Resin bendable grinding wheel, preparation method and equipment

A grinding wheel and bending technology, which is applied in the field of resin bendable grinding wheel and preparation, can solve the problems of sacrificing anti-aging ability, carbonization, sticking to the pot, etc., and achieve the effect of accelerating resin decomposition reaction, improving the yield of finished products, and improving the bonding stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

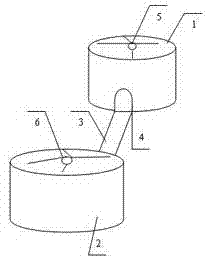

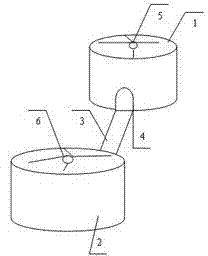

[0022] a. Mix 60 kg of brown corundum, 10 kg of calcined corundum, 20 kg of white corundum and 10 kg of black silicon carbide, put them into a small mixing pot 1, then add 6 kg of phenolic resin solution, and stir evenly with a small stirrer 5 , then add 6 kg of cryolite, 2 kg of barium sulfate, 5 kg of pyrite, and 2 kg of red iron oxide and stir evenly with a small agitator 5. After the mixed material is fully wet, open the valve 4 to mix the mixed material Put it into the large mixing pot 2 through the feeding chute 3, then add 18 kg of phenolic resin powder in the large mixing pot 2 and stir with the large agitator 6 until every grain of sand is evenly wrapped by the phenolic resin powder, and then put its into the bin;

[0023] b. Put the material box in the preheating constant temperature room for 3 hours, then take out the mixed material, beat loose, and sieve it into sand material, put the sieved sand material into the spreader, and carry out the first spread material,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com