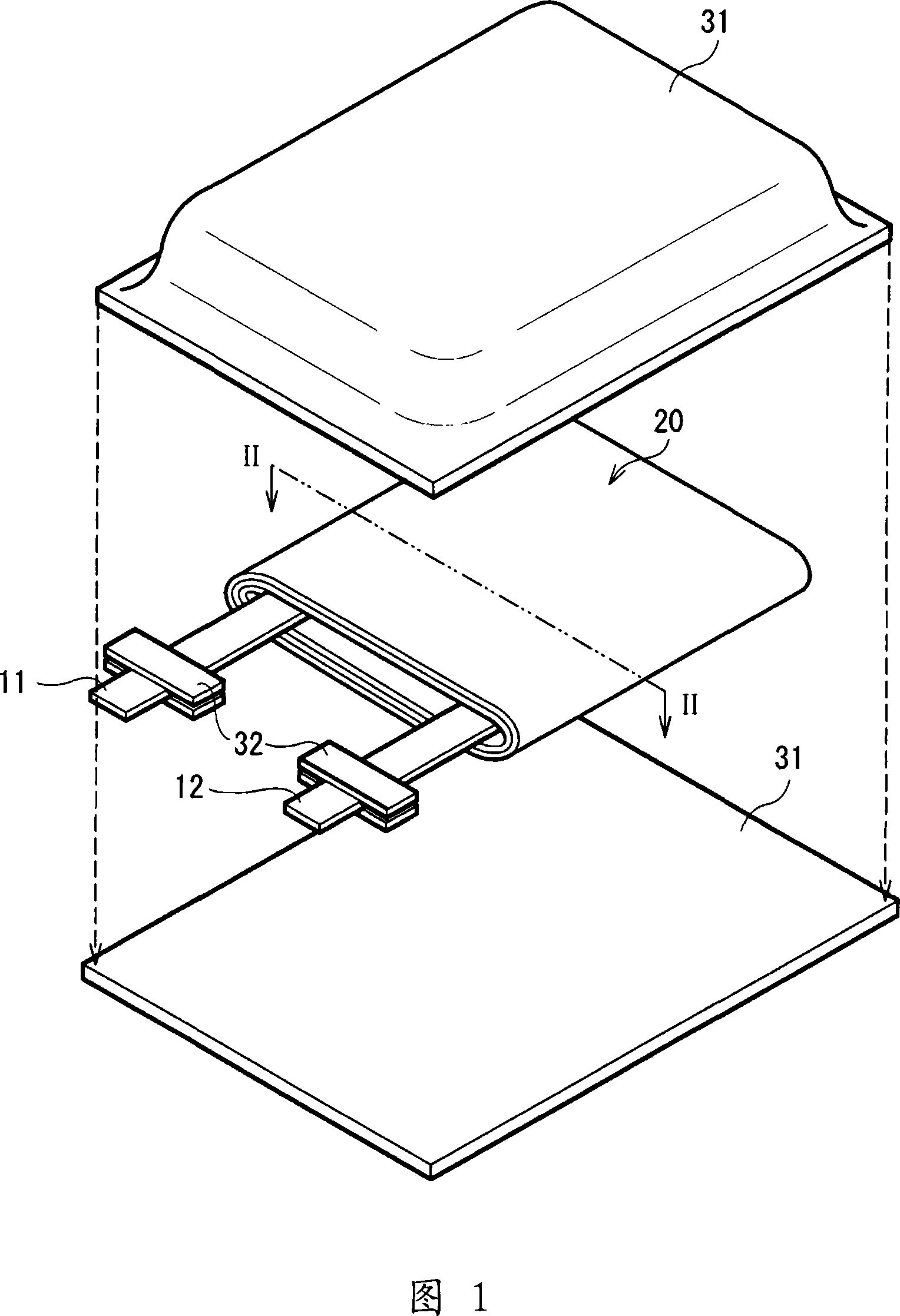

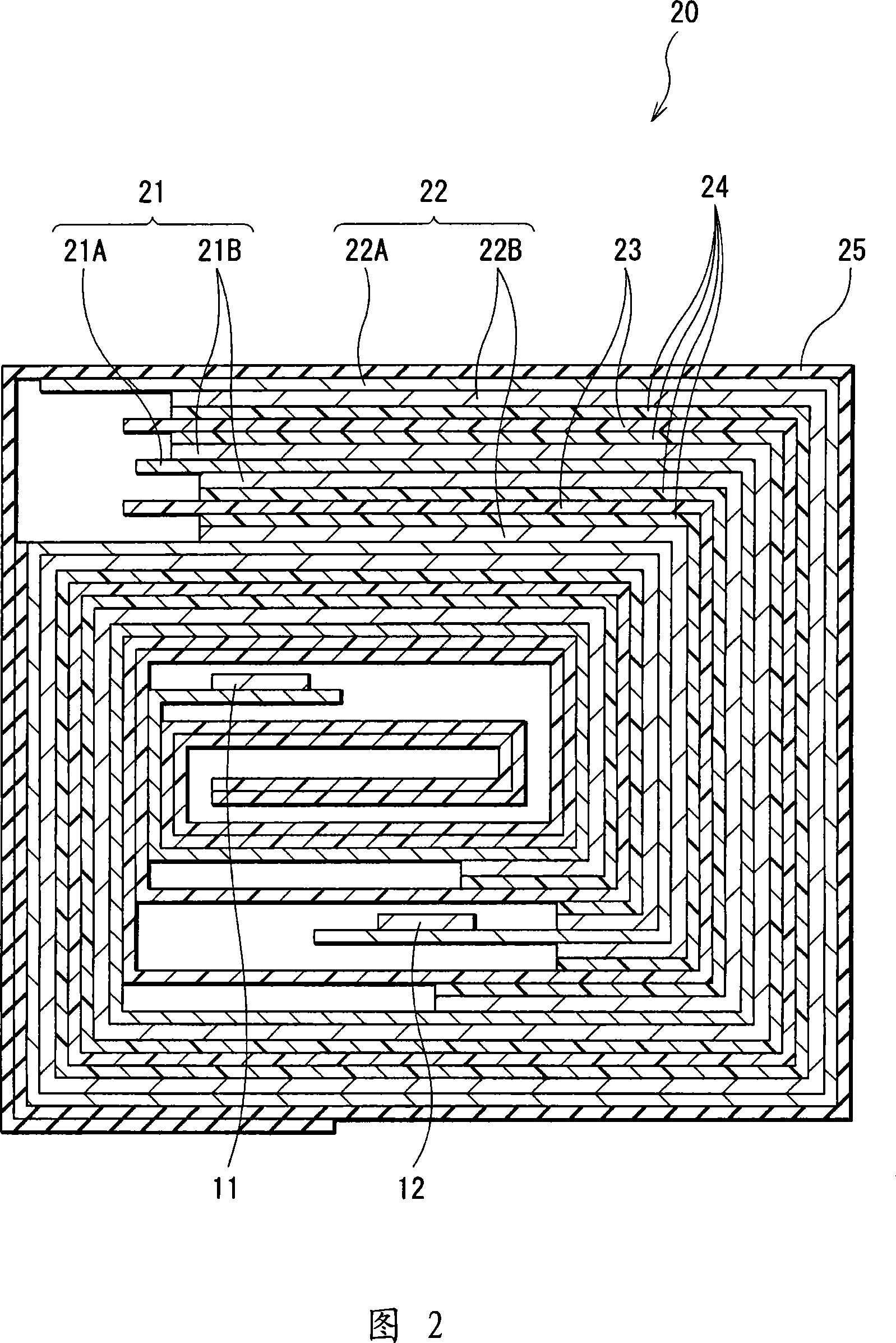

Electrolyte solution and battery

ActiveCN101124695AGood effectPrevent decomposition reactionOrganic electrolyte cellsActive material electrodesDischarge efficiencyHydrofluoric acid

Disclosed is an electrolyte solution which enables to improve battery characteristics such as battery swelling and charge / discharge efficiency. Also disclosed is a battery using such an electrolyte solution. Specifically disclosed is a battery wherein a positive electrode (21) and a negative electrode (22) are arranged in layers via an electrolyte layer (24). The electrolyte layer (24) is a gel containing an electrolyte solution and a polymer compound, and the electrolyte solution contains a compound having a proton-collecting function such as hexamethylenetetramine or hexaethylenetetramine. Consequently, a free acid such as hydrofluoric acid can be captured, thereby suppressing decomposition reaction of the electrolyte.

Owner:MURATA MFG CO LTD

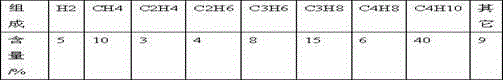

Method for preparing aromatic hydrocarbon from methanol or dimethyl ether

InactiveCN104557419AHigh yieldImprove utilization efficiencyMolecular sieve catalystsHydrocarbon from oxygen organic compoundsAromatizationFixed bed

The invention relates to a method for preparing aromatic hydrocarbon from methanol or dimethyl ether and mainly aims to solve the problems of low yield of aromatic hydrocarbon, serious heat release during reaction, rapid increase of temperature of a reactor and rapid deactivation of a catalyst in the aromatization process of methanol or dimethyl ether. According to the technical scheme of the invention, methanol or dimethyl ether as a raw material is enabled to be in contact with a reaction accelerator, a heat balance agent and a catalyst in a fixed bed reactor at the reaction temperature of 350-650 DEG C, and products of reaction are separated to obtain the methanol or dimethyl ether containing aromatic hydrocarbon. By adopting the technical scheme, the problems can be well solved. The method provided by the invention can be applied to the industrial production of aromatic hydrocarbon through conversion of oxygenated chemicals.

Owner:CHINA PETROLEUM & CHEM CORP +1

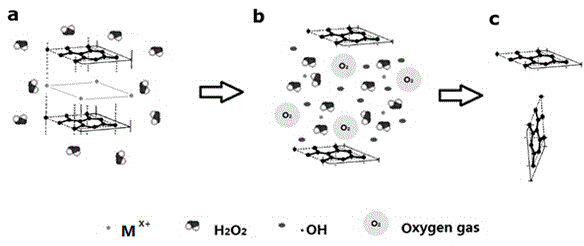

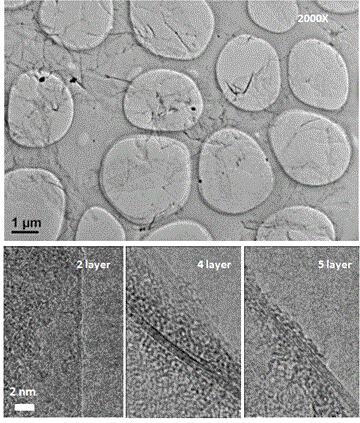

Graphene preparation method

The invention discloses a graphene preparation method comprising the following steps: a, graphite intercalation compound powder is added into a composite inflation fluid, and an inflation reaction is carried out under a temperature of 0-100 DEG C, such that inflated wormlike graphene aggregate suspension liquid is obtained; b, the wormlike graphene aggregate suspension liquid is subjected to a filtration treatment; c, the wormlike graphene aggregate is sequentially washed with a metal ion complexing agent and water, such that a wormlike graphene aggregate wet material with a pH value of 6-8 is obtained; d, the washed wormlike graphene aggregate wet material is added into water; an ultrasonic wave vibration treatment is carried out for 0.5-20h, such that stripping is realized and graphene is dispersed in water; and a graphene solution is obtained; and e, the water in the graphene solution is removed, such that graphene powder is obtained. With the method provided by the invention, hundreds of kilograms of a high-quality graphene product can be produced in one batch.

