Preparation method of single crystal gallium oxide and process equipment for preparing single crystal gallium oxide

A technology of process equipment and gallium oxide, which is applied to the process equipment for preparing single crystal gallium oxide and the field of preparation of single crystal gallium oxide, which can solve the problem of high cost of single crystal gallium oxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

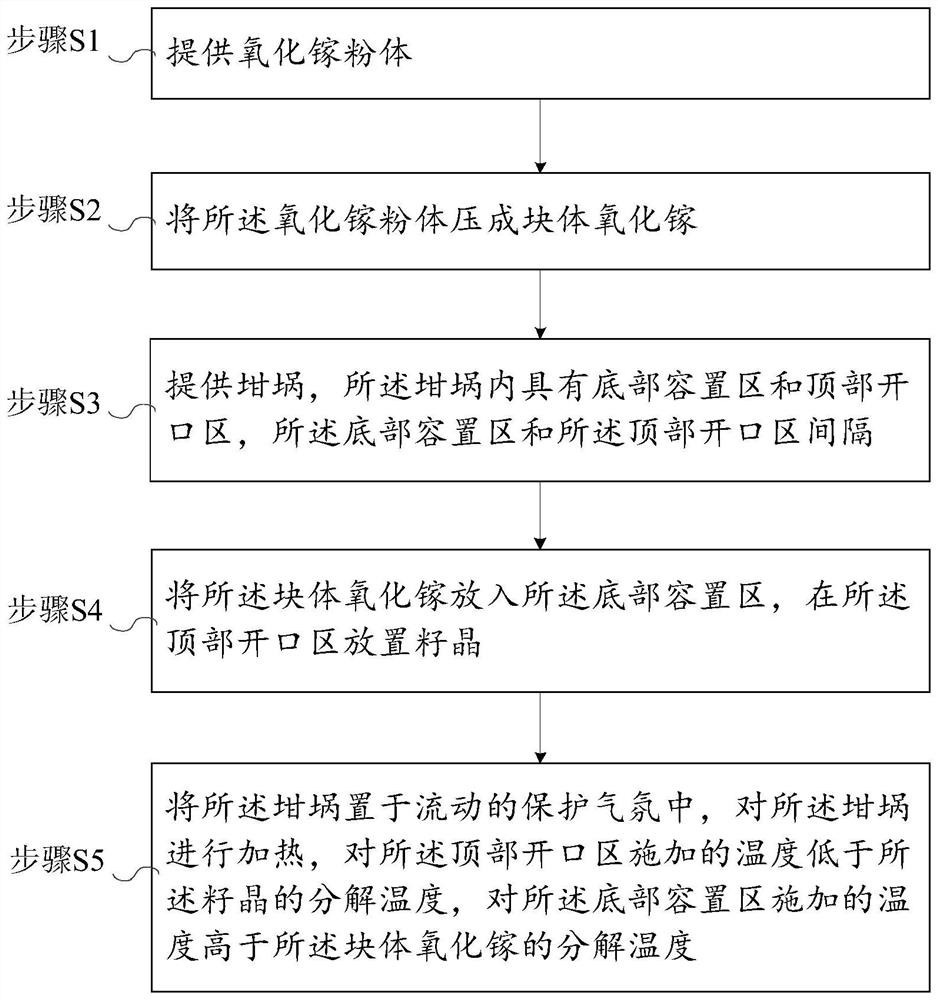

[0044] This embodiment provides a preparation method of single crystal gallium oxide, such as figure 1 shown, including the following steps:

[0045] Step S1: providing gallium oxide powder;

[0046] Step S2: pressing the gallium oxide powder into bulk gallium oxide 2;

[0047] Step S3: providing a crucible 1, the crucible 1 has a bottom accommodating area and a top opening area, and the bottom accommodating area and the top opening area are separated;

