Electrolyte solution and battery

An electrolyte and battery technology, applied in the field of electrolyte, can solve the problems of battery characteristics such as the reduction of charging and discharging efficiency, and achieve the effects of improving battery characteristics, reducing reactivity, and preventing decomposition reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

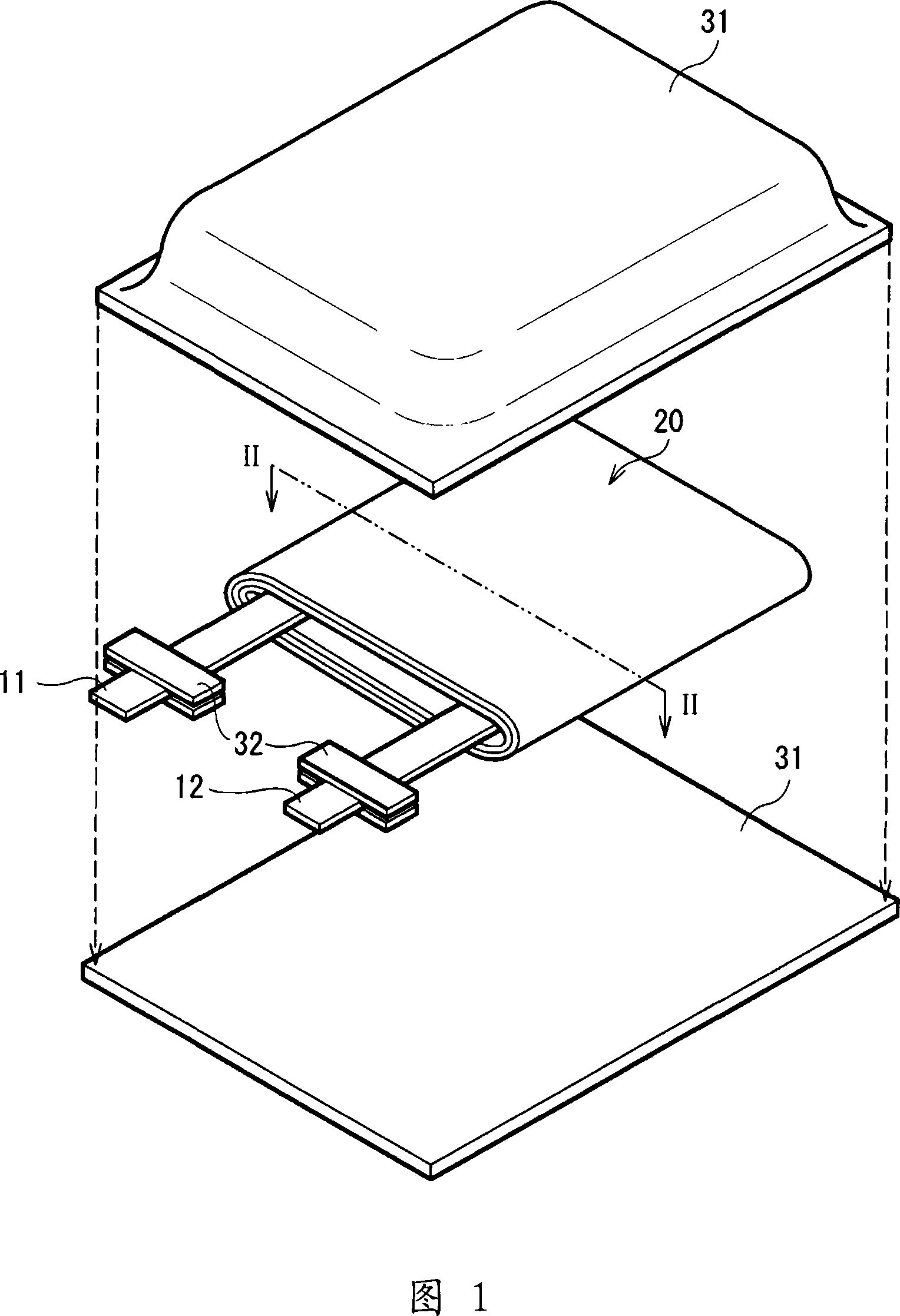

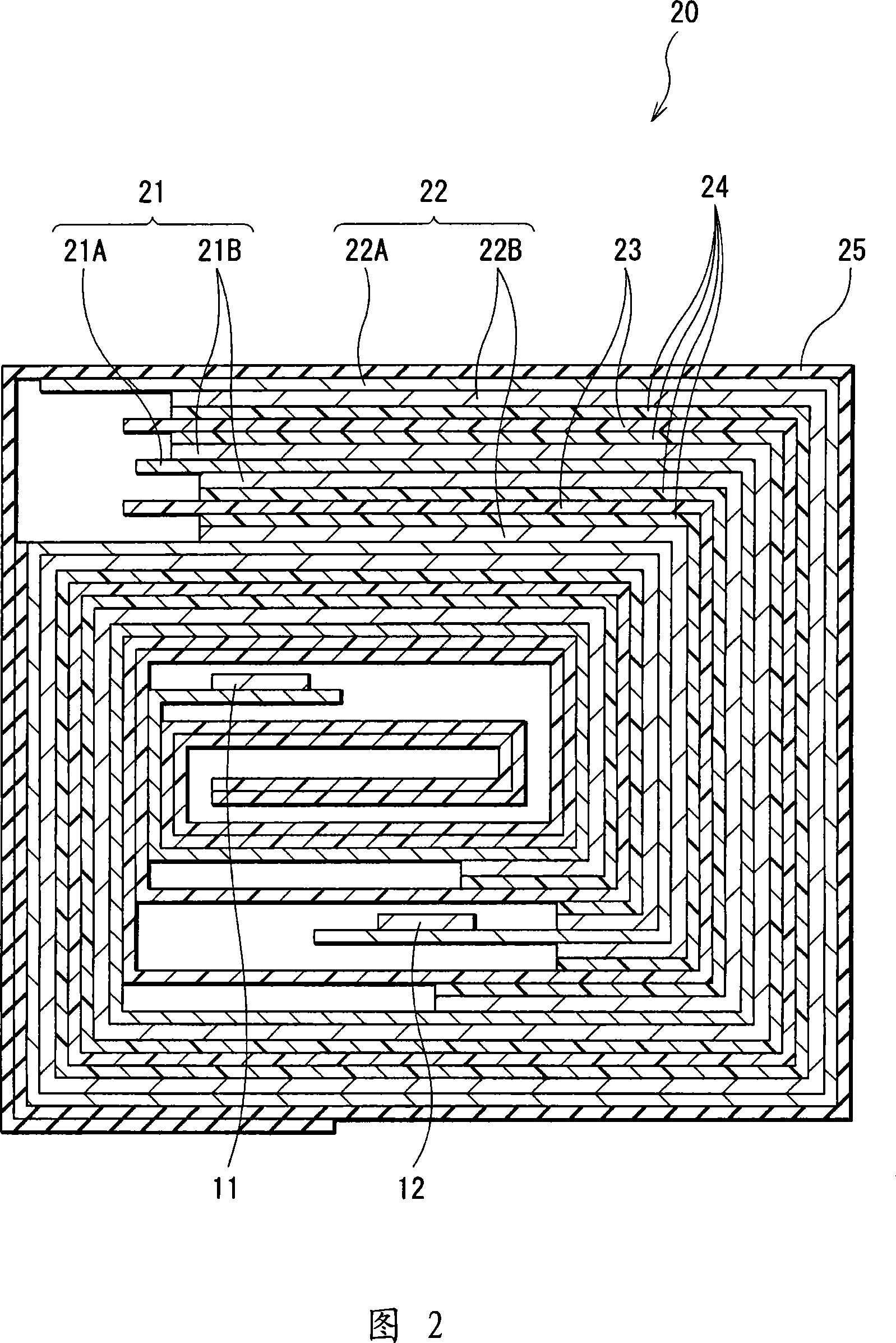

[0029] FIG. 1 shows an example of an exploded structure of a secondary battery according to a first embodiment of the present invention. The secondary battery is a so-called lithium ion secondary battery in which the capacity of the negative electrode is expressed by a capacity component due to intercalation and deintercalation of lithium as an electrode reactant. This secondary battery has a structure in which a spirally wound electrode body 20 to which a positive electrode lead 11 and a negative electrode lead 12 are connected is contained inside a film-like packaging member 31 .

[0030] The positive electrode lead 11 and the negative electrode lead 12 are, for example, strip-shaped, and are respectively drawn from the inside to the outside of the packaging member 31 in the same direction, for example. The cathode lead 11 is made of, for example, a metal material such as aluminum (Al). The negative electrode lead 12 is made of a metal material such as nickel (Ni).

[0031...

no. 2 approach

[0112] The secondary battery according to the second embodiment of the present invention is a secondary battery in which the negative electrode capacity includes a capacity component due to intercalation and deintercalation of lithium as an electrode reactant and a capacity component due to deposition and dissolution of lithium, and from which and express.