Owner:四川烯材科技有限公司

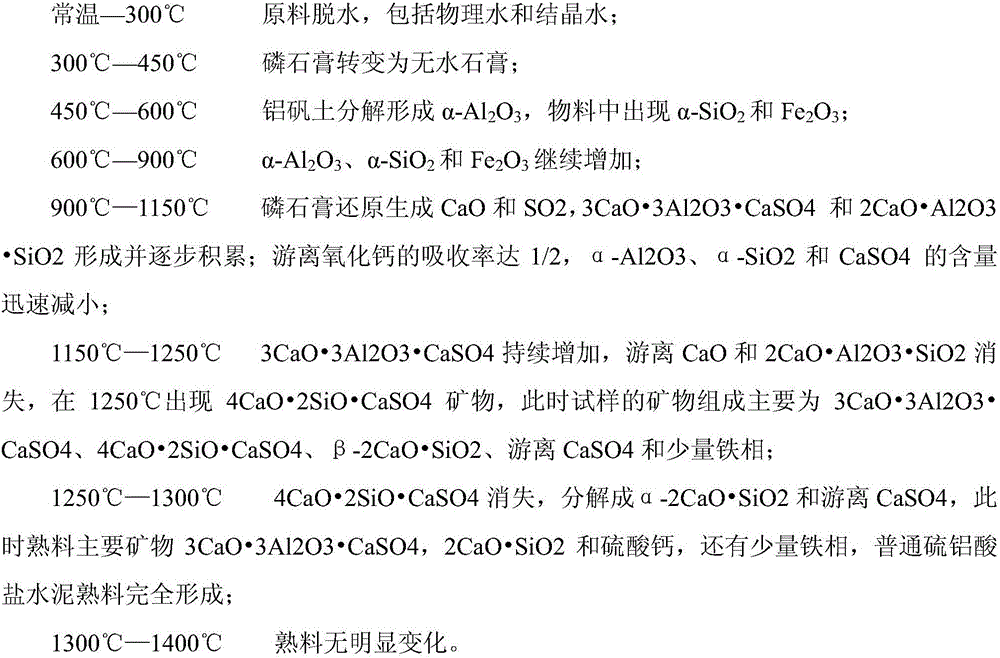

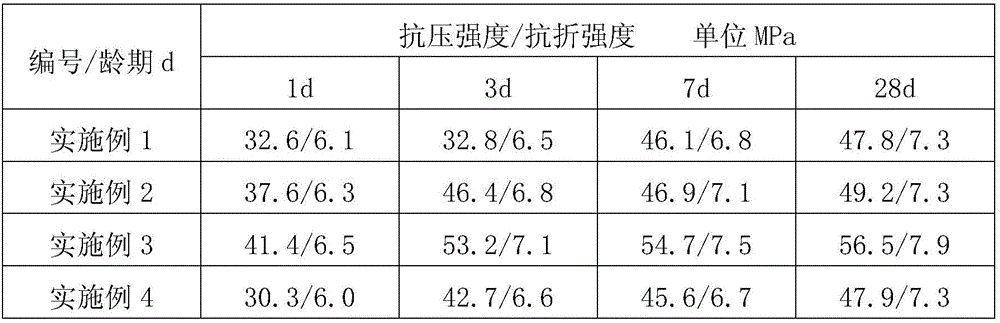

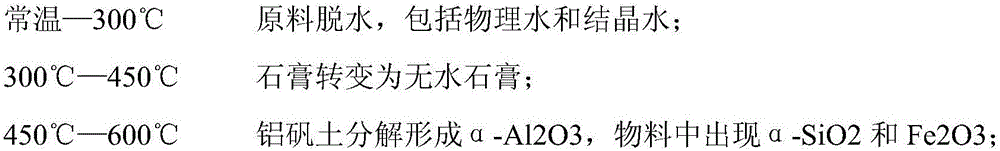

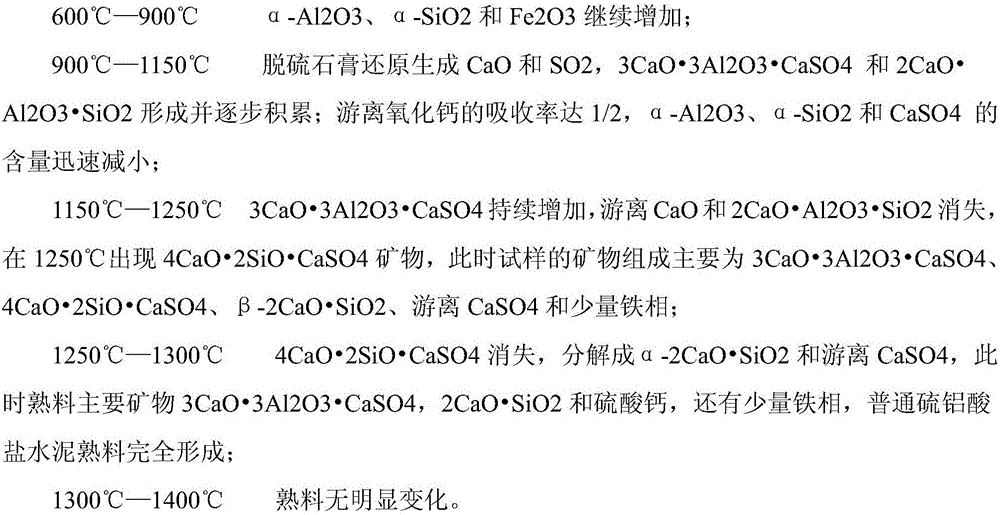

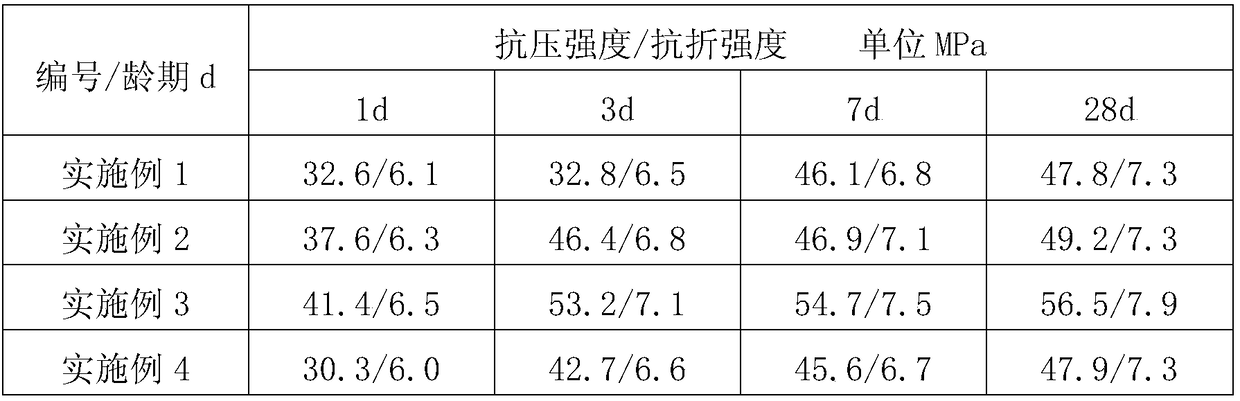

Method for preparing high-strength sulphoaluminate cement and coproducing sulfuric acid

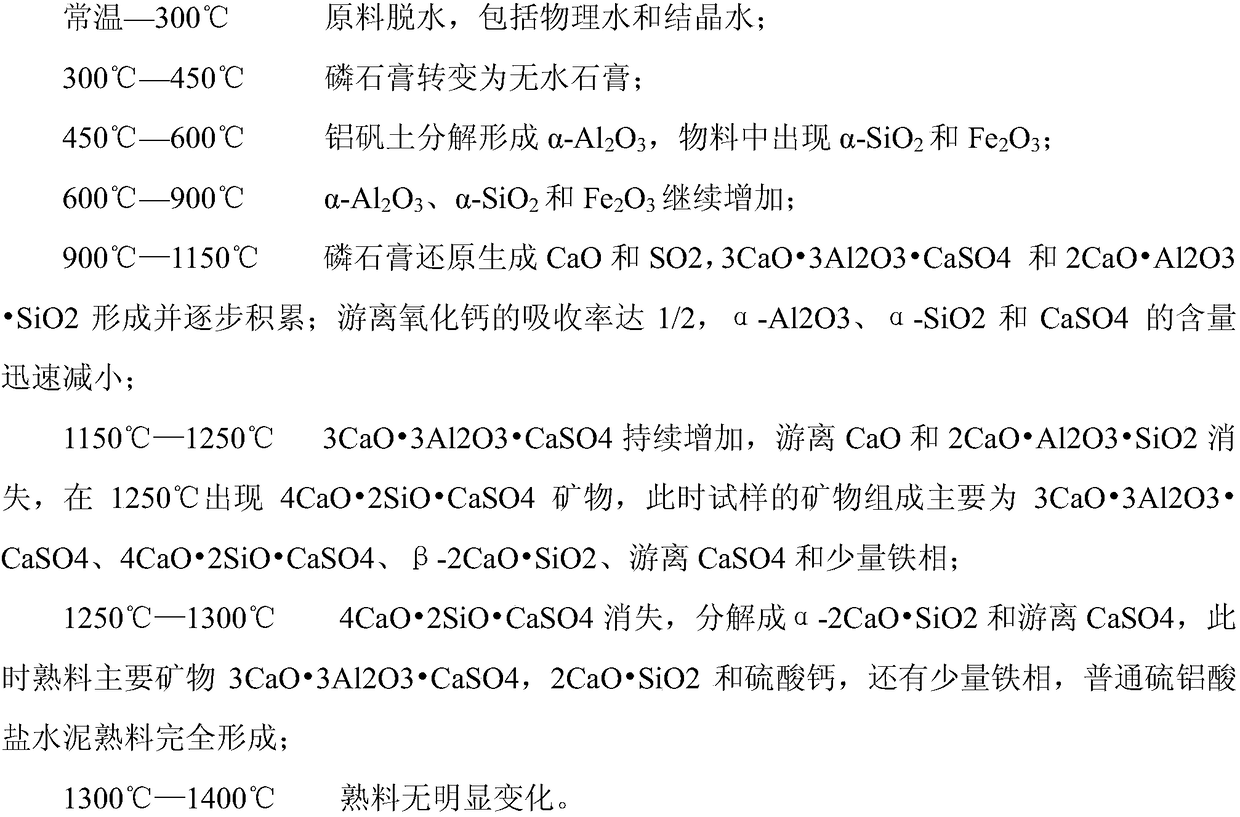

The invention relates to a method for preparing high-strength sulphoaluminate cement and co-producing sulfuric acid. The method comprises the following steps of adopting phosphogypsum for completely replacing limestone and natural gypsum, milling and homogenizing the phosphogypsum, bauxite, steel scoria, silica and pulverized anthracite, and then calcinating the milled and homogenized raw materials at a temperature of 1250-1300 DEG C. The method is capable of greatly improving the phosphogypsum utilization ratio, and high-concentration sulfur dioxide tail gas can be adsorbed to prepare sulfuric acid. The prepared sulphoaluminate cement clinker is high in hardening rate, high in early-stage strength, and stable in later-stage strength increase; performance tests indicate that the mechanical strength of the sulphoaluminate cement prepared by the method conforms to the rapid-hardening sulphoaluminate cement standard.

Owner:KINGENTA NORSTERRA CHEM CO LTD +1

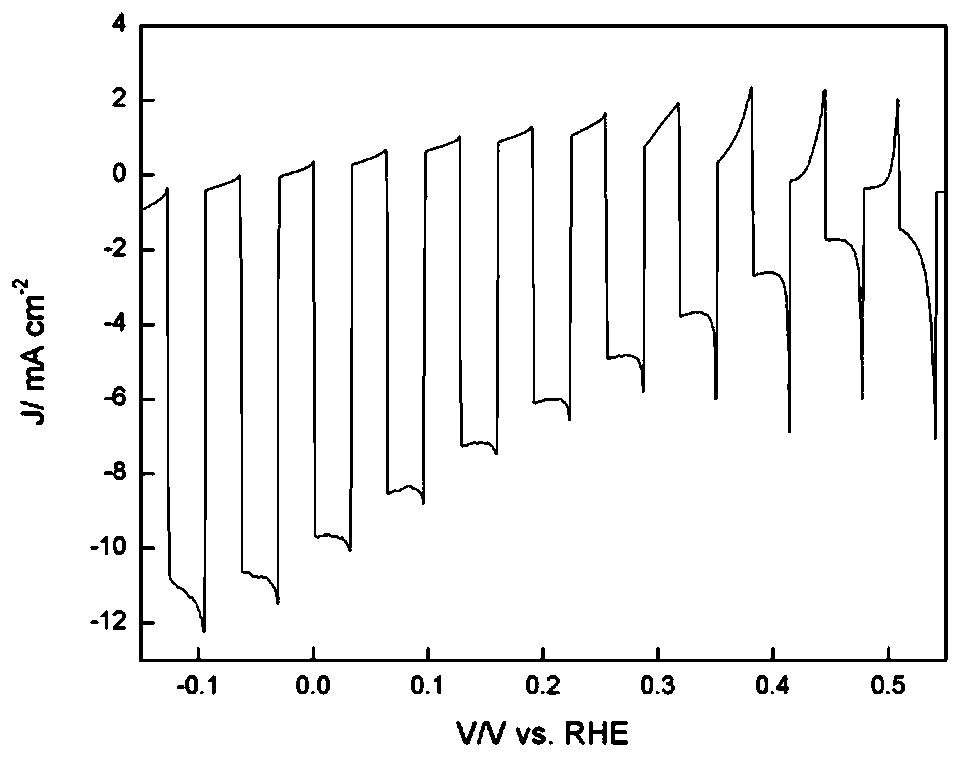

Cuprous oxide-based photocathode with enhanced nitrogen-doped back surface electric field

ActiveCN110983359AImprove performanceEasy to separateElectrolytic inorganic material coatingVacuum evaporation coatingChemical physicsPhotocathode

The invention discloses a cuprous oxide-based photocathode with an enhanced nitrogen-doped back surface electric field, wherein the structure of the photocathode comprises conductive glass, a nitrogen-doped cuprous oxide layer, a P-type cuprous oxide light absorption layer, an N-type layer, a titanium dioxide protection layer and a cocatalyst layer from bottom to top. According to the invention, the performance of the cuprous oxide-based photocathode is greatly enhanced, so that the photocurrent of the planar cuprous oxide-based photocathode under a bias voltage of 0 V vs.RHE reaches about 10mA cm<-2> and is close to a theoretical value of 14 mA cm<-2>; and the introduction of the nitrogen-doped cuprous oxide layer can replace a traditional precious metal back electrode (gold electrode) so as to substantially reduce the preparation cost of the device, so that the cuprous oxide-based photocathode has a good development prospect, and the commercial application of the cuprous oxide-basedphotocathode is expected to be promoted.

