Phosphogypsum desulfurization calcining treatment system and method

A calcination treatment, phosphogypsum technology, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problems of pipeline blockage, high cost of purification and acid production, low content, etc., to speed up dehydration and desulfurization speed, speed up dehydration And calcination decomposition, improve the effect of product fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

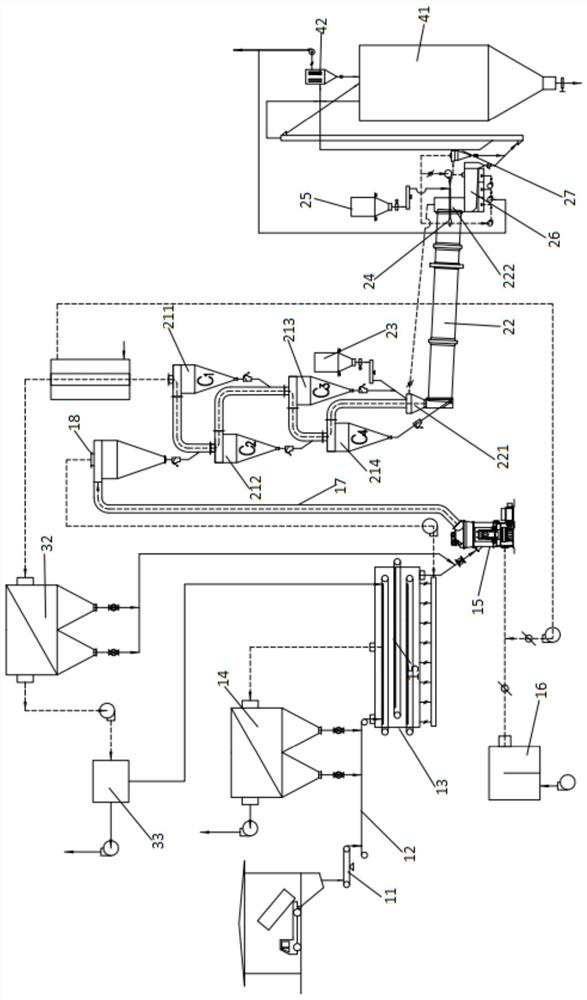

[0041] Such as figure 1 As shown, this embodiment provides a phosphogypsum desulfurization and calcination treatment system, including a low-temperature dehydration system, a high-temperature calcination system and an acid system, wherein the low-temperature dehydration system includes a dryer 13, a drying mill 15 and a tube furnace 17 in sequence, The high temperature calcination system includes a preheating device, a rotary kiln 22 and a cooling machine 26 in sequence.

[0042] The feed port of the dryer 13 is connected with the material conveying device, the discharge port of the dryer 13 is connected with the feed port of the drying mill 15, and the discharge port of the drying mill 15 is connected with the feed port of the tube furnace 17 The discharge port of the tube furnace 17 is connected with the air inlet of the preheating device, the air outlet of the preheating device is connected with the acid system 33, the discharge port of the preheating device is connected wi...

Embodiment 2

[0061] The steps of using this treatment system for domestic waste treatment are as follows;

[0062] 1. Preparation of anhydrous phosphogypsum

[0063] After the phosphogypsum enters the factory by vehicle, it is sent to the discharge pit in the discharge warehouse for discharge. After being weighed by a meter, it is sent to the mesh belt dryer by a belt conveyor for drying, at about 120-160°C The natural water is removed by low-temperature heating at a certain temperature. The heat source for drying comes from the low-temperature waste heat generated by the acid system and the hot flue gas generated after the material discharged from the pipeline furnace is separated by the cyclone separator. The flue gas generated after drying passes through the upper part of the dryer. The flue gas is sent to the bag filter, and the purified gas can be discharged without pollution.

[0064] The phosphogypsum from the mesh belt dryer enters the drying mill for powder and drying, and the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com