Preparation and application of transition metal phosphide/core-shell nitrogen-doped carbon nanofiber composite material

A carbon nanofiber and nanofiber technology is applied in the field of preparation and application of transition metal phosphide/core-shell nitrogen-doped carbon nanofiber composites, which can solve the problems of poor conductivity of transition metal phosphide and affecting applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

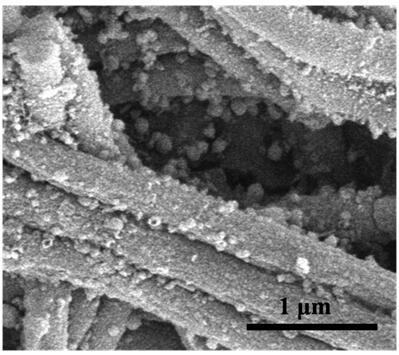

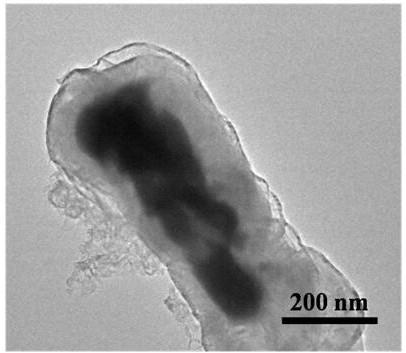

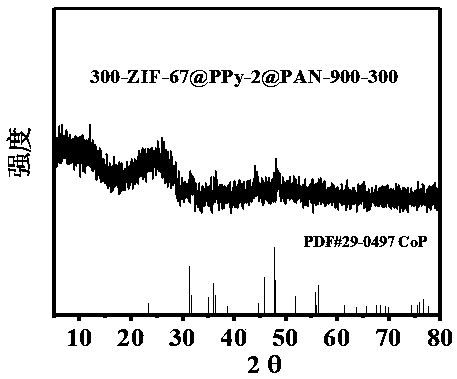

[0055] 1. Preparation of catalyst 300-ZIF-67@PPy-2@PAN-700-300

[0056] Take a certain amount of PAN (polyacrylonitrile), dissolve it in DMF, stir vigorously at room temperature to form a homogeneous solution with a mass concentration of 15 wt%, and then prepare the homogeneous solution into PAN ( Polyacrylonitrile) carbon nanofibers were vacuum-dried at 333 K to obtain PAN (polyacrylonitrile) carbon nanofibers;

[0057] Weigh 40 mg of PAN (polyacrylonitrile) carbon nanofibers, immerse in 50 mL of deionized water, and then add 0.6 g of FeCl to the solution 3 , 2 mg pyrrole (dissolved in 80 mL ethanol), stirred for 24 h, then washed with deionized water, and dried under vacuum at 333 K to obtain PPy-2@PAN;

[0058] Weigh 300 mg of PPy-2@PAN, 0.454 g Co(NO 3 ) 2 ·6H 2 O, add 20 mL of methanol and mix; stir the mixture for 1 h to form solution A; dissolve 0.513 g of 2-MIM (2-methylimidazole) in 20 mL of methanol to form solution B; add solution B to solution A Stir for 24 h....

Embodiment 2

[0070] 1. Preparation of catalyst 300-ZIF-67@PPy-2@PVP-700-300

[0071] Take a certain amount of PVP (polyvinylpyrrolidone), dissolve it in DMF, stir vigorously at room temperature to form a homogeneous solution with a mass concentration of 15 wt %; and then prepare the homogeneous solution into PVP ( Polyvinylpyrrolidone) carbon nanofibers were vacuum-dried at 333 K to obtain PVP (polyvinylpyrrolidone) carbon nanofibers;

[0072] Take 40 mg of PVP (polyvinylpyrrolidone) carbon nanofibers, soak them in 50 mL of deionized water, and then add 0.6 g of FeCl to the solution 3 , 2 mg pyrrole (dissolved in 80 mL ethanol), stirred for 24 h; washed several times with deionized water, and dried under vacuum at 333 K to obtain PPy-2@PVP;

[0073] Weigh 300 mg PPy-2@PVP, 0.454g Co(NO 3 ) 2 ·6H 2 O, add 20 mL methanol and mix; stir the mixture for 1 h to form solution A; dissolve 0.513 g 2-MIM (2-methylimidazole) in 20 mL methanol to form solution B; add solution B to solution A and s...

Embodiment 3

[0085] 1. Preparation of catalyst 300-ZIF-67@PPy-25@PAN-700-300

[0086] Take a certain amount of PAN (polyacrylonitrile), dissolve it in DMF (N, N-dimethylformamide), stir vigorously at room temperature to form a homogeneous solution with a mass concentration of 15 wt %; and process, the homogeneous solution is prepared into PAN (polyacrylonitrile) carbon nanofibers, and vacuum-dried at 333 K to obtain PAN (polyacrylonitrile) carbon nanofibers;

[0087] Weigh 40 mg of PAN (polyacrylonitrile) carbon nanofibers, immerse in 50 mL of deionized water, add 0.6 g of FeCl to the solution 3 , 25 mg pyrrole (dissolved in 80 mL ethanol), stirred for 24 hours. Then washed with deionized water and dried under vacuum at 333 K to obtain PPy-25@PAN;

[0088] Weigh 300 mg PPy-25@PAN, 0.454g Co(NO 3 ) 2 ·6H 2 O, add 20 mL methanol and mix. The mixture was stirred for 1 h to form solution A; 0.513 g of 2-MIM (2-methylimidazole) was dissolved in 20 mL of methanol to form solution B; soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com