Owner:ZHEJIANG UNIV

Phosphogypsum sulphoaluminate cement sulfuric acid coproduction method

ActiveCN106431031AIncrease profitRealize resource utilizationSulfur compoundsHigh concentrationPhosphogypsum

The invention relates to a phosphogypsum sulphoaluminate cement sulfuric acid coproduction method; wherein, phosphogypsum replacing completely limestone and natural gypsum, after being ground and homogenized with bauxite and anthracite culm, at 1250-1300 DEG C, calcinating and resulting in the sulphoaluminate cement. The exploitation rate of phosphogypsum in the method is increased to a large extent; high concentration of sulfur dioxide tail gas through absorption is prepared into sulfuric acid. The hardening speed of sulphoaluminate cement clinker is quick, the intensity of sulphoaluminate cement is high during the former and later phase, performance test shows that the mechanical strength of the sulphoaluminate cement prepared by the method accords with the standard of sulphoaluminate cement.

Owner:KINGENTA ECOLOGICAL ENG GRP +1

Combined production method for preparing sulphoaluminate cement and sulfuric acid from flue gas desulfurization gypsum

ActiveCN106365476AIncrease profitRealize resource utilizationSulfur compoundsHigh concentrationCalcination

The invention relates to a combined production method for preparing sulphoaluminate cement and sulfuric acid from flue gas desulfurization gypsum. According to the method, flue gas desulfurization gypsum which replaces limestone and natural gypsum completely is mixed with bauxite, silica and anthracite, and the sulphoaluminate cement is obtained after calcinations. The method can improve the utilization rate of flue gas desulfurization gypsum by a large margin, and the tail gas containing sulfur dioxide with a higher concentration can be absorbed to prepare sulfuric acid; the prepared sulphoaluminate cement clinker is fast in rate of hardening, high in early strength and further promotes the stability of later strength; through the performance tests, it is indicated that the mechanical strength of the sulphoaluminate cement prepared by the method meets the standard of rapid hardening sulphoaluminate cement.

Owner:KINGENTA NORSTERRA CHEM CO LTD +1

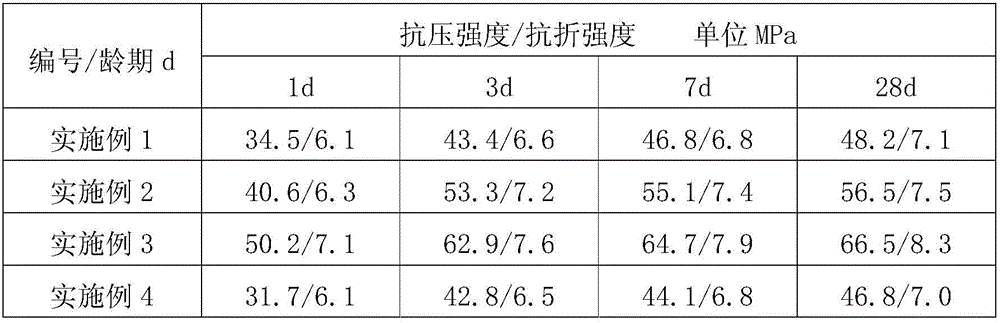

Phosphogypsum desulfurization calcining treatment system and method

PendingCN112142350ANo cloggingSmall finenessSulfur compoundsCalcium/strontium/barium oxides/hydroxidesThermodynamicsPortland cement

A phosphogypsum desulfurization calcining treatment system and method are included. the phosphogypsum desulfurization calcining treatment system comprises a low temperature dehydration system, a hightemperature calcination system and an acid making system, the low temperature dehydration system sequentially comprises a dryer, a drying mill and a pipeline furnace, the high temperature calcinationsystem sequentially comprises a preheating device, a rotary kiln and a cooler, natural water and crystal water are removed from phosphogypsum through low-temperature drying and high-temperature grinding and drying to obtain anhydrous gypsum, high-temperature calcination is carried out on the anhydrous gypsum, air cooling is carried out, the calcined anhydrous gypsum is sent to a cement productionline as a cement raw material, and gas generated in the calcination process is collected, and then sent to an acid making system to prepare sulfuric acid. According to the invention, a phosphogypsum acid making system and a cement system are separated, phosphogypsum dehydration, phosphogypsum decomposition, kiln gas acid making and resource comprehensive utilization of kiln slag are included, so that mutual interference between a desulfurization process and a cement process can be reduced, production of high-quality Portland cement and high-quality sulfuric acid is ensured, and harmless, resource and large-batch treatment of phosphogypsum is realized.

Owner:长沙中硅环保科技有限公司

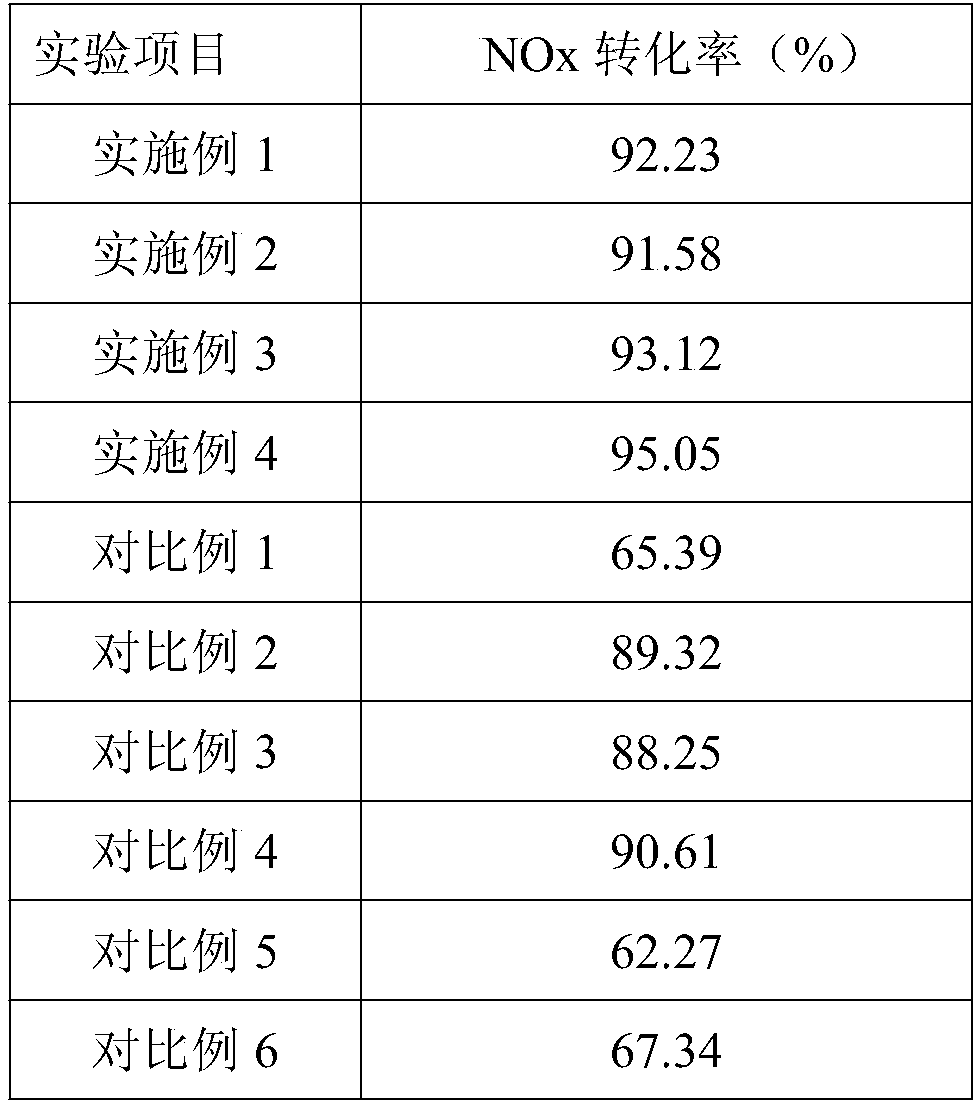

Catalyst-containing urea for automobiles and preparation method of urea

InactiveCN108499360AHigh NOx conversion ratePlay a synergistic roleGas treatmentHeterogenous catalyst chemical elementsAlcoholAmmonium metavanadate

The invention discloses catalyst-containing urea for automobiles and a preparation method of the urea and belongs to the technical field of automobile exhaust treatment. The catalyst-containing urea for automobiles is prepared from raw materials as follows: urea, high-purity water, ethanolamine, ethanol, ethylene glycol, ammonium bicarbonate, secondary alcohol ethoxylate, ammonium metavanadate, nano WO3 / MoO3-TiO2 through preparation of a catalyst, preparation of a urea solution, mixing, stirring and other steps. A reinforcing system formed by secondary alcohol ethoxylate, ammonium metavanadateand nano WO3 / MoO3-TiO2 is applied to the urea for the automobiles, and the NOx conversion rate is increased.

Owner:长沙小新新能源科技有限公司

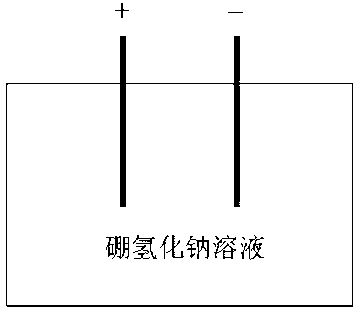

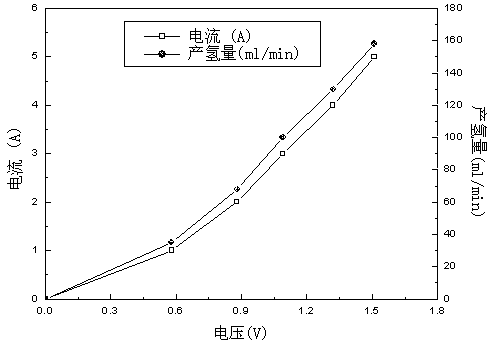

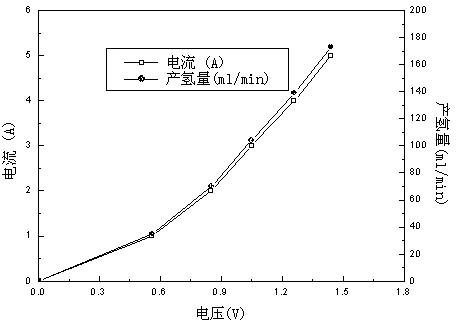

Method for preparing hydrogen by electrocatalysis of sodium borohydride solution

InactiveCN103172023ASave electricityStrong process controllabilityHydrogen productionPtru catalystDC - Direct current

The invention relates to a method for preparing hydrogen, and in particular relates to a method for preparing hydrogen by the electrocatalysis of a sodium borohydride solution. The method comprises the following steps: leading the sodium borohydride solution with the mass concentration of 0.1% to 35% into an electrolytic tank with a cathode electrode and an anode electrode; performing the electrocatalysis by applying a direct current voltage; and then performing a catalytic decomposition on the sodium borohydride solution on the surfaces of the electrodes, thereby generating the hydrogen. By utilizing the sodium borohydride solution and the direct current voltage, the transferring of electric charges on the interfaces of the electrodes and electrolytes is accelerated, so that the catalytic activity of electrode materials is improved; and by utilizing the electrocatalysis of the electrodes, the decomposition reaction of the sodium borohydride solution is promoted, so that the hydrogen is prepared in the electrocatalysis manner. The electric energy required by the electrocatalysis is far less than that required by the water decomposition, so that the electric energy is saved. Compared with the method for preparing the hydrogen by the catalytic decomposition of the sodium borohydride by directly utilizing commonly-used catalysts such as acid materials or metal catalysts, in the method provided by the invention, the starting and the ending of hydrogen generation as well as the hydrogen generation yield can be regulated through the current and the voltage between the electrodes, so that the controllability is improved greatly. In addition, the method provided by the invention is safe, environment-friendly and free of oxygen generation.