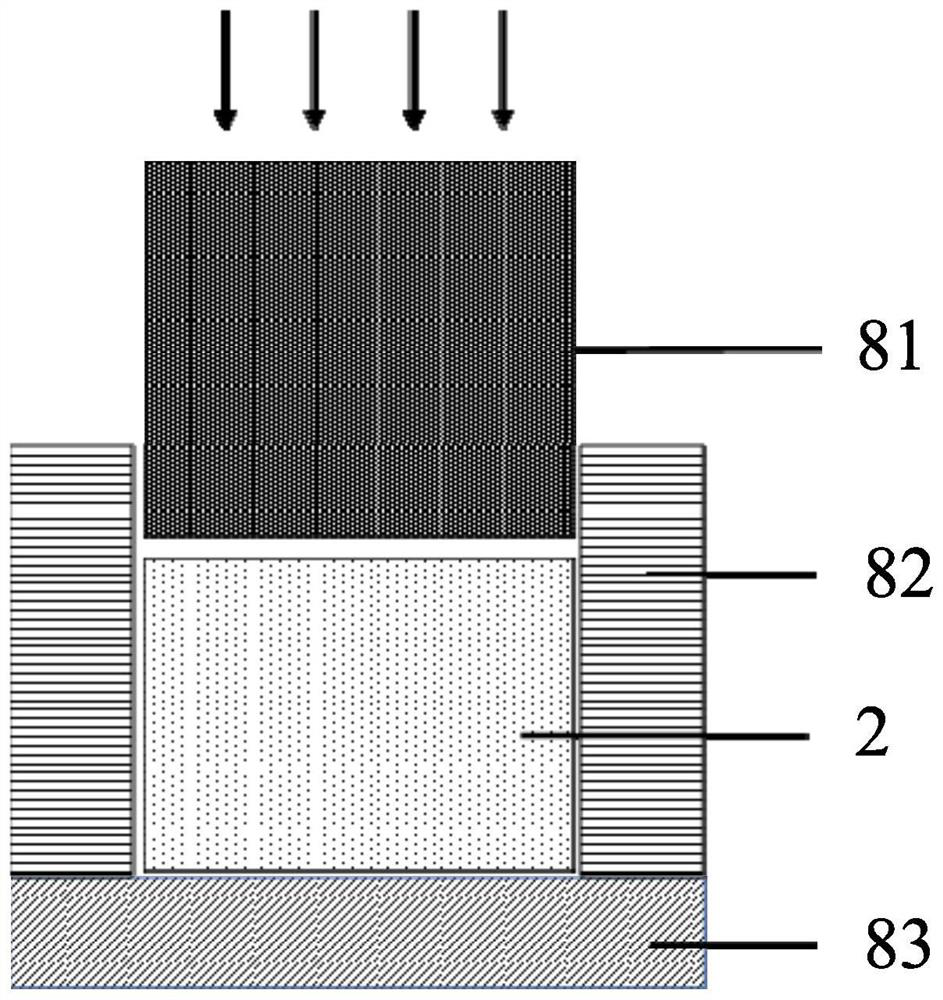

[0048] Step S4: Put the bulk gallium oxide 2 into the bottom accommodation area, and place the seed crystal 3 in the top opening area;

[0049] Step S5: placing the crucible 1 in a flowing protective atmosphere, heating the crucible 1, applying a temperature lower than the decomposition temperature of the seed crystal 3 to the top opening area, and accommodating the bottom The temperature applied in the region is higher than the decomposition temperature of the bulk gallium oxide 2 .

[0050] By placing the crucible 1 in a...

Embodiment 2

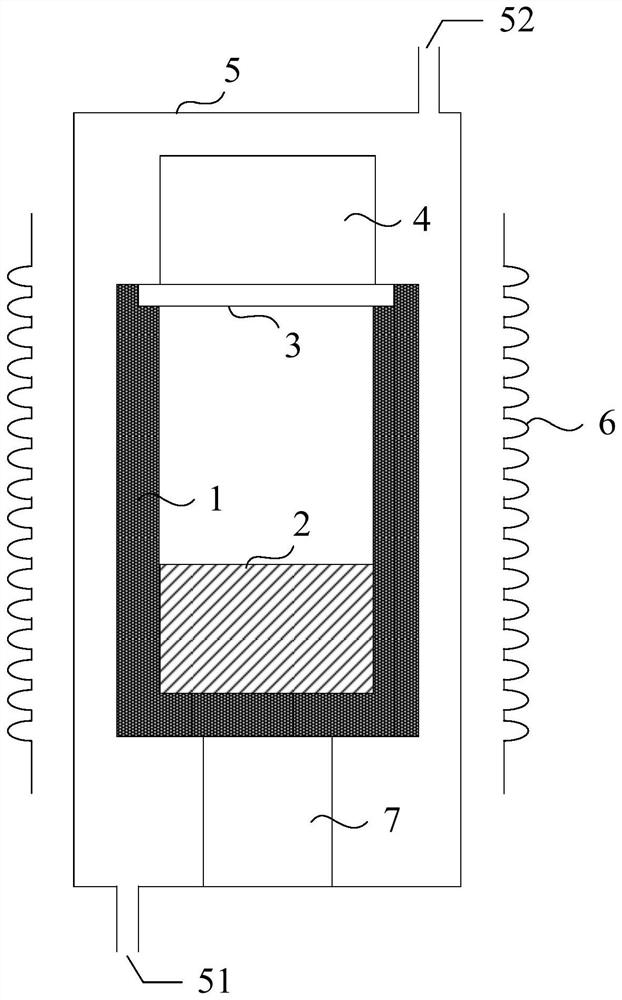

[0065] This embodiment provides a process equipment for preparing single crystal gallium oxide, such as image 3 As shown, it includes: a cavity 5; a crucible 1 located in the cavity 5, the crucible 1 has a bottom accommodating area and a top opening area, the bottom accommodating area and the top opening area are separated, the The top opening area is suitable for placing the seed crystal 3; the heating element 6, the heating element 6 is arranged around the side of the cavity tube 5, and the heating element 6 is suitable for heating the crucible 1, so that the The temperature of the top opening area is lower than the temperature of the bottom accommodating area; the air inlet pipe 51 and the air outlet pipe 52, the air inlet pipe 51 communicates with the end of the chamber pipe 5 near the bottom accommodating area, and the air outlet pipe 52 communicates with the end of the lumen 5 close to the top opening area.

[0066] By setting the inlet tube 51 and the outlet tube 52 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com