[0113] The secondary battery has a structure and effect similar to that of the secondary battery according to the first embodiment except that the structure of the negative electrode active material layer is different, and can be similarly manufactured. Therefore, a description is given here with reference to FIG. 1 and FIG. 2 by using the same symbols. Detailed descriptions for the same components will be omitted.

[0114] In the negative electrode active material layer 22B, for example, by setting the charging capacity of the negative electrode material capable of intercalating and extracting lithium to a value smaller ...

Embodiment 1-1 to 1-13

[0123] A battery in which the negative electrode capacity is expressed by a capacity component due to intercalation and deintercalation of lithium, a so-called lithium ion secondary battery, is manufactured.

[0124] First, lithium cobaltate (LiCoO 2 ), graphite as an electrical conductor, and polyvinylidene fluoride as a binder were mixed to prepare a positive electrode mixture. Subsequently, the cathode mixture was dispersed in N-methyl-2-pyrrolidone as a solvent to obtain a cathode mixture slurry. After that, the cathode current collector 21A made of aluminum foil was uniformly coated with the cathode mixture slurry, which was dried and compression molded by a roll press to form the cathode active material layer 21B and thus the cathode 21 . After that, the positive electrode lead 11 was attached to the positive electrode current collector 21A.

[0125] In addition, artificial graphite as an anode active material and polyvinylidene fluoride as a binder were mixed to prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com