Owner:浙江高成绿能科技有限公司

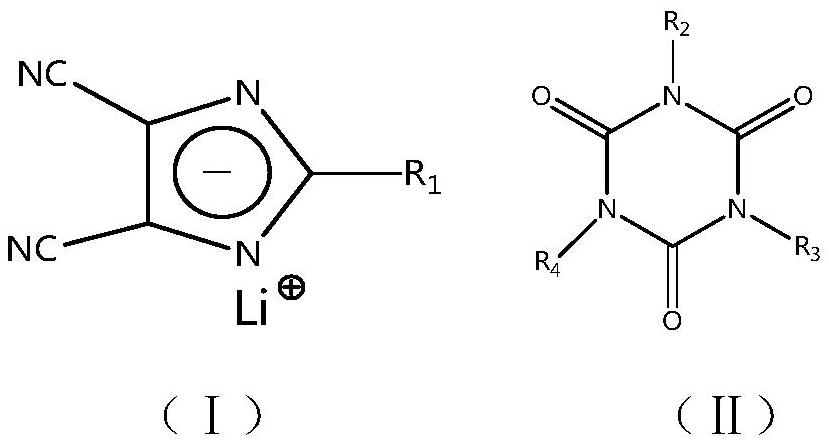

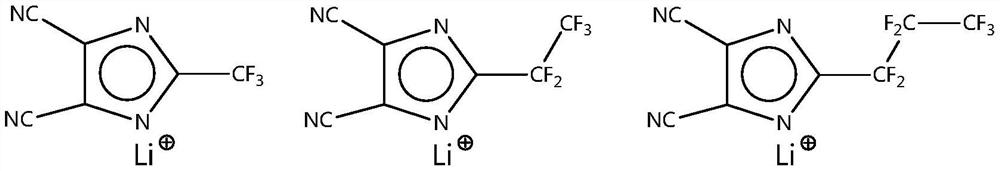

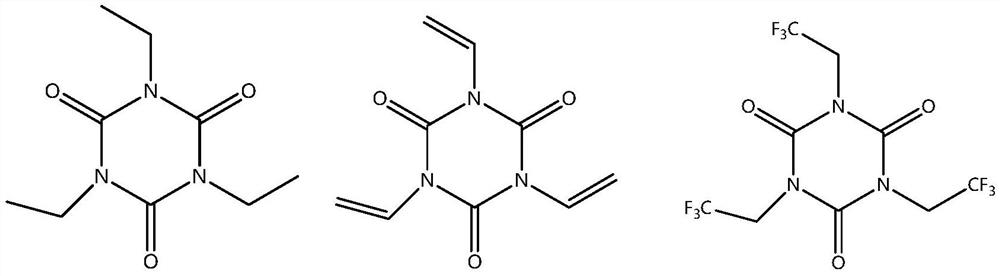

High-voltage lithium cobalt oxide lithium ion battery non-aqueous electrolyte and lithium ion battery

ActiveCN113078356AWide electrochemical windowLower impedanceSecondary cells servicing/maintenanceElectrolytic agentOrganic solvent

The invention discloses a high-voltage lithium cobalt oxide lithium ion battery non-aqueous electrolyte, which comprises a non-aqueous organic solvent, an electrolyte lithium salt and an additive, and the additive comprises at least one imidazole salt compound with a specific structure or an isocyanurate compound with a specific structure. The invention also discloses a lithium ion battery comprising a positive plate, an isolating membrane, a negative plate and the non-aqueous electrolyte of the high-voltage lithium cobalt oxide lithium ion battery. The imidazolium salt additive in the electrolyte can participate in negative electrode film forming, the dynamic performance and thermodynamic performance of a negative electrode are improved, and a formed passive film is low in impedance; the isocyanurate additive can be preferentially oxidized and decomposed on a positive electrode material interface under a high voltage condition to form a passive film, so that the oxidative decomposition of the carbonic ester solvent under the high voltage is avoided; and the fluorine cyanogen ester substance is used as the solvent, so that the electrochemical window of the electrolyte can be widened better.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

Novel textile product dyeing and finishing process

The invention relates to a novel textile product dyeing and finishing process, which comprises: preparing a boiling-bleaching liquid, and treating a cotton knitted product, wherein a low temperature scouring-bleaching aid composition, hydrogen peroxide, caustic soda, a stabilizer and an anti-wrinkle agent into water to prepare the boiling-bleaching liquid; adjusting the pH value of the boiling-bleaching liquid to 7, taking out the bamboo cotton blended fabric, placing the bamboo cotton blended fabric and a dyeing liquid into a dyeing machine, and carrying out slow color fixing; adding a cleaning liquid into the dyeing machine, and washing for 25-30 min at a temperature of 55-70 DEG C, wherein the cleaning liquid contains 5-7 g / L of sodium dithionite and 1.5-3 g / L of caustic soda; and placing the cleaned and reduced bamboo cotton blended fabric into a glacial acetic acid bath, heating to a temperature of 60-65 DEG C, carrying out thermal insulation for 10-15 min, completely neutralizing the residual alkali on the cloth surface, discharging the water, adjusting the PH value to 7-8, adding water, adding soaping enzyme at a room temperature, heating to a temperature of 85-90 DEG C, carrying out thermal insulation for 10-15 min, discharging the liquid, adding water, and carrying out water washing at a room temperature. According to the present invention, with the process, the produced fabric has characteristics of flat surface, uniform color, and high color fastness.

Owner:RUGAO XIAYUAN SCI & TECH ESTABLISH A BUSINESS SERVICES CO LTD

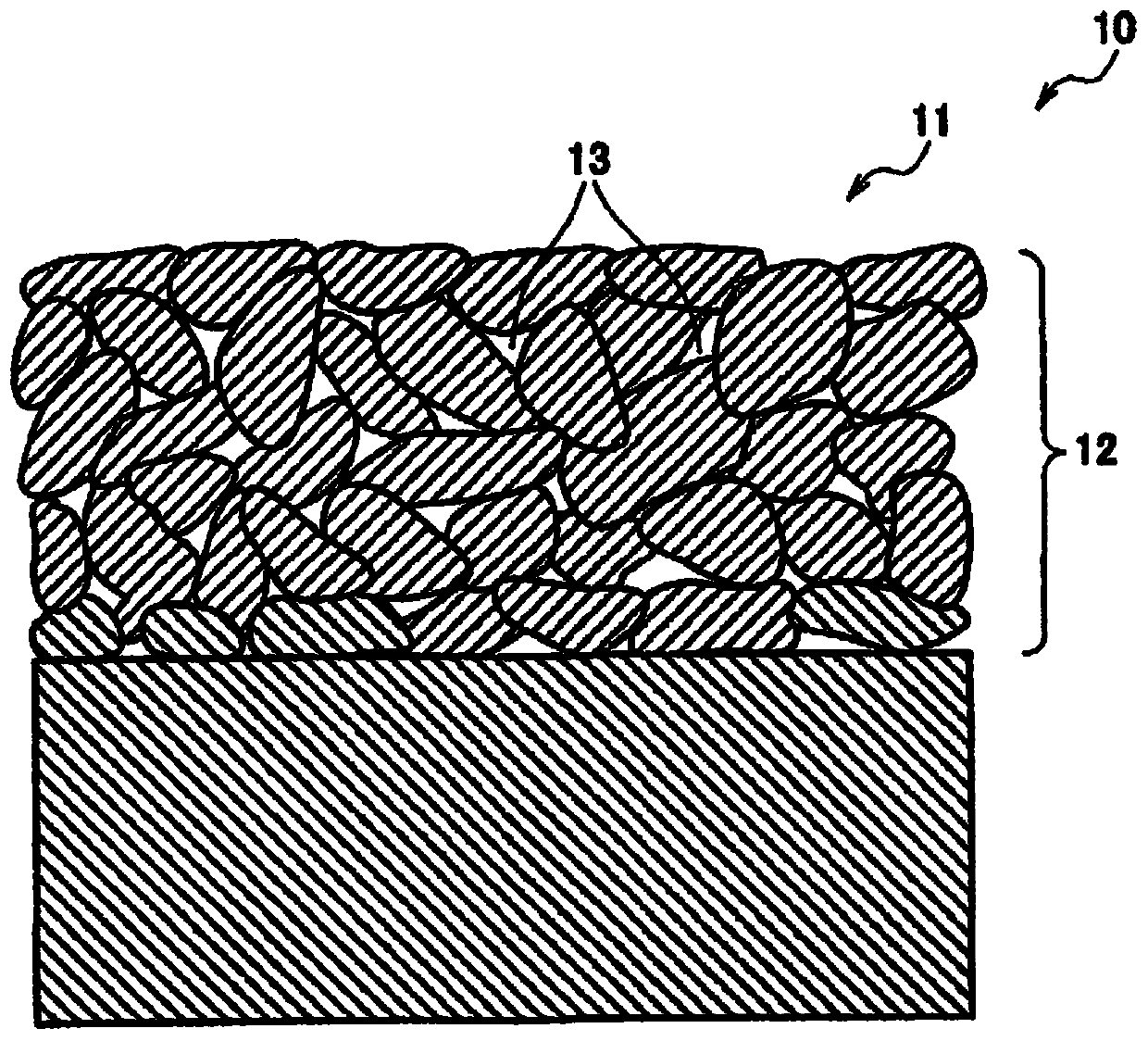

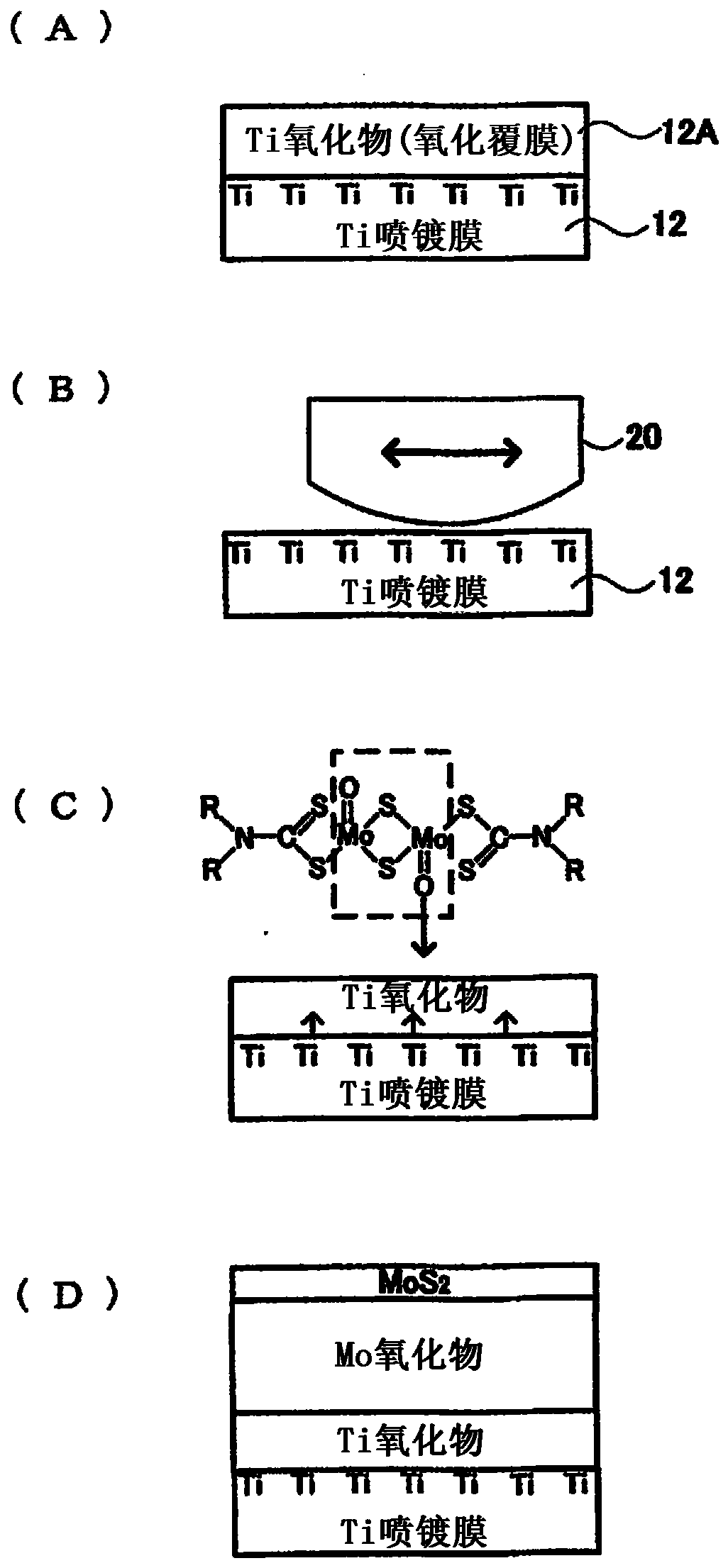

Sliding member and production method therefor

ActiveCN110857460AImprove economyReduce frictionPiston ringsMolten spray coatingThermal sprayingMetallic materials

A sliding member capable of improving friction characteristics under an environment of a lubricant containing Mo, and a production method therefor are provided. In a sliding member (10), a sliding portion (11) is formed of a metallic material, and the surface layer part of the sliding portion (11) has a Ti-containing thermally sprayed coating (12) formed by thermally spraying, as a thermal spraying material, a metallic material containing Ti as a composition. The sliding member (10) slides under the environment of the lubricant containing Mo as an additive, in which active Ti exposed on a surface by sliding accelerates decomposition reaction of the additive contained in the lubricant to form a molybdenum disulfide-containing low-friction coating having low friction on the surface of the sliding portion (11).

Owner:TOYOTA MOTOR EAST JAPAN +2

Preparation method of modified anti-felting wool fiber

InactiveCN109137513AImprove enzymatic hydrolysis efficiencyUniform passivationBiochemical treatment with enzymes/microorganismsGrip property fibresIonProtease

The invention discloses a preparation method of modified anti-felting wool fiber. The method particularly comprises the following steps that 1, an oxidative antibacterial solution is prepared; 2, theoxidative antibacterial solution is added into a stirring tank, water bath heating is conducted to reach 40-45 DEG C, and the wool fiber is poured into the stirring tank; 3, compound enzymatic hydrolysate is prepared; 4, the wool fiber processed in step 2 is soaked in the compound enzymatic hydrolysate, and a normal temperature enzymatic hydrolysis reaction is conducted; 5, a chitosan solution isprepared and added into the stirring tank, the wool fiber prepared in step 4 is added, stirring is conducted for 5 h and then fished out, and then air-drying is conducted at normal temperature. Accordingly, the wool fiber is oxidized, protein of the wool fiber is exposed, the exposed protein is subjected to enzymolysis through protease, by means of enzymolysis, negative ions on the surface of thewool fiber are increased, chitosan is adsorbed to the surface of the wool fiber conveniently, and the texture is soft while the wool fiber anti-felting property is improved.

Owner:合肥五凡工程设计有限公司

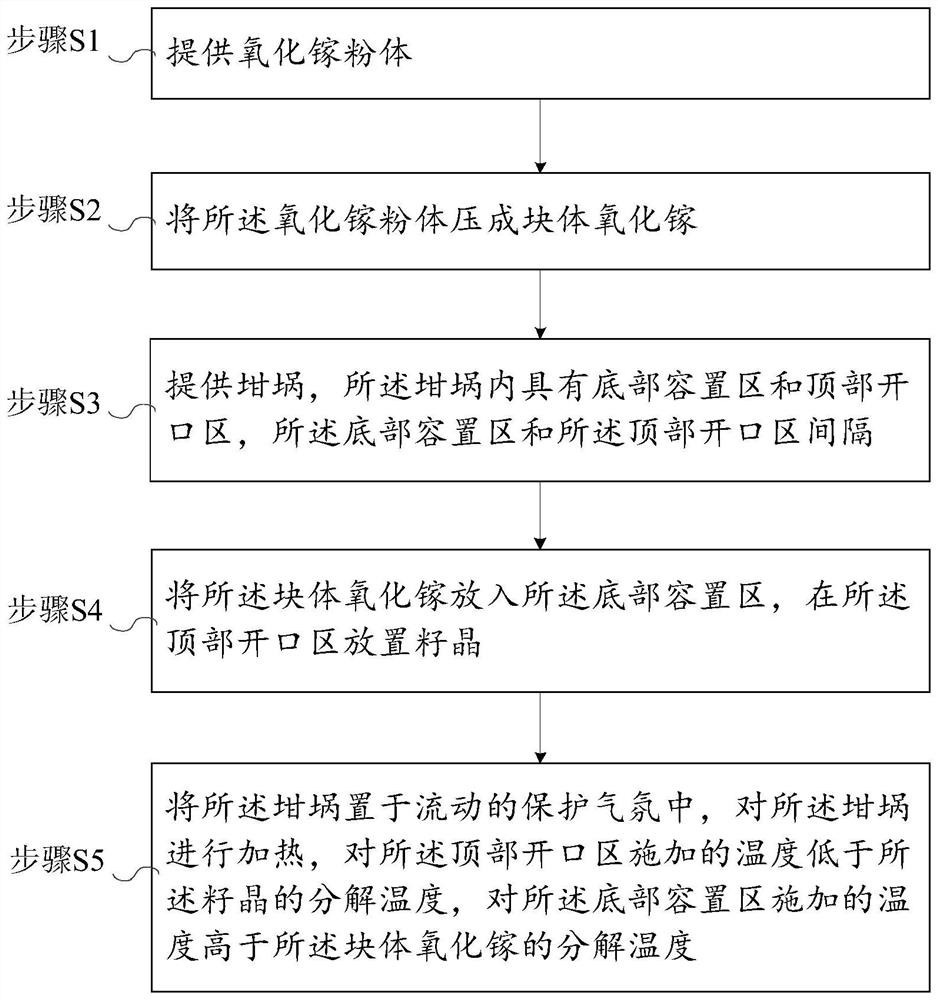

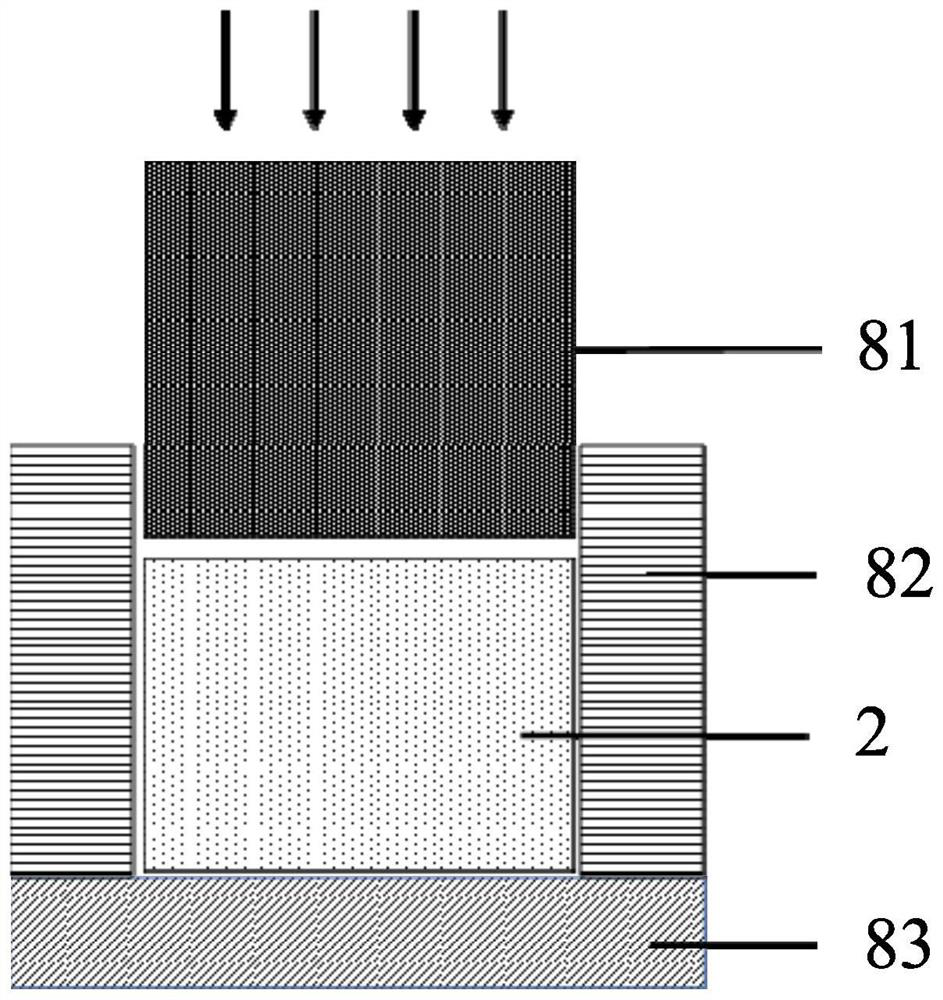

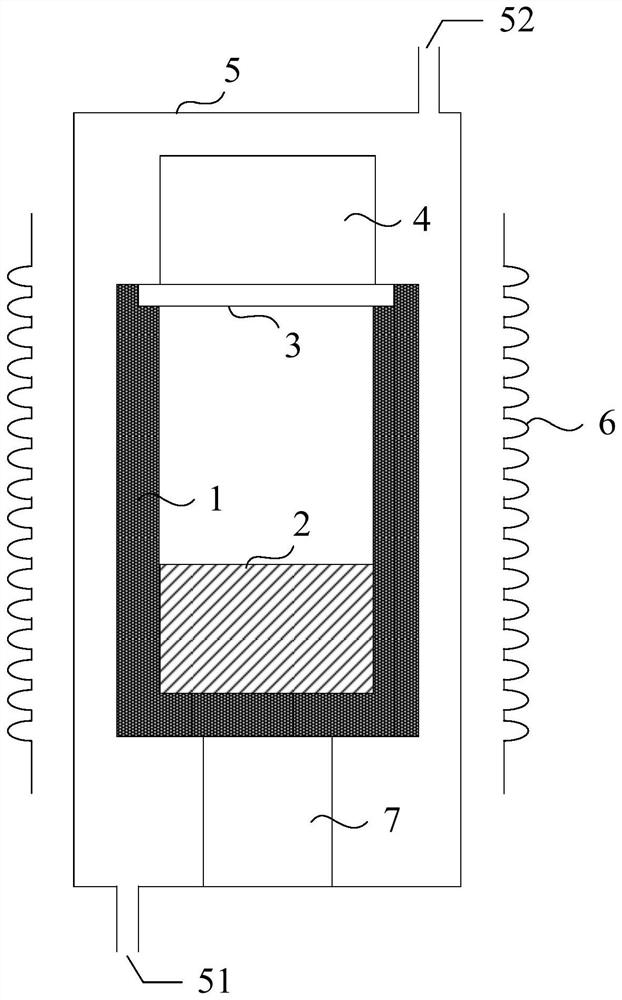

Preparation method of single crystal gallium oxide and process equipment for preparing single crystal gallium oxide

PendingCN114381800APromote decomposition reactionHigh speedPolycrystalline material growthFrom condensed vaporsProcess equipmentCrucible

The invention provides a preparation method of single crystal gallium oxide and process equipment for preparing the single crystal gallium oxide. The preparation method of the single crystal gallium oxide comprises the following steps: providing gallium oxide powder; pressing the gallium oxide powder into blocky gallium oxide; a crucible is provided, a bottom containing area and a top opening area are arranged in the crucible, and the bottom containing area and the top opening area are spaced; placing the block gallium oxide into the bottom accommodating area, and placing a seed crystal in the top opening area; the crucible is placed in a flowing protective atmosphere, the crucible is heated, the temperature applied to the top opening area is lower than the decomposition temperature of the seed crystal, and the temperature applied to the bottom containing area is higher than the decomposition temperature of the block gallium oxide. According to the method, the speed of decomposing the gallium oxide into the gas source is increased, so that the continuous growth speed of the single crystal gallium oxide is increased, the energy is saved, and the production cost is reduced.

Owner:苏州燎塬半导体有限公司

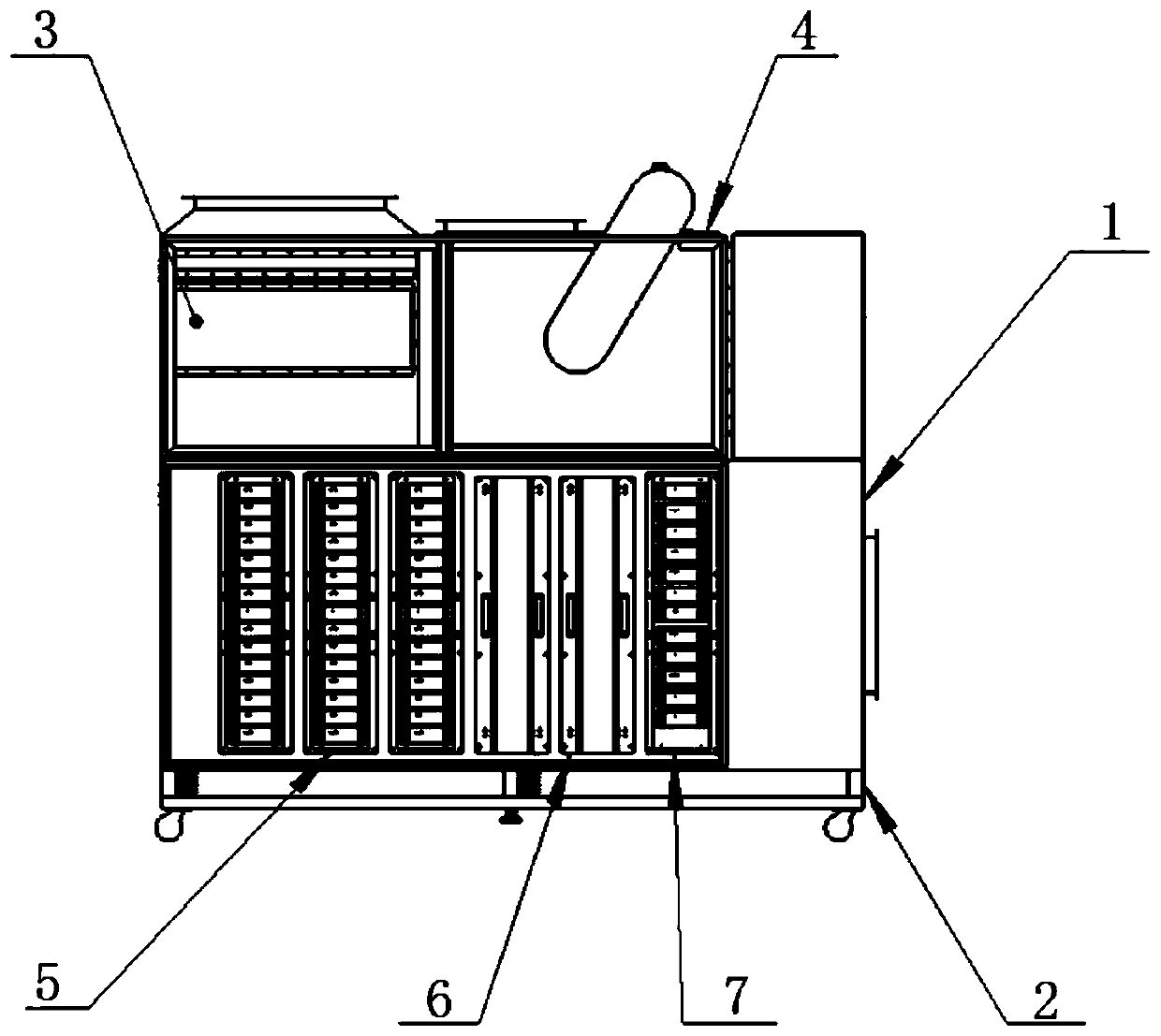

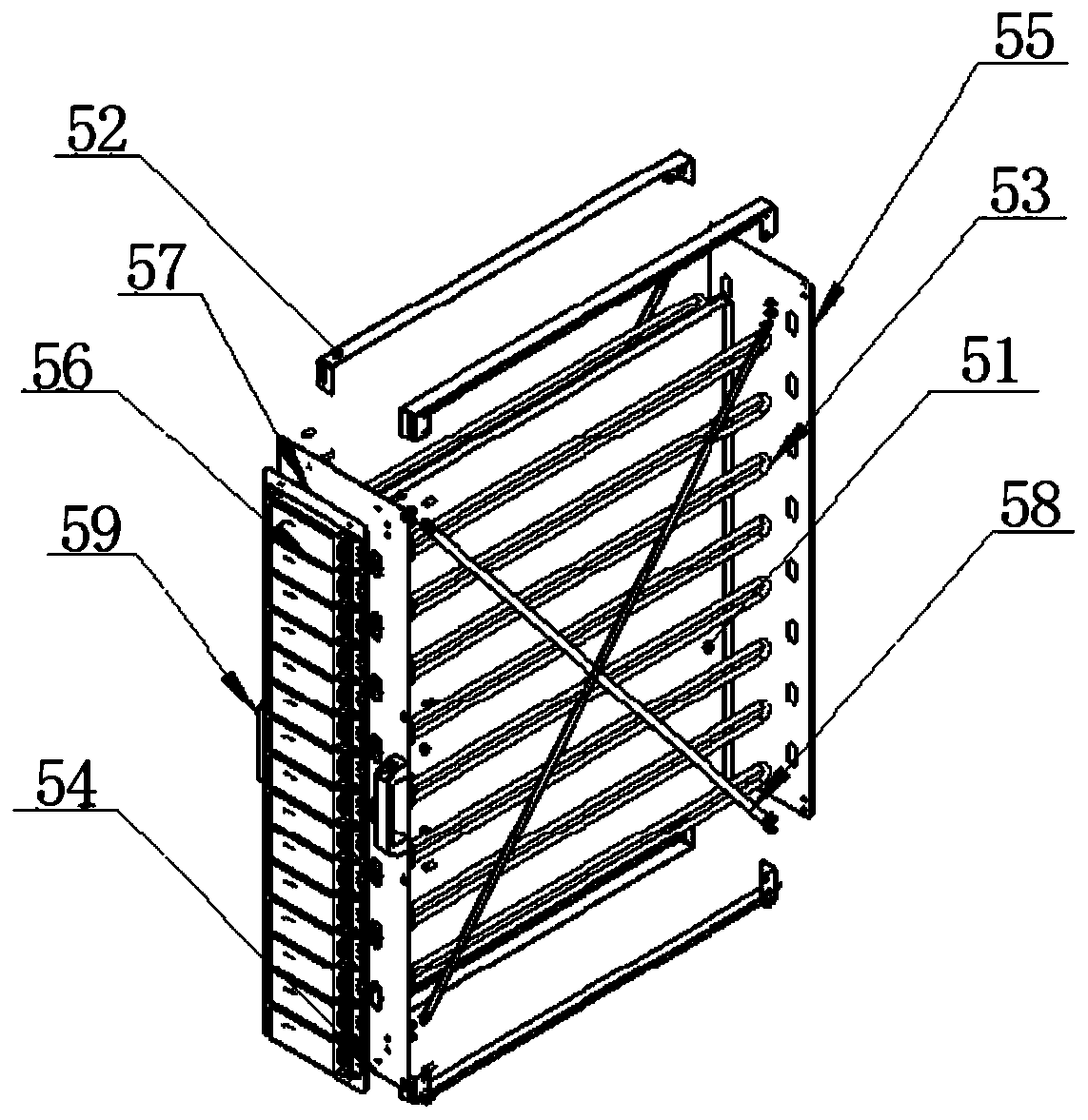

Integrated equipment for efficient treatment of volatile organic waste gas

PendingCN109847576AReliable performancePromote decompositionDispersed particle filtrationAir quality improvementDecompositionActivated carbon

The invention relates to the technical field of environmental protection, in particular to integrated equipment for the efficient treatment of the volatile organic waste gas. The equipment comprises ashell arranged on a base, wherein an electronic control cabinet is arranged in the shell, the interior of the shell is successively provided with a filtering module, a UV lamp module, an activated carbon module, an ozone removal module and an air-pumping module which are connected in a closed manner, the filtering module and the air-pumping module are arranged at the upper part of the interior ofthe shell, the UV lamp module, the activated carbon module and the ozone removal module, which can be disassembled, are arranged at the lower part of the interior of the shell, the upper part of thefiltering module is provided with a waste gas inlet, and the upper part of the air-pumping module is provided with a gas discharge outlet. The external waste gas is subjected to the dust removal by the filtering module, the waste gas decomposition and deodorization by the UV lamp module, the adsorption of the incompletely oxidized organic waste gas by the activated carbon module, the decompositionof the excess ozone by the ozone removal module, and discharge up to standard by the air-pumping module. The equipment integrates dust removal, VOCs waste gas treatment and ozone removal together, and has no secondary pollution and high purification efficiency.

Owner:富滇环保科技股份有限公司

Method for preparing sulphate aluminium cement through phosphogypsum

ActiveCN106431030ASimple process routeReduce manufacturing costSulfur compoundsHigh concentrationPhosphogypsum

The invention relates to a method for preparing sulphate aluminium cement through phosphogypsum. The method includes the steps that limestone and natural gypsum are completely replaced with the phosphogypsum, the phosphogypsum is subjected to powder grinding and homogenized through bauxite, solid waste steel residues and anthracite and calcined at the temperature of 1,250 DEG C to 1,300 DEG C to prepare the sulphate aluminium cement. By means of the method, the using rate of the phosphogypsum can be greatly increased, and high-concentration sulfur-dioxide tail gas can be prepared into sulfuric acid through absorption. The hardening speed of sulphate aluminium cement clinker prepared with the method is high, the earlier-stage strength is high, the later strength is also enhanced to be stable, and performance testing indicates that the mechanical strength of the sulphate aluminium cement prepared with the method meets the standard of the sulphate aluminium cement.

Owner:KINGENTA NORSTERRA CHEM CO LTD +1

Resin bendable grinding wheel, preparation method and equipment

InactiveCN101804602BAvoid carbonizationIncrease contentFlexible-parts wheelsGrinding devicesFiberglass meshCarbide silicon

The invention discloses a resin bendable grinding wheel, a preparation method and equipment, which are composed of brown corundum, calcined corundum, white corundum, black silicon carbide, phenolic resin powder, phenolic resin liquid, cryolite, barium sulfate, pyrite, oxidized Iron red, sea glue, non-alkali high tensile glass fiber mesh, non-woven black cloth. Compared with the prior art, the present invention greatly improves the strength, toughness and aging resistance of the grinding wheel through material selection and optimized configuration of the process, and also saves resources and energy consumption; the strength of the grinding wheel is greater than 80m / s , Grinding ratio ≥ 1:15, maximum bending angle of 40°, greatly improved tensile strength, extended damage life by about two times, reduced energy consumption by 5%-10%, and finished product yield of more than 99%.

Owner:GUIZHOU FUSUN INDAL

Desulfurization process for burning of mixing coal slime mixed with dolomite

ActiveCN101664632BHigh thermal efficiencyReduce heat lossDispersed particle separationComing outFlue gas

The invention discloses a desulfurization process for burning of coal slime mixed with dolomite. The process solves the problems that a present circulating fluidize beds has high desulfurization cost, unstable desulfurization index, influencing the load capacity of boilers, and the like, and has the advantages of low cost, convenient use, effective improvement of desulfurization efficiency, guarantee of boiler stability, and the like. The process comprises the following steps: (1) mixing coal slime and dolomite into mixed coal slime according to the weight part proportion of 100:(8-12) parts;(2) then uniformly mixing the coal slime and the mixed coal slime in a coal cabin in a mode that the mass percent of the coal slime is larger than 60 percent and then sending an obtained mixture intoa coal feeder; (3) sending the mixture of the coal slime and the mixed coal slime into a hearth by the coal feeder for burning; and (4) recovering burnt coal slag. Flue gas after burning is treated by electric precipitation, then stove ashes are recovered, and the flue gas treated by the electric precipitation is desulfurized after coming out of the hearth and exhausted.

Owner:JINAN QIQUAN THERMOELECTRICITY

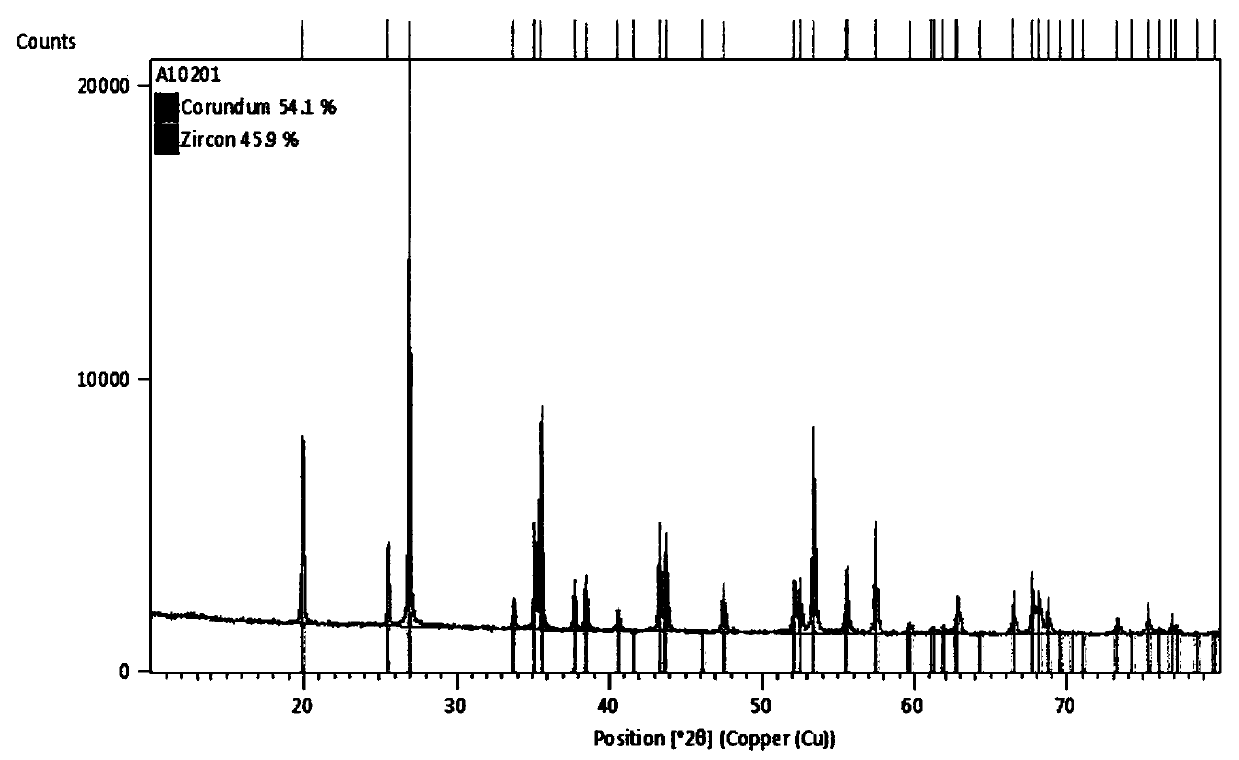

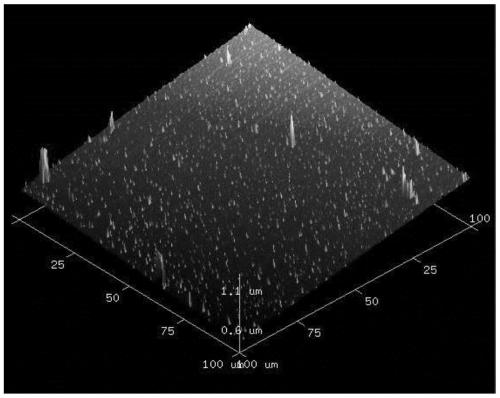

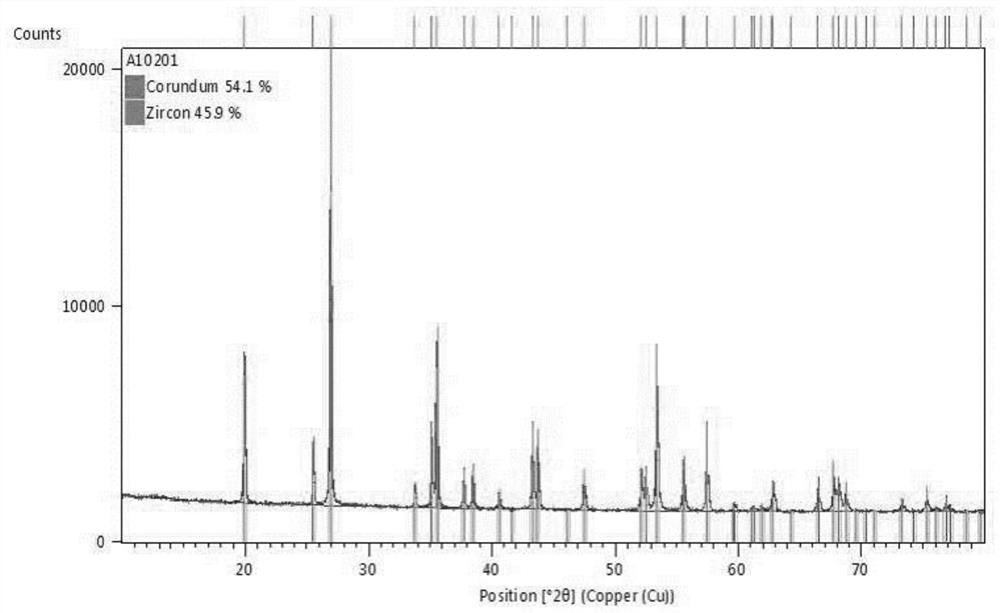

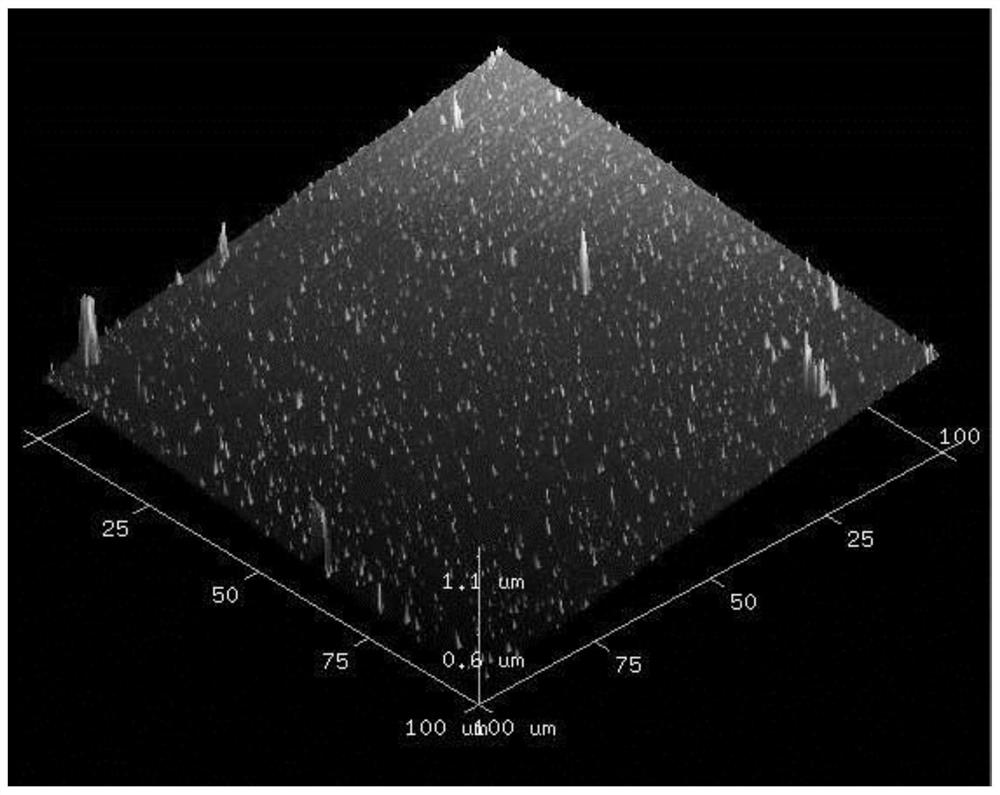

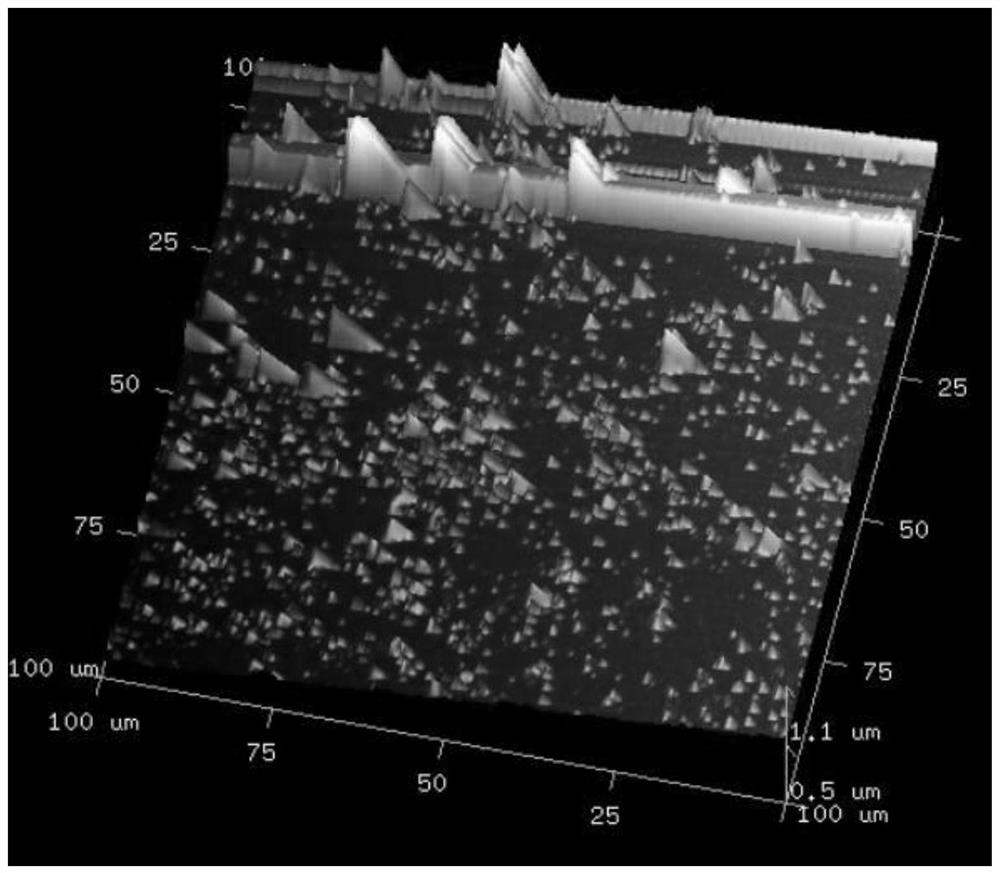

Composite polishing solution for blue glass optical filter, and preparation method thereof

ActiveCN111500198AImprove surface qualityImprove polishing efficiencyPolishing compositions with abrasivesAluminium hydroxideActive agent

The invention discloses a composite polishing solution for a blue glass optical filter, and a preparation method thereof. The composite polishing solution comprises aluminum hydroxide, zirconium hydroxide, silica sol, caustic soda liquid, a surfactant, a defoaming agent and water. The preparation method comprises the following steps: carrying out high-energy ball milling, drying granulation, calcination, high-energy ball milling and high-energy dispersion on aluminum hydroxide, zirconium hydroxide and silica sol to form a well dispersed material, and adding the caustic soda liquid, the surfactant, the antifoaming agent and water to prepare the stable composite polishing solution system. According to the composite polishing solution disclosed by the invention, the cutting rate of rough polishing and the surface quality of fine polishing are realized while one-step polishing is carried out, the process is simple, the cost is saved, the sewage discharge of a cleaning agent can be reduced,and the composite polishing solution has very good environmental benefits.

Owner:青岛福禄泰科表面材料科技有限公司

Septic tank waste treatment apparatus

ActiveCN106995264AEvenly mixedStir wellBiological treatment apparatusBiological sludge treatmentDecompositionSewage

The invention discloses a septic tank waste treatment apparatus. The septic tank waste treatment apparatus comprises a charging apparatus and a stirring apparatus; the stirring apparatus comprises a driving disc and a stirring paddle, and the stirring paddle is fixed at the outer wall of a piston barrel; the charging apparatus comprises the piston barrel, a hinge sheet, a piston and a resilient piece; the piston comprises a piston handle, a piston rod and a piston head; the piston rod is provided with a charging opening, a flow passage and a check valve; the hinge sheet is fixed at the outer wall of the piston barrel by virtue of a spring hinge, and a liquid outlet hole is formed in the lower portion of the piston barrel; a through hole is formed in the top center of the piston barrel, and the piston handle is fixed at the top of the piston rod; the piston head is fixed at the lower portion of the piston rod by virtue of threads; the upper end of the resilient piece is fixed at the top of the piston barrel, and the lower end of the resilient piece is fixed at the upper portion of a base; and the base and a rubber head are provided with a slide groove, and the inner wall of the piston barrel is provided with a slide bar. By adopting the septic tank waste treatment apparatus, the biological decomposition agent can be uniformly added, the decomposition of sewage and sediments in a septic tank can be rapidly realized, the clearing can be reduced and avoided, the pollution is reduced, and the accident of dangerous gas is avoided.

Owner:颍上县祥盛建设管理有限公司

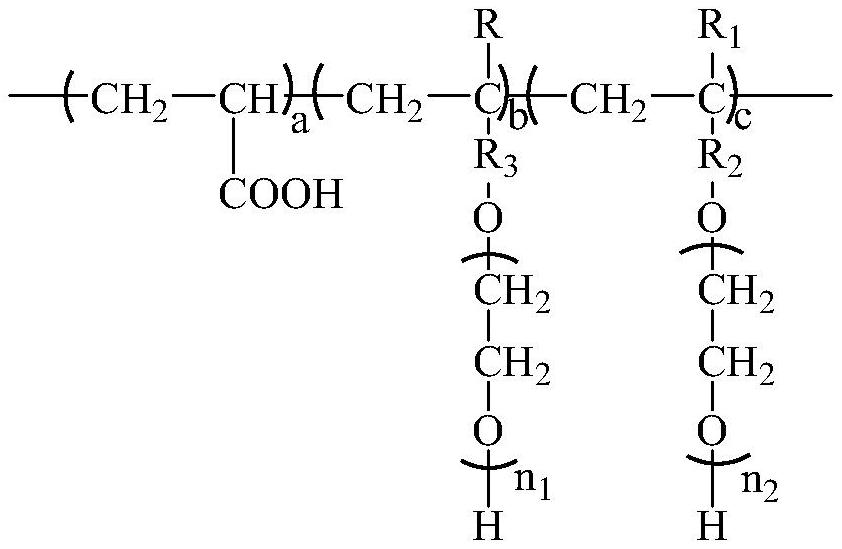

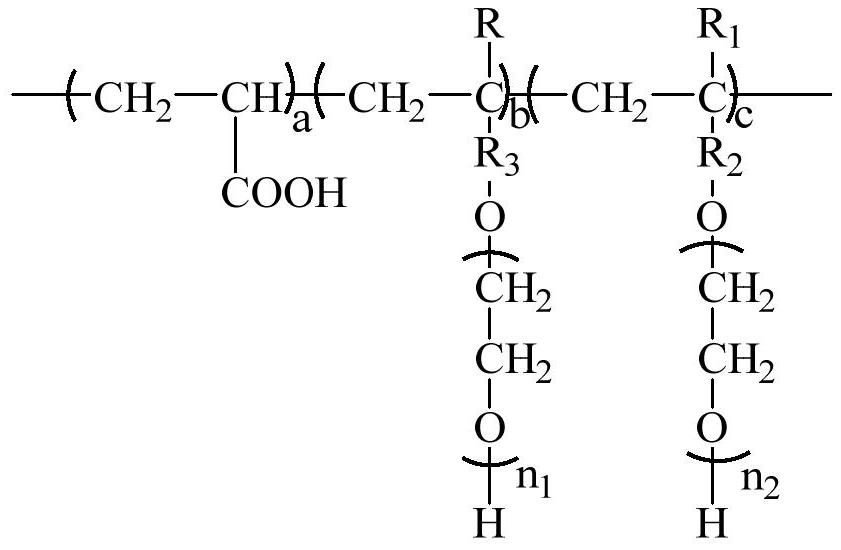

Super-long slump-retaining polycarboxylic acid pumping agent and preparation method thereof

The invention discloses a super-long slump-retaining polycarboxylic acid pumping agent, which is prepared from the following components in parts by weight: 15 to 20 parts of water-reducing polycarboxylic acid superplasticizer, 10 to 15 parts of slump-retaining polycarboxylic acid superplasticizer, 1 to 3 parts of reaction type hydration regulator, 0.01 to 0.2 part of air entraining agent, 0 to 2 parts of retarder, 0.5 to 2.5 parts of auxiliary retention agent, 0.3 to 0.8 part of water-retaining agent and the balance of water. Compared with the prior art, a water-reducing polycarboxylic acid superplasticizer and a gradient slow-release slump-retaining polycarboxylic acid superplasticizer which have water-reducing and retaining properties are adopted as mother liquor, so that gradient slow release in a cement system is possible, super-long slump retaining of concrete can be realized, and possibility is provided for long pumping in a relatively far construction site or a relatively long pumping pipeline.

Owner:重庆富普新材料有限公司

A method for preparing high-strength sulphoaluminate cement for co-production of sulfuric acid

ActiveCN106365477BIncrease profitRealize resource utilizationSulfur compoundsHigh concentrationPhosphogypsum

The invention relates to a method for preparing high-strength sulphoaluminate cement and co-producing sulfuric acid. The method comprises the following steps of adopting phosphogypsum for completely replacing limestone and natural gypsum, milling and homogenizing the phosphogypsum, bauxite, steel scoria, silica and pulverized anthracite, and then calcinating the milled and homogenized raw materials at a temperature of 1250-1300 DEG C. The method is capable of greatly improving the phosphogypsum utilization ratio, and high-concentration sulfur dioxide tail gas can be adsorbed to prepare sulfuric acid. The prepared sulphoaluminate cement clinker is high in hardening rate, high in early-stage strength, and stable in later-stage strength increase; performance tests indicate that the mechanical strength of the sulphoaluminate cement prepared by the method conforms to the rapid-hardening sulphoaluminate cement standard.

Owner:KINGENTA NORSTERRA CHEM CO LTD +1

A kind of composite polishing liquid for blue glass filter and preparation method thereof

ActiveCN111500198BImprove surface qualityImprove polishing efficiencyPolishing compositions with abrasivesAluminium hydroxideActive agent

The invention discloses a composite polishing solution for blue glass filters and a preparation method thereof. The composite polishing solution includes aluminum hydroxide, zirconium hydroxide and silica sol, liquid caustic soda, surfactant, defoaming agent and water. The preparation method adopts aluminum hydroxide, zirconium hydroxide and silica sol through high-energy ball milling, drying granulation, calcining, high-energy ball milling, and high-energy dispersion to form dispersed materials, and then adds liquid caustic soda, surfactants, defoamers and water to make a stable composite polishing liquid system, the composite polishing liquid disclosed by the invention realizes the cutting rate of rough polishing and the surface quality of fine polishing while polishing in one step, the process is simple, the cost is saved, and the discharge of cleaning agent sewage can be reduced. Has very good environmental benefits.

Owner:青岛福禄泰科表面材料科技有限公司

Treatment method of rare earth concentrate

ActiveCN109136538BPromote decomposition reactionImprove leaching rateProcess efficiency improvementMischmetalChloride

The invention discloses a treatment method for rare earth ore concentrates. The treatment method for the rare earth ore concentrates comprises the following steps: mixing chloride of magnesium with rare earth ore concentrates, and then roasting under the condition of air to form a roasted product, wherein the weight ratio of the chloride of the magnesium to the rare earth ore concentrates is 0.5-1.9-1, the weight ratio of MgCl2 in the chloride of the magnesium to the rare earth ore concentrates is 0.23-0.9: 1, the roasting temperature is 460-580 DEG C, and the roasting time is 30-200 minutes;and (2) directly leaching the cooled roasted product by using an acidic solution, wherein the leaching rate of rare earth metals is 95% or above. The high leaching rate can be realized at a low temperature, and the roasted product can be prevented from becoming a fused solution.

Owner:BAOTOU RES INST OF RARE EARTHS

Method for preparing sulfur dioxide and calcium oxide through anaerobic thermal decomposition of calcium sulfite

ActiveCN109911865ADry thoroughlyGood effectSulfur compoundsCalcium/strontium/barium oxides/hydroxidesSocial benefitsDecomposition

The invention discloses a method for preparing sulfur dioxide and calcium oxide through anaerobic thermal decomposition of calcium sulfite. High-purity calcium oxide and sulfur dioxide are obtained through indirect thermal decomposition of intermediate product calcium sulfite in wet desulfurization of flue gas under the anaerobic condition. Thermal decomposition of calcium sulfite comprises an aerobic drying preheating step, a vacuum deoxidation step and an anaerobic thermal decomposition step, wherein aerobic drying preheating can prevent calcium sulfite from being oxidized into calcium sulfate easily in the air at 450 DEG C or above, in the anaerobic thermal decomposition step, deoxidation of dried calcium sulfite in a micro negative pressure state is realized by use of an air lock valveat the lower part of a cyclone separator and a vacuum fan of a thermal-insulating flow stabilization bin. High-temperature anaerobic thermal decomposition of calcium sulfite is realized by use of a three-stage closed screw decomposition furnace, hot air obtained through anaerobic thermal decomposition performs stepped preheating on a three-stage heat preheater, and recycling of energy is realized. The method has excellent economic, environmental protection and social benefits and is suitable for promotion and application.

Owner:但建明

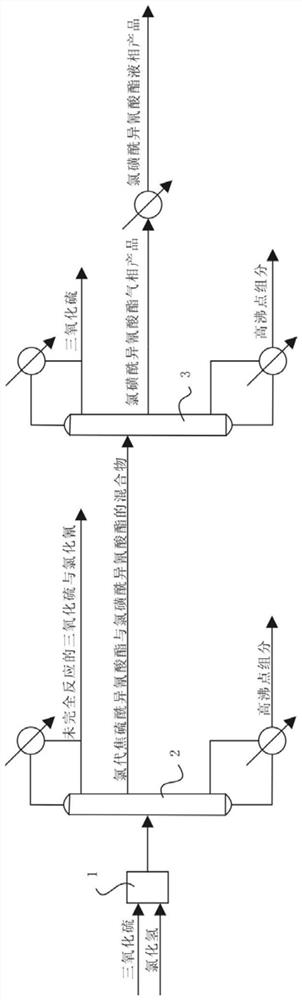

Process method for preparing chlorosulfonyl isocyanate through continuous reactive distillation

PendingCN112174860AInhibit side effectsHigh yieldOrganic compound preparationChemical industryFluid phaseReactive distillation

The invention provides a process method for preparing chlorosulfonyl isocyanate through continuous reactive distillation, and relates to the technical field of fine chemical engineering, and the process method comprises the following steps: enabling sulfur trioxide and cyanogen chloride to enter a reactor for primary reaction; continuously feeding the reaction liquid into a first reactive distillation tower, extracting heavy components from the bottom of the tower, extracting sulfur trioxide and cyanogen chloride which do not react completely from the top of the tower, and extracting a chlorosulfonyl isocyanate crude product liquid containing a small amount of chlorinated pyrosulfonyl isocyanate after preliminary concentration from a side liquid phase; continuously feeding the crude product liquid into a second reactive distillation tower, extracting a small amount of sulfur trioxide and cyanogen chloride generated by decomposing chlorinated pyrosulfonyl isocyanate from the top of thetower, extracting a small amount of heavy components from the bottom of the tower, and extracting a qualified chlorosulfonyl isocyanate product from a side gas phase. The preparation efficiency of thechlorosulfonyl isocyanate is improved.

Owner:天津昊然分离科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com